Patents

Literature

269 results about "Magnesium Sulfate whiskers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood plastic composite composition, wood plastic composite and preparation method thereof

ActiveCN101747639AImprove mechanical propertiesImprove toughnessGlass fiberMagnesium Sulfate whiskers

The invention discloses a wood plastic composite composition, wood plastic composite and a preparation method thereof. The wood plastic composite composition comprises wood powder, resin, compatilizer, reinforcing agent and coupling agent, wherein the compatilizer is the copolymer of rubber and maleic anhydride, and the reinforcing agent is basic magneislum crystal whisker and / or glass fiber. Theinvention also discloses a wood plastic composite and a preparation method thereof, comprising the following steps: extruding the wood plastic composite composition to obtain an extruding product, and shaping the extruding product to obtain the wood plastic composite. The wood plastic composite disclosed by the invention has high mechanical property and favourable toughness.

Owner:BYD CO LTD

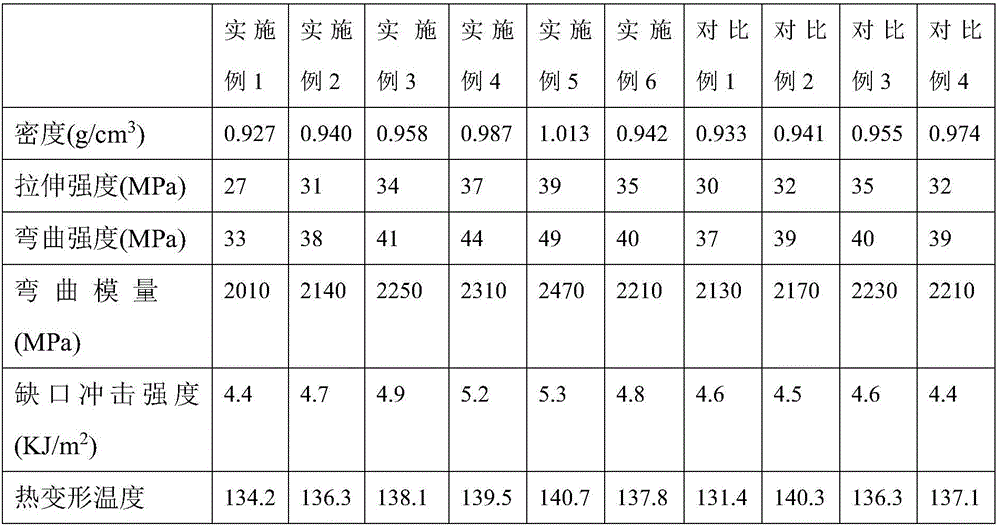

Active basic magnesium sulfate whisker modified polypropylene composite material and preparation method thereof

The invention discloses an active basic magnesium sulfate whisker modified polypropylene composite material and a preparation method thereof. The composite material consists of polypropylene, basic magnesium sulfate whiskers, a flexibilizer, a processing agent, a coupling agent, acid dilution and a heat stabilizer. An engineering part made of the composite material disclosed by the invention is developed towards the lightweight; the composite material is beneficial to the reduction of the use quantity of the material and the reduction of the use cost of the material; and moreover, the product is green and environmental-friendly and is suitable to prepare automobile interior parts.

Owner:ORINKO NEW MATERIAL CO LTD

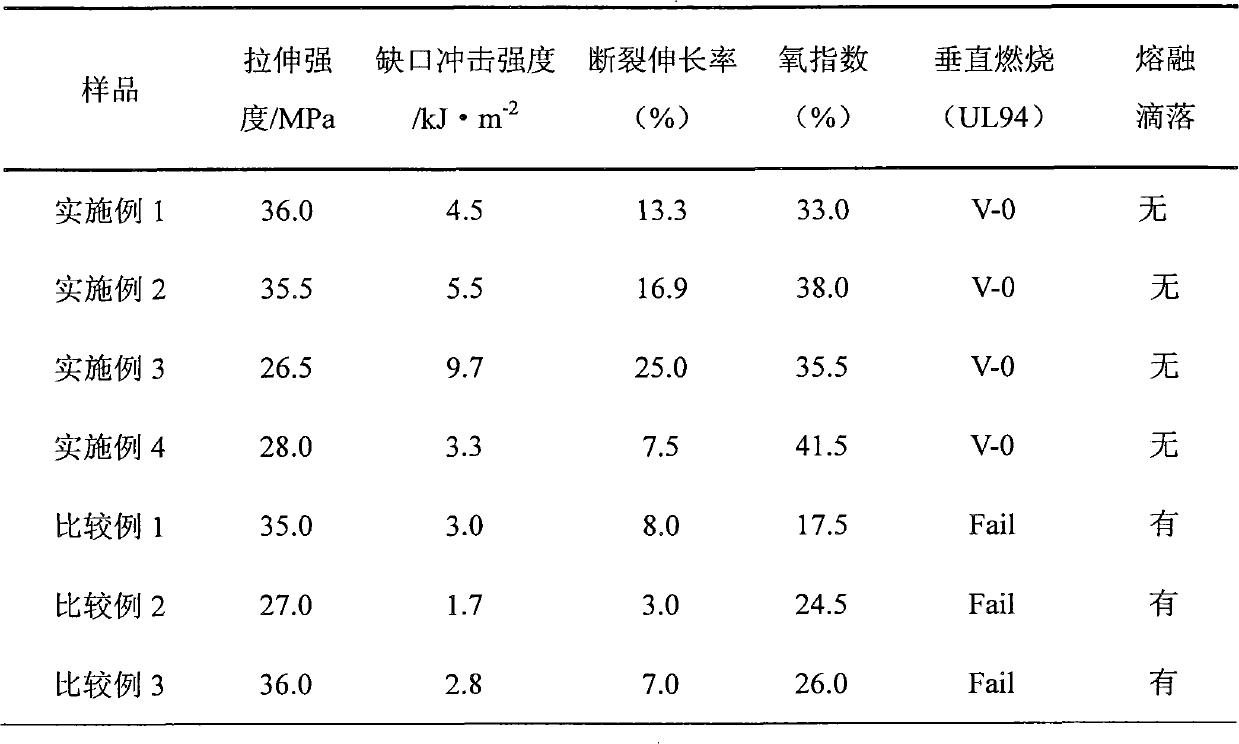

Enhanced toughened halogen-free flame-retardant polypropylene mixture and preparation method thereof

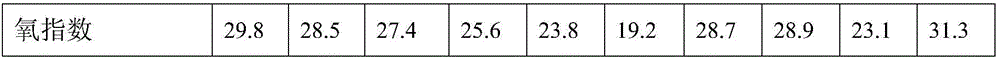

The invention discloses an enhanced toughened halogen-free flame-retardant polypropylene mixture and a preparation method thereof. The method comprises the steps of: diluting 0.5-3 parts by weight of surfactants with 20-30 parts by weight of absolute ethyl alcohol, then adding into 100 parts by weight of alkaline magnesium sulfate whiskers, mixing for 15-30 min in a mixer, and then drying in a dryer to obtain the modified alkaline magnesium sulfate whiskers, wherein the alkaline magnesium sulfate whiskers is required to be 10-60 mum in average length and less than 10 mu m in diameter; adding polypropylene resin firstly on an open type warming mill with double-roll temperature of 170-180 DEG C, sequentially adding an antioxidant, a toughened modifier, the modified alkaline magnesium sulfate whiskers, a synergistic flame retardant, a molten-drop prevention modifier and a compatibilization modifier after the polypropylene resin is molten and covers the rolls, and evenly mixing to obtain the enhanced toughened halogen-free flame-retardant polypropylene mixture. The polypropylene mixture prepared in the invention has the advantages of high strength, good toughness, low smoke, no toxicity, no molten drop, remarkable flame retardant property and the like.

Owner:SOUTH CHINA UNIV OF TECH

Polypropylene composite material

The present invention relates to a kind of polypropylene composite and its preparation method. The said polypropylene composite includes the following components with weight ratio: polypropylene (PP) 30-60, DCP 0.3-0.6, BPO 0.05-0.3, MAH 2.0-6.0, AA 0-3, St 0-3, POE 10-20, talcum powder 10-20, magnesium sulfate whisker 15-25, nano-level carbonate calcium 5-15.0. By adding inorganic filler and POE into polypropylene, the crystal form of polypropylene is modified, thus the shrink of polypropylene is limited, and the surface polarity of polypropylene is improved to make it easy to be coated.

Owner:杨育农 +3

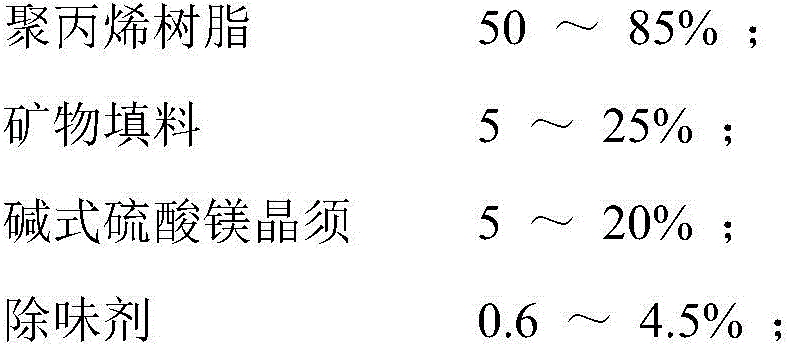

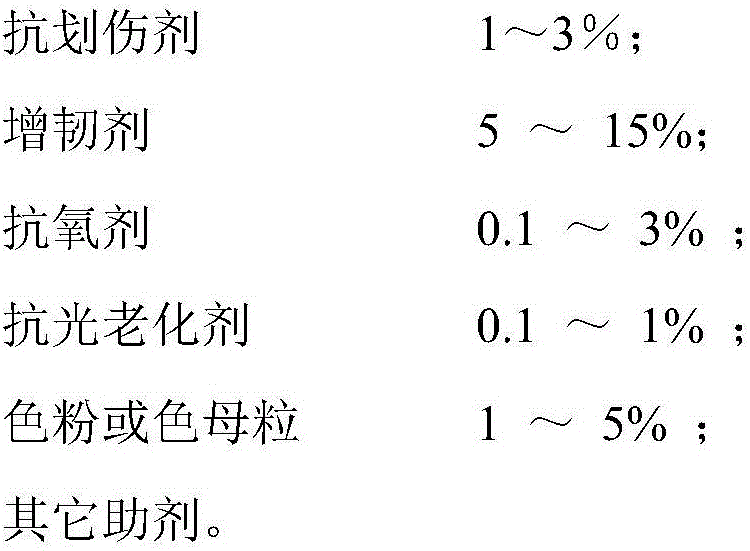

High-mobility low-odor scratch-resistant automobile trim polypropylene material and preparation method thereof

The invention discloses a high-mobility low-odor scratch-resistant automobile trim polypropylene material and a preparation method thereof. The polypropylene material is made from, by weight, 50-85% of polypropylene resin, 5-25% of mineral filler, 0-20% of basic magnesium sulfate whiskers, 0.6-4.5% of odor-adsorbing masterbatch, 1-3% of a scratch resistant, 5-15% of a toughener, 0-3% of an antioxidant, 0-1% of a light aging resistant, 0-5% of a toner or color masterbatch, and other aids. The material prepared herein has zero-lost mechanical properties and mobility, has significantly reduced odor and greatly improved scratch resistance, and fully meets the requirement of automobile trims for high mobility, scratch resistance and low odor of material.

Owner:NANJING DELLON ENG PLASTICS

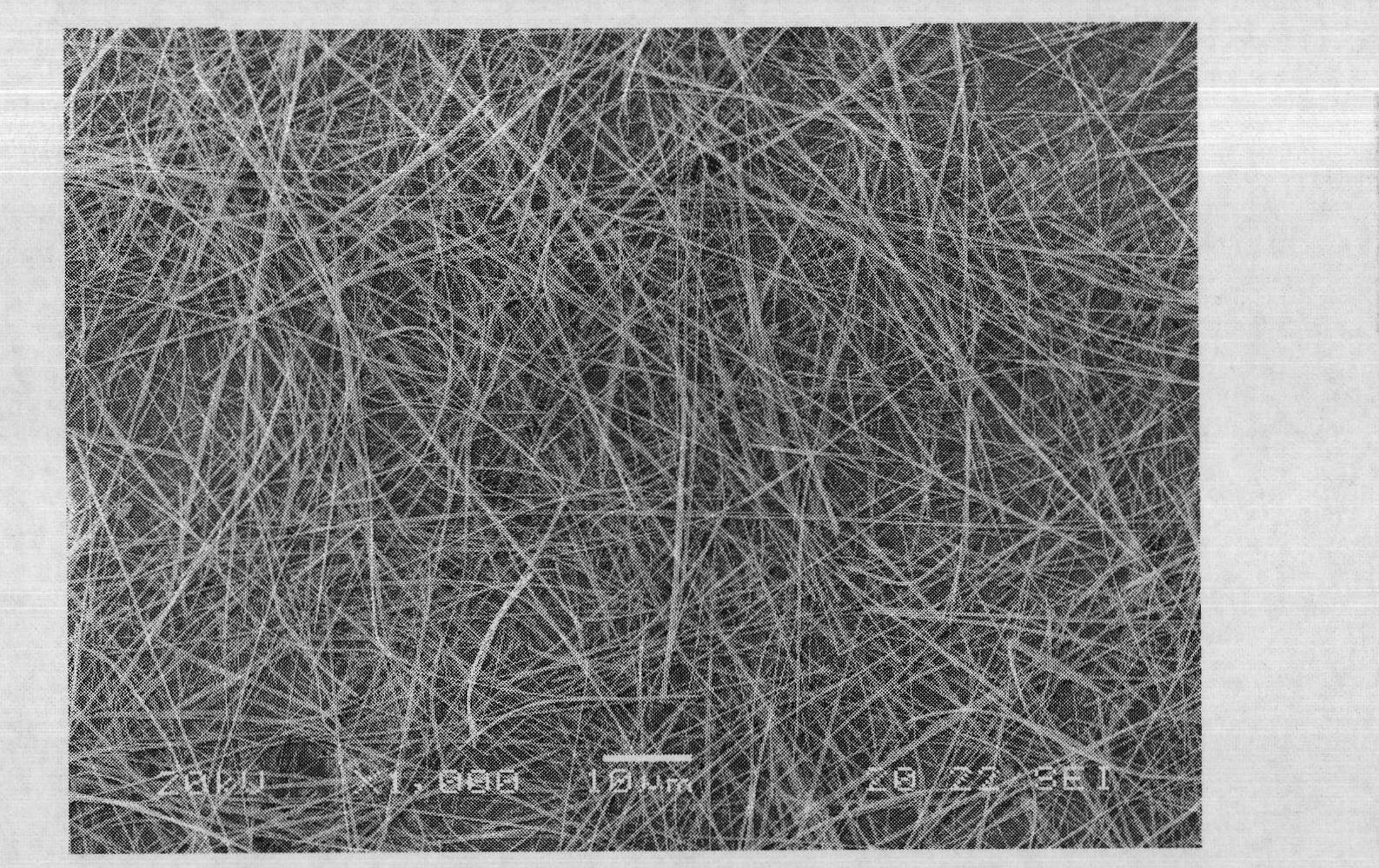

New method of rapid synthesis of basic bitter salt

InactiveCN1482287AImprove solubilityImprove uniformityPolycrystalline material growthFrom normal temperature solutionsSolubilityMagnesium salt

