Patents

Literature

154results about How to "Low molar ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed matrix membranes with low silica-to-alumina ratio molecular sieves and methods for making and using the membranes

InactiveUS7138006B2Low molar ratioReduce contentSemi-permeable membranesIsotope separationMolecular sieveProduct gas

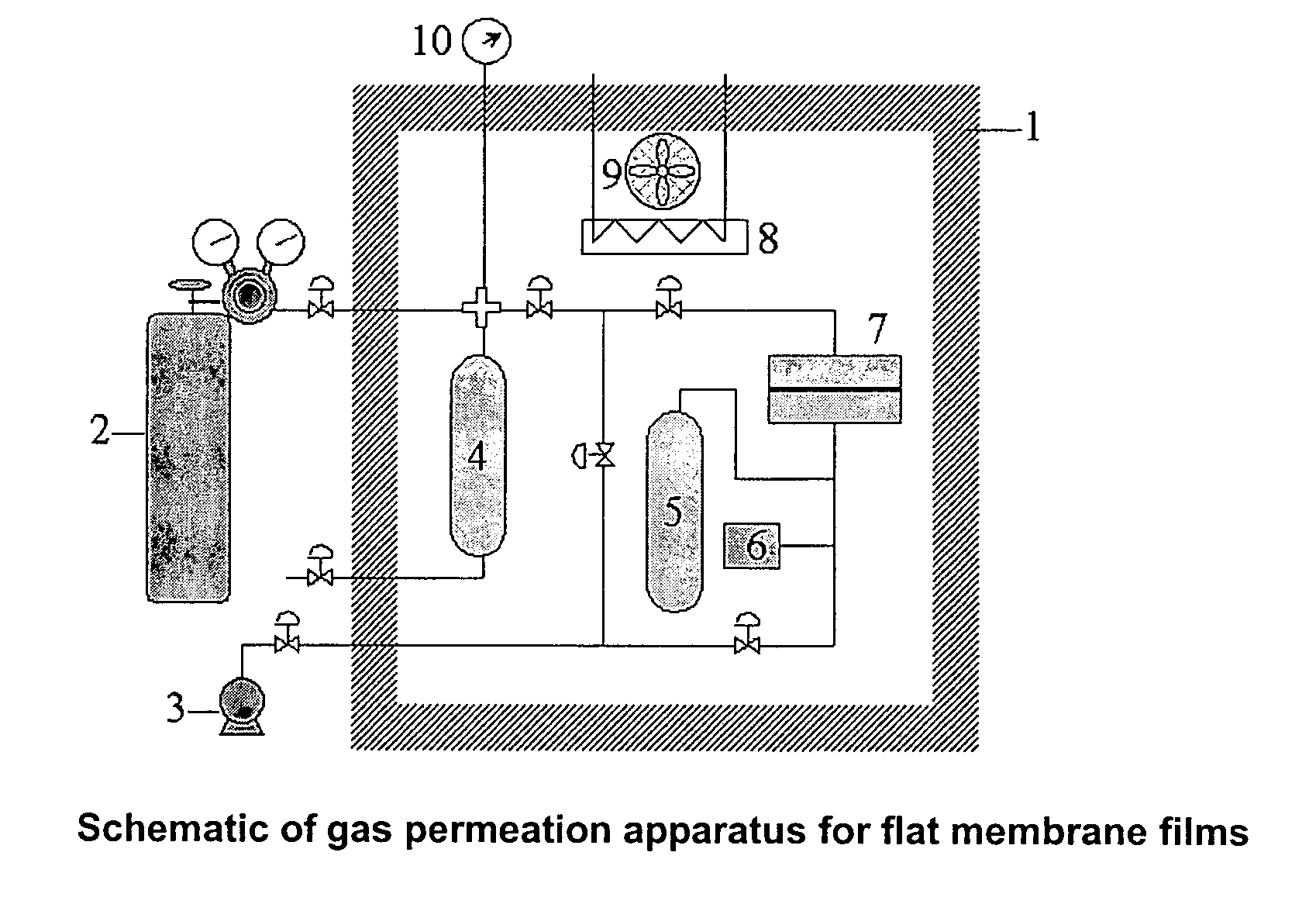

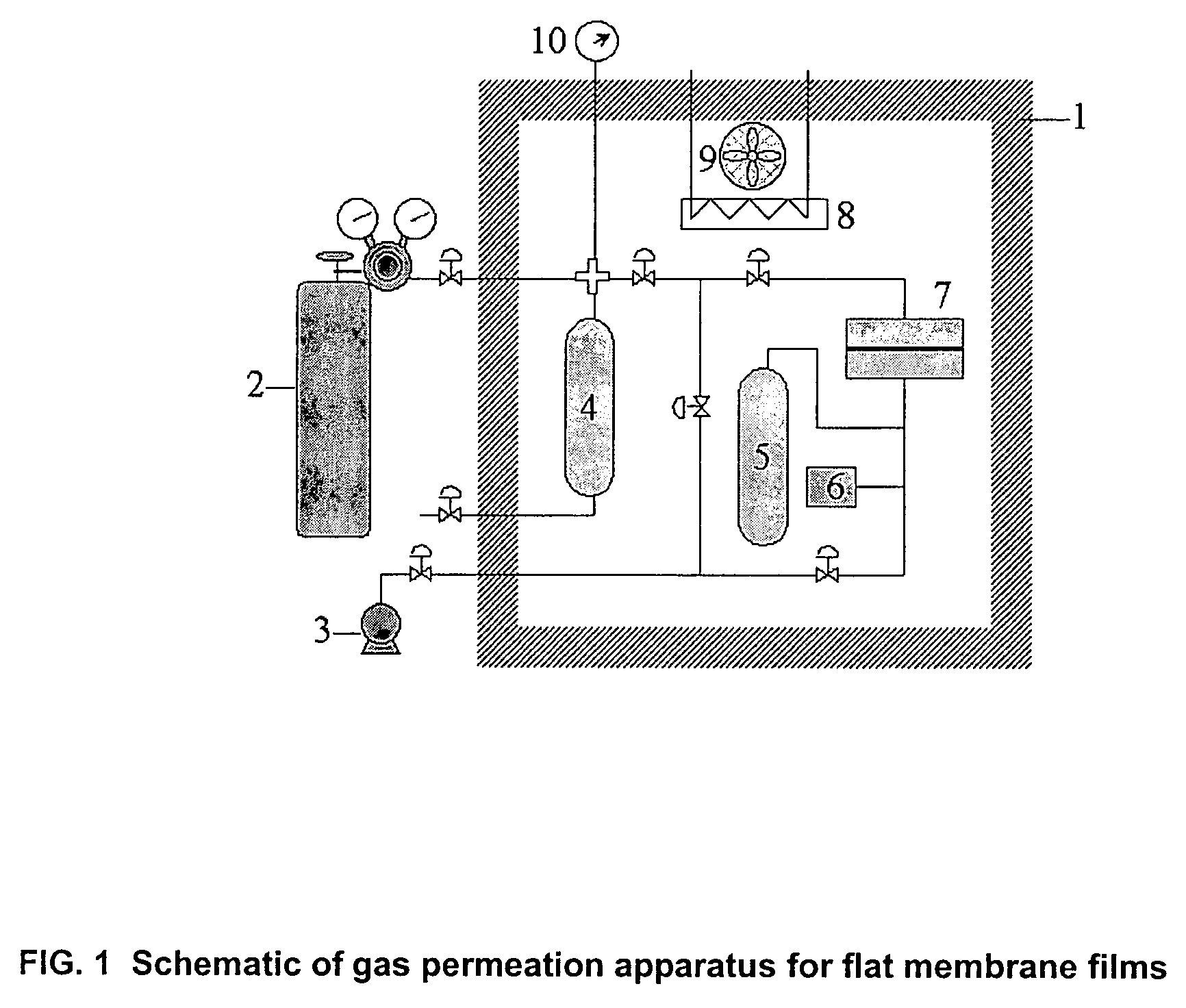

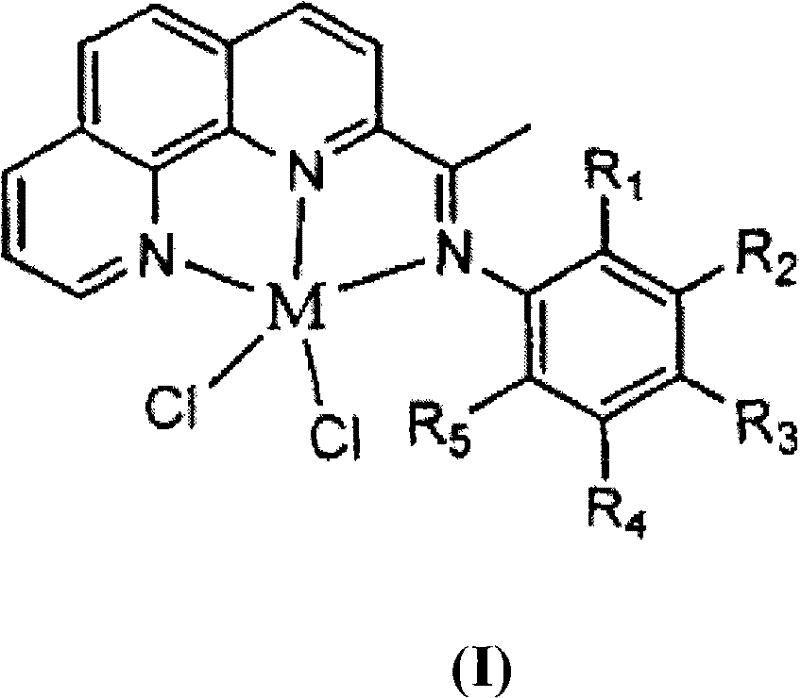

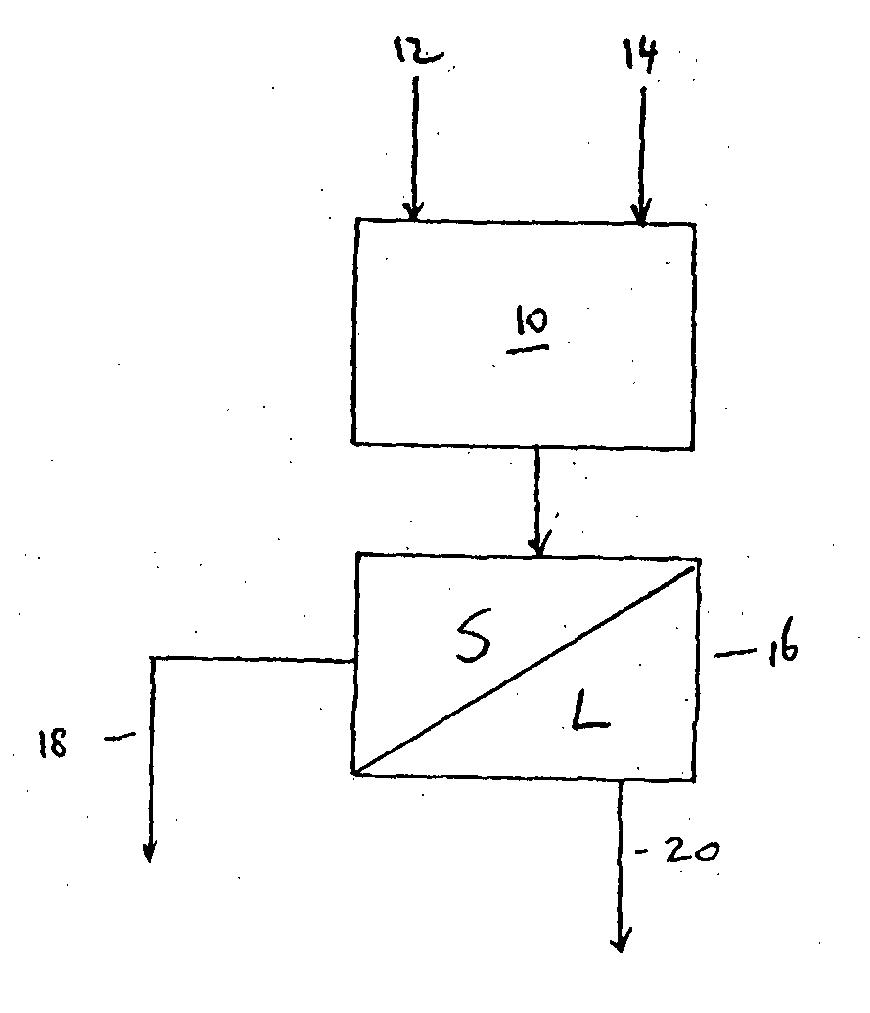

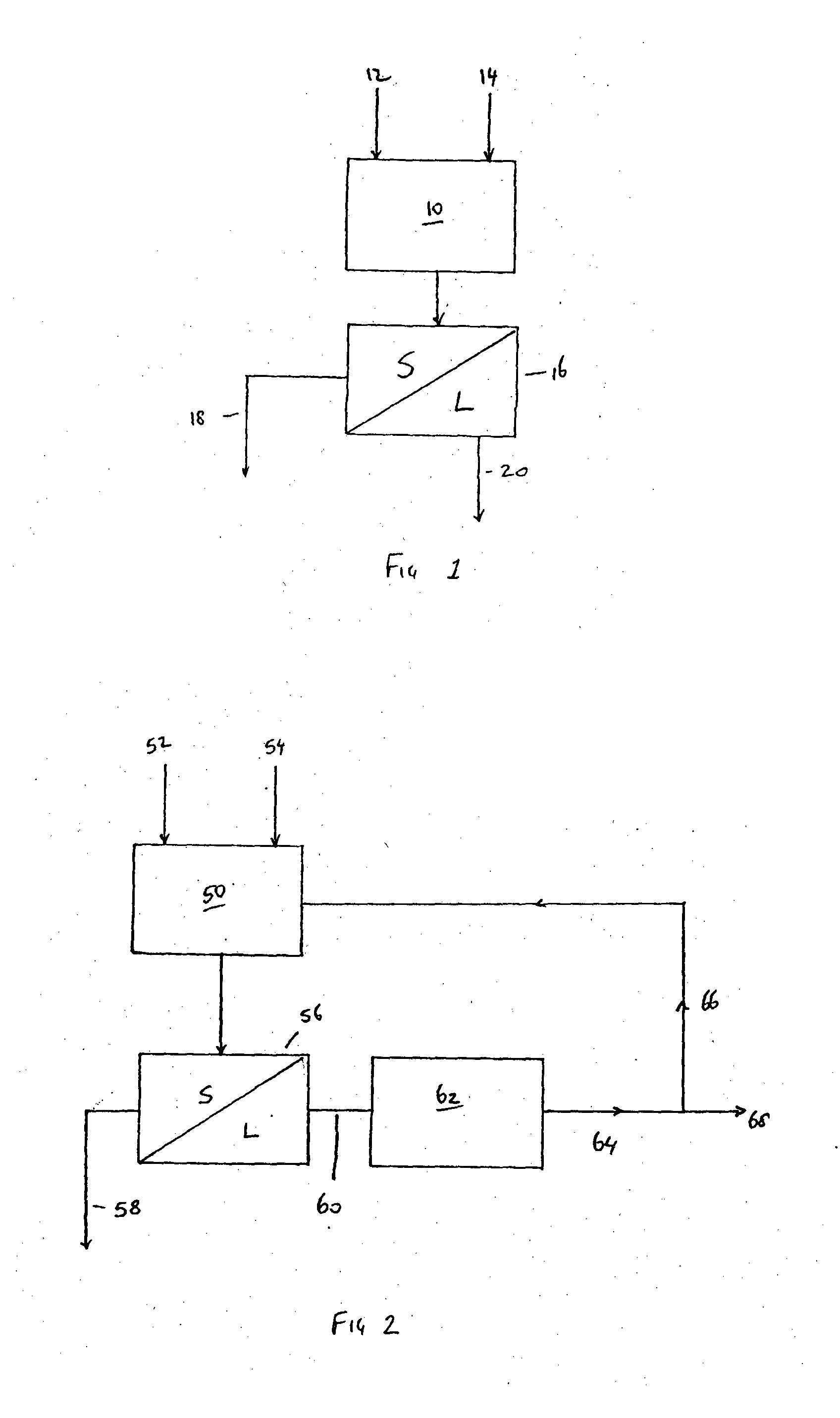

A mixed matrix membrane is provided which comprises a continuous phase organic polymer and small pore alumina containing molecular sieves dispersed therein. The molecular sieves have a silica-to-alumina molar ratio of less than 1.0, more preferably, less than 0.3, and most preferably less than 0.1. In some cases, the molecular sieves have no appreciable amounts of silica. Exemplary compositions include aluminophosphates (AlPO) and silicoaluminophosphates (SAPO). When these molecular sieves are properly interspersed with a continuous phase polymer, the membrane will exhibit a mixed matrix membrane effect, i.e., a selectivity increase of at least 10% relative to a neat membrane containing no molecular sieves. The molecular sieves have pores with a largest minor crystallographic free diameter of 4.0 Angstroms or less. Finally, methods for making and using such mixed matrix membranes to separate gases from a mixture containing two or more gases are also disclosed.

Owner:CHEVROU USA INC

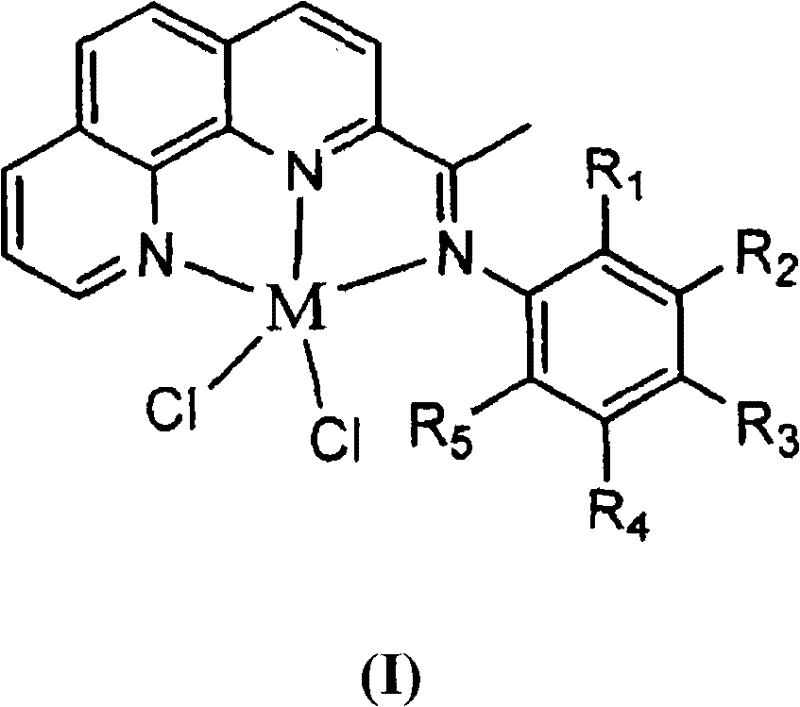

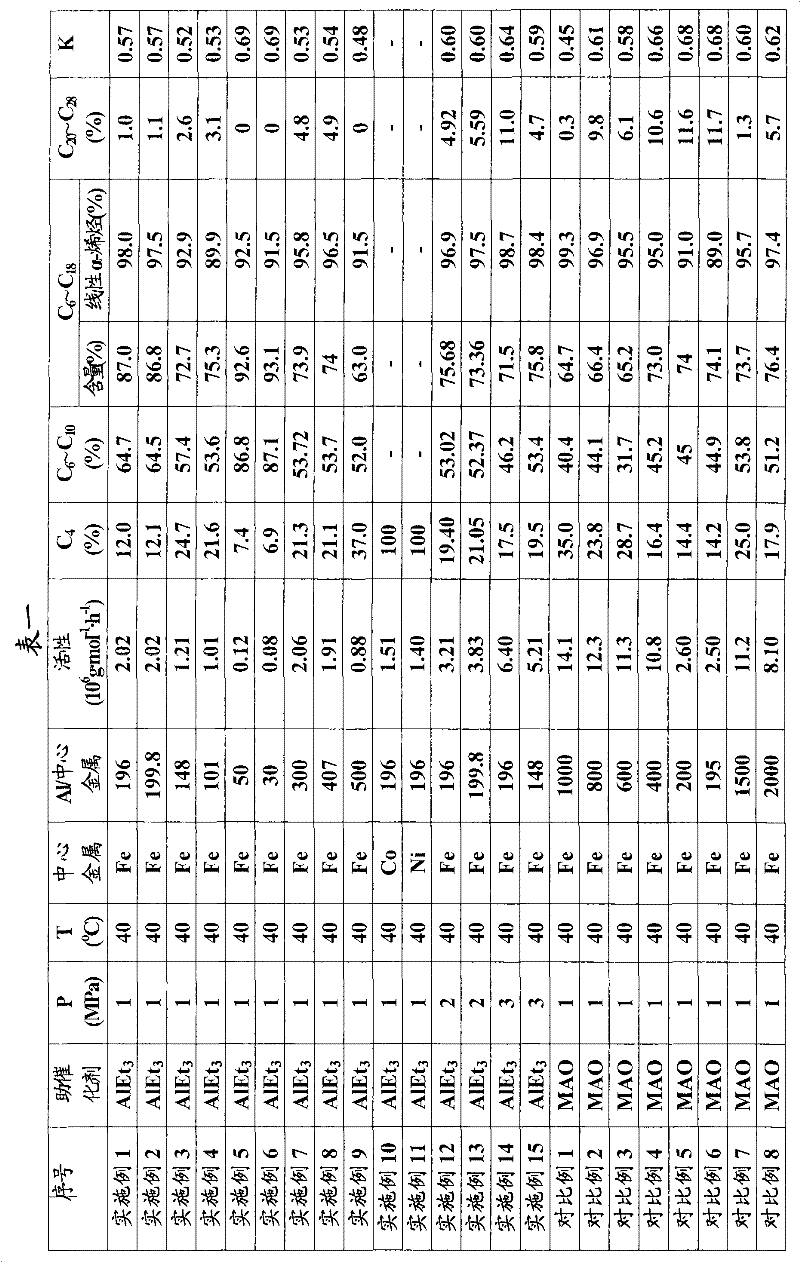

Ethylene oligomerization method

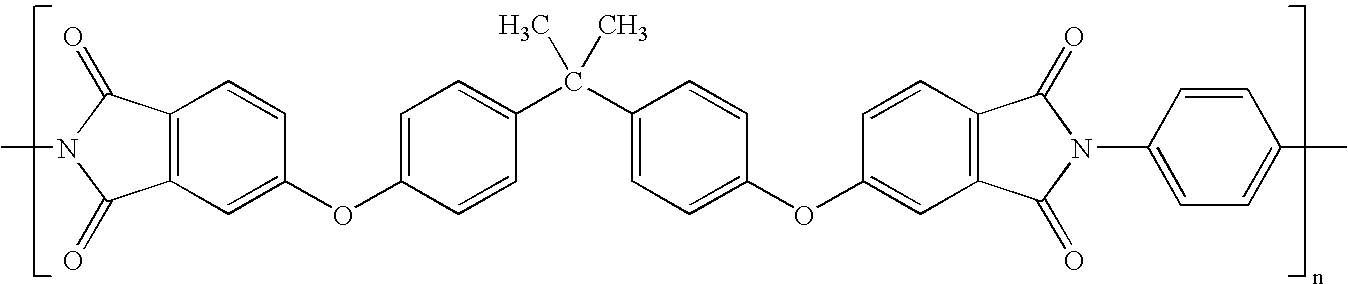

InactiveCN102206127ALow molar ratioMolar ratio (Al/M) decreasedHydrocarbonsHydrocarbon preparationPhenanthrolineChloride

