Prepn process of MCM-48 medium-pore molecular sieve with ternary mixed cationic, non-ionic and anionic surfactant as template agent

A technology of surfactants and mixed cations, which is applied in the field of preparing silicon-based MCM-48 mesoporous molecular sieves, can solve the problems of narrow ingredient range and achieve the effects of simple operation, high regularity and reduced concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 and 2

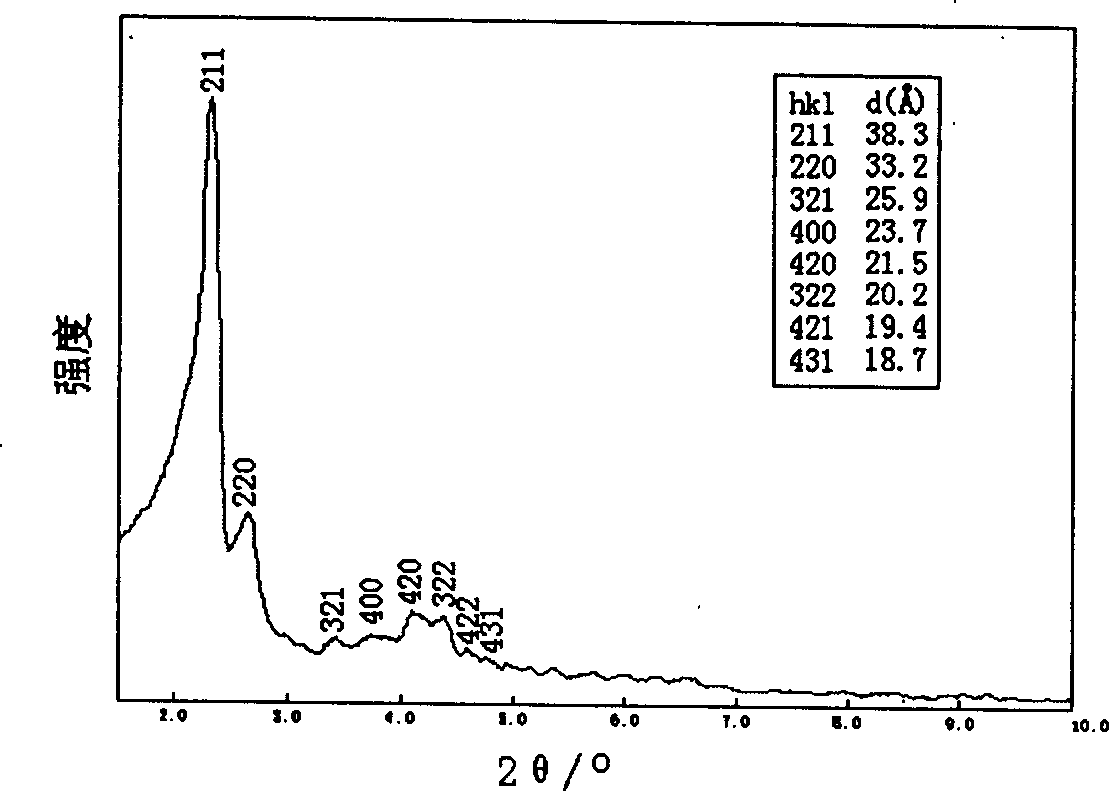

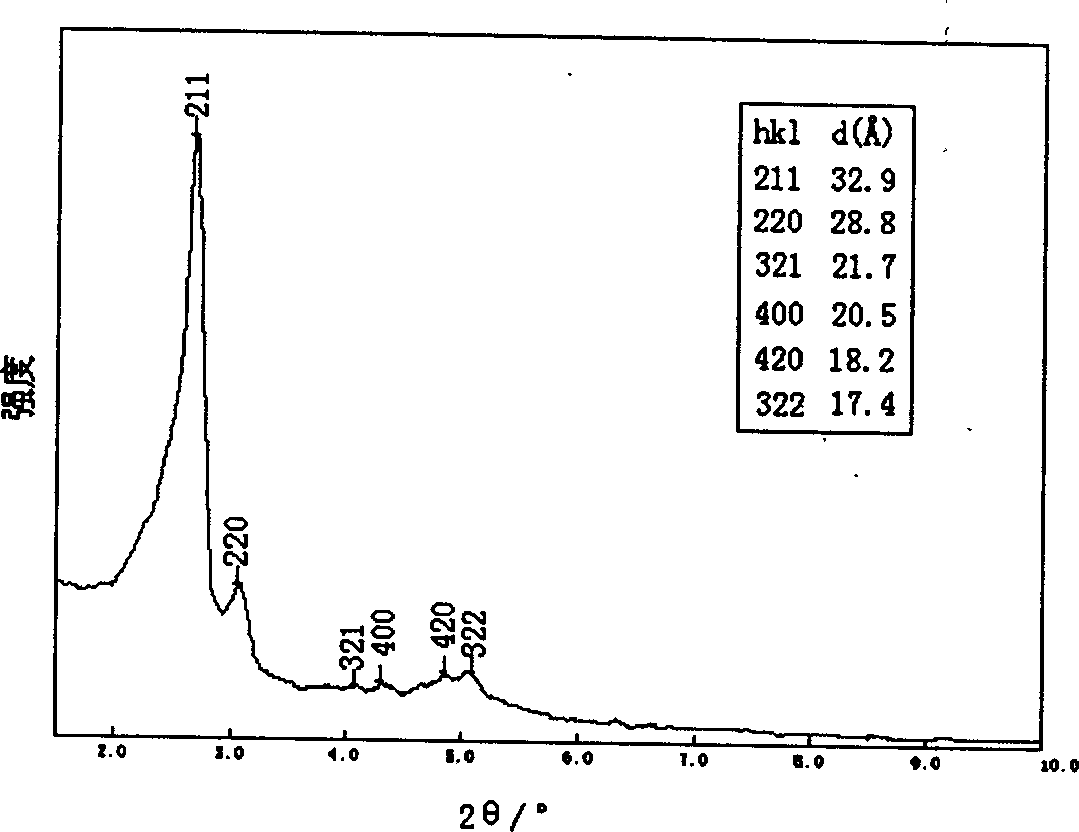

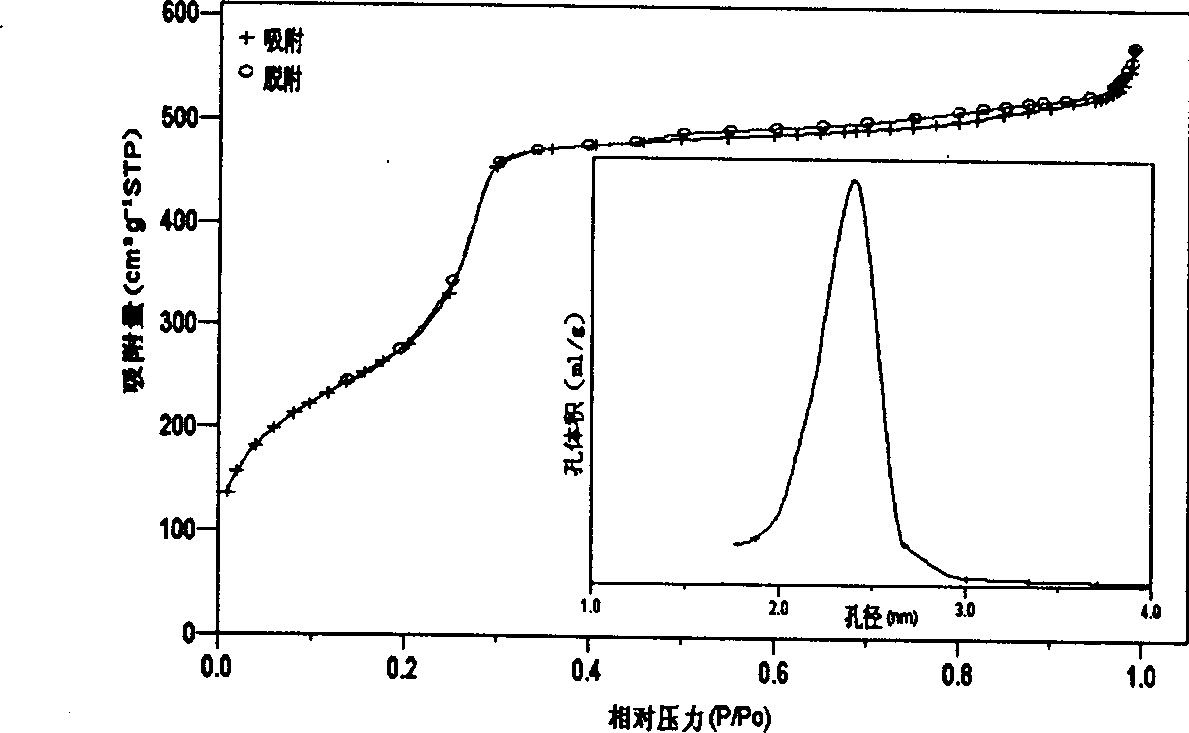

[0030] Under constant stirring speed, dissolve 0.03mol cetyltrimethylammonium bromide, 0.014mol polyethylene glycol octylphenyl ether and 0.008mol sodium dodecyl carboxylate in appropriate amount of deionized water respectively, mix and stir , then add a certain amount of NaOH solution, after stirring evenly, dropwise add the equivalent of 1mol SiO 2 The silicon source tetraethyl orthosilicate, the mixture was stirred for 1 hour, and then moved into a stainless steel reactor with a polytetrafluoroethylene liner for crystallization at 100°C or 110°C for 4-4.5 days. The product is filtered, washed, and dried at 80°C to obtain the synthetic raw powder. The synthetic raw powder was heated up to 550°C for one hour under nitrogen flow and then fired for 5 hours at 550°C in air to obtain a fired sample. Typical XRD pattern, SEM and TEM photos, N 2 The adsorption-desorption isotherm curve is shown in Figure 1 to Figure 6 .