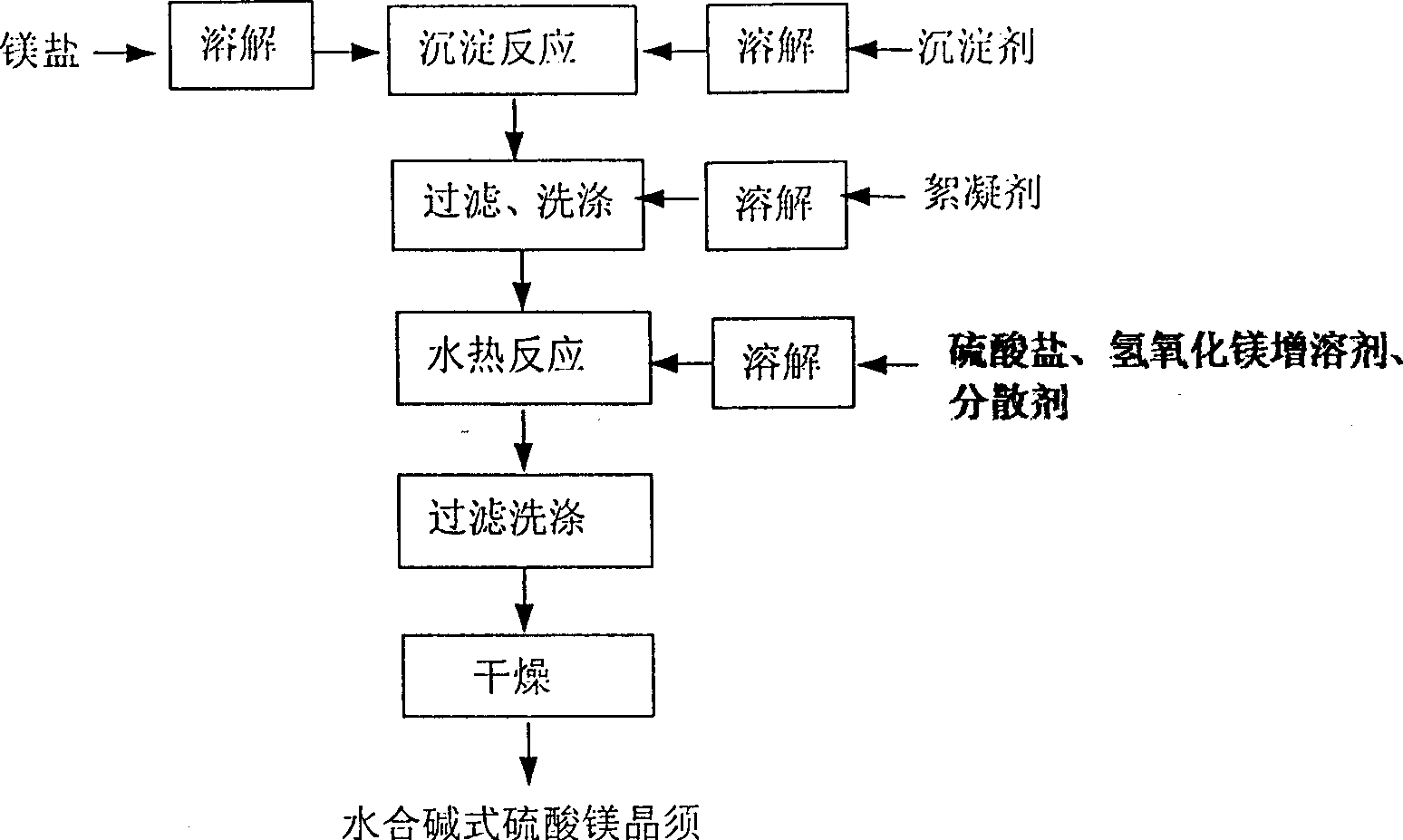

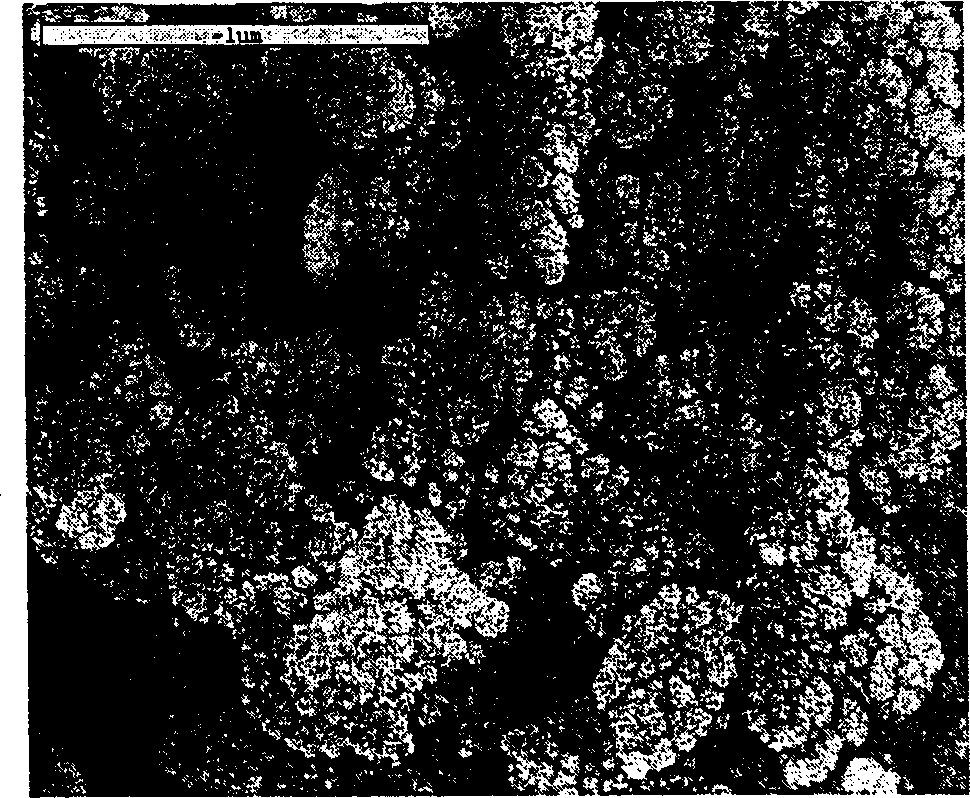

The present invention is the preparation process of hydrated basic magnesium sulfate whisker in the field of inorganic chemical material preparation. The preparation process of hydrated basic magnesium sulfate whisker with magnesium salt material as side product of salt producing process includes the normal temperature fast mixing to prepare high solubility and high dispersivity nano level magnesium hydroxide precursor; fast hydrothermal reaction of the precursor with water solution of sulfate, magnesium hydroxide as solubilizer and dispersant; and subsequent filtering, washing and drying. The hydrated basic magnesium sulfate whisker is homogeneous in size, regular in appearance and high in dispersivity, has the composition of 5Mg(OH)2.MgSO4.3H2O, average length of 5-50 microns and average diameter of 0.1-2 microns. The product may be used as reinforcer and fire retardant in preparing high strength rubber, plastic, resin, ceramic and other composite material.

Owner:TSINGHUA UNIV

Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

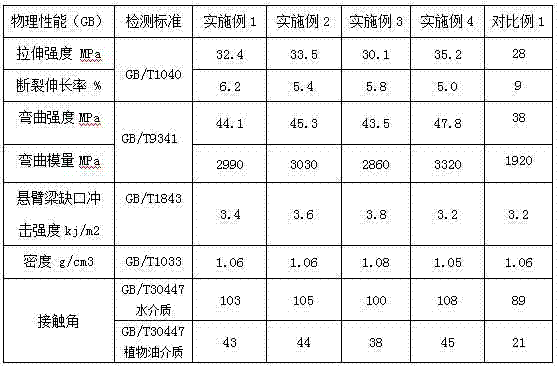

ActiveCN104744818ALower surface free energyGood oil resistancePolypropylene compositesPolymer science

The invention provides a reinforced greasy-dirt-resistant high-gloss polypropylene composite material and a preparation method thereof. The reinforced greasy-dirt-resistant high-gloss polypropylene composite material is prepared form the following components in parts by weight: 60-80 parts of PP resin, 10-15 parts of superfine precipitated barium sulfate, 6-10 parts of reinforced magnesium sulfate whiskers, 2-5 parts of fluoride, 0.2-0.4 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 0.5-1 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the reinforced greasy-dirt-resistant high-gloss polypropylene composite material prepared by the method disclosed by the invention, the surface polarity of the material is changed and the greasy dirt resistance of the material is improved; meanwhile, the composite material meets the European Union Regulation (EC) No.1935 / 2004 of related food contact materials, and has the characteristics of being high in gloss, low in after shrinkage, high in rigidity, and the like. The material is applied to a housing of a kitchen appliance, so that the surface of the kitchen appliance has capacity of resisting greasy dirt and self-cleaning capacity, and the self-cleaning anti-greasy-dirt environmental requirements of modern kitchen appliance are met.

Owner:ORINKO NEW MATERIAL CO LTD

Surface flame-retardant wood-plastic composite material plate and preparation thereof

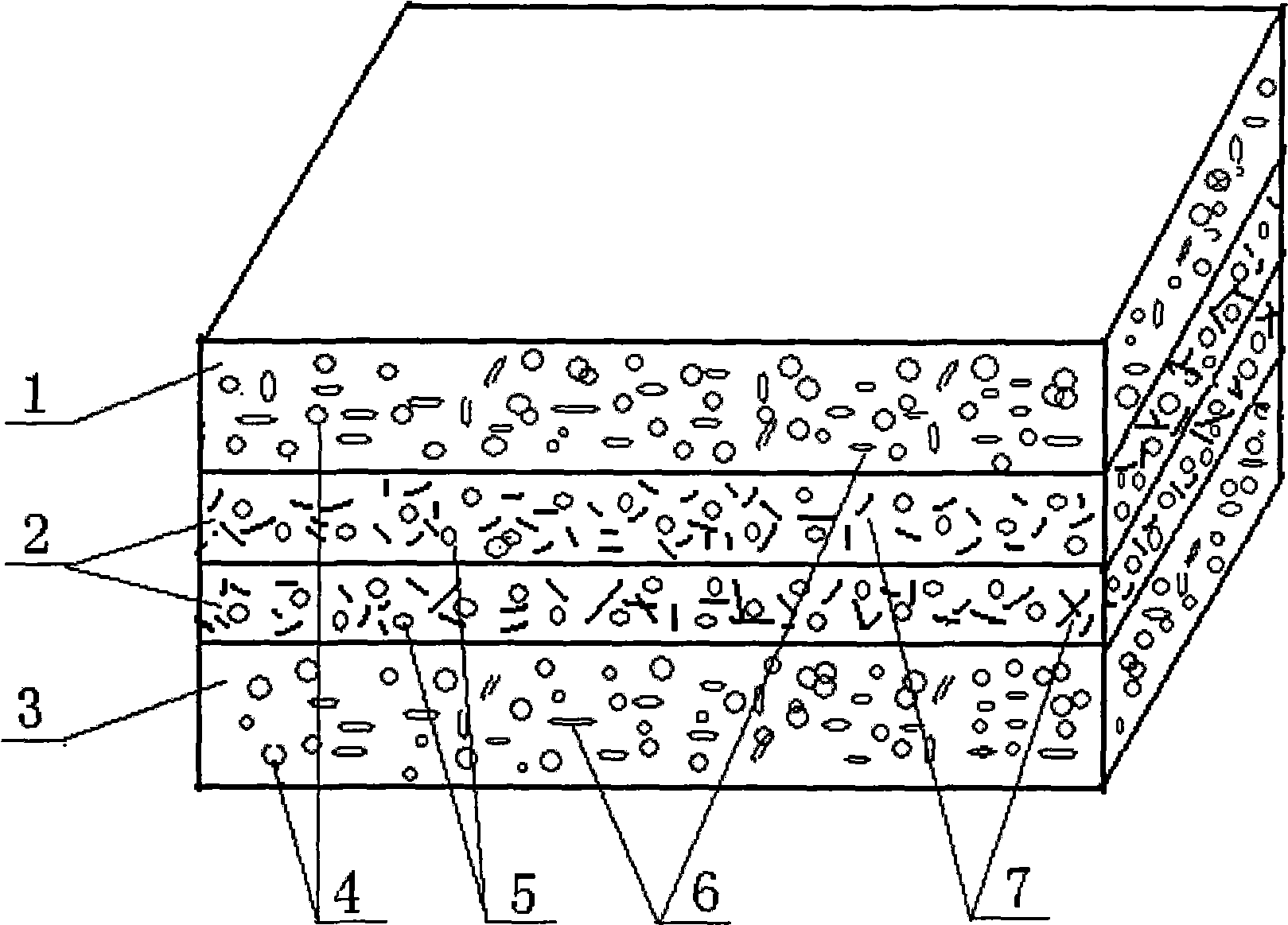

InactiveCN101486267AReasonable designSimple structureSynthetic resin layered productsFiberMagnesium Sulfate whiskers

The invention relates to a surface flame retarded wood plastic composite plate and a method for preparing the same, which relates to a composite material, an environment-friendly material and a method for preparing the same. The composite material is applicable to making the following products: floor boards, shelf boards, and the like for means of transportation such as automobiles, planes, and the like in the field of transportation; road slabs, fences, wallboards, aisle guard bars, and the like in the field of construction; and outdoor desks and chairs, office partition boards, storage boxes, flower boxes, adjustable shelves, beach chairs, and the like in the furniture industry. The surface flame retarded wood plastic composite plate consists of two layers of crystal whisker modified plastic layers and plant fiber reinforced plastic layers, wherein the plant fiber reinforced plastic layers are arranged between the two layers of the crystal whisker modified plastic layers through die stamping. The crystal whisker modified plastic layers are made from modified basic magnesium sulfate whiskers, plastic particles, and the like through mixed calendering. The plant fiber reinforced plastic layers are made from plastic particles and plant fibers through mixed calendering.