The invention provides an ethylene oligomerization method. Chloride of Fe<2+>, Co<2+> and Ni<2+> with 2-imino-1, 10-phenanthroline coordinated is taken as a main catalyst, Triethylaluminium is taken as a cocatalyst for replacing a high-price methylaluminoxane and the like, and the mol ratio of aluminum in the cocatalyst of triethylaluminium to central metal in the main catalyst is more than 30 and less than 200 or more than 200 and less than 500, The amount of the cocatalyst is greatly reduced, therefore the cost of the ethene oligomerization reaction is greatly reduced, the invention has a broad industrialization prospect.

Owner:CHINA PETROLEUM & CHEM CORP

Mixed matrix membranes with low silica-to-alumina ratio molecular sieves and methods for making and using the membranes

InactiveUS20050139065A1Low silica contentGood choiceSemi-permeable membranesIsotope separationMolecular sieveSilicon dioxide

A mixed matrix membrane is provided which comprises a continuous phase organic polymer and small pore alumina containing molecular sieves dispersed therein. The molecular sieves have a silica-to-alumina molar ratio of less than 1.0, more preferably, less than 0.3, and most preferably less than 0.1. In some cases, the molecular sieves have no appreciable amounts of silica. Exemplary compositions include aluminophosphates (AIPO) and silicoaluminophosphates (SAPO). When these molecular sieves are properly interspersed with a continuous phase polymer, the membrane will exhibit a mixed matrix membrane effect, i.e., a selectivity increase of at least 10% relative to a neat membrane containing no molecular sieves. The molecular sieves have pores with a largest minor crystallographic free diameter of 4.0 Angstroms or less. The molecular sieves may be selected from the group having IZA structure types including AEI, CHA, ERI, LEV, AFX, AFT, and GIS. Examples of preferred molecular sieves include: AIPO-18, SAPO-18, AIPO-34, SAPO-34, SAPO-44, SAPO-47, AIPO-17, SAPO-17, CVX-7, SAPO-35, SAPO-56, ALPO-52, and SAPO-43. Finally, methods for making and using such mixed matrix membranes to separate gases from a mixture containing two or more gases are also disclosed.

Owner:CHEVROU USA INC

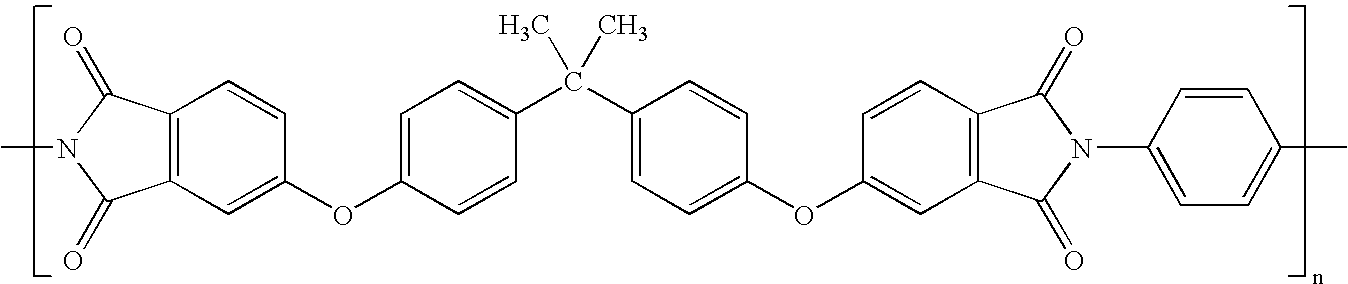

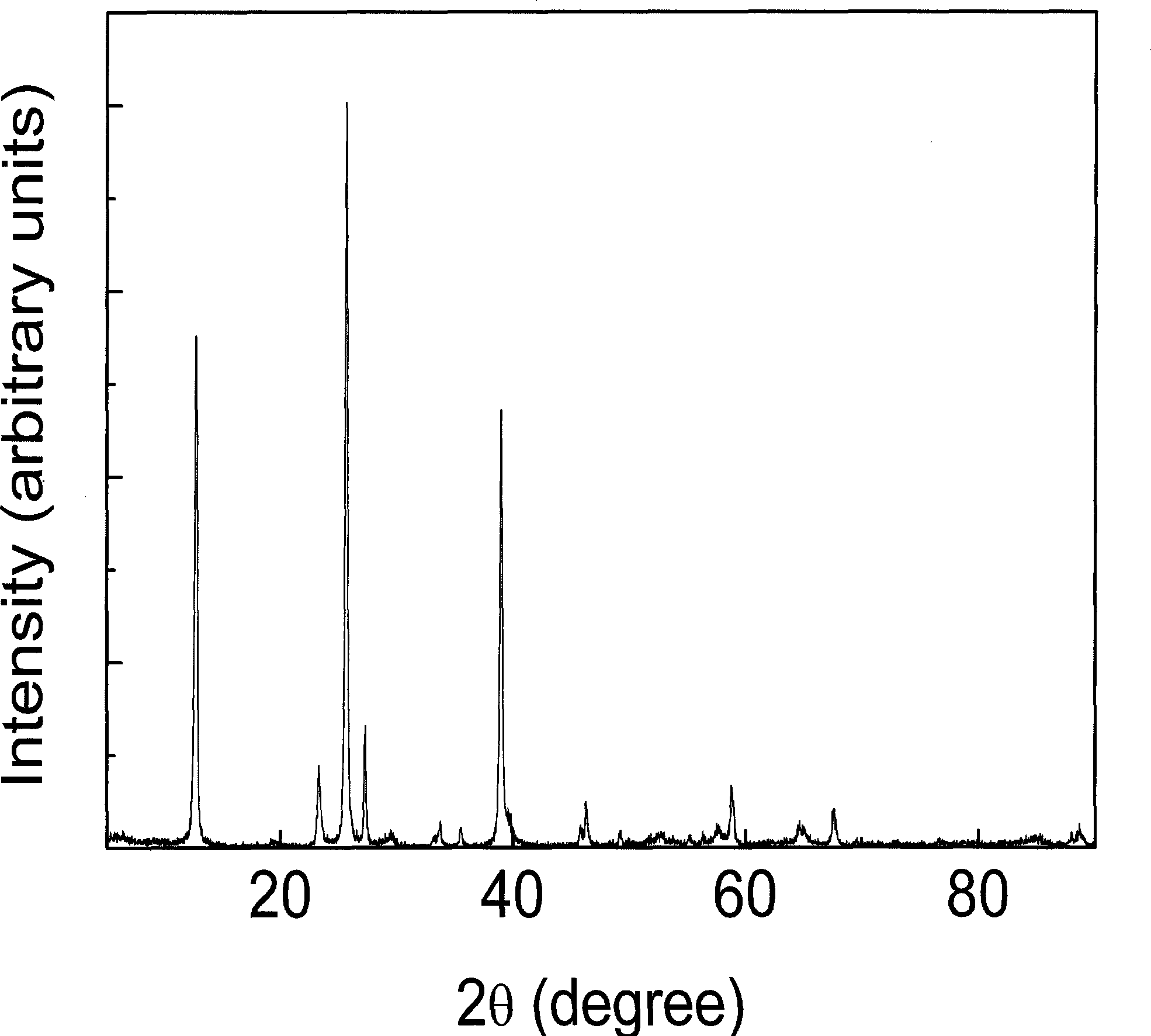

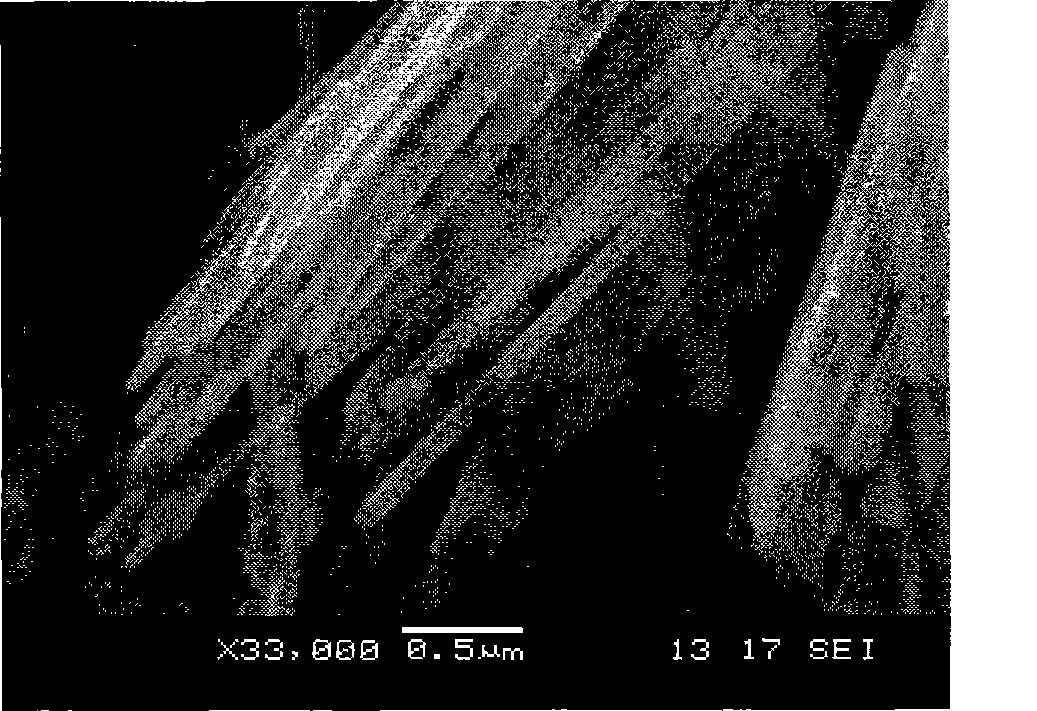

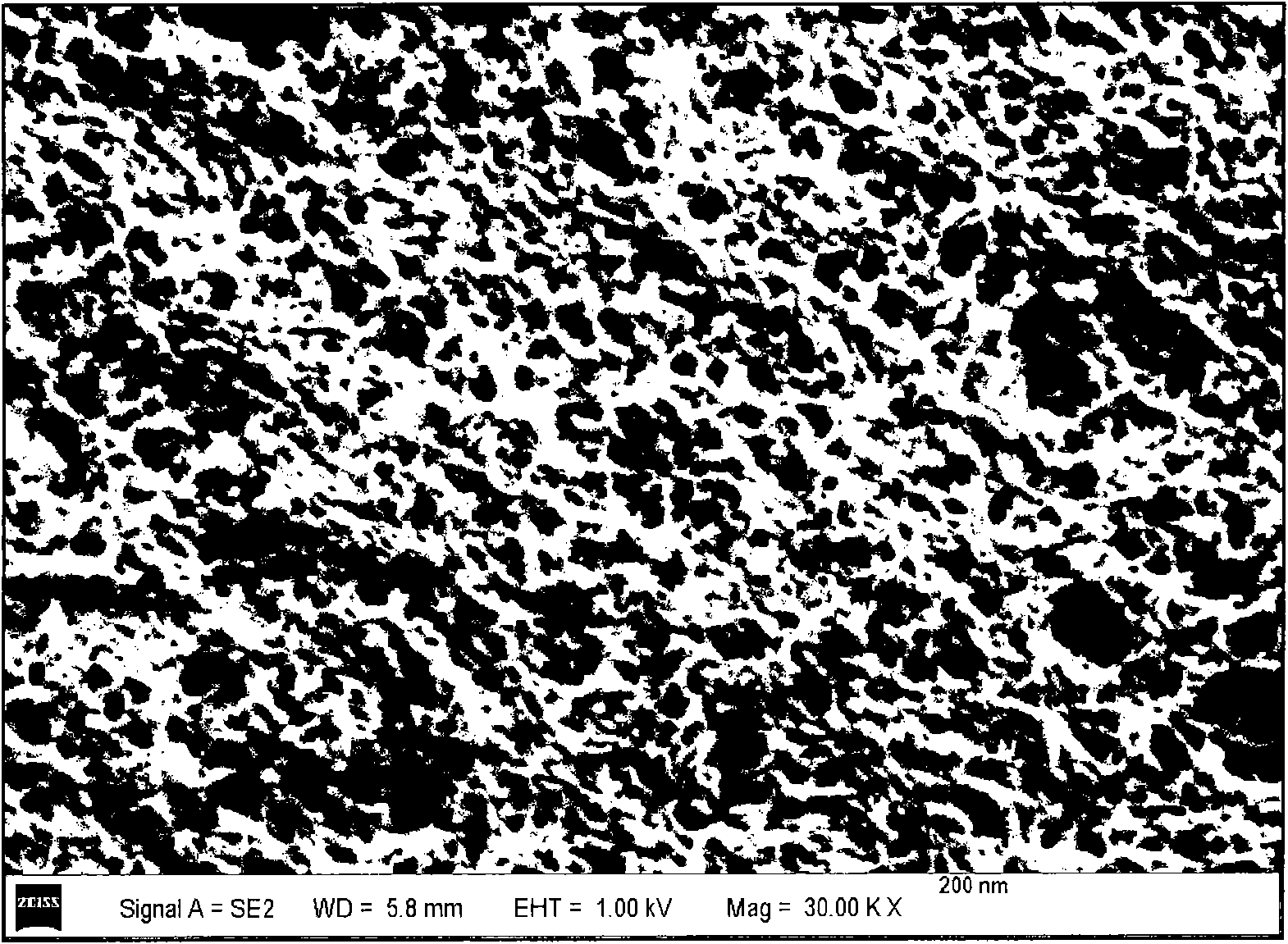

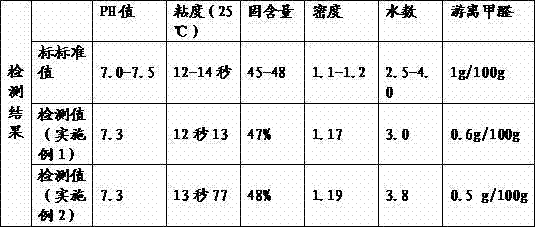

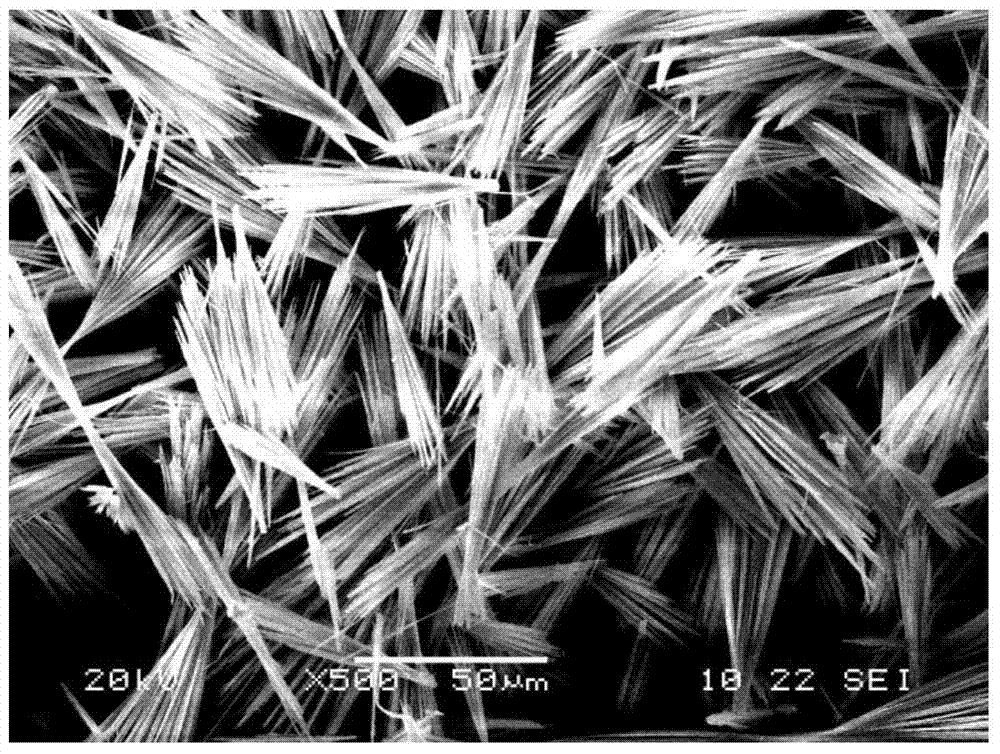

Preparation method of ZSM-22 molecular sieve nanosheet

ActiveCN104671253AExtended service lifeImprove diffusivityCrystalline aluminosilicate zeolitesMolecular sievePotassium hydroxide

The invention discloses a preparation method of a ZSM-22 molecular sieve nanosheet, relates to a preparation method of a ZSM-22 molecular sieve, and aims at solving the problems that an organic template agent adopted by an existing method for synthesizing the ZSM-22 molecular sieve is large in amount and high in cost, and molecular sieve grains exist in a form of an aggregate with a relatively large dimension. The preparation method comprises the following steps: 1, preparing prefabricated seed crystal from aluminum sulfate octadecahydrate, ethyl orthosilicate, 1,6-hexamethylendiamine, potassium hydroxide and deionized water; 2, preparing gel from aluminum sulfate octadecahydrate, silica sol, potassium hydroxide and deionized water; and 3, crystallizing and roasting. The ZSM-22 molecular sieve prepared by the method is in a regularly arranged laminated nanometer structure; the sheet thickness is only about 20nm; the amount of the organic template agent is significantly reduced in the synthesis process; the crystallization time is shortened; and the cost is reduced.

Owner:HEILONGJIANG UNIV

Dual zone aromatic alkylation process

ActiveUS20080171900A1High selectivityLow molar ratioMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkylation

A process for the catalytic alkylation of an aromatic substrate with an alkylating agent is disclosed that comprises contacting the aromatic substrate and the alkylating agent in sequential alkylation zones to obtain an alkylaromatic. The first catalyst comprises UZM-8 zeolite and the second catalyst comprises beta zeolite. The process is particularly well suited for the alkylation of benzene with propylene to produce cumene.

