Preparation method of cadmium sulfide-titanium oxide nanosheet composite photocatalyst

A titanium oxide, nanosheet technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low quantization efficiency and limitation of photo-generated electron-hole high recombination rate titanium oxide photocatalysts. Titanium oxide photocatalyst has problems such as light energy utilization rate and unfavorable photo-generated electron transfer, so as to achieve the effect of improving atom utilization rate, ensuring photocatalytic activity and improving photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of layered protonated titanate

[0039] 1) 3.22g of anhydrous potassium carbonate (commercially available), 0.55g of anhydrous lithium carbonate (commercially available), and 7.68g of titanium oxide (commercially available) were mixed and ground for 1 hour and then calcined at 1000°C for 20 hours to obtain 10g of alkali metal Layered titanate K 0.8 Ti 1.73 Li 0.27 o 4 ;

[0040] The alkali metal layered titanate is composed of negatively charged plates on the surface of titanyl octahedra and positively charged potassium ions between the layers, and lithium ions occupy the positions of some titanium atoms in the plate titanyl octahedrons;

[0041] 2) Weigh 2.3g of the above-mentioned alkali metal layered titanate K 0.8 Ti 1.73 Li 0.27 o 4 , impregnated in 200mL with a concentration of 1mol L -1 Hydrochloric acid aqueous solution and magnetic stirring, replace the hydrochloric acid aqueous solution every 24h, filter and wash after three days, and o...

Embodiment 2

[0049] Other implementation steps are the same as in Example 1, only the concentration of cadmium nitrate is changed, and the concentration of cadmium nitrate in the added cadmium nitrate aqueous solution is changed to 0.1mol / L to obtain a yellow cadmium sulfide-titanium oxide nanosheet composite photocatalyst.