Owner:NANJING FORESTRY UNIV

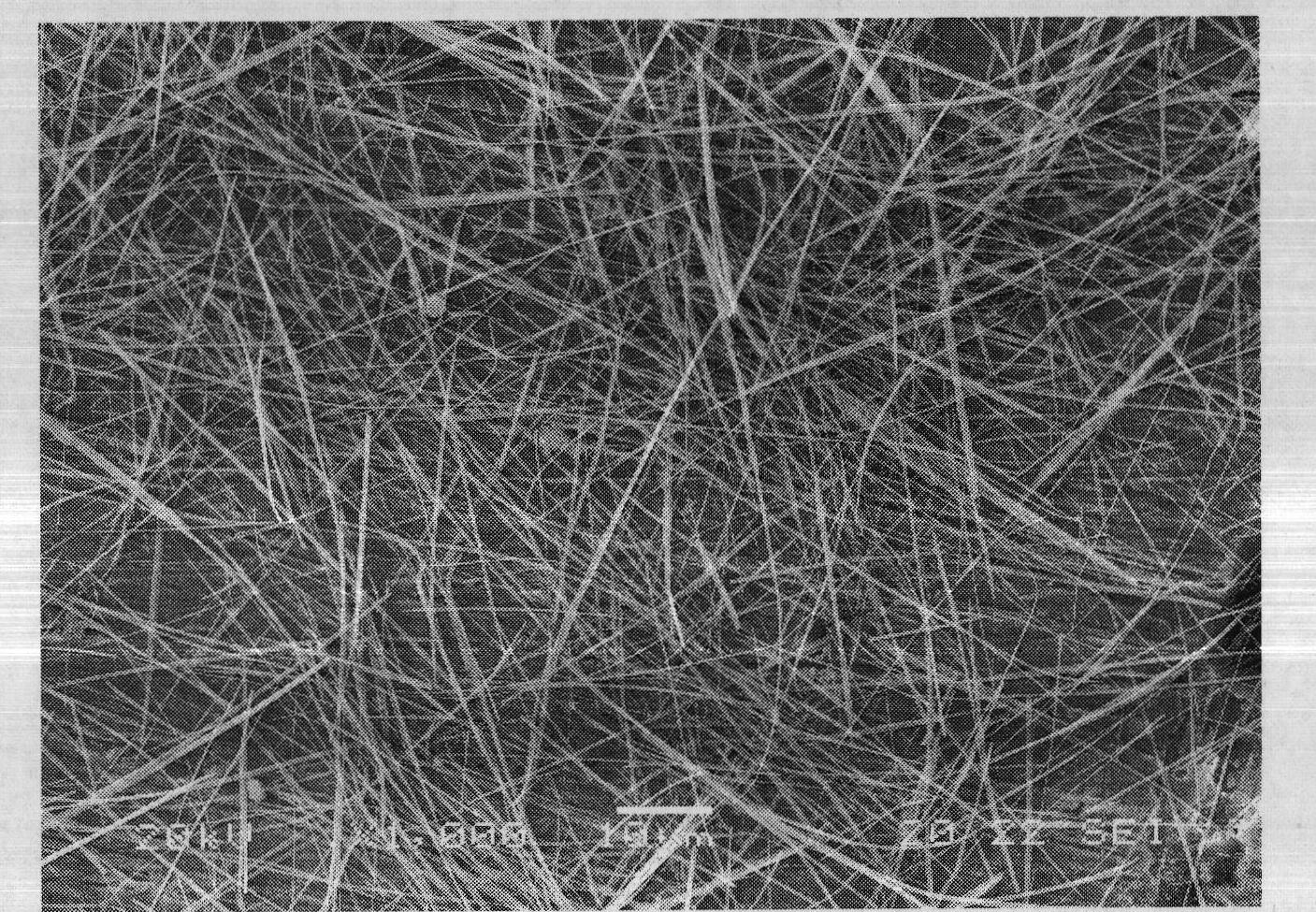

Preparation of high length-diameter ratio magnesium hydroxide sulfate hydrate whisker

InactiveCN101348937AReduce supersaturationHigh crystallinityPolycrystalline material growthFrom normal temperature solutionsMagnesium saltCrystallinity