Owner:UOP LLC

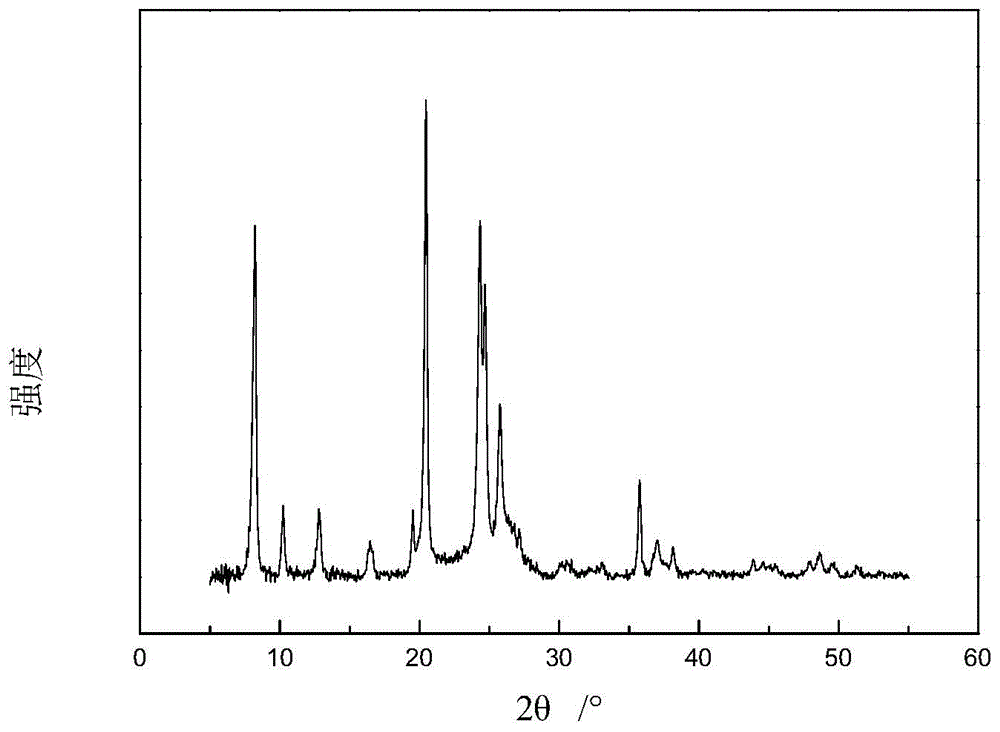

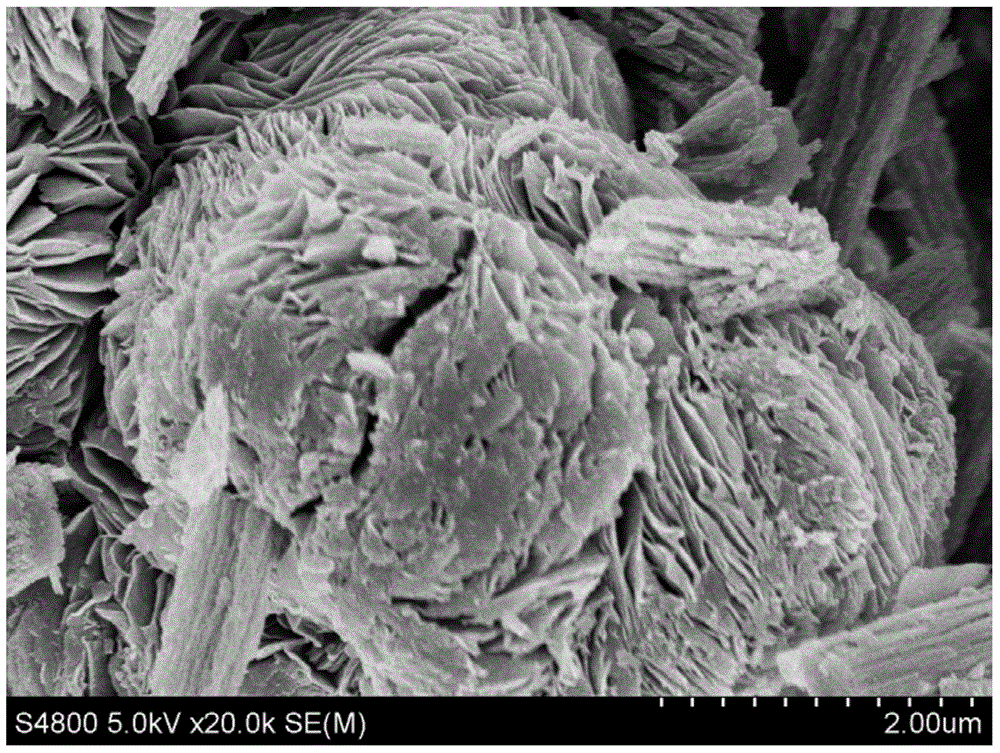

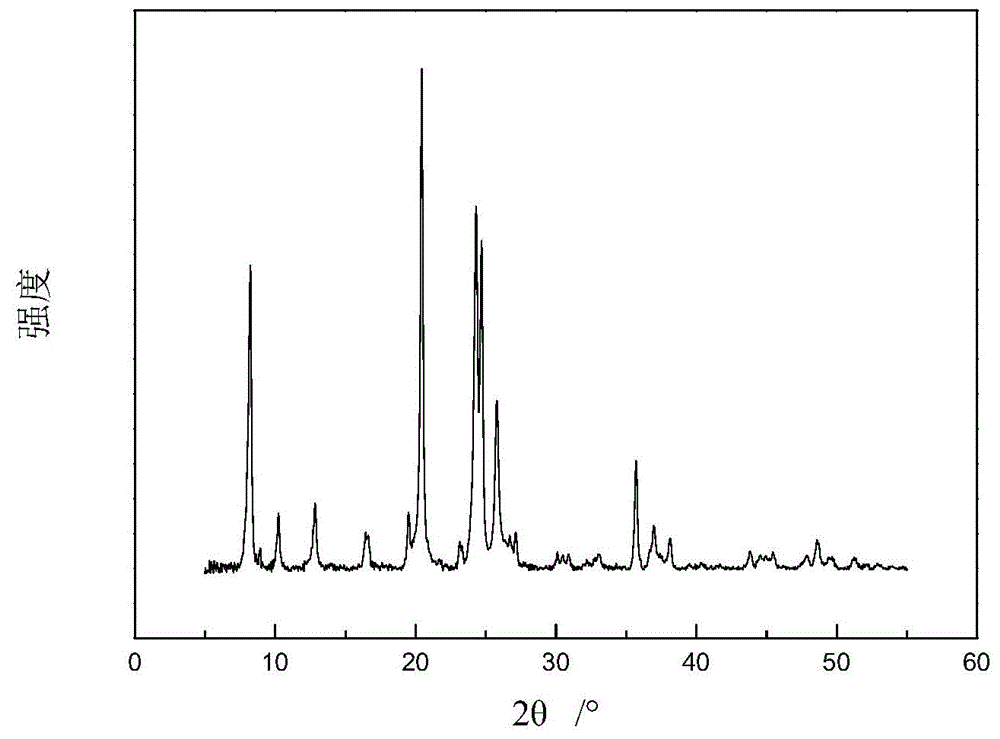

Method for synthesizing rod-like and echinoid molybdena-based nano-material

InactiveCN101412541ALow costUniform scaleNanostructure manufactureMolybdenum oxides/hydroxidesMolybdenum trioxidePeroxide

The invention relates to a quick and efficient non-template agent hydro-thermal synthesizing method. The system can synthesize an alpha-molybdenum trioxide nanometer rod and a high-density echinoid molybdenum oxide based nanometer materials. Molybdenum peroxide acid prepared from molybdenum trioxide and aqueous hydrogen peroxide solution is used as a precursor, is produced into scattered alpha-molybdenum trioxide nanometer rod by hydro-thermal synthesis at a temperature of between 80 and 180 DEG C, and is produced into the peroxide modified molybdenum oxide hydrate by hydro-thermal synthesis at a temperature of between 65 and 75 DEG C. The hydrate is a multiscale structure; a nanometer thin slice, a micron prism and a nanometer rod-shaped structure unit are divergently assembled into a micron-size high-density echinoid structure. The hydrate is roasted to obtain high-density echinoid alpha-molybdenum trioxide. Modulation of the synthesizing condition can realize fine adjustment for appearance of the nanometer rod, the micron-size echinoid structure and the structure unit thereof. The method uses raw materials with low cost, has the advantages of simple technical process, controllable conditions and the like, and can promote research and application of the molybdenum oxide in the fields of sensors, field transmission, electrode materials and so on.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

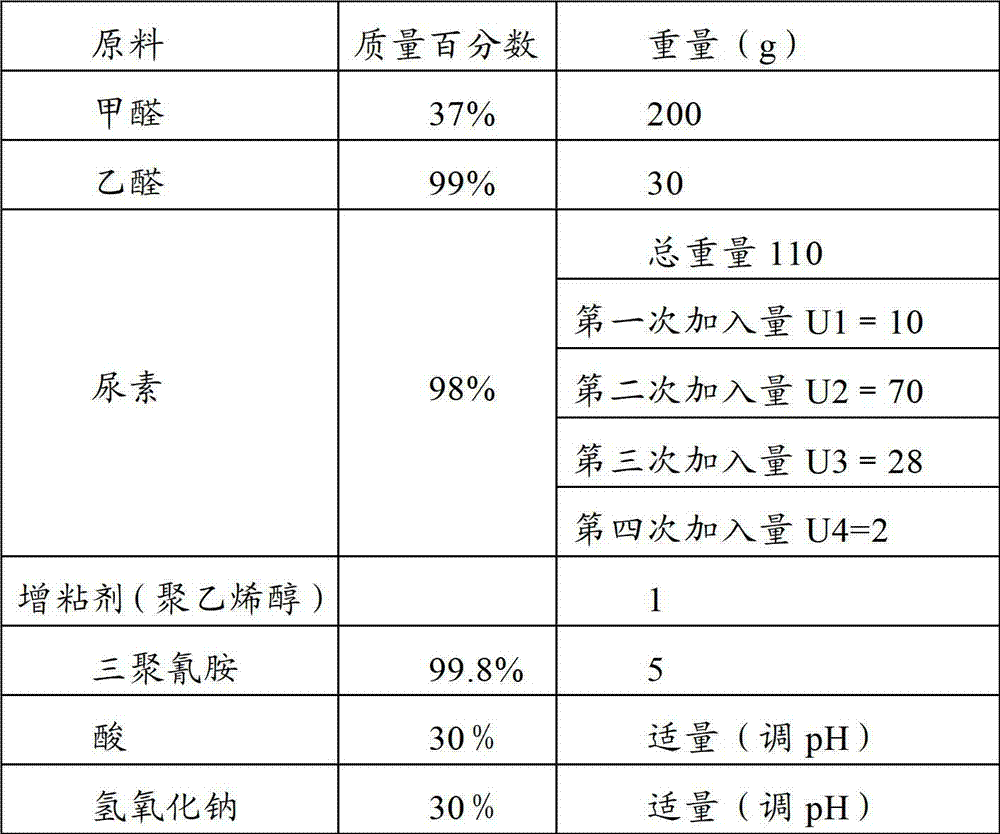

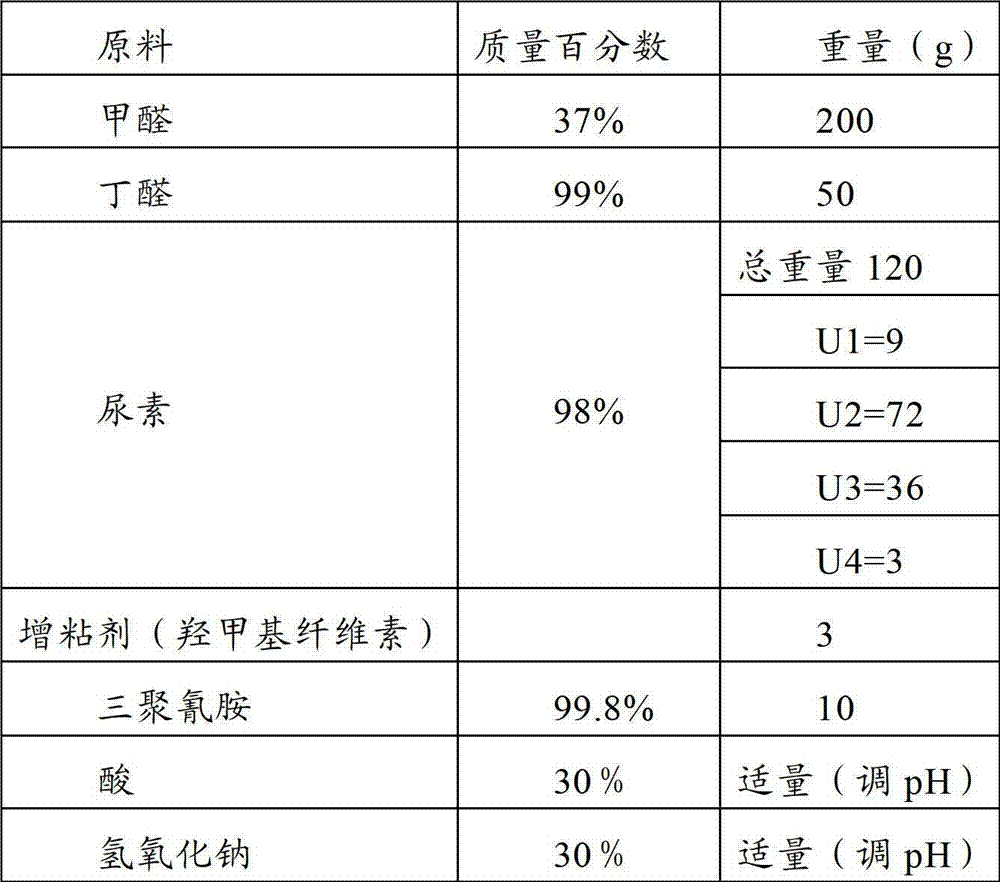

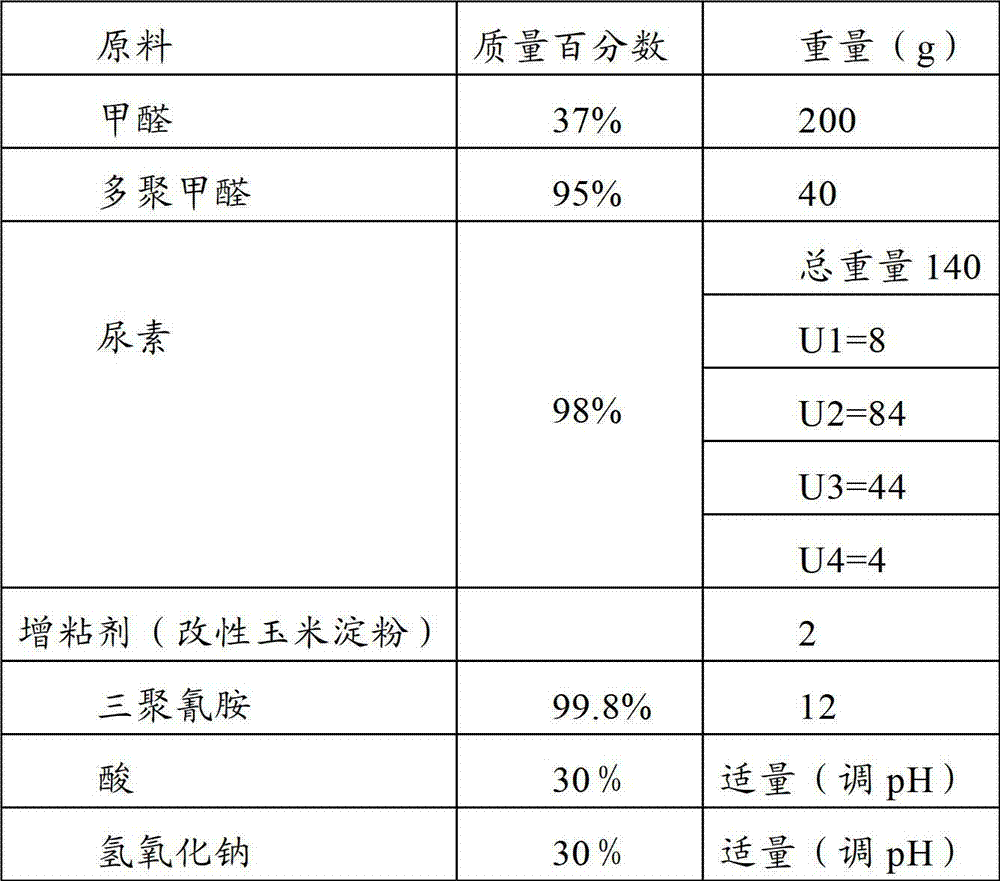

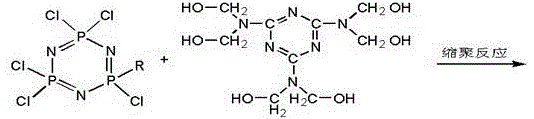

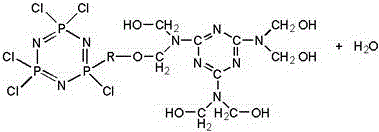

Adhesive for veneering of artificial board and preparation method of adhesive

InactiveCN103031095AReduce penetrationReduce generationMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSolubilityAdhesive

The invention relates to an adhesive for a veneering of an artificial board and a preparation method of the adhesive. The adhesive comprises the components in parts by weight: 200 parts of formaldehyde, 20-50 parts of a modifier, 110-140 parts of urea, 5-15 parts of tripolycyanamide, and 1-10 parts of a tackifier. By addition of appropriate parts of modifier, on the one hand, the high solid content adhesive can be prepared without dehydration, moisture brought to a base material during coating is reduced, permeation of the adhesive is reduced, and glue penetration is reduced. In addition, through addition of the modifier, the molar ratio of formaldehyde and urea in the polycondensation phase in the urea resin synthetic process can be greatly reduced, so that hydrophilic radicals in the resin structure are greatly decreased. Meanwhile, tripolycyanamide in appropriate parts is added to modify, so that the water-solubility of the adhesive is reduced, the hydrophobicity of the adhesive is enhanced, and glue penetration is beneficially reduced. The tackifier in appropriate parts is added to improve the initial adhesion of the adhesive and reduce malposition of a veneer on the base material, so that the product quality is improved.

Owner:EVERFIRST WISEFUND TECH BEIJING

High-gloss anti-crack adhesive for multilayer plywood and method for manufacturing multilayer plywood

ActiveCN103265921AImprove clarityImprove plasticizing effectLaminationLamination apparatusWear resistantRoom temperature

A high-gloss anti-crack adhesive for multilayer plywood is provided. The multilayer plywood is mutually glued and laminated by a single layer material. The adhesive includes a urea-formaldehyde resin adhesive and additive and added additives therein, a melamine resin adhesive and added additives therein. The preparation methods of the urea-formaldehyde resin adhesive and the melamine resin adhesive are creatively improved by inventors. The free formaldehyde in the obtained adhesive is less than 0.1%. Operation is easy, equipment is easy to get, no pollution generates, implementation is easy and price is inexpensive. The high-gloss anti-crack adhesive can be used for the multi-layer plywood, has excellent pre-pressing property, can mold at room temperature in 30-40 min, and has bonding strength >= 1.0 MPa, formaldehyde emission <= 1.0 mg / L, which is below requirements of GB / T18580-2001 E1 level, and gloss >= 85 DEG. In the environment with sudden changes in temperature, the high-gloss anti-crack adhesive has the advantages of preventing wear-resistant material cracking and bubbling as a result of thermal expansion and cool contraction.