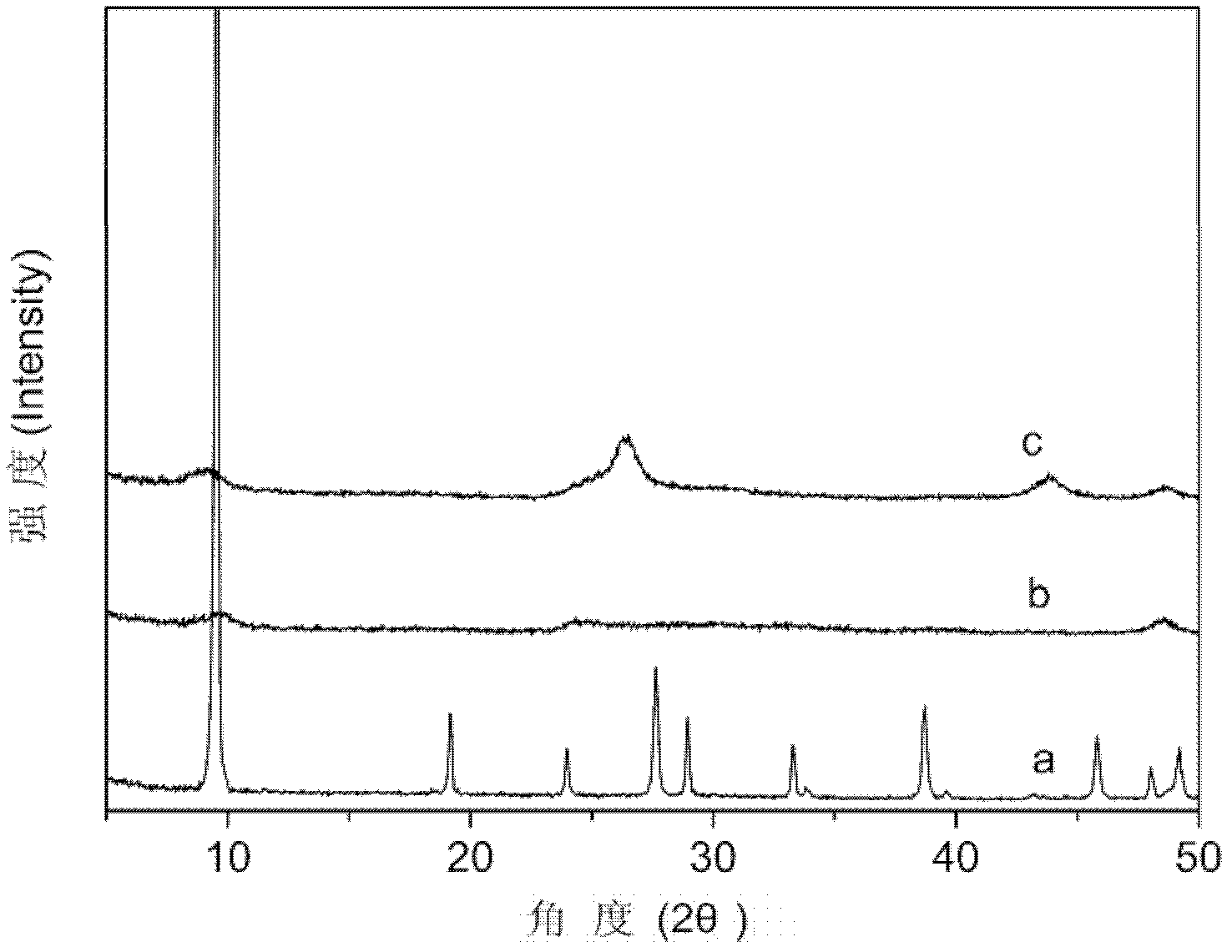

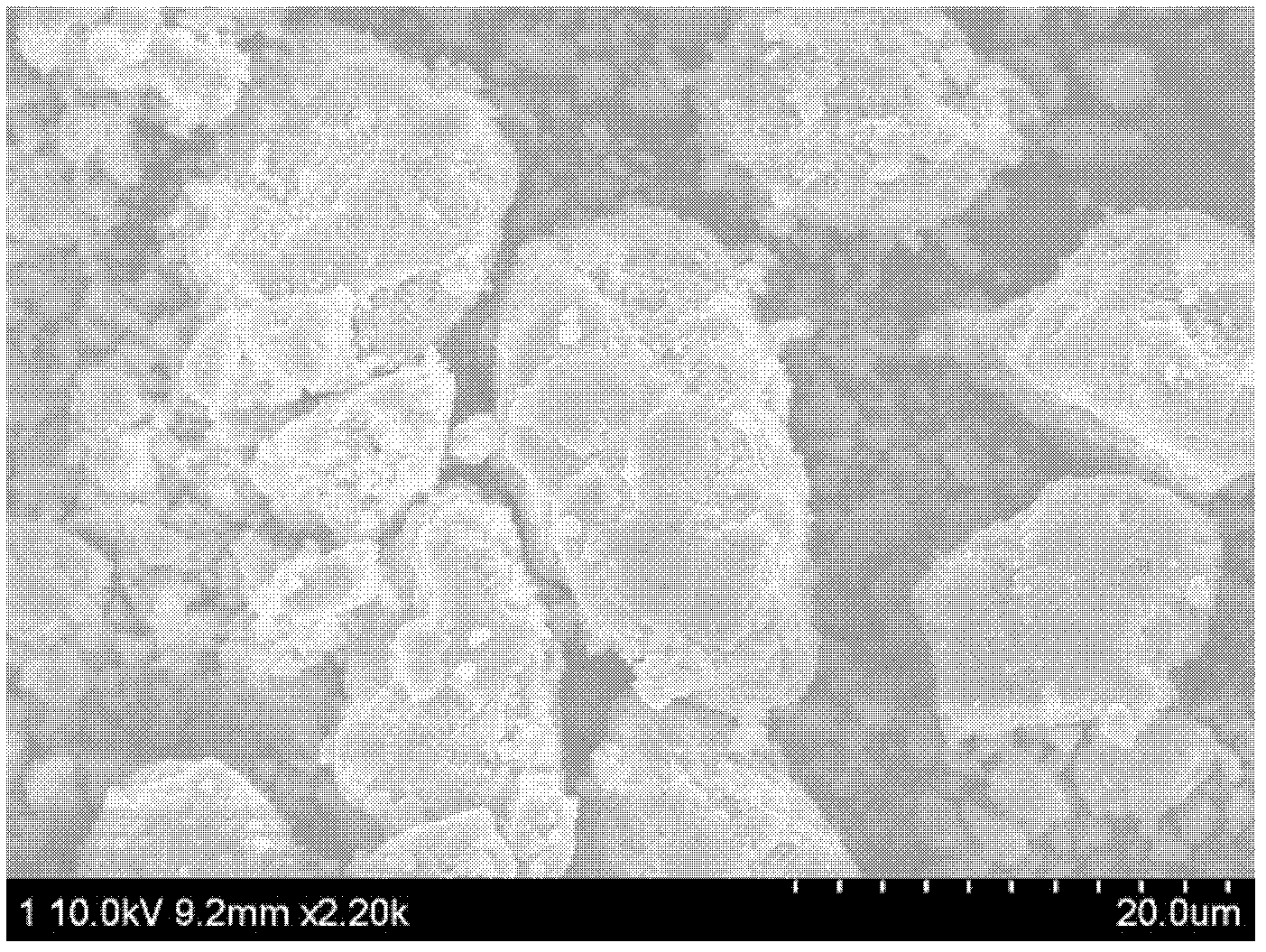

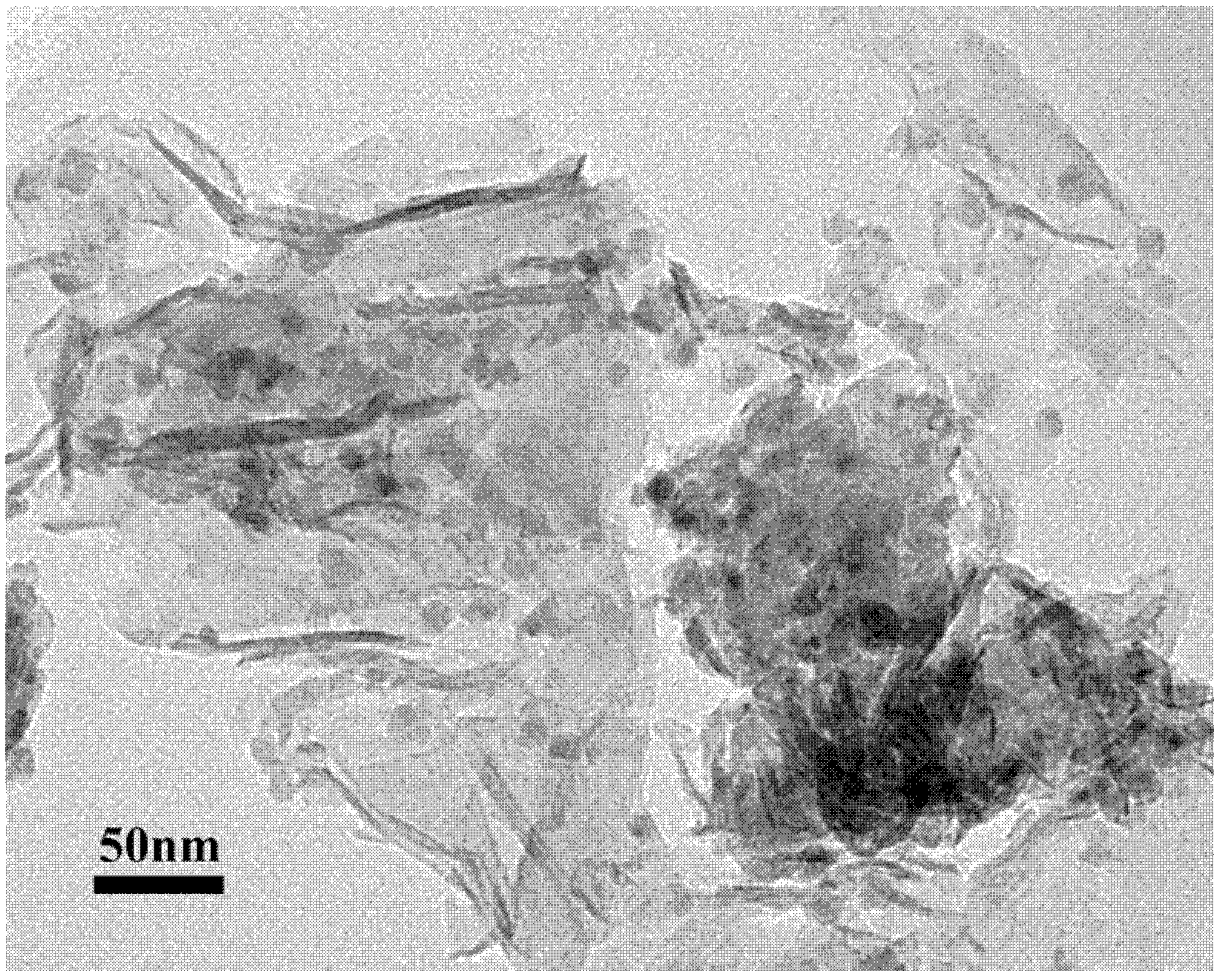

[0050] The X-ray diffraction (XRD) pattern shows that the cadmium sulfide in the cadmium sulfide-titanium oxide nanosheet composite photocatalyst is a cubic phase; The morphology is a disordered stacking structure; the transmission electron microscope photos show that the size of the cadmium sulfide nanoparticles generated between the titanium oxide nanosheets is nanoscale, while the titanium oxide nanosheets still maintain their two-dimensional sheet structure; the ultraviolet-visible absorption spectrum It shows that after being sensitized by cadmium sulfide, the obtained cadmium sulfide-titanium oxide nanosheet composite photocatalyst has obvious spectral response i...

Embodiment 3

[0052] Other implementation steps are the same as in Example 1, only the concentration of cadmium nitrate is changed, and the concentration of cadmium nitrate in the added cadmium nitrate aqueous solution is changed to 0.3mol / L to obtain a yellow cadmium sulfide-titanium oxide nanosheet composite photocatalyst.

[0053]The X-ray diffraction (XRD) pattern shows that the cadmium sulfide in the cadmium sulfide-titanium oxide nanosheet composite photocatalyst is a cubic phase; The morphology is a disordered stacking structure; the transmission electron microscope photos show that the size of the cadmium sulfide nanoparticles generated between the titanium oxide nanosheets is nanoscale, while the titanium oxide nanosheets still maintain their two-dimensional sheet structure; the ultraviolet-visible absorption spectrum It shows that after being sensitized by cadmium sulfide, the obtained cadmium sulfide-titanium oxide nanosheet composite photocatalyst has obvious spectral response in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com