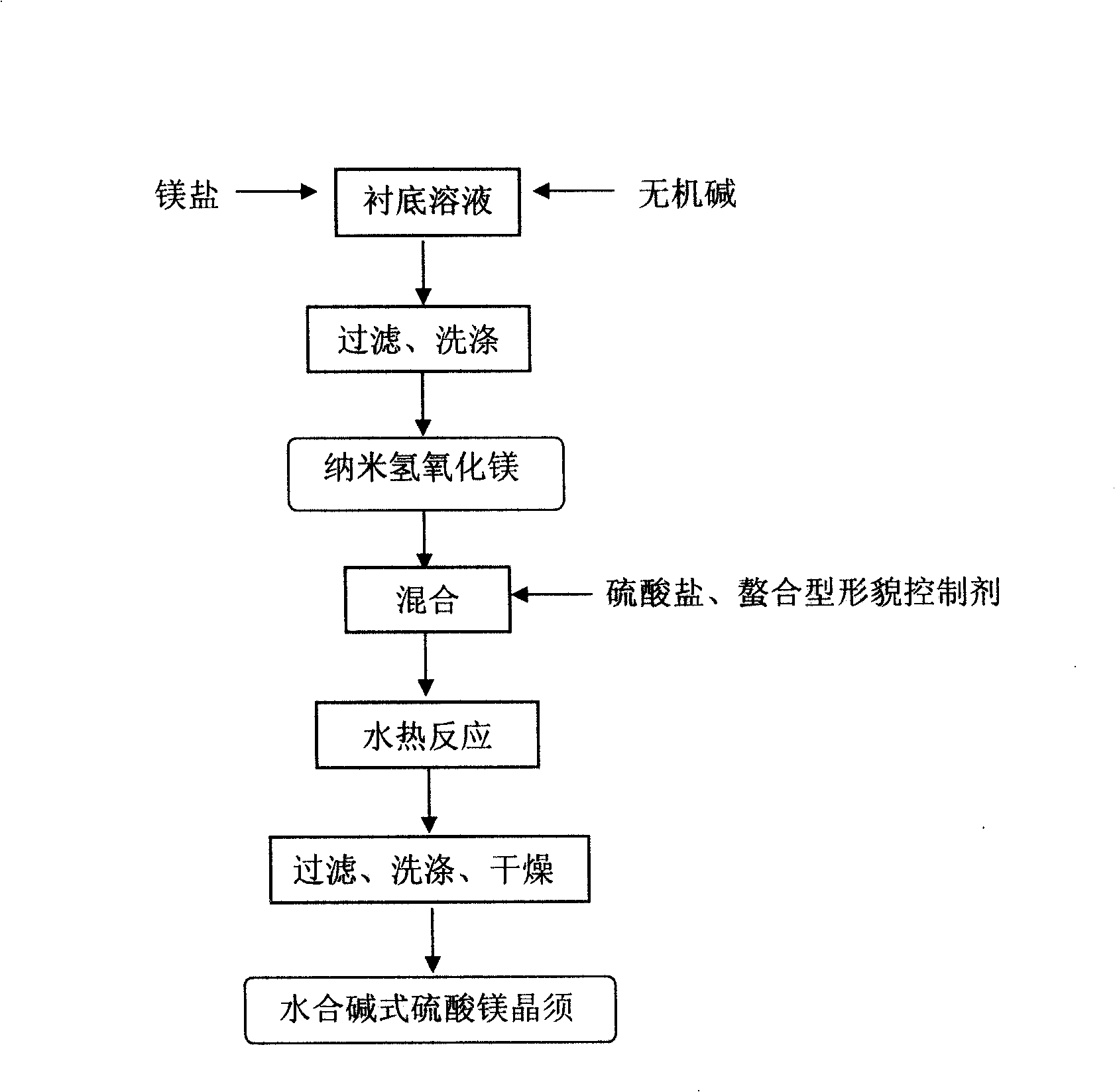

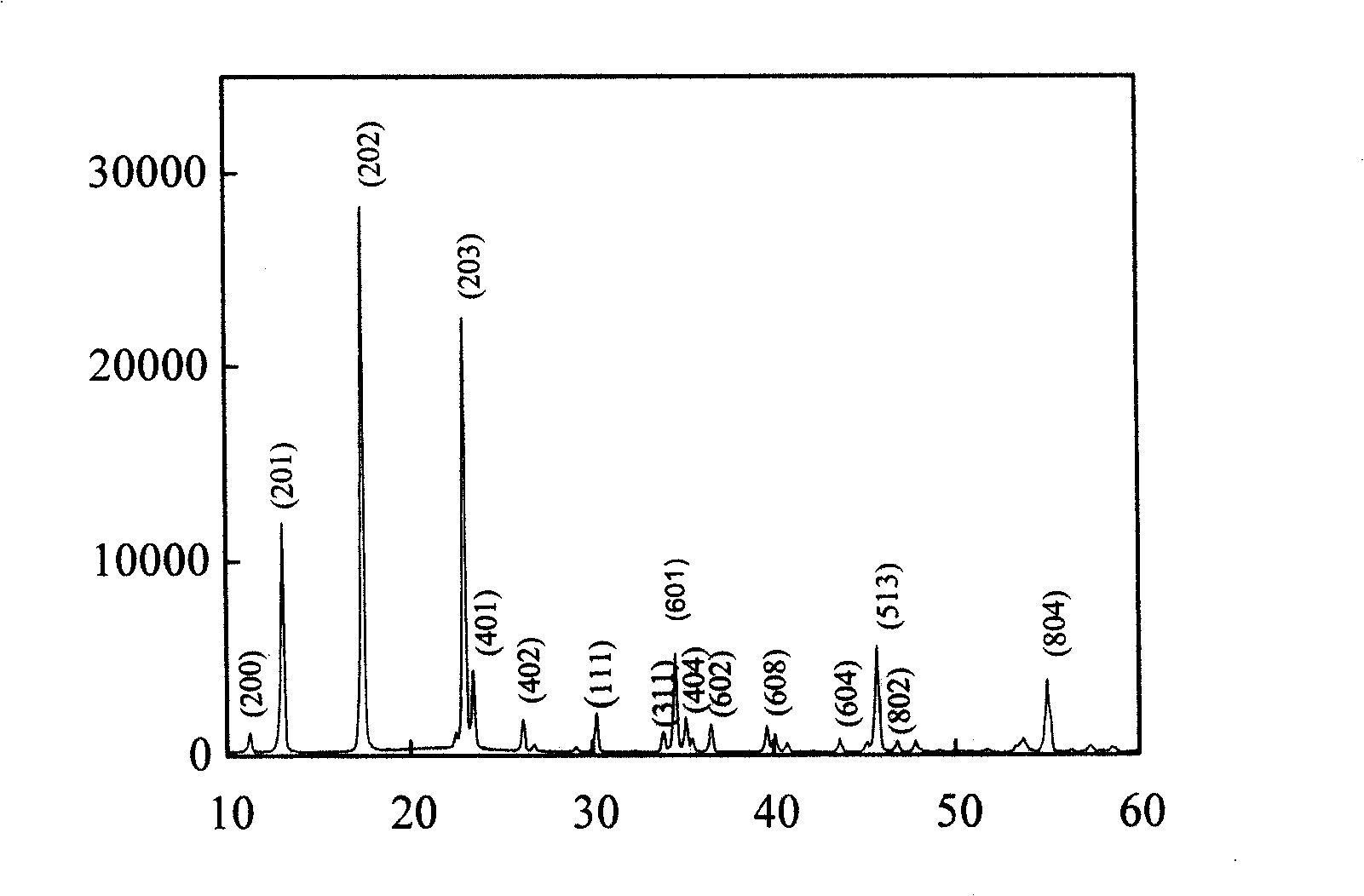

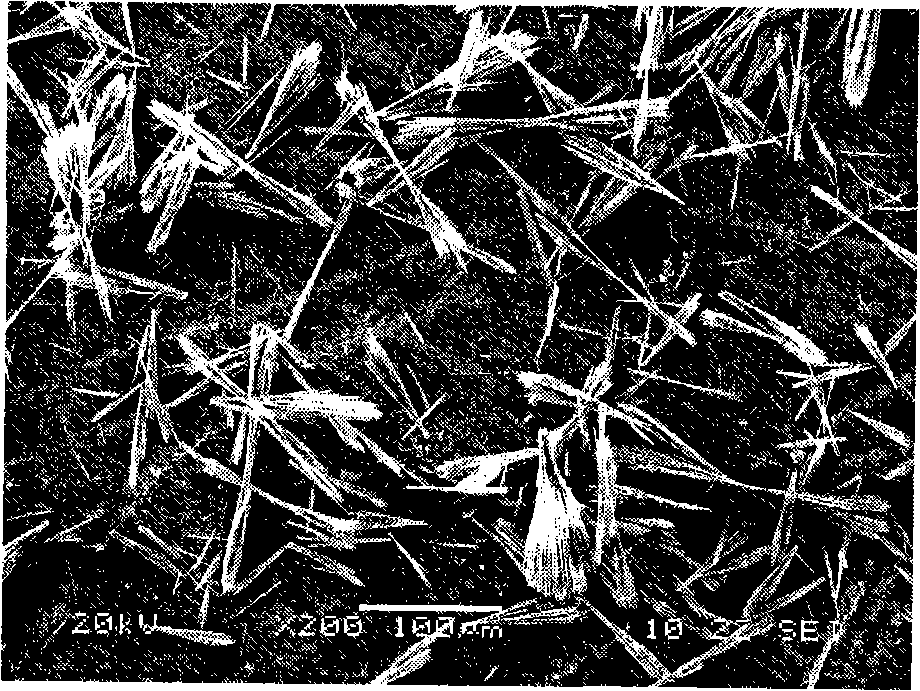

A preparation method for hydrated basic magnesium sulfate crystal whisker with high-aspect ratio belongs to the technical field of inorganic chemical material preparation. The method comprises the following steps: water-soluble magnesium salt and inorganic base are taken as raw materials so as to prepare a precursor for nano magnesium hydroxide with better crystallinity and dispersivity in a substrate double-injection synthesis mode at a temperature between 10 and 90 DEG C; then the precursor is added into aqueous solution containing sulfate and micro chelated morphological control agent so as to carry out hydrothermal reaction at a temperature between 100 and 250 DEG C for 2 to 20 hours; and finally, one-dimensional growth of hydrothermal products is promoted by means of the selective adsorption and slow release action of the morphological control agent so as to prepare the hydrated basic magnesium sulfate crystal whisker with the average length of between 40 and 400mu m, the average diameter of between 0.05 and 0.2 mu m, the aspect ratio of between 200 and 2,000 and the main content more than 98 percent. The preparation method has the advantages of simple process, low cost, high added value of the product and easy industrial popularization; moreover, the product can be used in industries such as plastics, rubber, resin and ceramics as a reinforcing material.

Owner:TSINGHUA UNIV

Frost-resistant concrete

The invention relates to the technical field of concrete, especially a kind of antifreeze concrete; its composition by mass is as follows: 100-200 parts of cement, 50-100 parts of fine aggregate sand, 50-100 parts of coarse aggregate sand, 10-60 parts of glass fiber 10-30 parts of dispersible latex powder, 12-25 parts of nano-silica powder, 5-12 parts of calcium lignosulfonate, 3.6-10 parts of basic magnesium sulfate whiskers, 5.4-10 parts of sodium carboxymethyl cellulose 10.8 parts, 8-16 parts of antifreeze agent, 2.8-6.4 parts of water reducing agent, 3.6-8 parts of concrete modifier, 3.6-9 parts of air-entraining agent; the antifreeze concrete of the present invention has abundant raw materials, low price, low cost In addition, it has the characteristics of good frost resistance, high compressive strength, good durability, and a wide range of strength grades. The concrete of the invention can be widely used in shipbuilding industry, machinery industry, ocean development, geothermal engineering and the like.

Owner:许偏奎

High heat-resistant, halogen-free and flame-retardant type jute fiber-reinforced polypropylene composite material and preparation method thereof

InactiveCN106674741AImprove flame retardant performanceAbundant resourcesPolypropylene compositesPolymer science

The invention discloses a high heat-resistant, halogen-free and flame-retardant type jute fiber-reinforced polypropylene composite material and a preparation method thereof. The jute fiber-reinforced polypropylene composite material is prepared from the following raw materials in parts by weight: 30 to 80 parts of polypropylene, 10 to 40 parts of jute fiber, 1 to 5 parts of whisker, 1 to 10 parts of halogen-free flame-retardant agent, 1 to 10 parts of compatilizer, 1 to 2 parts of coupling agent, 0.1 to 2 parts of antioxidant, and 0.2 to 1 part of lubricating agent. The jute fiber-reinforced polypropylene composite material has the advantages that the jute fiber with low cost, rich resource, high specific modulus and low density is used for preparing the vehicle reinforced polypropylene composite material, so that the production cost is reduced; by adding a certain amount of alkaline type magnesium sulfate whiskers into the polymer composite material on the basis of original basic formula, the high temperature-resistant property is improved; by adding a smaller amount of novel phosphor-containing organosilsesquioxane halogen-free flame-retardant agent, the flame-retardant property of the jute fiber-reinforced polypropylene composite material is improved.

Owner:CHONGQNG PRET NEW MATERIAL +4

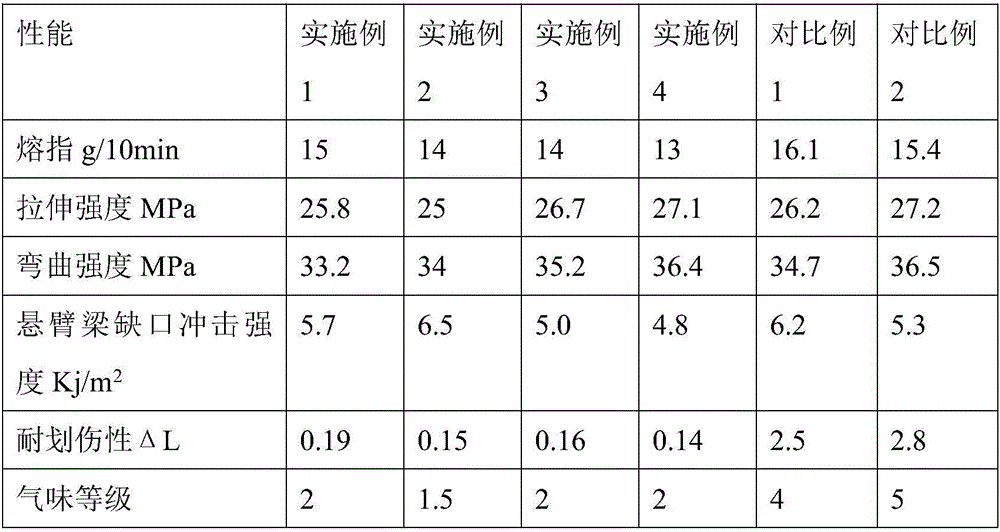

Composite reinforced modified polypropylene composition for vehicle parts, and preparation method thereof

The invention relates to a composite reinforced modified polypropylene composition for vehicle parts. The composite reinforced modified polypropylene composition is characterized by comprising, by weight, 50-78% of a polypropylene resin, 15-25% of a toughening agent, 6-22% of an inorganic filler, 0.1-1% of an antioxidant, and 0.1-1.5% of a processing auxiliary agent, wherein the melting index of the polypropylene resin at a temperature of 230 DEG C under a test condition of load of 2.16 kg is 30-40 g / 10 min, the toughening agent is a polyolefin elastomer, the inorganic filler is magnesium sulfate crystal whisker, talc powder, or a combination of the magnesium sulfate crystal whisker and the talc powder, the antioxidant is selected from butylated toluene or a combination thereof, and the processing auxiliary agent is selected from a fatty acid ester, a metal soap, or a combination of the fatty acid ester and the metal soap. The composite reinforced modified polypropylene composition has characteristics of excellent flexural modulus, excellent impact strength and excellent fluidity, wherein the mechanical property can meet requirements of practicality and safety of the vehicle part when the thickness of the vehicle part is reduced by 1 / 3.

Owner:SHANGHAI KINGFA SCI & TECH +1

Manufacturing method of negative oxygen ion flame-retardant polyester BCF (bulk continuous filament) yarn

ActiveCN103046156AWith negative oxygen ionsWith flame retardant functionFlame-proof filament manufactureFilament/thread formingFiberYarn

The invention relates to a manufacturing method of negative oxygen ion flame-retardant polyester BCF (bulk continuous filament) yarns. The manufacturing method comprises the following steps: performing mixing, roasting, dispersion and plasma treatment on three nano-scale fibers, namely basic magnesium sulfate whiskers, basic magnesium chloride whiskers and magnesium salt whiskers; then performing filtration, drying and other pretreatment; performing stirring and dispersion on the whiskers after pretreatment and a flame-retardant element material, namely aluminum oxide, a red phosphorus flame retardant, barium stearate, nano-scale tourmaline composite powder and a PP-g-MAH (maleic anhydride grafted polypropylene) compatibilizer in a mixing machine to get a flame-retardant whisker blend; preparing negative oxygen ion flame-retardant polyester from the flame-retardant whisker blend through a copolyester or blending method; and preparing the negative oxygen ion flame-retardant polyester BCF yarn through a composite spinning technology.

Owner:东南新材料(杭州)股份有限公司

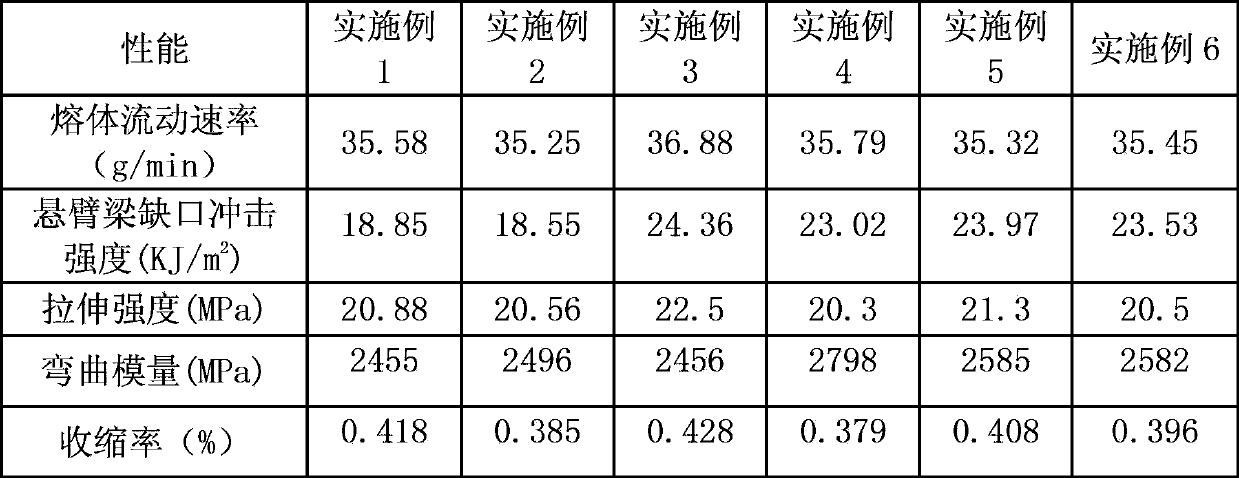

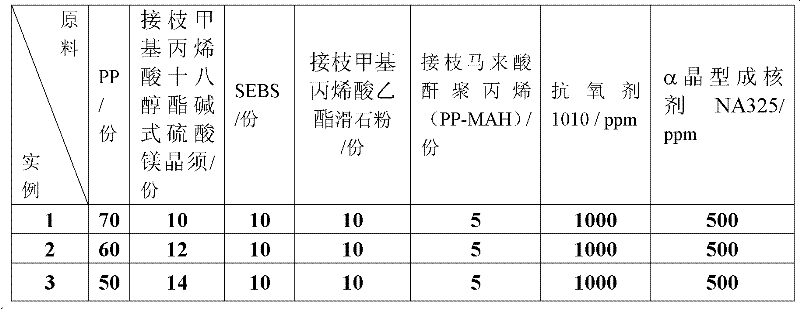

Polypropylene (PP) alloy material with low molding shrinkage and preparation method thereof

The invention discloses a polypropylene (PP) alloy material with low molding shrinkage. The PP alloy material is prepared from the following raw materials in part by weight: 5-20 parts of SEBS (Styrene-Ethylene-Butylene-Styrene), 5-30 parts of mixture of basic magnesium sulfate whiskers and inorganic filler, 50-90 parts of PP resin and 2-10 parts of compatilizer. The invention further discloses apreparation method for the PP alloy material. Due to the adoption of the PP alloy material with low molding shrinkage provided by the invention, the molding shrinkage of the PP is effectively lowered, and the original performance of the PP is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP

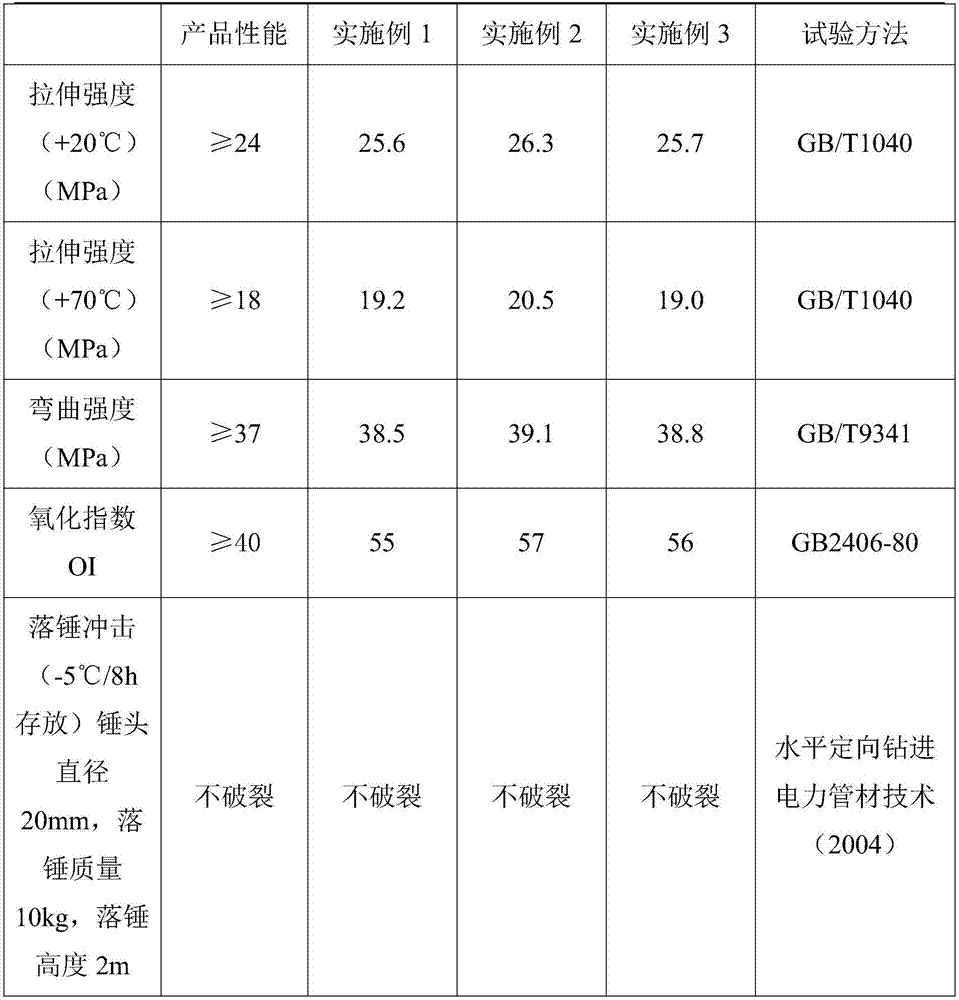

MPP electrostatic tube of force and preparation method thereof

InactiveCN106947170AImprove flame retardant performanceComply with safe use requirementsLow speedAntioxidant

The invention provides an MPP electrostatic tube of force and a preparation method thereof. The MPP electrostatic tube of force comprises the following raw materials: MPP, light calcium carbonate, a plasticizer, a stabilizer, a compatilizer, a lubricant, CPE resin, a vinyl-propylene copolymer, graphene, modified whiskers, a compound inorganic flame retardant, vinyl trimethoxy silane, polyisocrotyl succinimide, an antioxidant and a colorant; the compound inorganic flame retardant is composed of rare earth hydroxide, aluminum hydroxide, magnesium hydroxide and ferric oxide; the modified whiskers are surfactant modified magnesium hydroxide sulfate whiskers. The preparation method comprises the following steps of: adding the raw materials into a mixer for mixing and stirring uniformly, wherein the mixing temperature is 100-120 DEG C and the mixing time is 10-15 minutes; after mixing uniformly, transferring into a cooling stirrer for stirring for 3-5 minutes at 40-50 DEG C at a low speed; and finally, plasticizing and slicing the raw materials in a cone-shaped twin-screw extruder to obtain MPP electrostatic tube particles of force, and then performing extrusion molding. The electrostatic tube of force provided by the invention has a good flame retardant property, impact resistance and heat resistance.