Owner:ZHEJIANG DILONG NEW MATERIAL

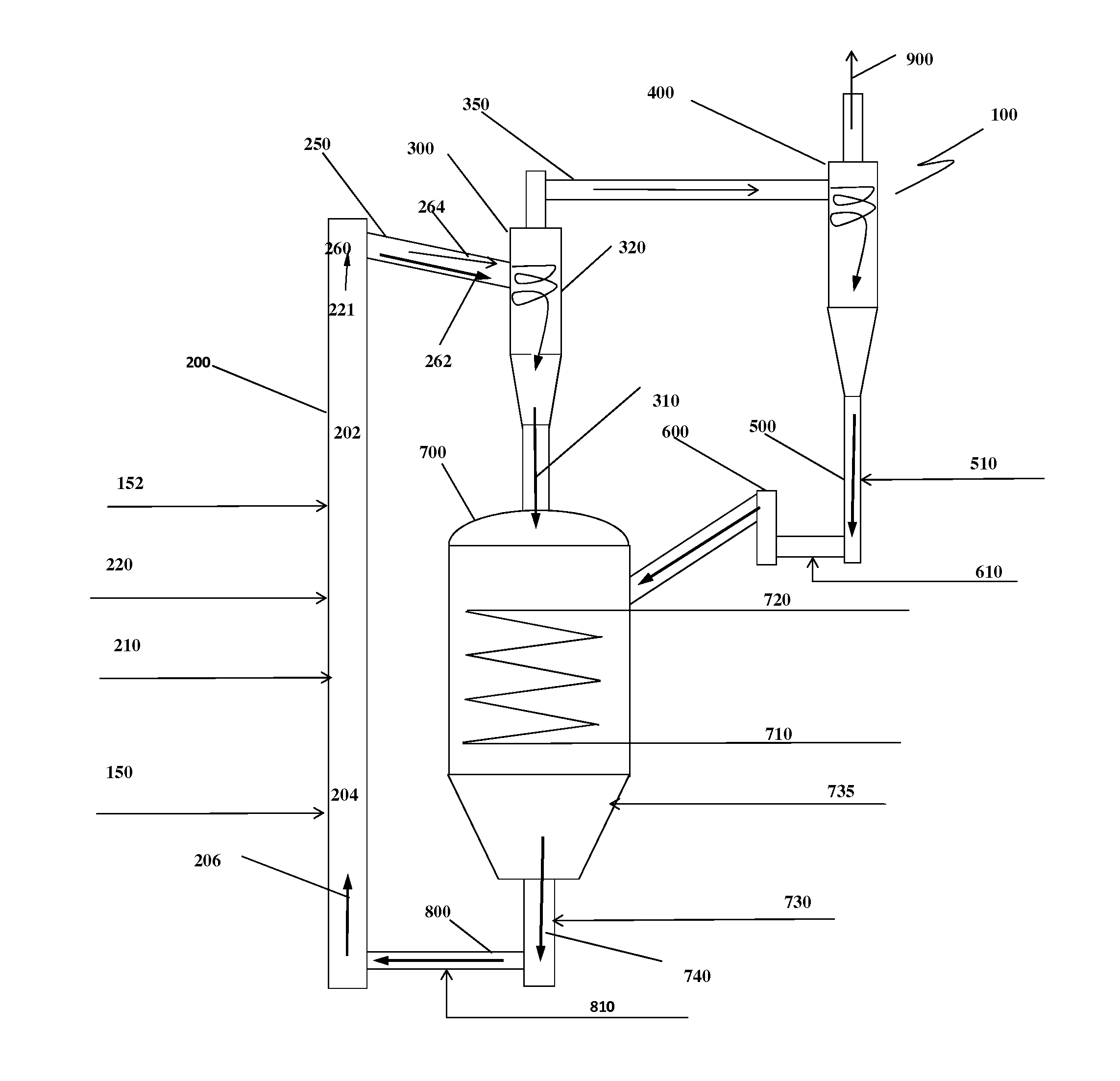

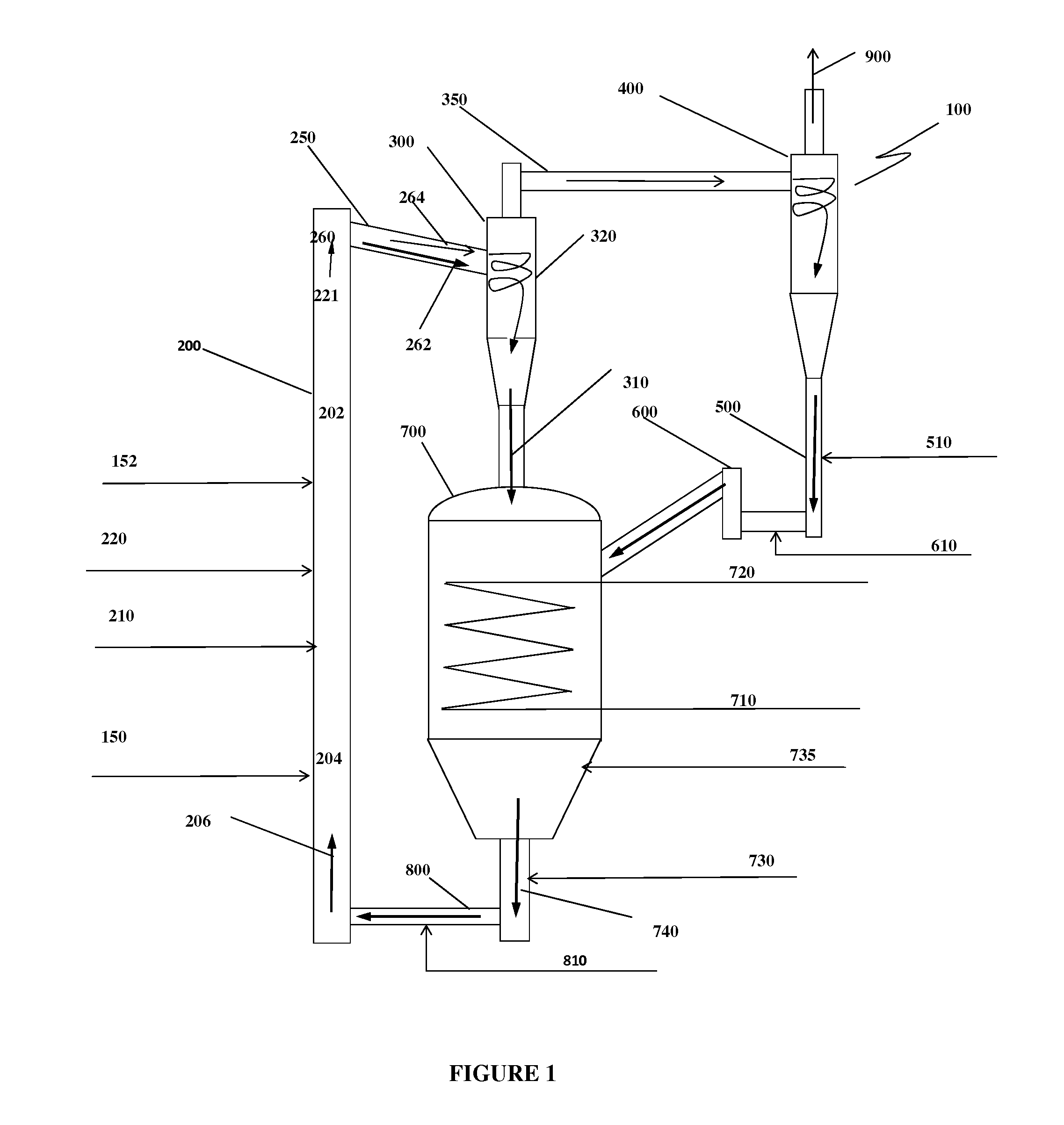

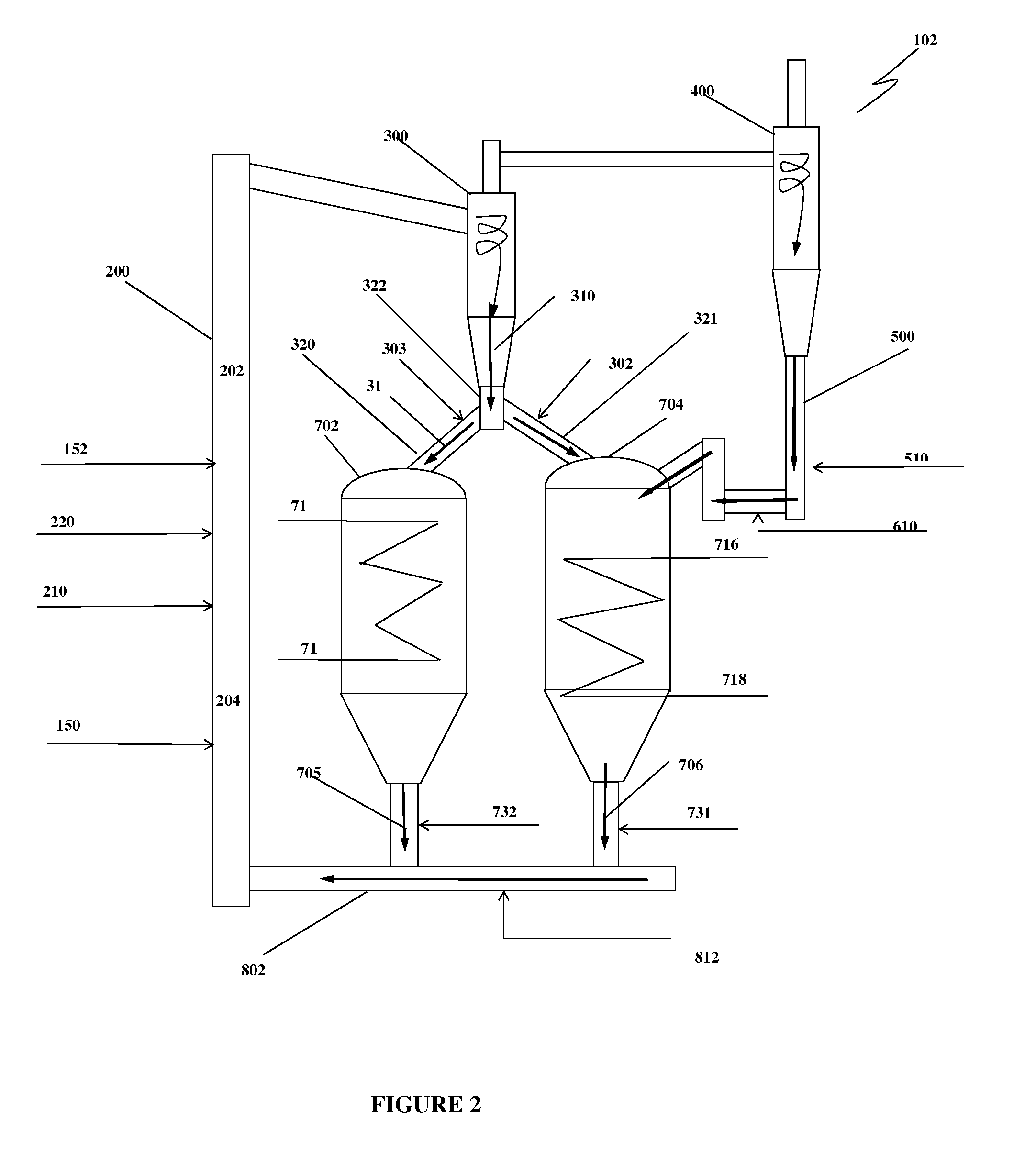

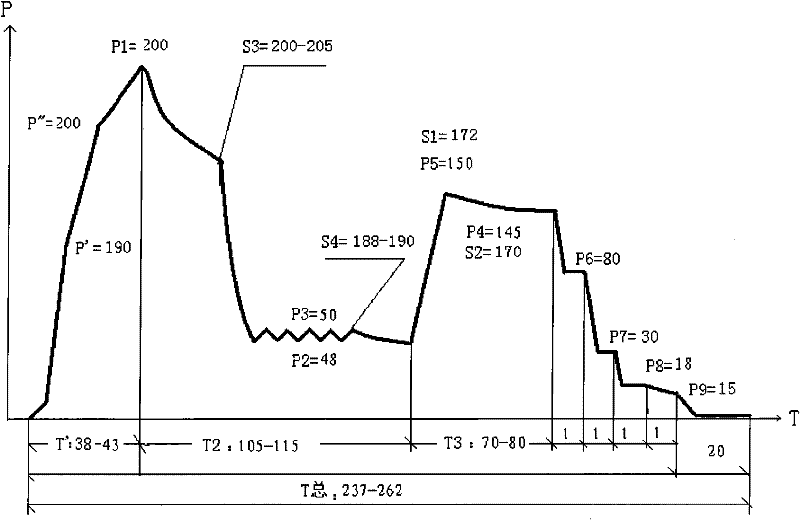

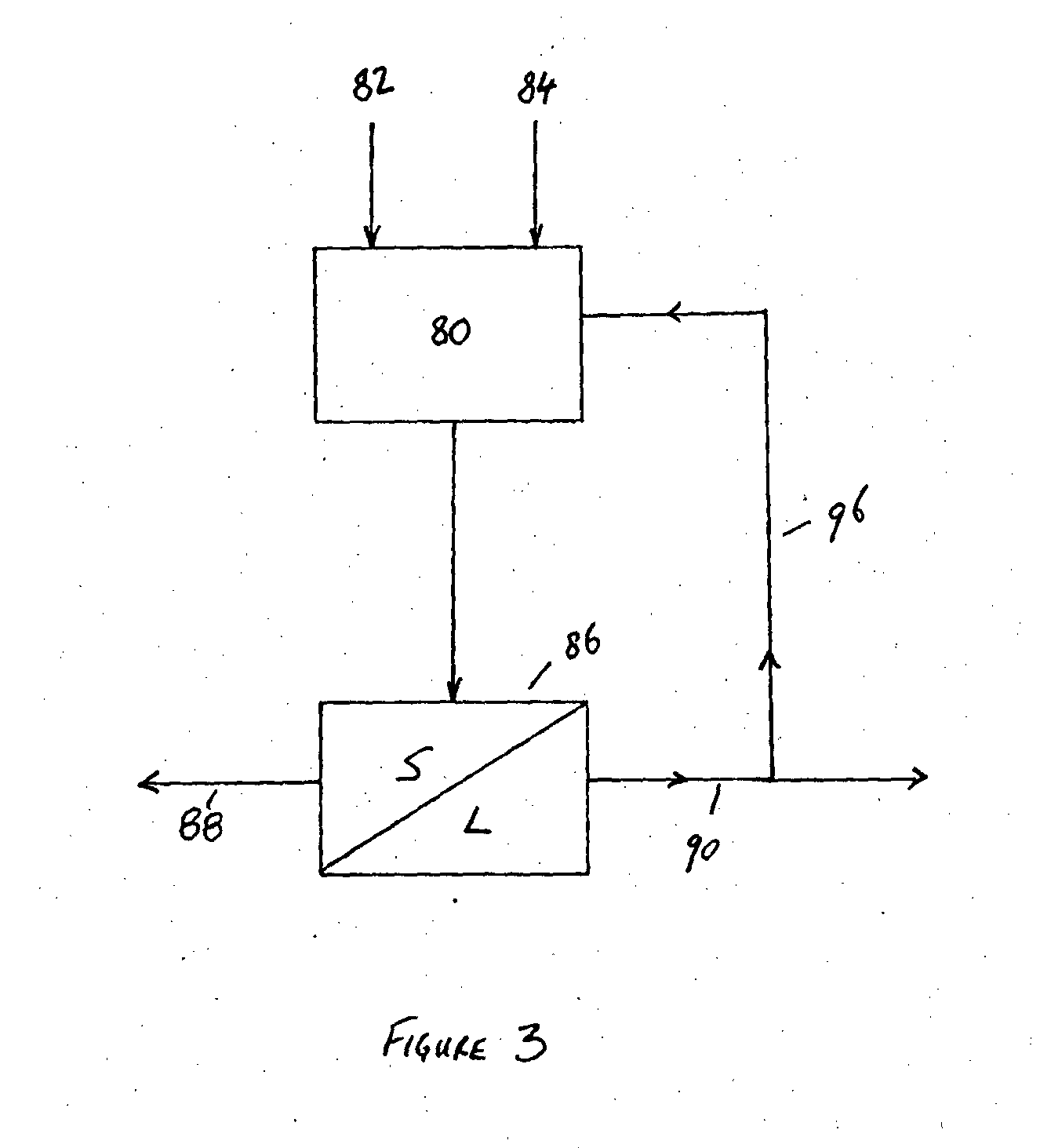

Oxycombustion In Transport Oxy-Combustor

ActiveUS20130055936A1Efficient removalReduce operating costsFluidized bed combustionSteam generation using pressureFlue gasMoisture condensation

A pressurized transport oxy-combustor with different configurations is disclosed. Substantially pure oxygen is fed to the transport oxy-combustor under pressure to combust fossil fuels, generating steam for power generation. The end product is the flue gas containing substantially pure CO2 after moisture condensation. The low excess oxygen necessary to achieve complete combustion in the combustor is scavenged by adding another fuel so that substantially all oxygen fed to the combustor is completely consumed. The capability to operate the transport oxy-combustor as a circulating fluidized bed combustor at very high solids circulation rates makes it unnecessary to use recycled CO2 or flue gas as a means to moderate and control the combustion temperature. The temperature in the combustor is effectively controlled by relatively cooler circulating solids that enter the combustion zone. A small amount of CO2 is recycled for aeration and to convey solids fuel to the combustor.

Owner:THE SOUTHERN CO

Preparation method and application of N-acyl acidic amino acid or salt thereof

ActiveCN103435509ASatisfaction conversion rateLow costCosmetic preparationsOrganic compound preparationNeutral Amino AcidsSolvent

The invention discloses a preparation method of N-acyl acidic amino acid or a salt thereof. According to the preparation method, fatty acyl chloride and an amino acid are subjected to an amidation reaction under an alkaline condition. The preparation method is characterized in that in the amidation reaction, water is used as a solvent, an acidic amino acid or a salt thereof is used as a main raw material and a small amount of a neutral amino acid or a salt thereof is used as an auxiliary raw material. The preparation method comprises the following steps: under a stirring condition, dropping the fatty acyl chloride into the aqueous solution of the acidic amino acid or the salt thereof; adding an alkali to adjust the pH value of the reaction solution; after a certain amount of fatty acyl chloride is dropped, adding the aqueous solution of the neutral amino acid or the salt thereof, continue to drop the fatty acyl chloride until the dropping is finished and stirring to maintain the reaction. According to the preparation method, the mixed amino acid and the fatty acyl chloride react under a water-phase system, so that the conversion rates of the mixed amino acid and the fatty acyl chloride can be remarkably increased and the amount of residual amino acids is greatly reduced. The product can be directly used as a surfactant after being treated simply, and thus the cost is greatly reduced.