example 3

[0032] Under constant stirring speed, dissolve 0.024mol polyethylene glycol octylphenyl ether, 0.03mol cetyltrimethylammonium bromide and 0.003mol sodium dodecyl carboxylate in appropriate amount of deionized water respectively, mix and stir , then add a certain amount of NaOH solution, after stirring evenly, dropwise add the equivalent of 1mol SiO 2 The silicon source tetraethyl orthosilicate, the mixture continued to stir for 1 to 1.5 hours, and then moved into a stainless steel reactor with a polytetrafluoroethylene liner and crystallized at 110°C for 4 days. The product is filtered, washed, and dried at 80°C to obtain the synthetic raw powder.

example 4

[0034] Under constant stirring speed, dissolve 0.004mol polyethylene glycol octylphenyl ether, 0.06mol cetyltrimethylammonium bromide and 0.006mol sodium dodecyl carboxylate in appropriate amount of deionized water respectively, mix and stir , then add a certain amount of NaOH solution, after stirring evenly, dropwise add the equivalent of 1mol SiO 2 Silicon source tetraethyl orthosilicate, the mixture was stirred for 1 to 1.5 hours, and then moved into a stainless steel reactor with a polytetrafluoroethylene liner for crystallization at 100°C for 4 days. The product is filtered, washed, and dried at 80°C to obtain the synthetic raw powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com