Owner:ANHUI GUODENG PIPE IND TECH CO LTD

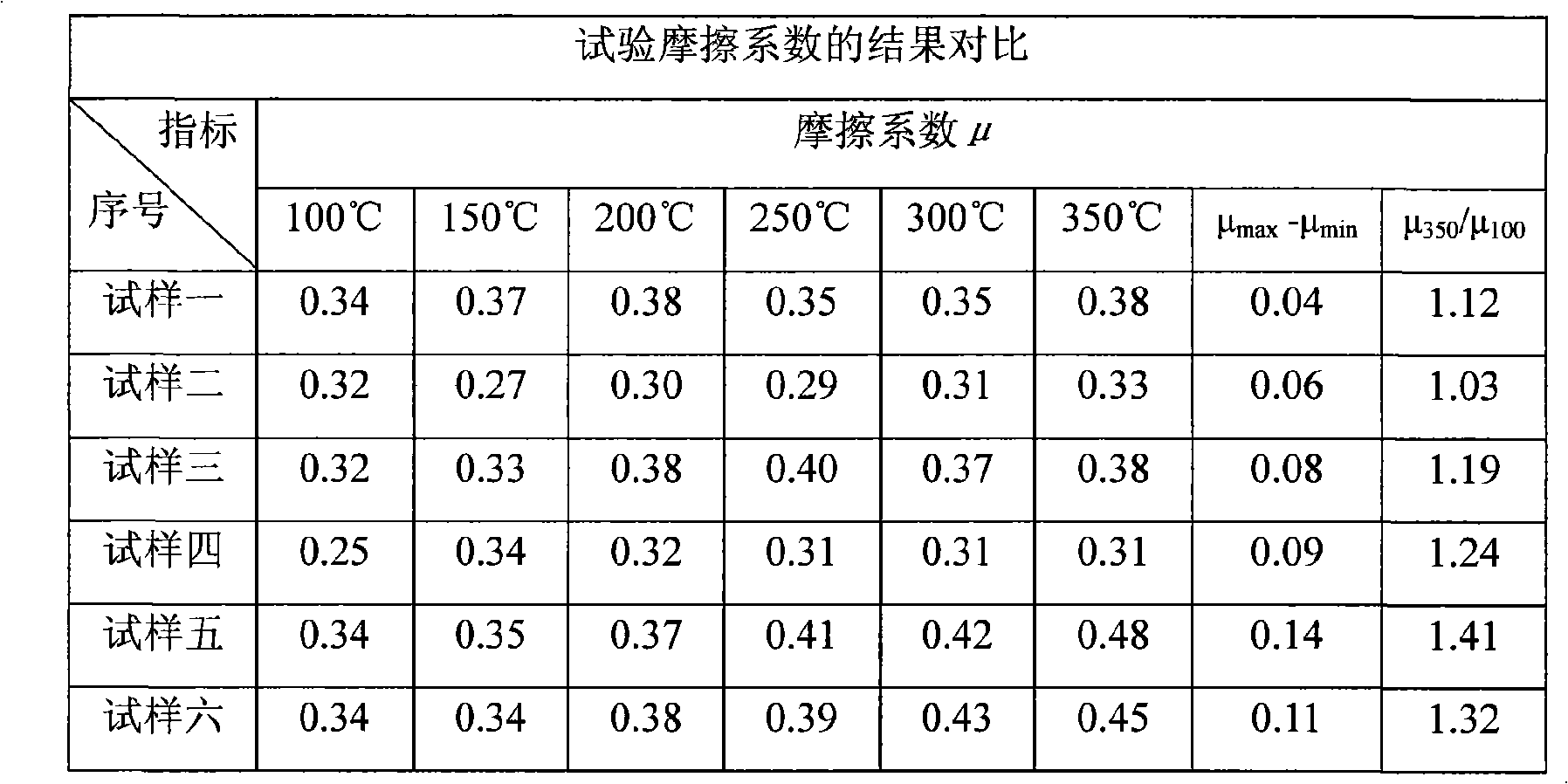

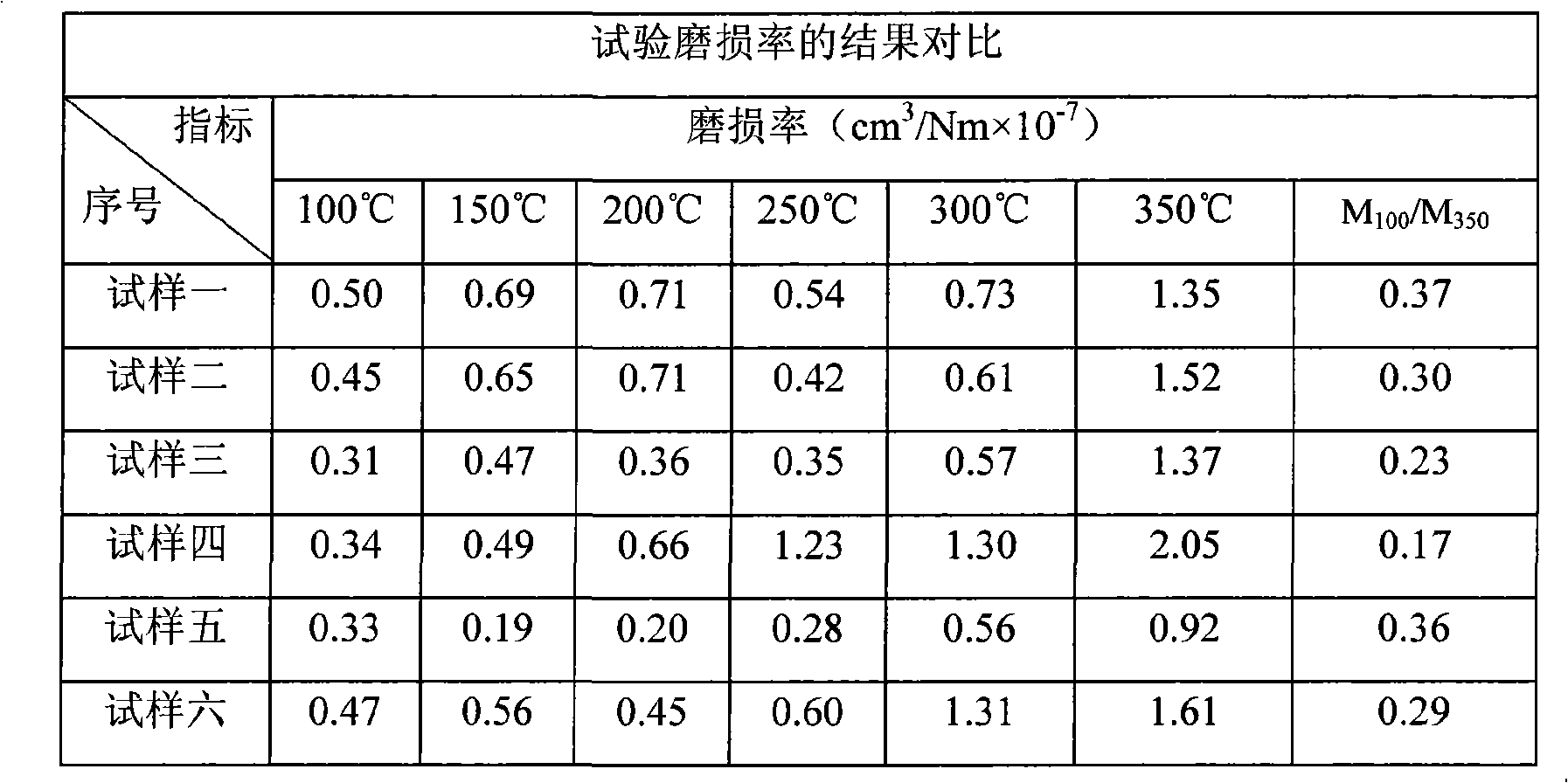

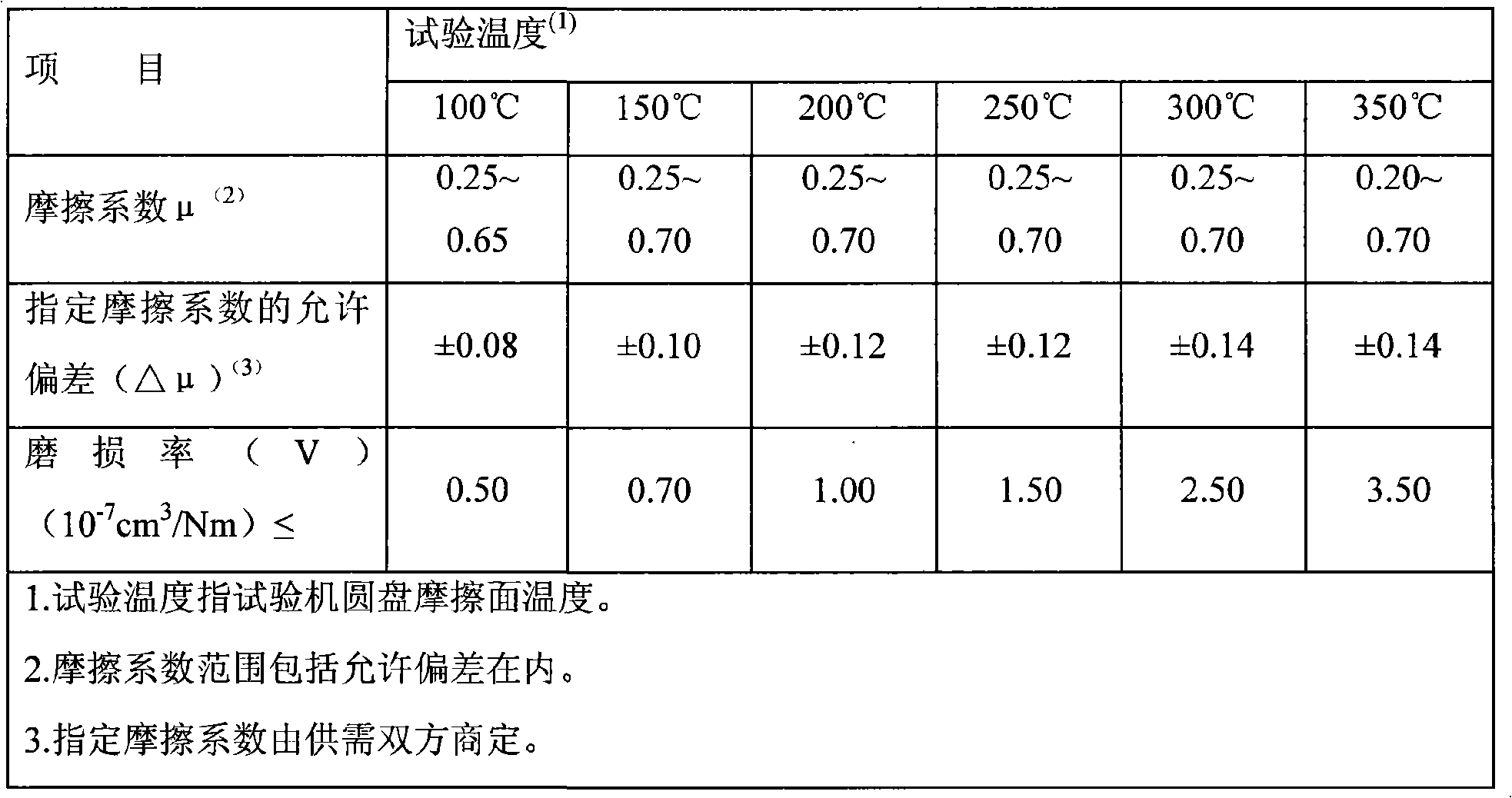

Vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof

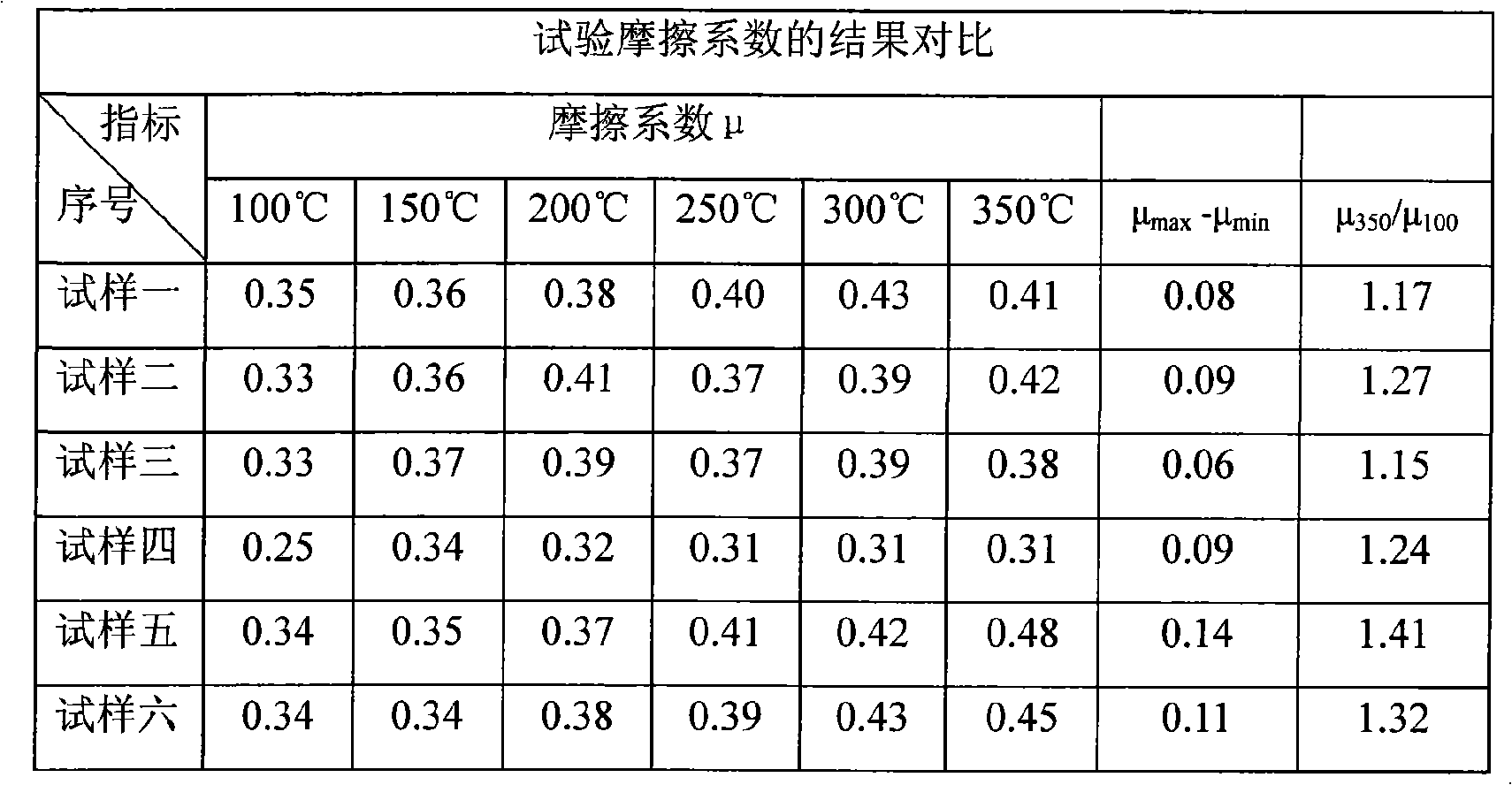

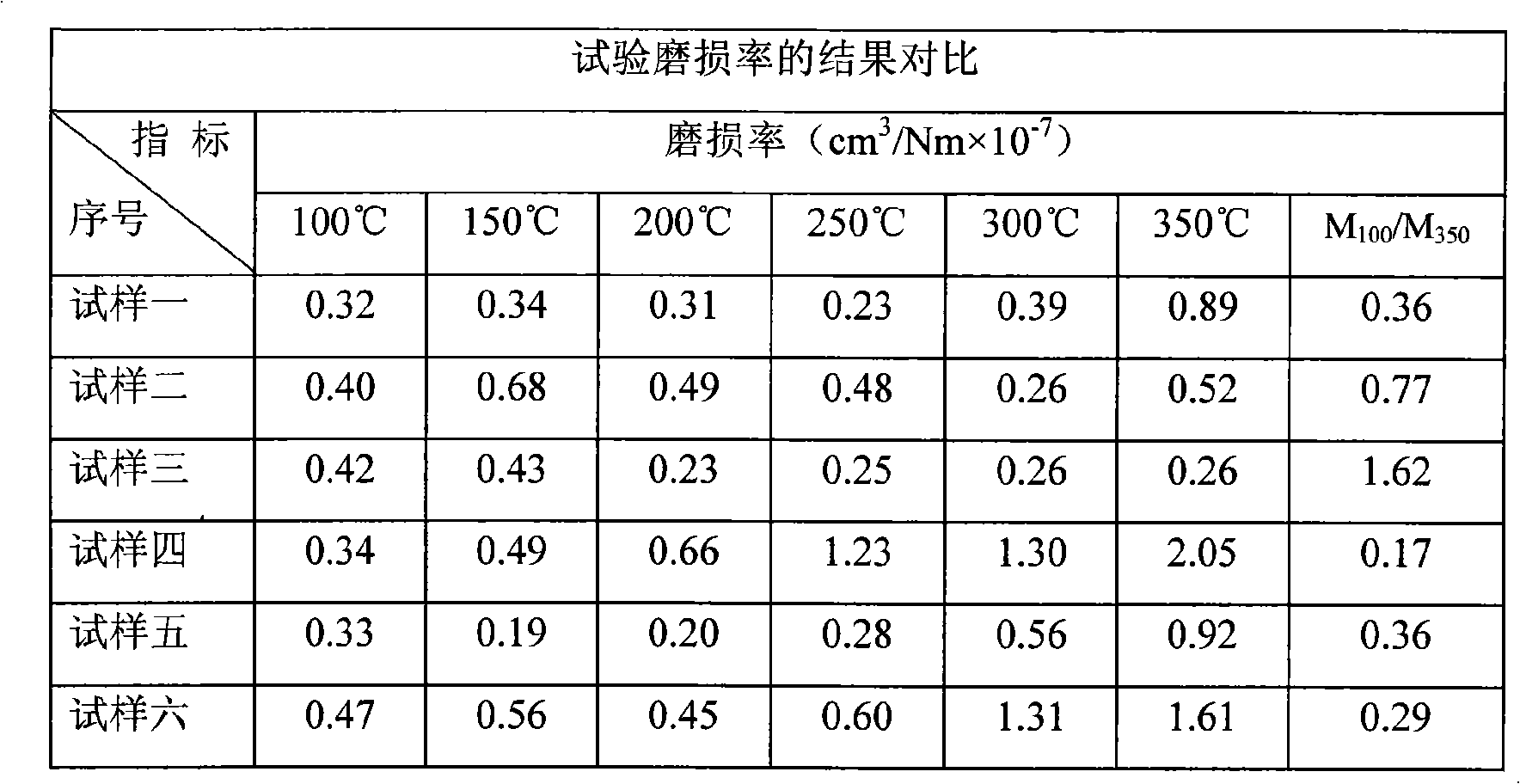

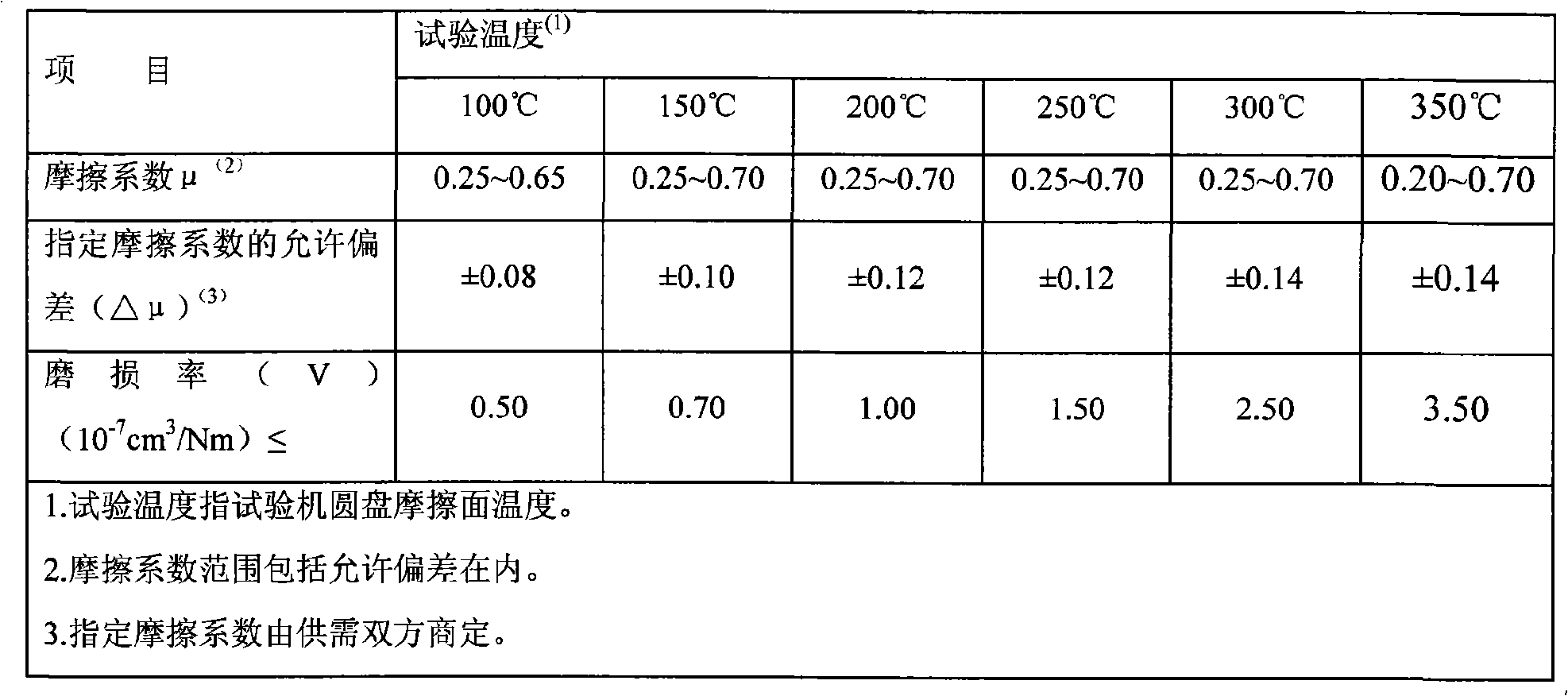

InactiveCN101514251AStable coefficient of frictionReduce wear rateFriction liningPyrophylliteConfusion

The present invention provides a vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof. The raw materials of composite friction material is composed of bamboo fiber, phenolic resin, magnesium sulfate crystal whisker, steel fiber, copper powder, graphite dust, pyrophyllite powder, aluminum oxide, iron oxide, barium sulfate and zinc stearate. The preparing method comprises the following steps: preprocessing the raw materials, mixing the raw materials, hot pressing shaping and heat processing. The invention uses the bamboo fiber with low cost for reinforcing the phenolic resin. The proper amount of wear-increasing agent, anti-wear agent and filling agent for exerting the cooperative coupling function among the substrate, the fiber / crystal whisker and filling agent, thereby obtaining the novel vehicle braking composite material which has the advantages of stable friction coefficient under different temperatures, low wear rate, high heat fading resistance, excellent braking effect, shock absorbing, noise reduction and low cost.