Owner:NANJING HUASHI NEW MATERIAL

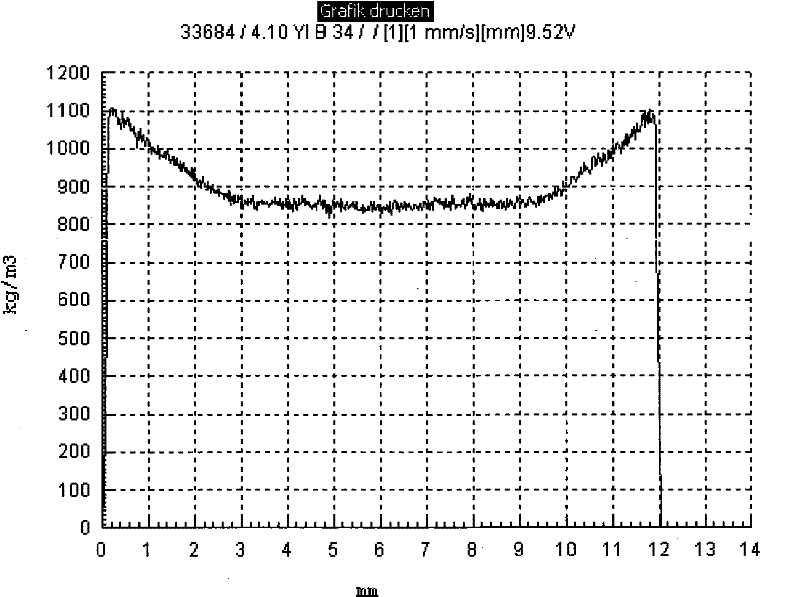

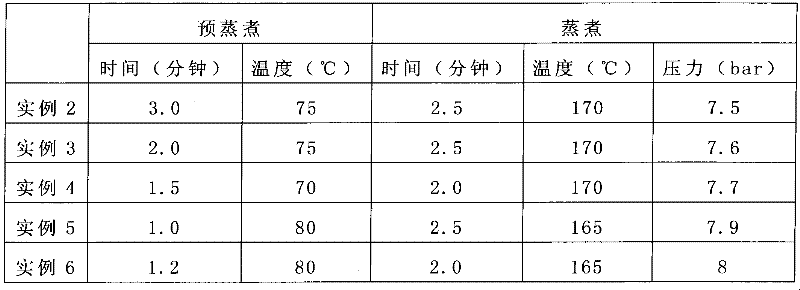

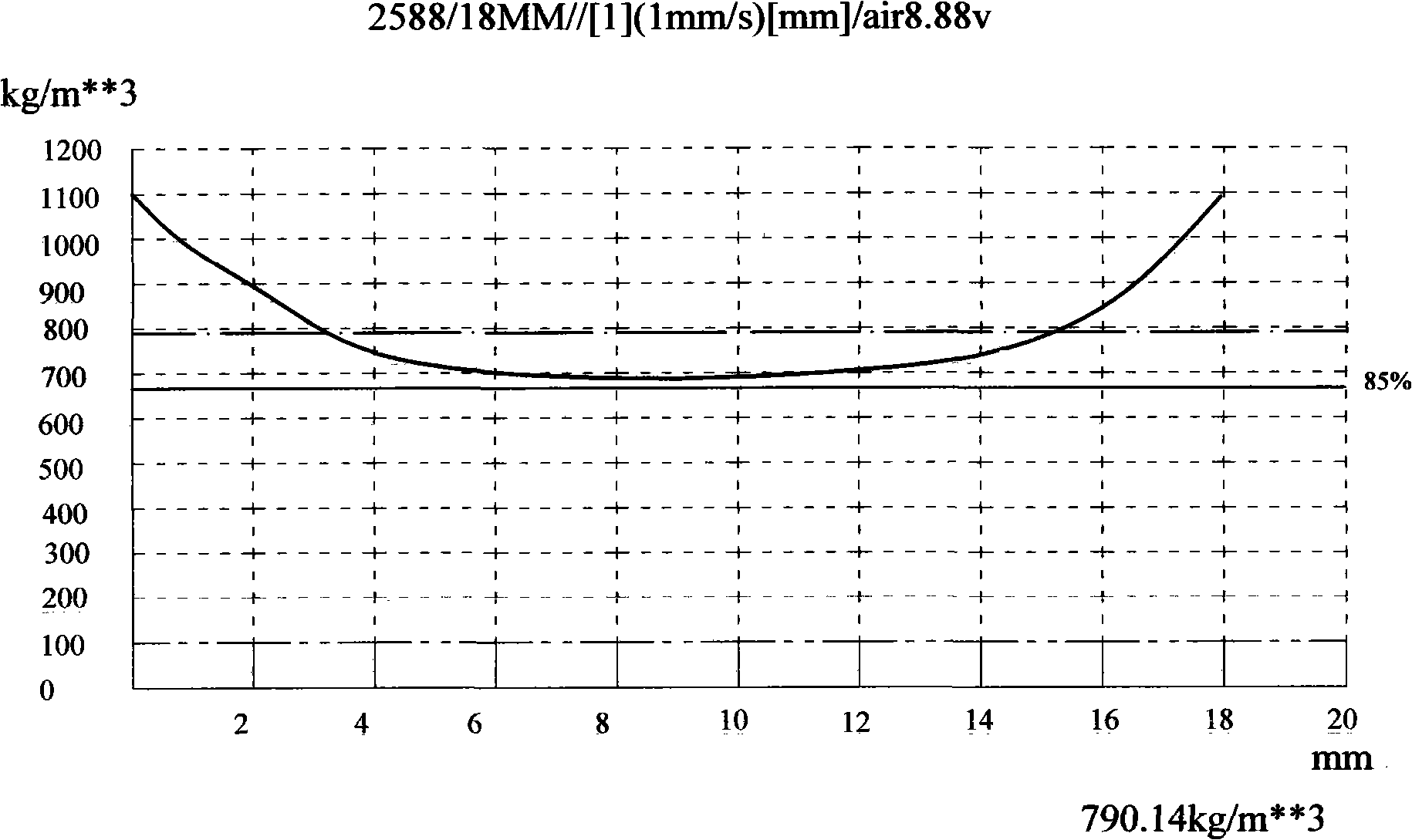

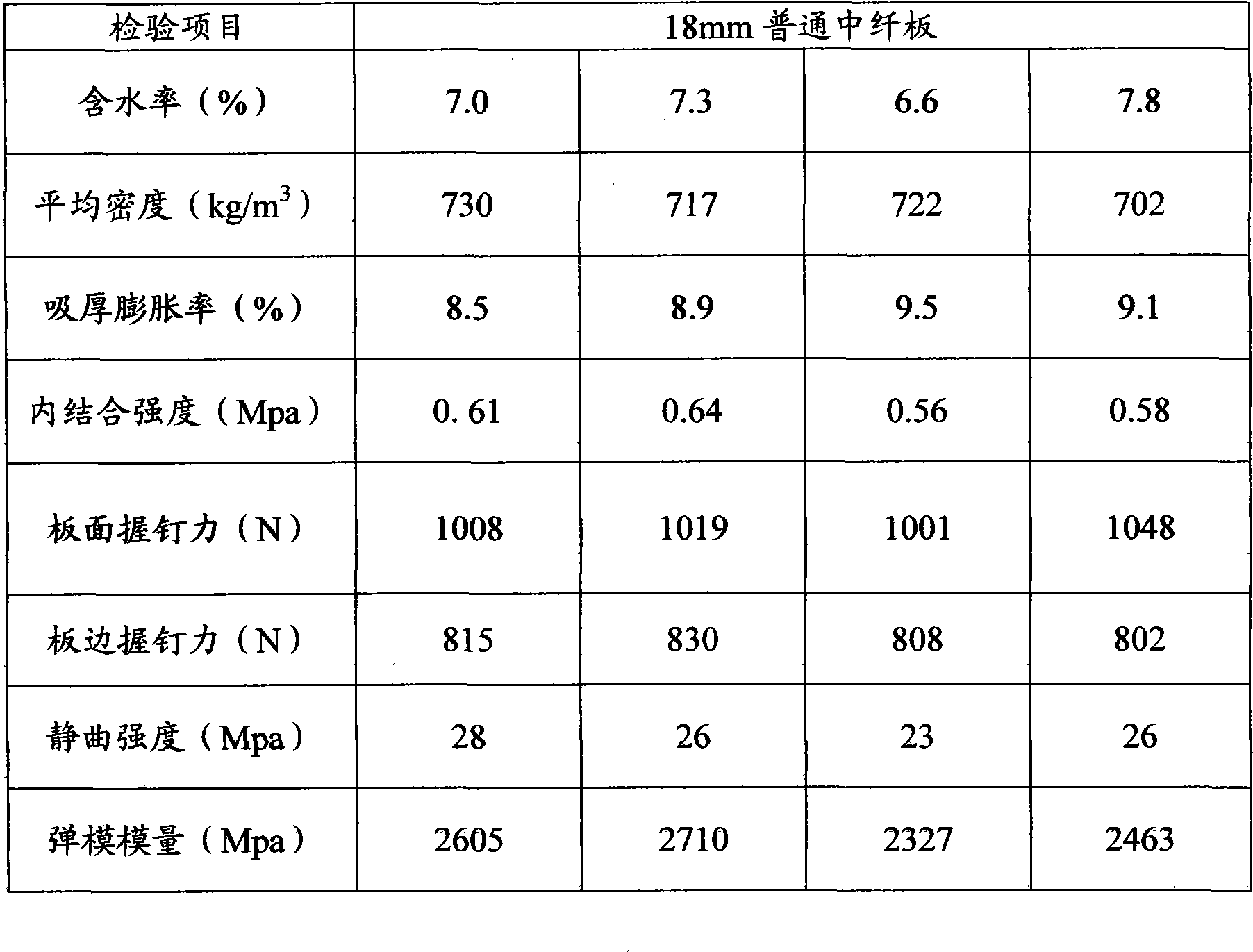

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

Eastern larch bark rapid pyrolysis oil modified phenolic resin adhesive

InactiveCN101328396ALow molar ratioUniform molecular weight growthAldehyde/ketone condensation polymer adhesivesEnvironmentally friendlyPhenols

The invention relates to a preparation method for a low-cost environmentally friendly (low formaldehyde release) larch bark pyrolyzed oil modified phenol-formaldehyde resin adhesive for manufacturing wood composite material. According to the invention, larch bark quickly pyrolyzed oil is used to replace 40 percent of the dosage of phenol, and the pyrolyzed oil modified phenol-formaldehyde resin adhesive is prepared by the means of adding pyrolyzed oil at the middle period to control a mild reaction temperature, and adding formaldehyde and sodium oxide batch by batch. Testing results show that: compared with pure phenol-formaldehyde resin, the modified phenol-formaldehyde resin with a pyrolyzed oil substitution rate of 40 percent can reduce the raw material cost by 33 percent and meet the production requirements of plywood and particle boards; the larch bark pyrolyzed oil modified phenol-formaldehyde resin adhesive reaches GB requirements and makes the formaldehyde release reach the environmental protection requirements of E1 grade and even reach the environmental protection standards of E0 if required; and if the particle boards adopt the pyrolyzed oil modified phenol-formaldehyde resin for glue application layer by layer, the thickness of a surface procuring layer can be effectively reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Copolycondensation resin type formaldehyde catching agent and preparation method thereof

InactiveCN102675574AReduce formaldehyde emissionEasy and flexible operationAldehyde/ketone condensation polymer adhesivesUrea-formaldehydeMelamine

The invention provides a melamine-urea-formaldehyde copolycondensation resin type formaldehyde catching agent which is made of urea, melamine and formaldehyde by means of copolycondensation reaction, wherein the final molar ratio F / U of the formaldehyde to the urea is 1:2.4-4.0, the formaldehyde is added once, the urea is added twice, the reaction temperature ranges from 85 DEG C to 95 DEG C, and the reaction time is 2-3 hours. The formaldehyde catching agent can be mixed and used with various urea resin adhesives and especially applicable to urea resins prepared with low molar ratio of the formaldehyde to the urea. Strength of main adhesives of urea resins is unaffected within a certain weight addition proportional range. The melamine-urea-formaldehyde copolycondensation resin type formaldehyde catching agent has the advantages of flexibility in use, high comprehensive performances and the like and is applicable to production of various indoor artificial boards.

Owner:SOUTHWEST FORESTRY UNIVERSITY

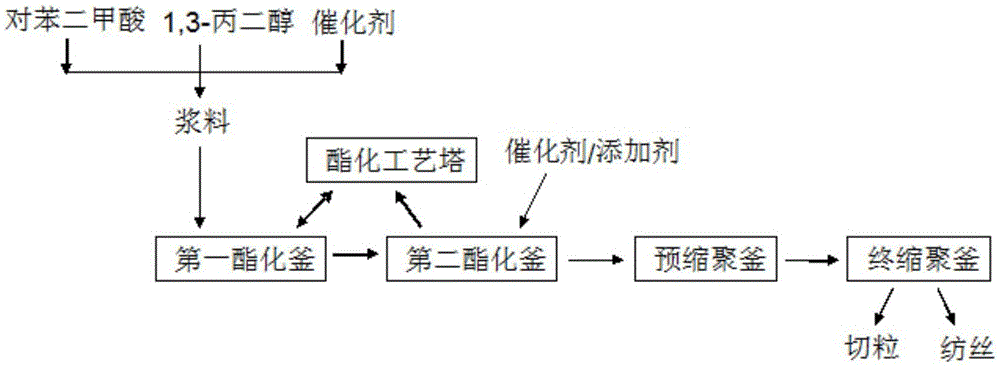

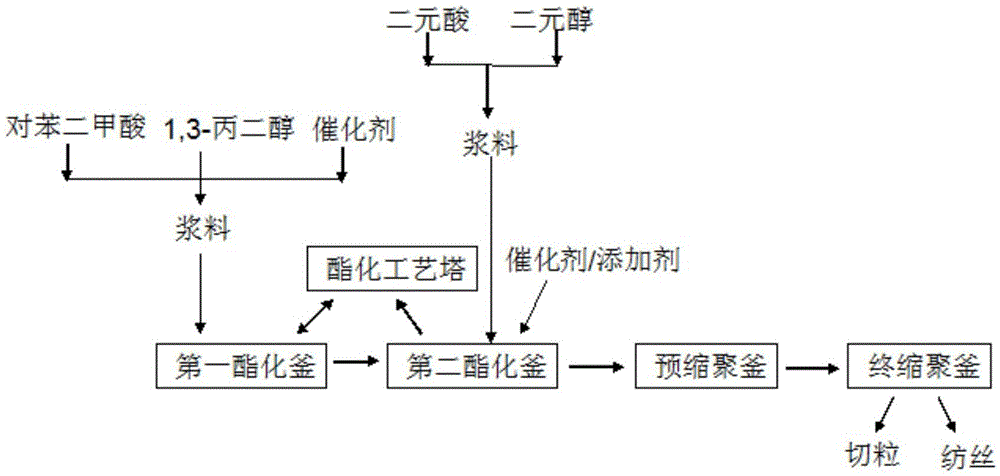

Preparation methods of high-viscosity polytrimethylene terephthalate and copolyester thereof

The invention discloses a preparation method of high-viscosity polytrimethylene terephthalate. The preparation method of high-viscosity polytrimethylene terephthalate comprises the following steps: mixing: preparing polyterephthalic acid and 1,3-propanediol into a slurry under atmospheric pressure; primary esterification: continuously delivering the slurry into a first esterification kettle, and carrying out primary esterification reaction to obtain a first esterification product; secondary esterification: delivering the first esterification product into a second esterification kettle, and carrying out secondary esterification reaction to obtain a second esterification product; pre-polycondensation: continuously delivering the second esterification product into a pre-polycondensation kettle, and carrying out polycondensation to remove small molecules, thereby obtaining a polytrimethylene terephthalate prepolymer; and final polycondensation: continuously delivering the polytrimethylene terephthalate prepolymer into a final polycondensation kettle, and carrying out condensation polymerization to remove small molecules, thereby obtaining the polytrimethylene terephthalate high polymer. The invention also discloses a preparation method of the high-viscosity polytrimethylene terephthalate copolyester. The products have the advantages of high inherent viscosity and high quality.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD

Dual zone aromatic alkylation process

ActiveUS7420098B2High selectivityLow molar ratioMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkylation

A process for the catalytic alkylation of an aromatic substrate with an alkylating agent is disclosed that comprises contacting the aromatic substrate and the alkylating agent in sequential alkylation zones to obtain an alkylaromatic. The first catalyst comprises UZM-8 zeolite and the second catalyst comprises beta zeolite. The process is particularly well suited for the alkylation of benzene with propylene to produce cumene.

Owner:UOP LLC

Process for producing alkylene glycol

ActiveCN1721385AReduce swellingImprove thermal stabilityBulk chemical productionPreparation by hydrolysisHydration reactionReaction temperature

The present invention is preparation process of alkylene dyhydric alcohol, and aims at prolonging the service life of catalyst and raising its heat tolerance while maintaining its high conversion rate and selectivity. The technological scheme of the present invention is that the material including alkylene oxide and water in the molar ratio of 1 to 5-15 and macroporous composite resin catalyst are made to contact and react to produce alkylene dyhydric alcohol in the conditions of reaction temperature 60-150 deg.c, reaction pressure 0.5-2 MPa and liquid space velocity 3-6 / hr. The macroporous composite resin catalyst includes monomer, copolymerized monomer, nanometer material, initiator and two assistants and is treated with OH-, Cl-, HSO4-, CHO3- or HCOO- anionic compound. The present invention may be used in industrial production of ethylene oxide catalyzed synthesis of dyhydric alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

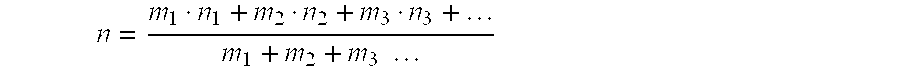

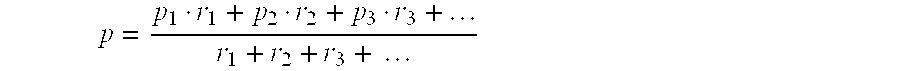

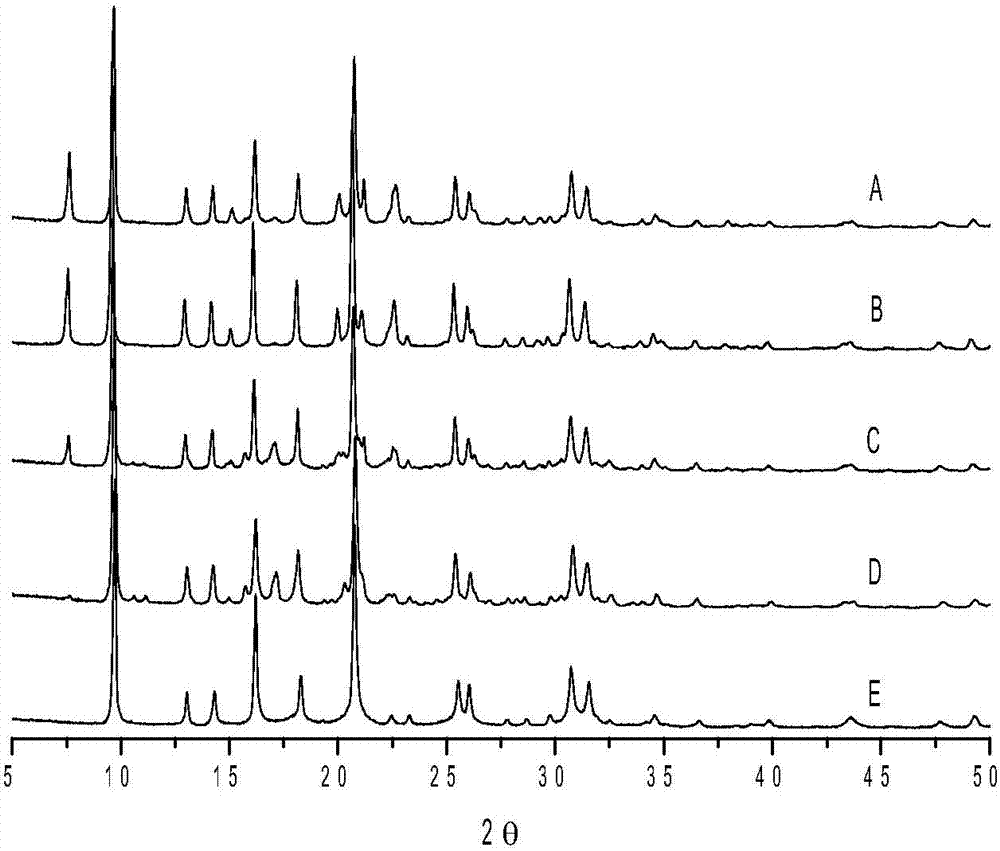

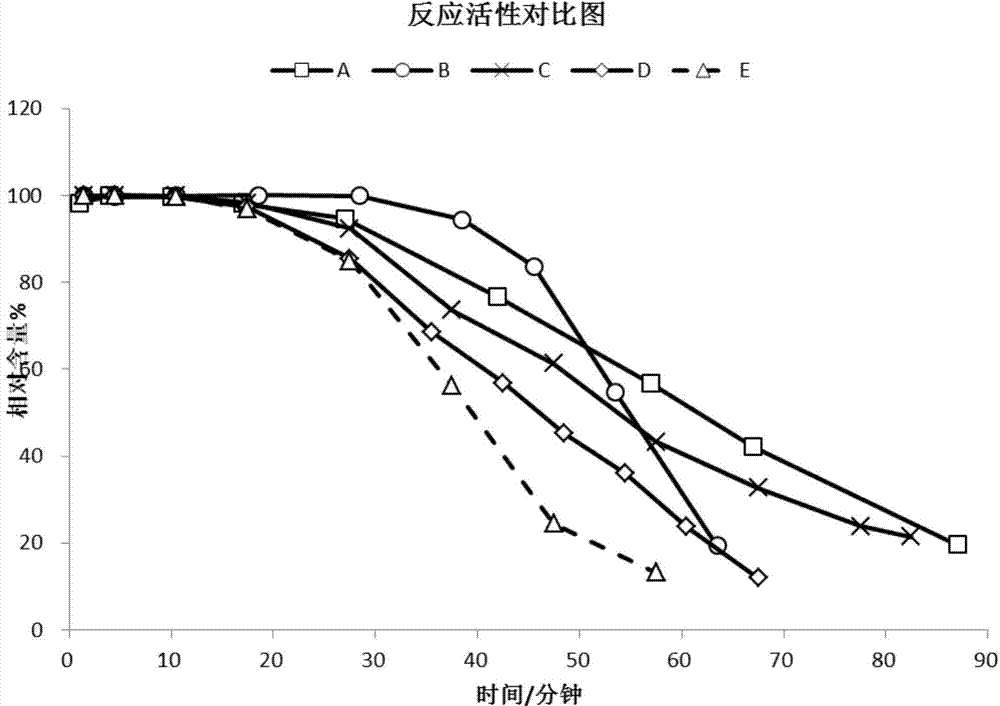

Low-silicon composite molecular sieve, and synthetic method and application thereof

ActiveCN104326483AIncrease profitReduce the feed ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveComputational chemistry

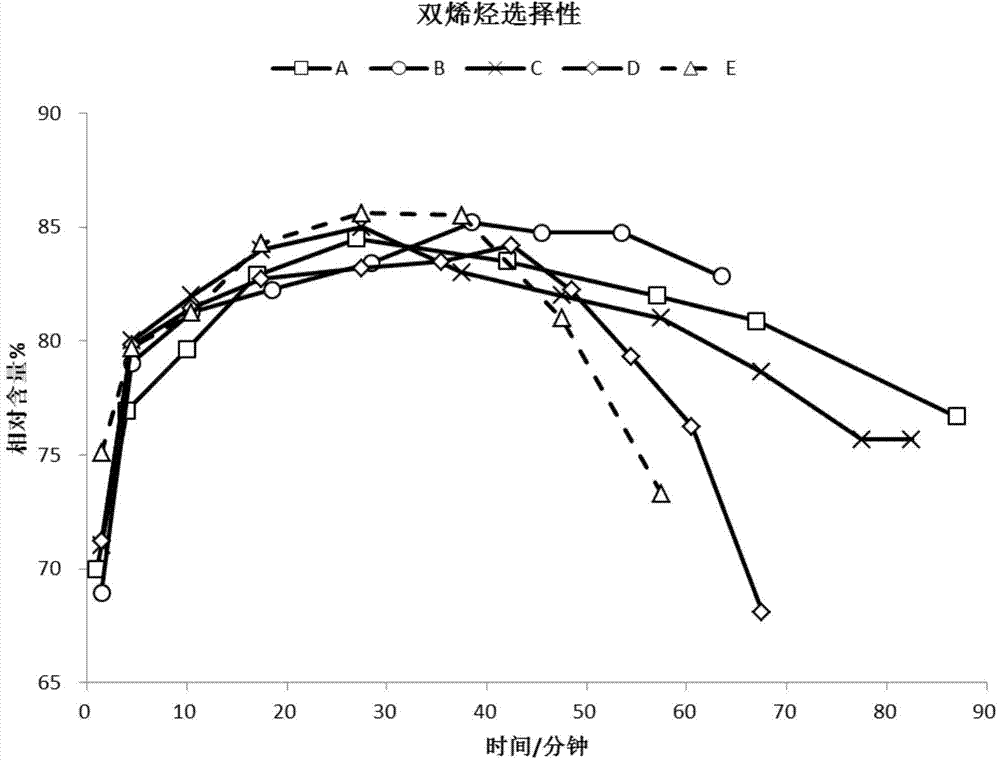

A low-silicon composite molecular sieve comprises, by mass, 2-25% of an SAPO-5 molecular sieve and 75-98% of an SAPO-34 molecular sieve, and a molar ratio of SiO2 / Al2O3 is 0.07-0.15. The low-silicon composite molecular sieve has the advantages of low silicon, low cost, simple synthesis technology, high average diolefin selectivity in a methanol-to-olefin reaction, and long life.

