High-temperature-resistant cementing material system

A technology of high temperature resistance and well cementing, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor high temperature resistance of oil well cement, and achieve the effects of low cost, reduced environmental pollution, and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

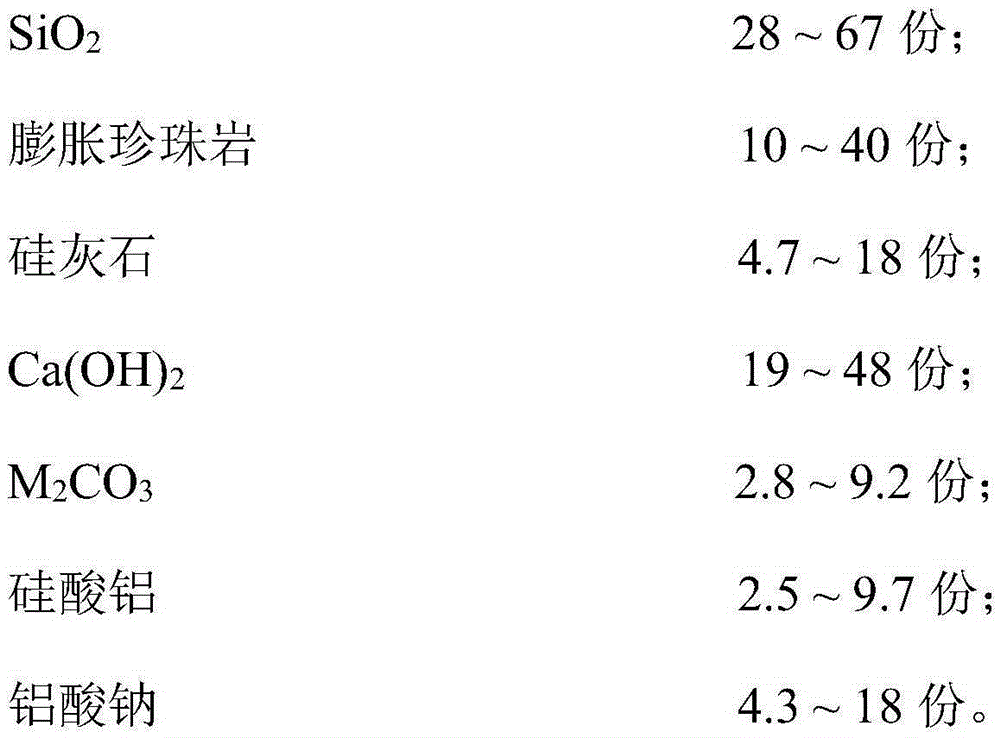

[0027] Example 1: Composition of high temperature resistant cementing material system

[0028] A high-temperature-resistant cementing material system can be composed of the following oxygen-containing compounds such as silicon, calcium, and aluminum, and the mass parts of each substance are specifically: SiO 2 42.2 parts, expanded perlite 13.5 parts, wollastonite 5.7 parts, Ca(OH) 2 22.3 parts, Li 2 CO 3 4.5 parts for aluminum silicate, 2.7 parts for aluminum silicate, and 9.1 parts for sodium aluminate.

Embodiment 2

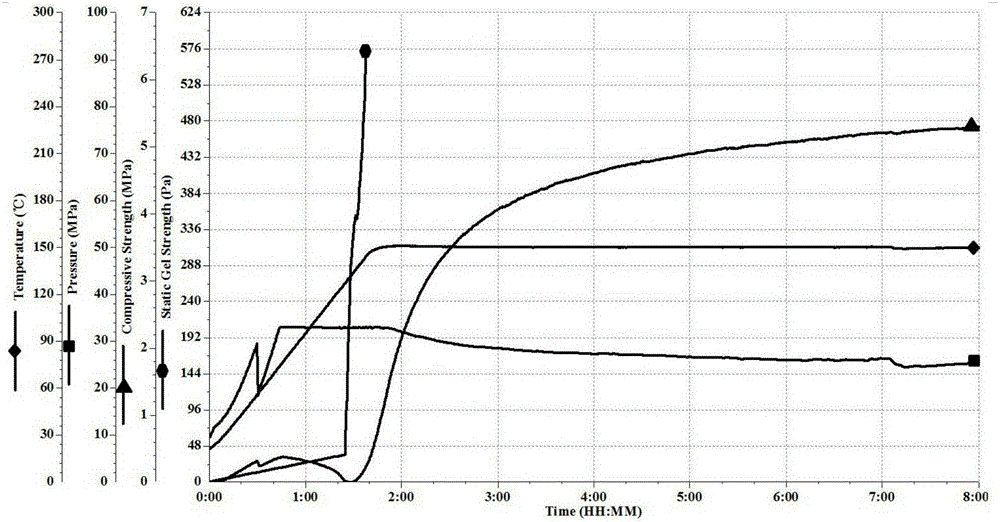

[0029] Example 2: Performance test of high temperature resistant cementing material system slurry

[0030] Taking the high temperature resistant cementing material system in Example 1 as the test object, first weigh and mix the solid dry ash component and the liquid water component of the high temperature resistant cementing material system for slurry preparation, and then mix them according to the standard GB / T19139- 2003 "Oil well cement test method" to prepare slurry. The test results are shown in Table 1.

[0031] Table 1. Slurry properties of high temperature resistant cementing material system

[0032] Numbering

Embodiment 3

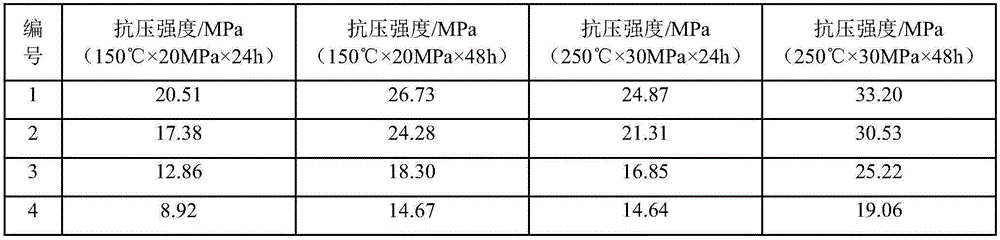

[0033] Example 3: Compressive Strength Test of High Temperature Resistant Cementing Material System

[0034] Taking the high-temperature cementing material system in Example 1 as the test object, first weigh and mix the solid dry ash component and the liquid water component of the high-temperature cementing material system for slurry preparation, and then press the standard GB / T19139-2003 " Oil well cement test method "Prepare slurry, measure compressive strength after high temperature and high pressure curing, test results are shown in Table 1.

[0035] Table 2 Compressive strength performance of high temperature resistant cementing material system

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com