Owner:FUZHOU UNIV

Friction material for brake block of heavy-duty automobile

InactiveCN106147124AImprove stress resistanceImprove impact resistanceOther chemical processesFriction liningAcrylic rubberHeat stability

The invention discloses a friction material for a brake block of a heavy-duty automobile. The friction material is prepared from, by weight, 20-35 parts of phenolic resin, 2-5 parts of acrylic rubber, 3-8 parts of amph-POSS, 2-8 parts of quartz fibers, 10-20 parts of high silica fibers, 3-10 parts of silica fibers, 3-12 parts of aluminum borate whiskers, 3-10 parts of basic magnesium sulfate whiskers, 20-35 parts of nano-palygorskite, 15-35 parts of barium carbonate, 3-10 parts of aluminum powder, 3-10 parts of nano powdered carbon, 5-15 parts of boron nitride, 3-12 parts of emery powder, 2-6 parts of vermiculite, 0.5-5 parts of mica, 3-5 parts of molybdenum trioxide, 2-6 parts of natural graphite, 2-10 parts of micron zirconia balls and 2-8 parts of graphene oxide. The friction material for the brake block of the heavy-duty automobile has excellent high temperature resistance, wear resistance and heat stability and is used for the brake block of the heavy-duty automobile, and is good in braking performance and long in service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

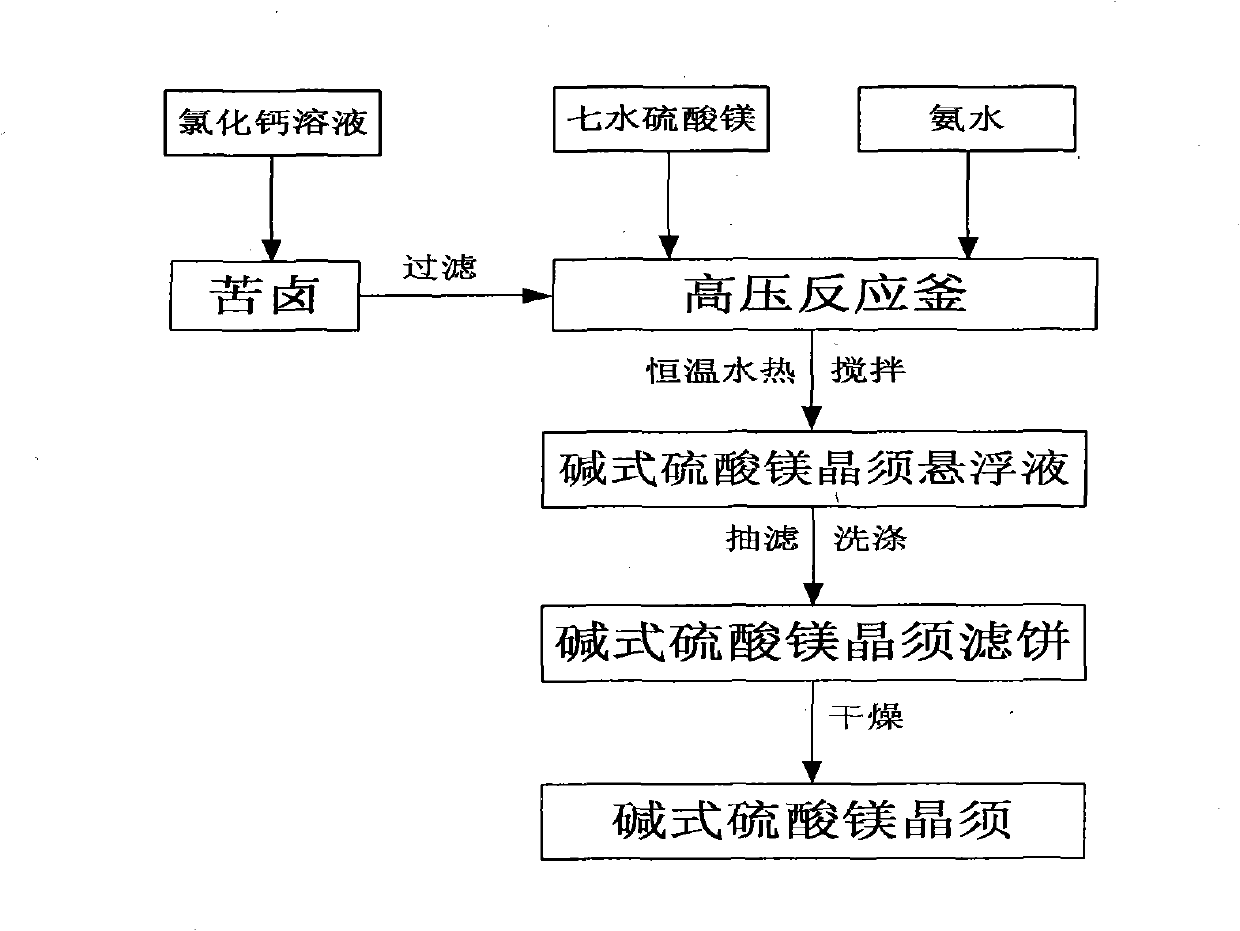

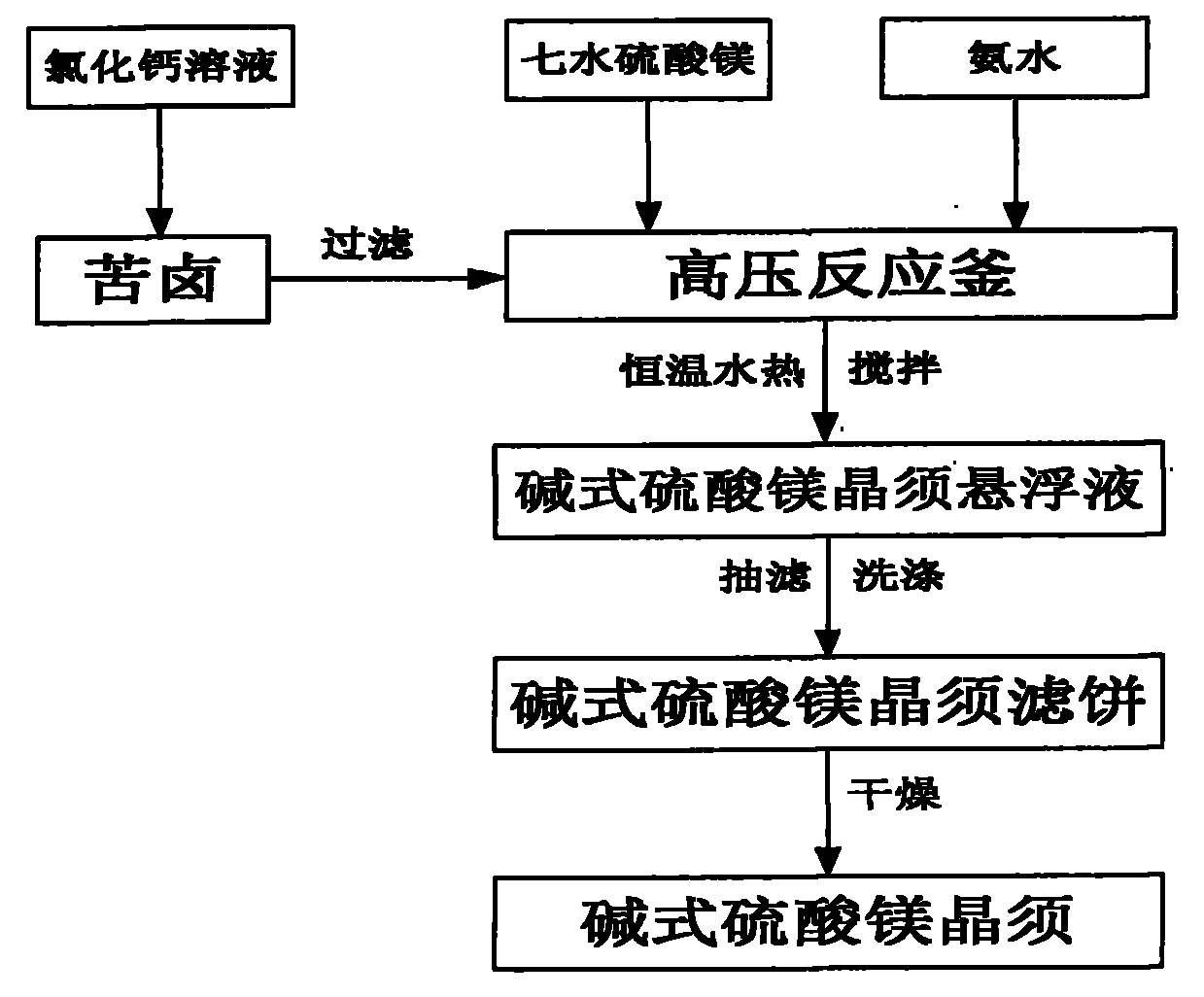

Method for directly synthesizing basic magnesium sulfate whiskers by brine

ActiveCN102002751ALow costImprove use valuePolycrystalline material growthFrom normal temperature solutionsMagnesium Sulfate whiskersWhiskers

The invention discloses a method for directly synthesizing basic magnesium sulfate whiskers by brine. The brine after salt manufacturing, ammonia water and magnesium sulfate heptahydrate are taken as raw materials to synthesize the basic magnesium sulfate whiskers. The method comprises the following steps of: performing thermostatic hydrothermal reaction on the pretreated brine, ammonia water and magnesium sulfate heptahydrate in a high-pressure reaction kettle to prepare basic magnesium sulfate whisker suspension, wherein the molar ratio of magnesium ions (Mg2+) of the brine to the ammonia water (NH3.H2O) to magnesium sulfate (MgSO4.7H2O) in the reaction kettle is 1.0:2.0-2.2:2.0-3.0, the stirring speed is 300 to 500rpm, the temperature is raised to 120-200DEG C, and the reaction time is 4 to 8 hours; and performing solid-liquid separation on the basic magnesium sulfate whisker suspension, washing the solid with running water, and drying a filter cake obtained after washing to obtain the basic magnesium sulfate whisker product. The technological process is simple, the cost of raw materials is low, the energy consumption is low, the product purity and quality are high, and after the synthesized whiskers are added into a composite material taking rubber and plastics as a matrix, the composite material has good reinforced property and flame retardancy.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Special environment-friendly paint prepared by using raw lacquer as biomass base for furniture and cabinets

InactiveCN103911033AImprove adhesionImprove heat resistance (high temperature)Natural resin coatingsLacquerMagnesium salt

The invention provides a special environment-friendly paint prepared by using a raw lacquer as a biomass base for furniture and cabinets and aims at providing a furniture and cabinet paint which is mainly prepared from raw lacquer, is environment-friendly and has excellent ecological properties. The environment-friendly paint comprises components such as the raw lacquer, a filler, a diluent and auxiliaries; the environment-friendly paint is technically characterized in that every 100 parts of raw lacquer is blended with 0.5-10 parts of magnesium salt whiskers. The high temperature resistance and the oil resistance of the raw lacquer for a cabinet are remarkably improved; when a traditional raw lacquer is applied to a cabinet tabletop, the high temperature requirement of the traditional raw lacquer hardly reaches the special heat resistance requirement of the cabinet tabletop, and the modern chemical paint cannot be comparable with the traditional raw lacquer in term of the heat resistance; consequently, the modern cabinet tabletops are seldom coated with the paint. The special environment-friendly paint completely overcomes the shortcoming; especially, as the paint is added with basic magnesium sulfate whiskers are added to the special environment-friendly paint, the heat resistance of the paint is obviously improved, and the comprehensive cost caused by use of the basic magnesium sulfate whiskers is not higher than the cost caused by use of the raw lacquer according to the traditional technology.