Owner:天津众智科技有限公司

Routing plate processing technique

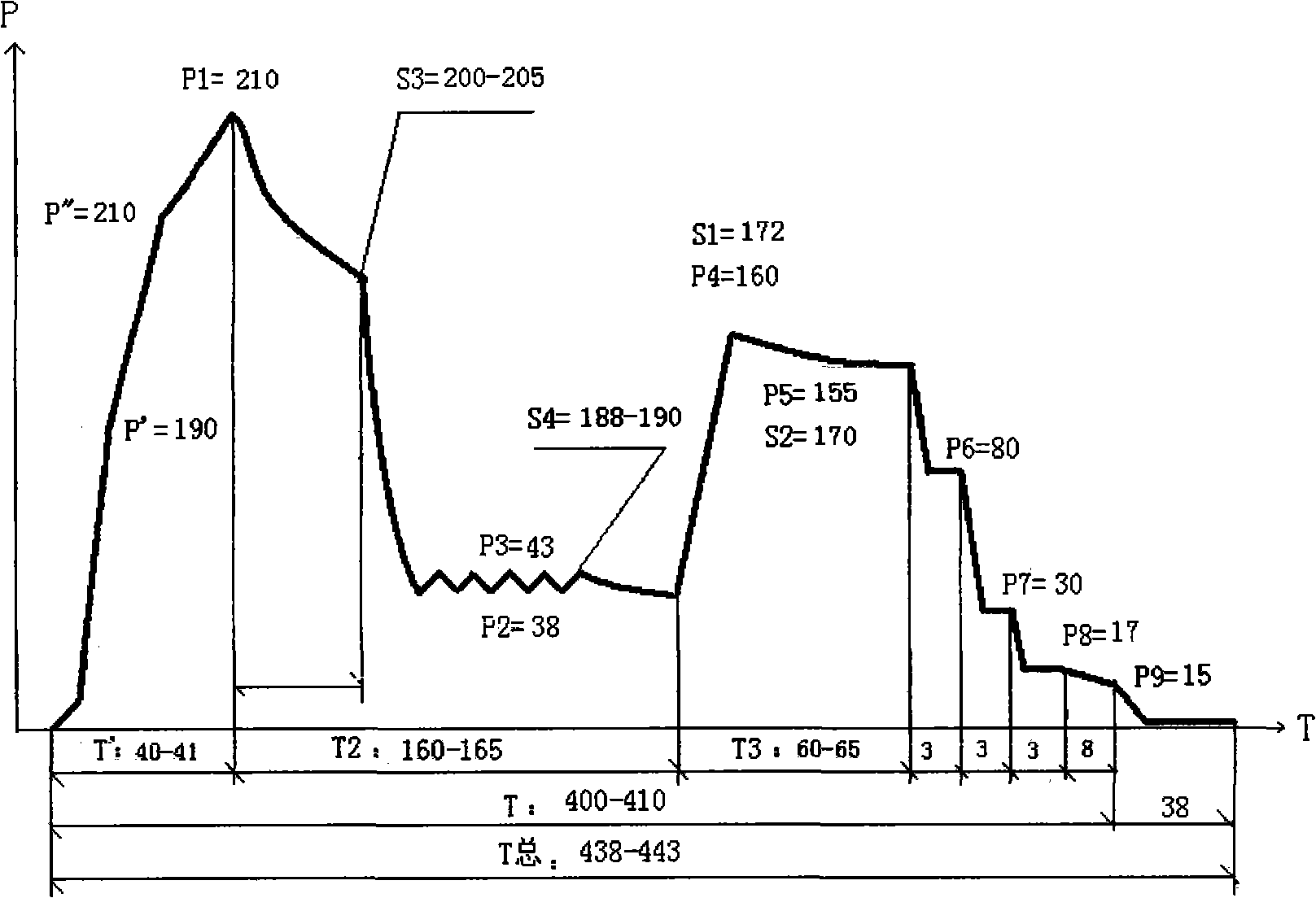

ActiveCN101298159AStable mechanical propertiesIncrease productivityVeneer manufactureAldehyde/ketone condensation polymer adhesivesQuenchingHeat press

The invention provides a processing technology for a routing plate, comprising the processing steps as follows: chipping and selecting of wood, pre-steaming and steaming, fiber separation, preparing the E1-class urea-formaldehyde, preparing the curing agent, adding the urea-formaldehyde, curing agent and paraffin, drying the fiber of the added the urea-formaldehyde, curing agent and paraffin, uniformly paving the dried wood fiber and smoothly pre-pressing the wood fiber under the pressure of 3.0-5.0MPa, heat pressing under the temperature of 180-185 DEG C, cooling, quenching and tempering, sanding and sawing, classifying and packaging. The plate prepared by the process has reasonably distributed density, moderate strength and low release quantity of formaldehyde.

Owner:DARE WOOD BASED PANEL GRP

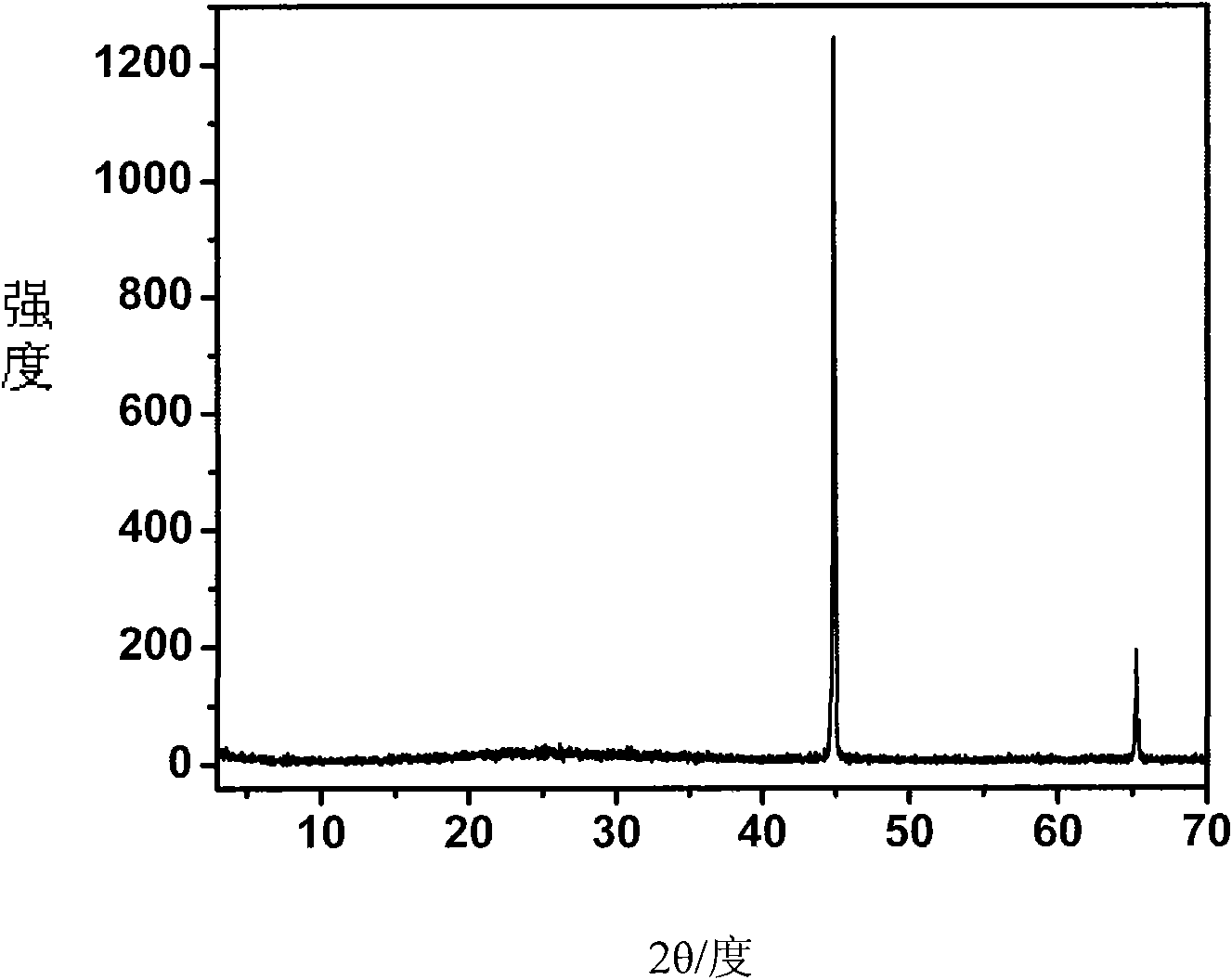

Preparation method for titanium-based low-precious-metal-content oxide coating anode

The invention discloses a preparation method for a titanium-based low-precious-metal-content oxide coating anode. The preparation method comprises the following steps of: performing sand blasting and polishing treatment on a titanium substrate, removing oil stain, and putting into deionized water for performing ultrasonic cleaning; preparing chloro-iridic acid, ruthenium trichloride, trichloride antimony and tin tetrachloride into a masking liquid under the condition that the mole percent of chloro-iridic, ruthenium trichloride or a mixture of chloro-iridic and ruthenium trichloride is 2.5-30 percent, the mole percent of trichloride antimony is 10-15 percent and the mole percent of tin tetrachloride is 60-87.5 percent, coating onto the titanium substrate, drying at the temperature of 70-90 DEG C for 5 minutes, sintering at the temperature of 500-550 DEG C for 5 minutes, repeating the process till an oxide coating is up to 1.5-2.0 mg / cm<2>, and sintering at the temperature of 500-550 DEG C for one hour. The anode provided by the invention can be widely applied in the fields of seawater electrolysis chlorine preparation, electroflotation, electroosmosis, electrodeionization and the like. The anode has stable performance and high current efficiency, the precious metal molar ratio is lowered to 2.5-30 percent, and the cost can be lowered remarkably.

Owner:ZHEJIANG UNIV

Hydrotalcite-like structuring catalyst and method for catalytic synthesis of pseudo-ionone

InactiveCN101816950ALow molar ratioProcess environmental protectionOrganic compound preparationCatalyst activation/preparationCatalytic effectAluminum substrate

The invention discloses a hydrotalcite-like thin membrane which is grown on an aluminum substrate with surface anode oxidation and used as a structuring catalyst in the field of membrane catalysis, so as to catalyze the optimal feed ratio of citral to acetone during the aldol condensation reaction of the citral and the acetone. The in-situ synthesis technology is adopted for preparing the hydrotalcite-like thin membrane on an aluminum sheet after the surface anode oxidation, the high-temperature calcination and the re-hydration are further carried out, and the hydrotalcite-like structuring catalyst which takes aluminum as the substrate is finally obtained. The prepared structuring catalyst can be effectively used for the aldol condensation reaction of the citral and the acetone, solve a series of problems caused by a liquid base catalyst and a solid base catalyst and lead the process to meet the requirements on environmental protection and sustainable development; more importantly, the use of the structuring catalyst can effectively reduce the molar ratio of acetone / citral to 1, thereby obtaining great catalytic effect.

Owner:BEIJING UNIV OF CHEM TECH

Impregnated paper finished OSB composite floor and preparation method

ActiveCN105464335ALow costGood value for moneyAldehyde/ketone condensation polymer adhesivesFlooringPulp and paper industryUltimate tensile strength

The invention relates to a plate, in particular to an impregnated paper finished OSB composite floor and a preparation method. The impregnated paper finished OSB composite floor sequentially comprises an OSB base material layer, a veneer layer, a buffer paper layer, a balance paper layer and a sprayed decorative paper layer from bottom to top. The longitudinal static bending intensity of the OSB base material layer is larger than or equal to 50 MPa, and the water absorption thickness swelling rate of the OSB base material layer is smaller than or equal to 12%. The veneer layer is a poplar bleached veneer, and the thickness ranges from 0.6 mm to 1.2 mm. The buffer paper layer is impregnated kraft paper with the thickness of 0.4 mm to 0.6 mm, and the glue quantity is 80% or above. The weight of the balance paper layer ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The weight of the sprayed decorative paper ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The impregnated paper finished OSB composite floor has high environment friendliness, stability and water resistance.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Low formaldehyde resin adhesive for decorative impregnating paper and preparation method thereof

ActiveCN103045140ALow molar ratioGuaranteed physical index requirementsNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

The invention discloses a low formaldehyde resin adhesive for decorative impregnating paper and a preparation method thereof, wherein the resin adhesive contains: 60% by weight of 37% formaldehyde, 40% by weight of 98% urea, and 1.0-1.5% by weight of composite auxiliary agents which contains 0.2-0.3% by weight of curing agent, 0.5-0.8% by weight of cross-linking agent, and 0.3-0.4% by weight of reinforcing agent. The resin adhesive has the characteristics of low free formaldehyde content and high water resistance, and enhances the internal bonding force of the resin adhesive while reduces the mol ratio, which reduces the free formaldehyde releasing amount of the impregnating paper in the impregnating paper production process, and makes sure the each physical index demand of the decorative plate in the secondary hot pressing process.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

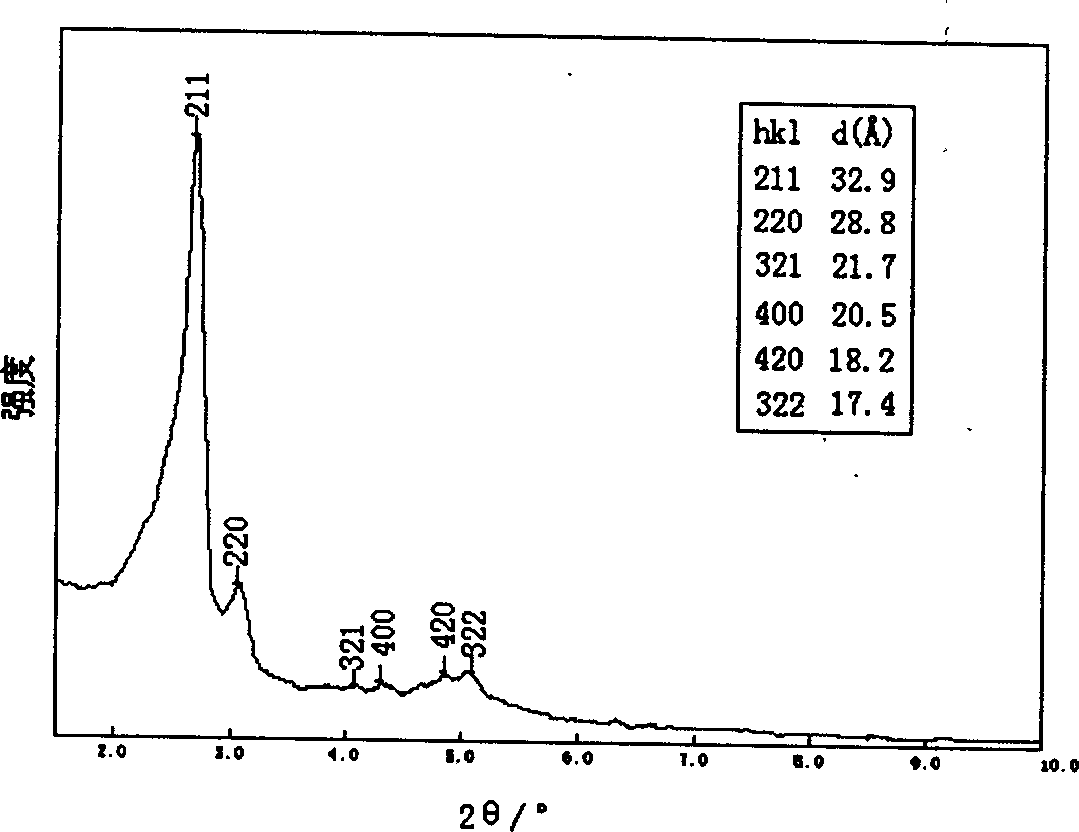

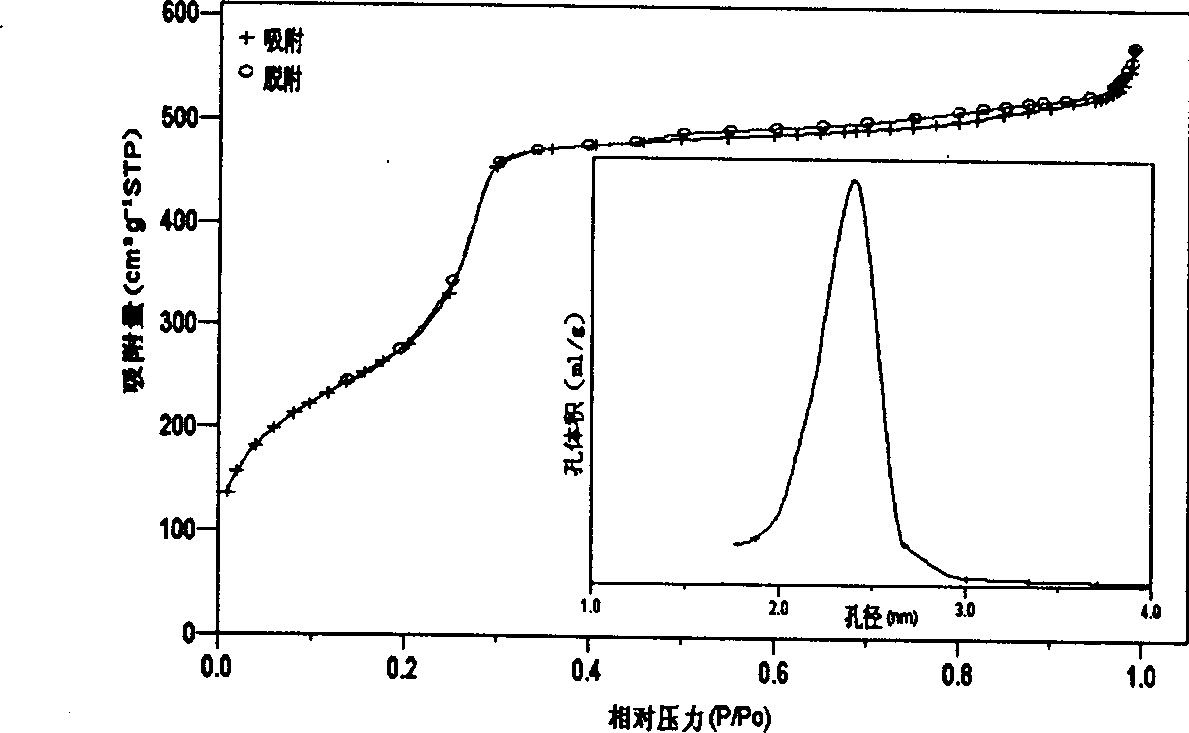

Prepn process of MCM-48 medium-pore molecular sieve with ternary mixed cationic, non-ionic and anionic surfactant as template agent

InactiveCN1440928ALow molar ratioReduce the molar ratio (eg ≈0.05:1)SilicaMolecular-sieve silica-polymorphsMolecular sievePolyethylene glycol

The present invention prepares high-regularity, high-specific surface area and high-quality silicon-base MCM-48 molecular sieve with ternary mixed water solution of CTAB as cationic surfactant, OP-10 as non-ionic surfactant and SL as anionic surfactant as templating agent, TEOS as silicon source and under very low CTAB / SiO2 molar ratio and very low total surfactant concentration. Into the ternary mixture, alkali source and silicon source are added, and through crystallization, stoving and roasting, the preparation process is completed. The said preparation process has low cost and simple operation, and is environment friendly and suitable for large-scale production.

Owner:FUDAN UNIV

Method for treating arsenic containing materials

A method for selectively removing arsenic from a sulphide material containing arsenic by conducting a leaching step that includes contacting the material with a leaching solution that leaches arsenic from the material to form a pregnant liquor containing dissolved arsenic and a solid of a sulphide material of reduced arsenic content, and subsequently separating the solid from the pregnant liquor. The fresh leaching solution that is provided to the leaching step is an alkaline solution having a sulphide-containing compound present in an amount of from 0 to 1.0 times the amount of sulphur containing compound required to react with the arsenic present in the material.

Owner:TOOWONG PROCESS

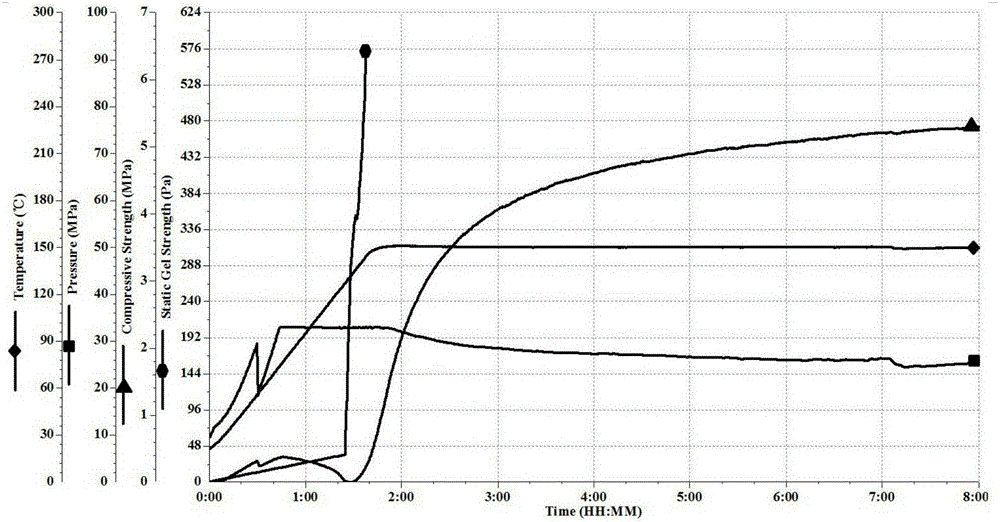

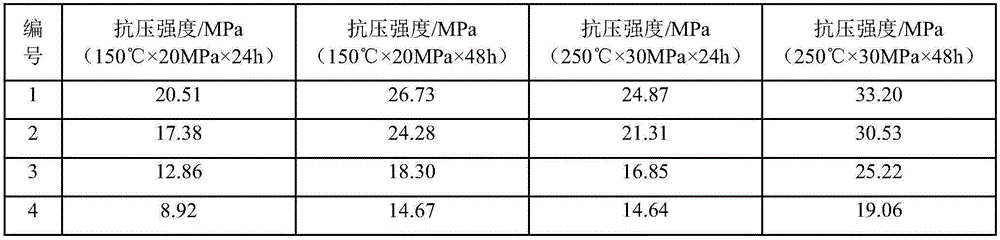

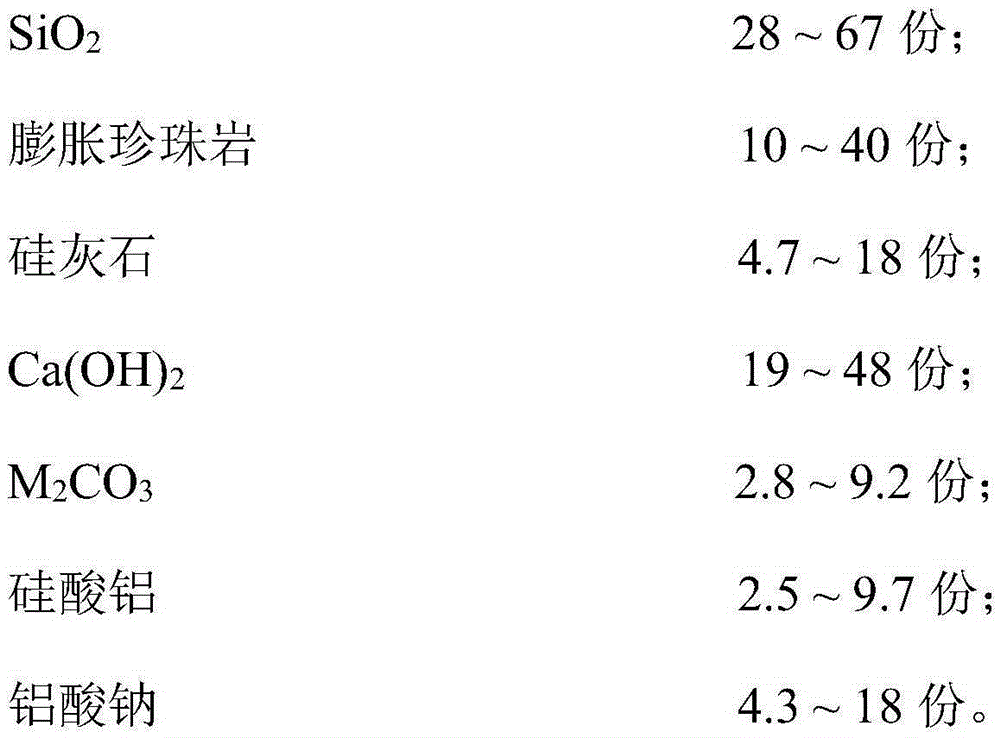

High-temperature-resistant cementing material system

ActiveCN105255464AEmission reductionReduce pollutionDrilling compositionArray data structureAluminum silicate

The invention provides a high-temperature-resistant cementing material system which mainly solves the problems that in existing oil well cement, the high-temperature strength is declined and the high-temperature mechanical stability is poor and is suitable for the field of high-temperature cementing of oil gas wells. The high-temperature-resistant cementing material system is prepared from, by mass, 28-67 parts of SiO2, 10-40 parts of expanded perlite, 4.7-18 parts of wollastonite, 19-48 parts of Ca(OH)2, 2.8-9.2 parts of M2CO3, 2.5-9.7 parts of aluminum silicate and 4.3-18 parts of sodium aluminate. The high-temperature-resistant cementing material system can meet well cementing operation in deep formation under the high-temperature high-pressure conditions and has the advantages of being convenient to construct on site and low in cost; in addition, compared with the process of producing oil well cement, the CO2 emission load can be significantly decreased, and the application prospect is wide.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

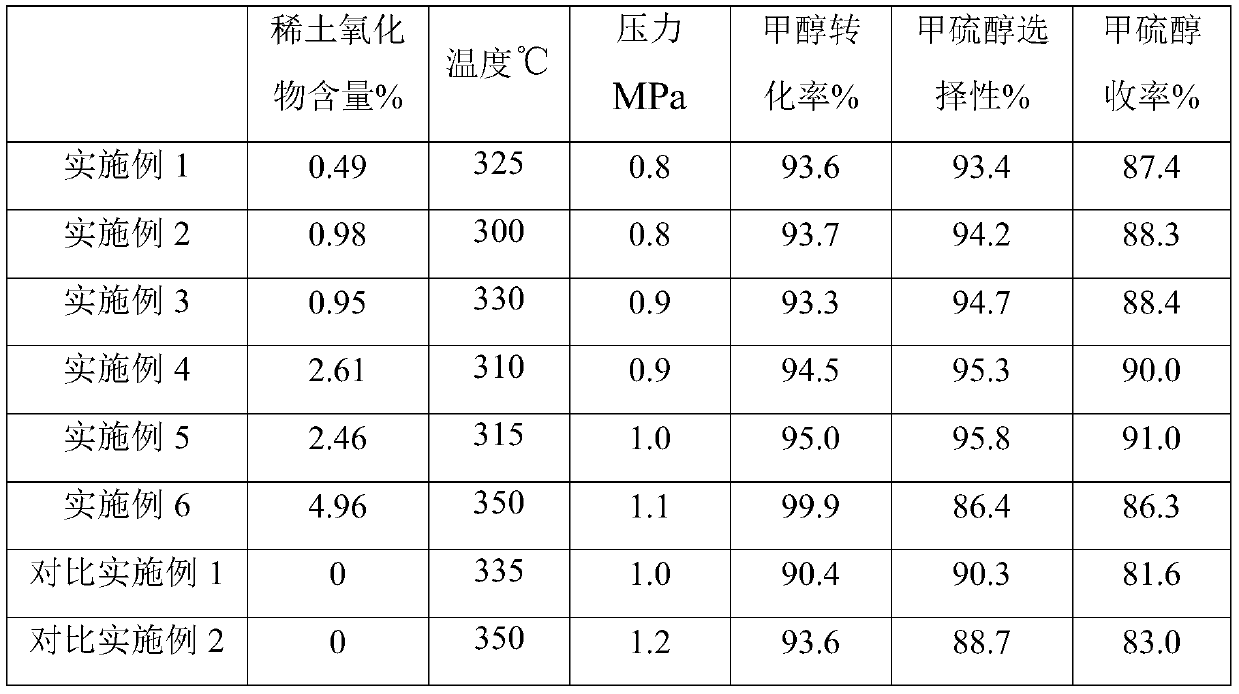

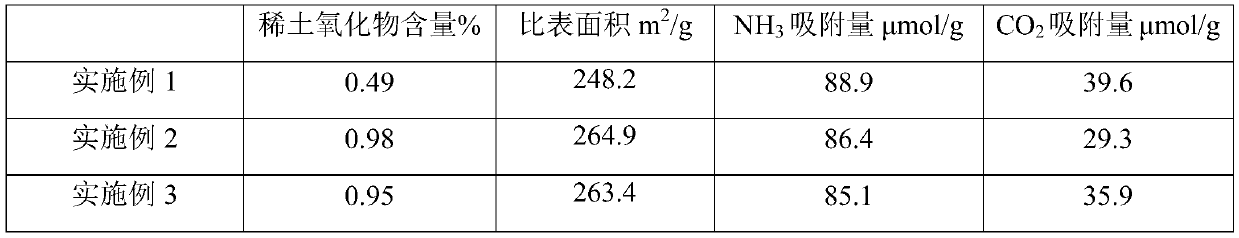

Supported rare earth-modified metal catalyst, and preparation method and application thereof

PendingCN110918086ALarge specific surface areaEvenly dispersedThiol preparationCatalyst activation/preparationRare-earth elementPtru catalyst

The invention discloses a supported rare earth-modified metal catalyst which comprises a rare earth element-modified alumina carrier and active components supported on the rare earth element-modifiedalumina carrier, and the active components comprise an alkali metal element and a tungsten element; in the supported rare earth-modified metal catalyst, the mass percentage content of rare earth elements is 0.4-5% based on oxide. After the rare earth elements are added into the supported rare earth-modified metal catalyst for modification, the supported rare earth-modified metal catalyst has better catalytic performance when applied to preparation of methyl mercaptan through a reaction of methanol and hydrogen sulfide, the selectivity and yield of methyl mercaptan are improved, and the reaction temperature and the circulation amount of hydrogen sulfide are reduced.

Owner:ZHEJIANG NHU CO LTD +2

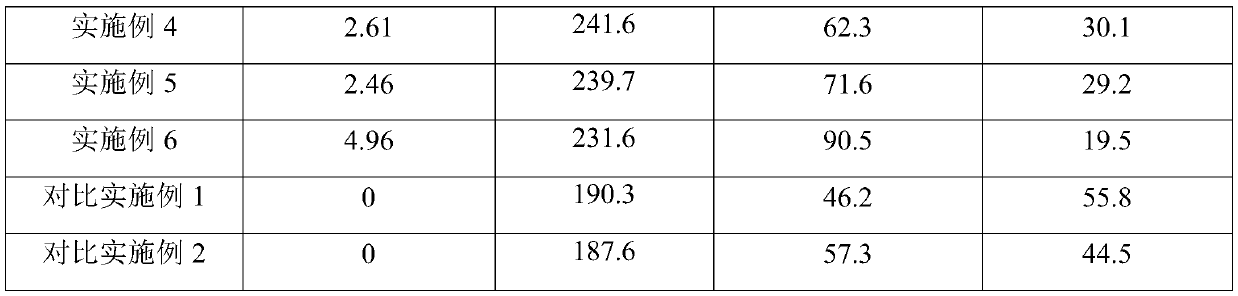

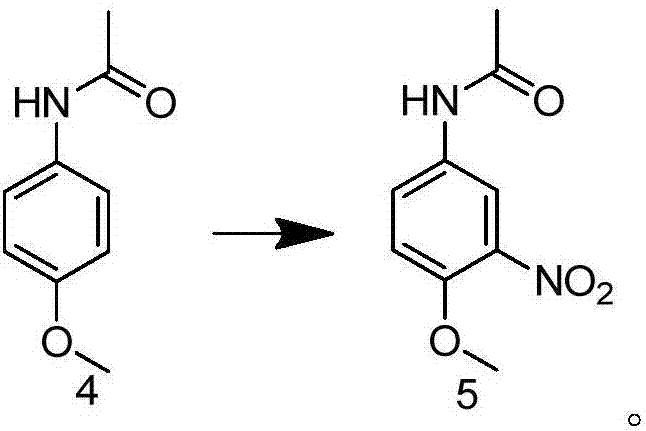

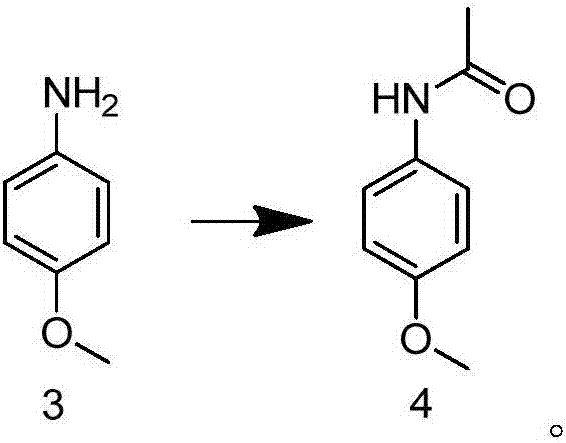

Preparation method of 2-methoxy-5-acetamidoaniline

InactiveCN107286043AEasy to recycleReduce pollutionOrganic compound preparationCarboxylic acid amides preparationHydrogenReaction temperature

The invention discloses a preparation method of 2-methoxy-5-acetamidoaniline. The preparation method comprises the following step: in a solvent, under the action of a catalyst Pd / C, performing a reduction reaction as shown below on a compound as shown in a formula 5 and hydrogen to obtain a compound as shown in a formula 6. The preparation method is low in pollution, high in yield rate, low in cost, convenient in catalyst or solvent recycling, short in reaction time, low in reaction temperature, high in safety and mild in reaction condition.

Owner:SHANGHAI ANOKY GRP +1

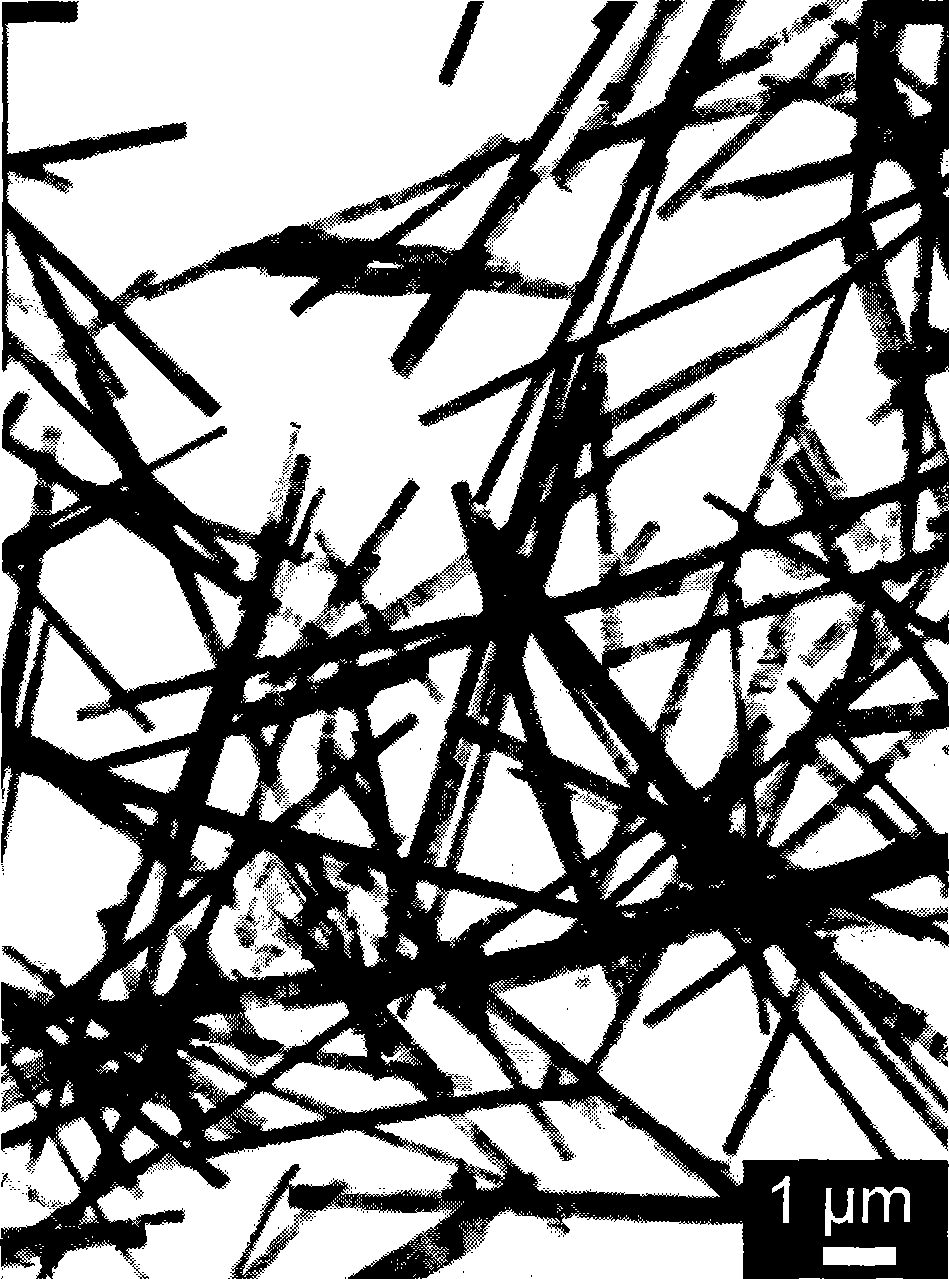

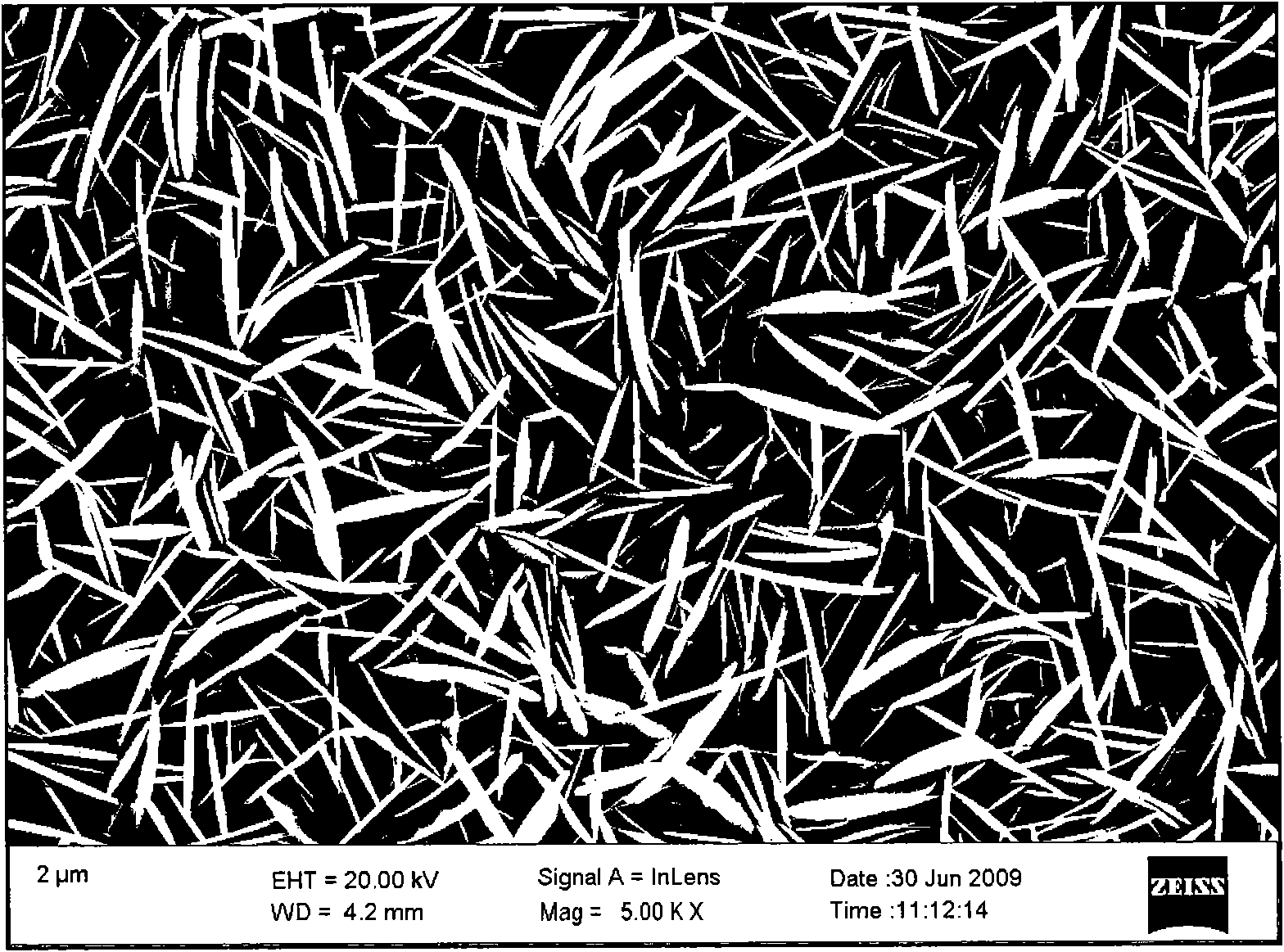

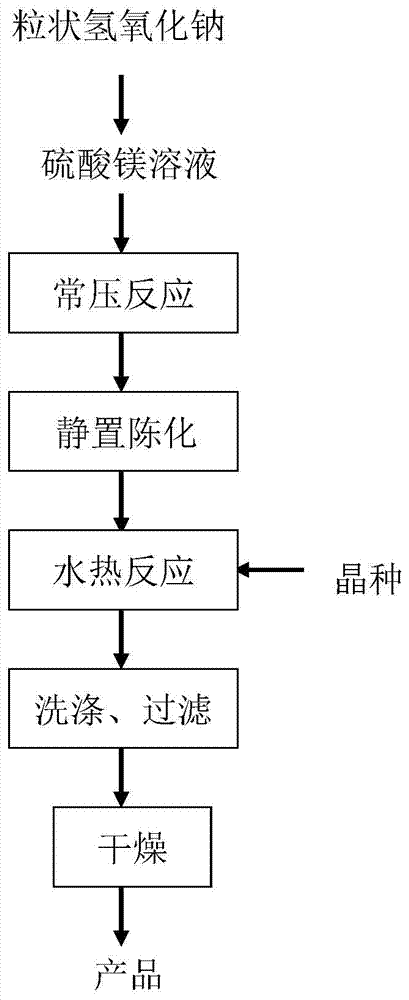

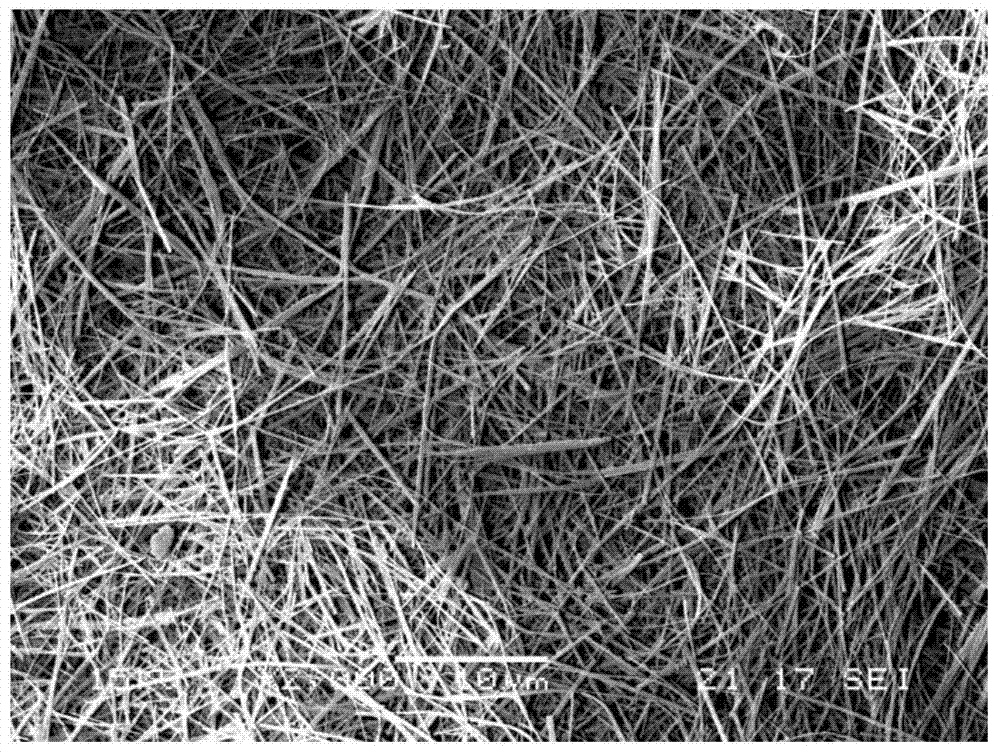

Preparation method of fibrous alkali magnesium sulfate whisker

ActiveCN103789819AIncrease profitLow costPolycrystalline material growthFrom normal temperature solutionsMagnesium Sulfate whiskersWhiskers

The invention relates to the preparation field of chemical industrial materials, and particularly relates to a preparation method of a fibrous alkali magnesium sulfate whisker. The preparation method of the fibrous alkali magnesium sulfate whisker comprises the following steps: (1) preparing a magnesium sulfate solution by using MgSO4.7H2O, stirring and adding NaOH granular caustic soda, aging for 2-24 hours at the temperature of 25 to 100 DEG C to obtain a slurry; (2) transferring the slurry obtained in the step (1) into a hydrothermal reactor, wherein the filling degree is 50-80 percent, adding 0.5-5 percent of seed crystal according to the mass of the NaOH granular caustic soda, uniformly stirring, and reacting the slurry for 2-12 hours at the temperature of 130-180 DEG C; (3) cooling after finishing the reaction of the step (2), filtering, washing and drying a obtained white turbid liquid to obtain the fibrous alkali magnesium sulfate whisker. According to the preparation method, the seed crystal is added into the reaction slurry, alkali magnesium sulfate is easily subjected to nucleus formation growth, and the preparation concentration of the reaction slurry can be relatively high; the whisker nucleation time is reduced, and the whisker growth time also can be shortened.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

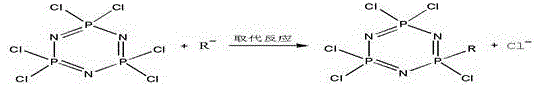

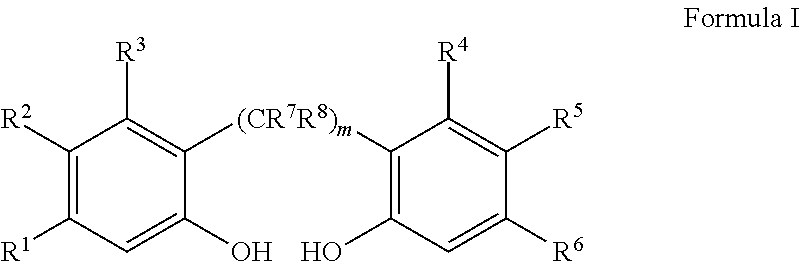

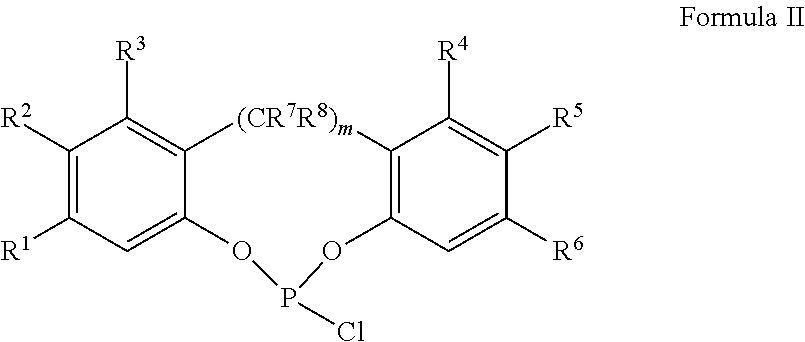

Slurry process for synthesis of bisphosphites and situ use thereof for producing bisphosphite

ActiveUS20110196166A1Reduce solubilityHigh yieldPhosphorus organic compoundsSolubilityOrganic solvent

The present invention provides a step-wise process for preparation of a bisphosphite. In step (a) the process prepares a phosphoromonochloridite in high yield, by contacting phosphorus trichloride with an aromatic diol in a slurry under reaction conditions and in the presence of a second aromatic diol to produce a mixture comprising the phosphoromonochloridite, the second aromatic diol, and excess PCl3. The slurry comprises less than 5 mole percent of a nitrogen base, and the organic solvent is selected for its low hydrogen chloride solubility. After removing the excess PCl3, a nitrogen base is added to effect condensation of the phosphoromonochloridite with the second aromatic diol to yield the bisphosphite. The invention particularly provides a process for preparing 6,6′-(3,3′,5,5′-tetra-tert-butylbiphenyl-2,2′-diyl)bis(oxy)didibenzo[d,f][1,3,2]dioxaphosphepine by the above route.

Owner:DOW TECH INVESTMENTS

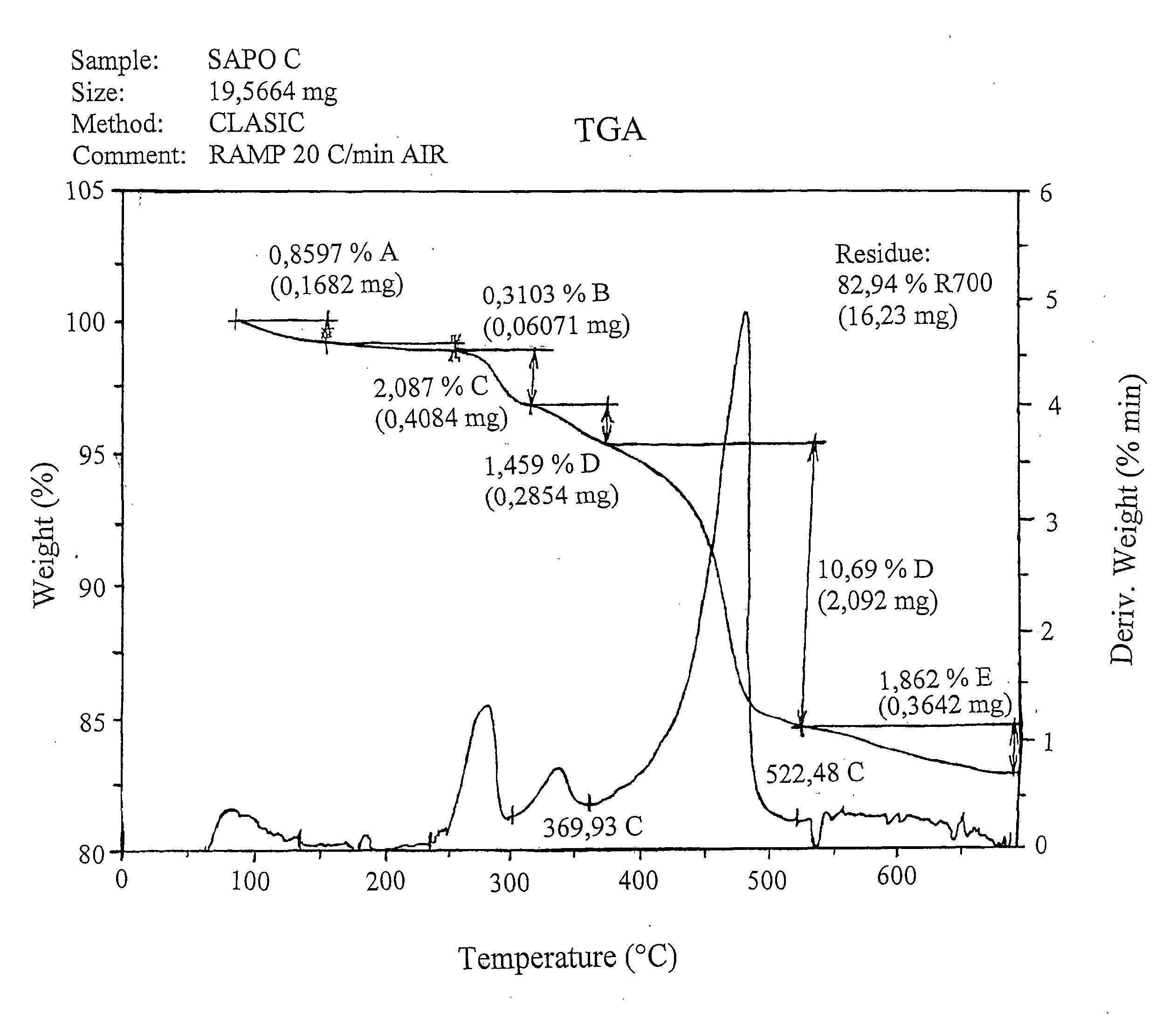

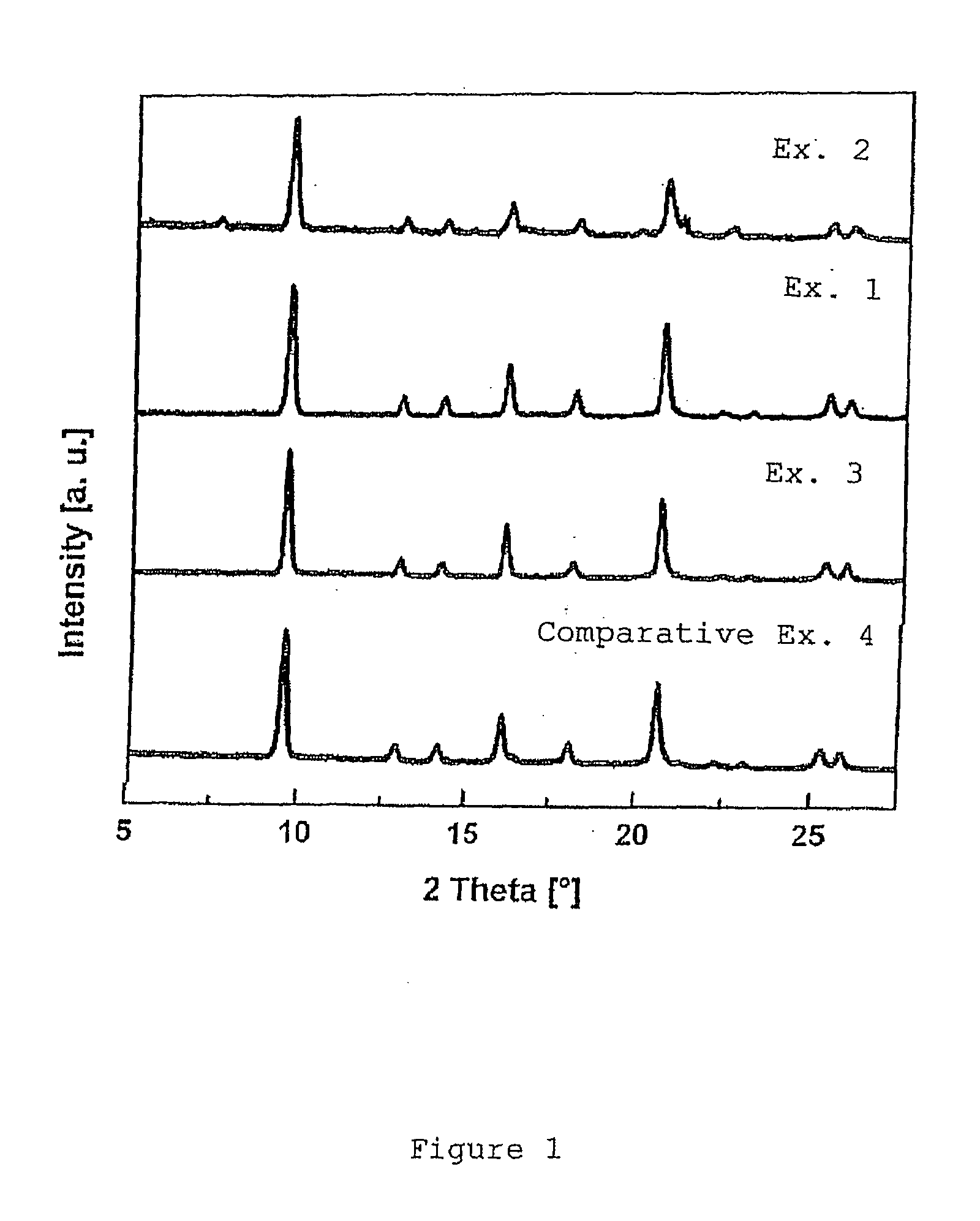

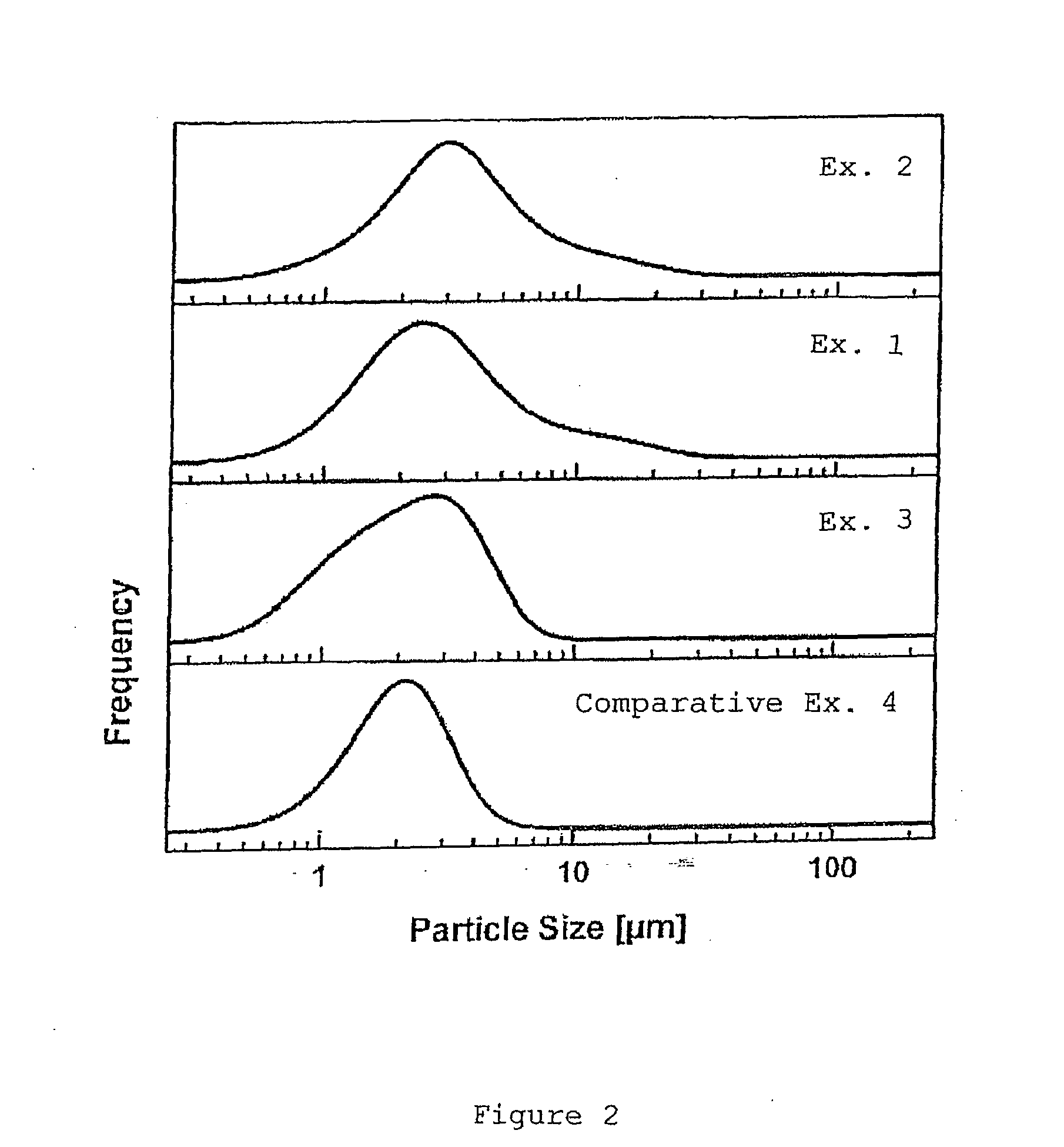

Process for preparing silicoaluminophosphate (SAPO) molecular sieves, catalysts containing said sieves and catalytic dehydration processes using said catalysts

ActiveUS20100292071A1High yieldLower synthesis costAluminium compoundsEthylene productionSlurryDigestion

A new process for producing a SAPO molecular sieve is disclosed wherein a mixture of a P source with an Al source is subjected to a digestion step under stirring before adding a Si source and a template. The slurry resulting after addition of all chemicals is subjected to a pH adjustment followed by the usual hydrothermal treatment at higher temperature in an autoclave. In this way, very pure highly crystalline SAPO molecular sieves such as SAPO-34 are obtained with a very high yield. In addition, the SAPOs produced this way have an exceptional activity in the dehydration reactions and can be employed as a active component of catalysts for the production of valuable dehydration products from methanol such as, but not limited to, olefins and dimethylether (DME).

Owner:CASALE CHEM SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com