Owner:湖南鸿扬家居木制品有限公司

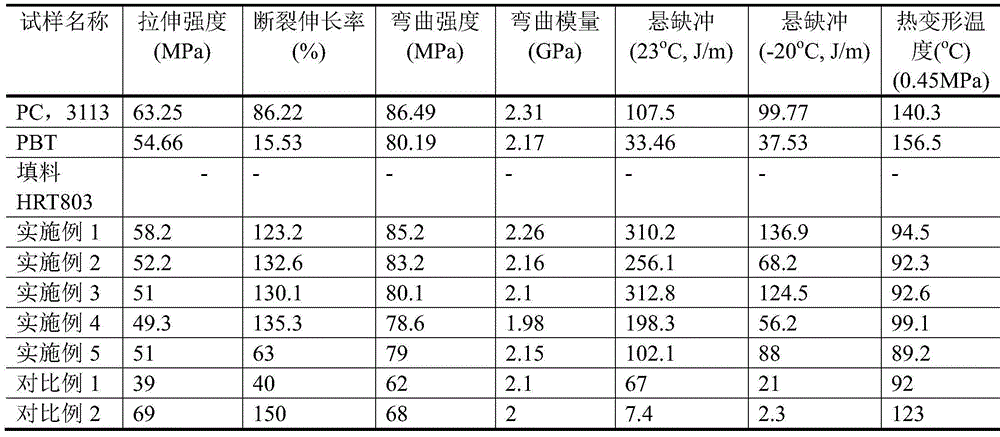

Composite reinforcing agent and PC/PBT alloy, and applications of composite reinforcing agent and PC/PBT alloy

ActiveCN105623029AMake up for rigidityMake up resiliencePolytetramethylene terephthalatePolyethylene terephthalate

The invention relates to a plastic alloy, and in particular, relates to a composite reinforcing agent and a polycarbonate-polybutylene phthalate (PC / PBT) plastic alloy. The composite reinforcing agent includes basic magnesium sulfate whiskers, rubber and a silane coupling agent. The alloy comprises polycarbonate, polyethylene terephthalate and the composite reinforcing agent. The invention also provides an application of the composite reinforcing agent and an application of the alloy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing basic magnesium sulfate whiskers by recycling mother liquor

InactiveCN101956234ASolve the pollution of the environmentSave resourcesPolycrystalline material growthFrom normal temperature solutionsRoom temperatureMagnesium Sulfate whiskers

The invention relates to a method for preparing basic magnesium sulfate whiskers by recycling mother liquor. The method comprises the following steps of: (1) concentrating and freezing the mother liquor for preparing the basic magnesium sulfate whiskers to separate sodium sulfate out, and filtering the sodium sulfate to obtain solid sodium sulfate decahydrate and the filtered mother liquor; (2) adding solid MgSO4.7H2O into the filtered mother liquor obtained in the step (1), diluting the mother liquor into solution with distilled water, and adding solid sodium hydroxide (NaOH) with stirring to obtain slurry; (3) transferring the slurry into a magnetic reaction kettle, performing reaction for 6 to 12 hours at the temperature of between 130 and 180 DEG C, and naturally cooling the slurry to the room temperature to obtain white solids; and (4) washing, filtering and drying the white solids in turn to obtain the basic magnesium sulfate whiskers. The method of the invention has the advantages of simple process, low production cost, short cycle, low energy consumption, no pollution and easy realization of large-scale industrial production.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Whisker modified polypropylene (PP) composite material and preparation method thereof

InactiveCN105111580ASolve the shortcomings of warping deformationMeet size assembly requirementsPolypropylene compositesMagnesium Sulfate whiskers

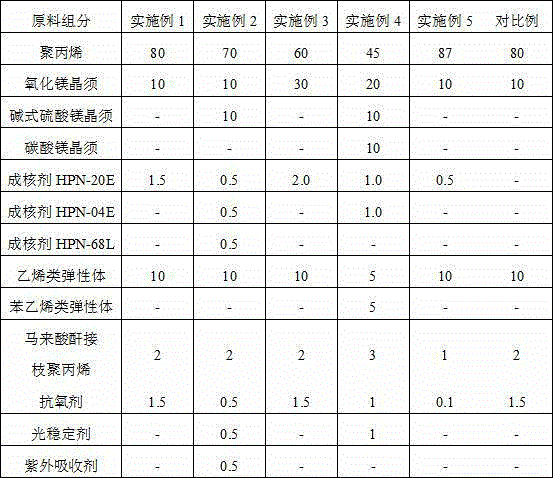

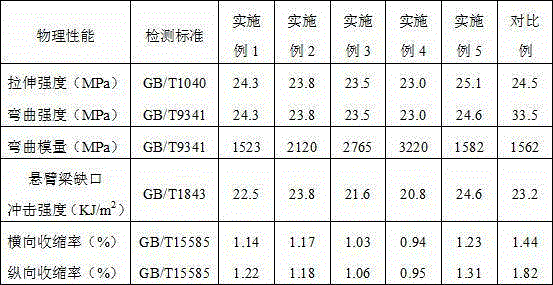

The invention provides a whisker modified polypropylene (PP) composite material. The PP composite material is prepared from 45-87 parts of PP, 10-40 parts of whiskers, 0.5-2 parts of nucleating agent, 3-15 parts of toughening agent, 1-3 parts of compatilizer and 0.1-2 parts of other additives, wherein the whiskers are at least one of magnesium oxide whiskers, basic magnesium sulfate whiskers and magnesium carbonate whiskers. By adding the nucleating agent and the whiskers, such as magnesium oxide, the prepared PP composite material has smaller difference of contractility in each direction, has the characteristic of isotropy, has the effect of overcoming the defect of warping deformation of products caused by non-uniformity of contraction, meets the dimensional assembling requirements of parts and has the effect of extending the application range of the whisker modified material.

Owner:ORINKO NEW MATERIAL CO LTD

Preparation method of alkali type magnesium sulfate crystal whisker

InactiveCN101319378ANo need to control concentrationReduce difficultyPolycrystalline material growthMagnesium sulfatesMagnesium Sulfate whiskersMagnesium sulphate heptahydrate

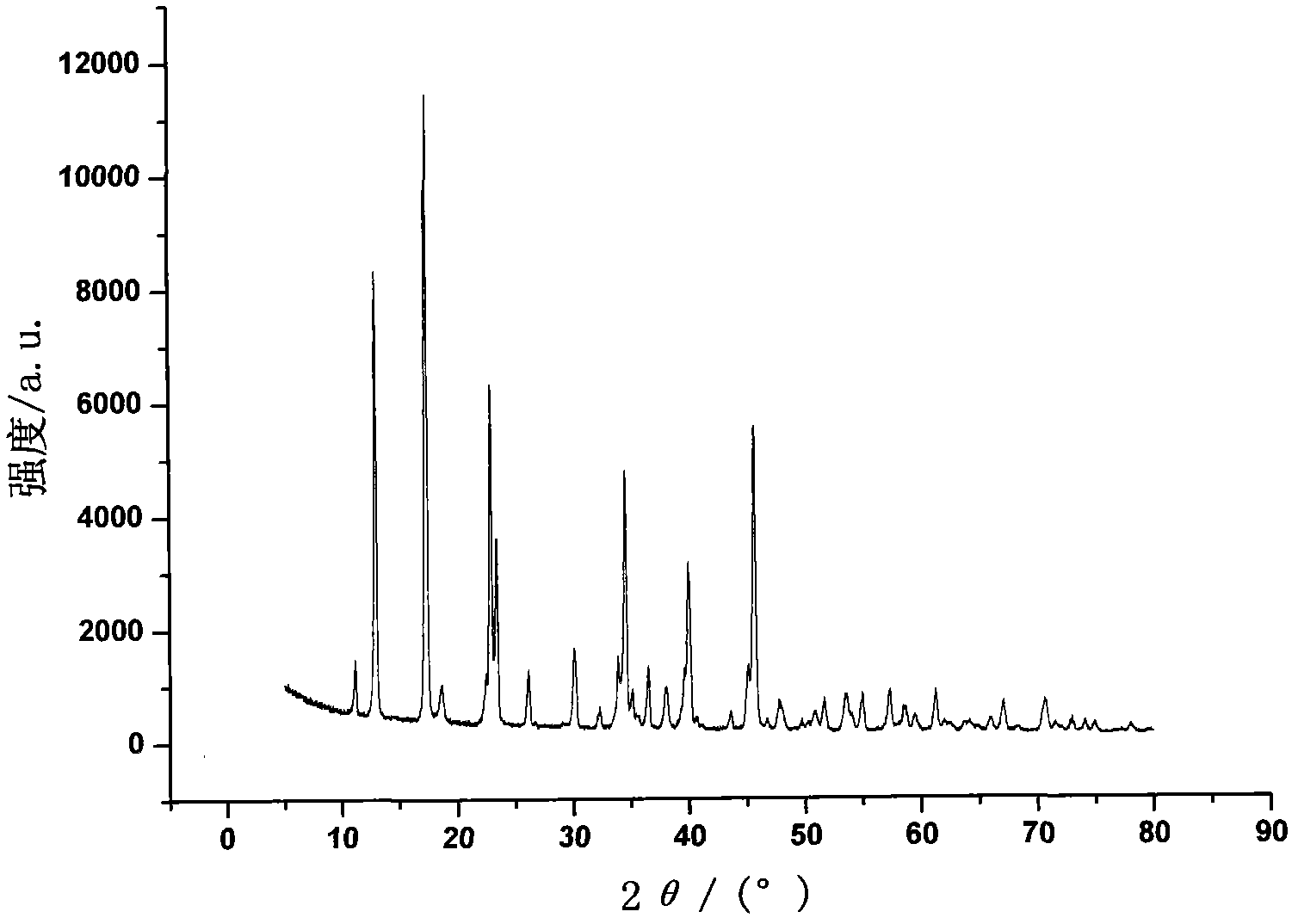

The invention provides a method for preparing a basic magnesium sulfate whisker material, comprising the following steps that: a magnesium sulfate solution and sodium hydroxide solid are mixed according to a mol ratio of 0.6:1.0 to 1.0:1.5, the mixture is stirred at normal temperature so that an even magnesium hydroxide sol-magnesium sulfate solution reaction precursor is generated after the reaction; and the obtained reaction precursor is transferred into a hydrothermal reaction kettle to react at a temperature of between 130 and 180 DEG C for 6 to 20 hours, the solid and the fluid are separated after the reaction mixture is cooled naturally, the solid is pumped and filtered by distilled water and is washed until a sulfate ion is removed as well as is dried so that the basic magnesium sulfate whisker product is produced. The technology is easy to control, has simple operation, short preparation cycle, low production cost, low energy consumption and high quality of product, and is used to prepare the basic magnesium sulfate whisker product with high purity quotient, good quality and a yield coefficient more than 90 percent. The whisker product is identified to be pure phase by the X-ray diffraction. The method can obtain basic magnesium sulfate whiskers with different phases by controlling the reaction condition.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of flame-retardant droplet-resistant terylene

ActiveCN102978735AFlame-proof filament manufactureMonocomponent copolyesters artificial filamentMagnesium saltVacuum furnace

The invention discloses a preparation method of flame-retardant droplet-resistant terylene. The preparation method comprises the following steps of: A) evenly mixing four materials including a flame-retardant droplet resistant basic magnesium sulfate whisker, a beta-type silicon nitride whisker, a tetrapod-like zinc oxide whisker and a magnesium salt whisker, baking the mixture in a vacuum furnace; stirring and dispersing the mixture in a sodium hexametaphosphate solution, carrying out atmospheric pressure plasma treatment, and then filtering and baking the solution by a filter with 200 meshes; B) mixing the whiskers obtained from the step A) with flame-retardant melamine cyanurate, a microencapsulated red phosphorus retardant, and a silane coupling agent under the condition of 75 DEG C; C) preparing a flame-retardant droplet resistant whisker ethylene glycol solution by a flame-retardant droplet resistant whisker obtained in the step B); and D) preparing a flame-retardant droplet resistant polyester from the flame-retardant droplet resistant whisker in a blending or copolyester manner, and preparing the sheath-core flame-retardant droplet resistant terylene of taking the flame-retardant droplet resistant polyester as a skin layer by using a compound spinning technology.

Owner:ZHEJIANG SHENGYUAN CHEM FIBER

Foaming plastic wood composite material board and preparation method thereof

The invention relates to a foaming plastic wood composite material board and a preparation method thereof. The preparation method comprises the following steps: processing wood powder by using an aluminic ester coupling agent to obtain coupling agent modified wood powder; evenly stirring the coupling agent modified wood powder, plastic particles, alkali magnesium sulfate whisker and lead sulfate tribasic, extruding and pelleting to obtain composite material particles; evenly stirring the composite material particles, azodicarbonamide, composite foaming agent, terpene resin, ethylene bis stearamido and light stabilizer, and extruding to prepare the foaming plastic wood composite material board. The invention has the advantages of convenient production, low production cost, small use amount of plastics, environment friendliness, no aging or discoloration, no buckling deformation, low density, light weight and high impact strength, and has the function of adsorbing gas. The foaming plastic wood composite material board can be widely applied to households, office buildings and other buildings, can be manufactured to photo frames, picture frames, skirting and suspension plates, or can be used for manufacturing suspension cross beams, pergolas, and the like.

Owner:江苏森诺塑胶科技有限公司

Low after-shrinkage polypropylene composite for car bumper bar and preparation method of low after-shrinkage polypropylene composite

The invention provides a low after-shrinkage polypropylene composite for a car bumper bar and a preparation method of the low after-shrinkage polypropylene composite. The low after-shrinkage polypropylene composite is prepared from 100 parts of polypropylene, 15-30 parts of acrylonitrile-butadiene-styrene, 15-45 parts of basic magnesium sulfate crystal whiskers, 10-35 parts of high-mesh talcum powder, 25-45 parts of flexibilizer, 0.25-0.5 part of nucleating agent, 0.4-0.8 part of lubricating agent, 0.2-0.3 part of coupling agent and 0.15-0.4 part of antioxygen. An acrylonitrile-butadiene-styrene copolymer, the basic magnesium sulfate crystal whiskers, the nucleating agent, the flexibilizer and the like are added into polypropylene to influence the crystallization property of PP, therefore, the shrinkage rate of the PP composite is reduced, the shrinkage rate change before and after coating of the prepared polypropylene composite is smaller than 0.1%, and the requirement of the car bumper bar is met.

Owner:HEFEI GENIUS NEW MATERIALS

Method for preparing flame retardant viscose fiber

ActiveCN102965750AHigh strengthImprove stiffnessArtificial filaments from viscoseCellulosePolymer science

The invention discloses a method for preparing flame retardant viscose fiber. The method comprising the following steps: A) mixing nano fiber having a flame retardant function, basic magnesium sulfate whisker, basic magnesium chloride whisker and magnesium salt whisker, then roasting the mixture in an oven of 400 DEG C, carrying out dispersion in absolute ethyl alcohol containing sodium hexametaphosphate, carrying out plasma treatment at normal pressure, carrying out ultrasonic dispersion and cleaning, filtering by a filter of 400 meshes and drying; B) uniformly mixing and drying the whisker and a titanate coupling reagent, adding and mixing antimonous oxide, hexabromocyclododecane, (HDPE+SEBS)-g-MAH and calcium stearate, and then adding cellulose spinning viscose to prepare flame retardant cellulose spinning viscose; and C) preparing the flame retardant viscose fiber by means of a wet or dry process spinning technology. The flame retardant viscose fiber is good in strength, stiffness, abrasive resistance and flame retardance.

Owner:嘉兴貂帅服饰有限公司

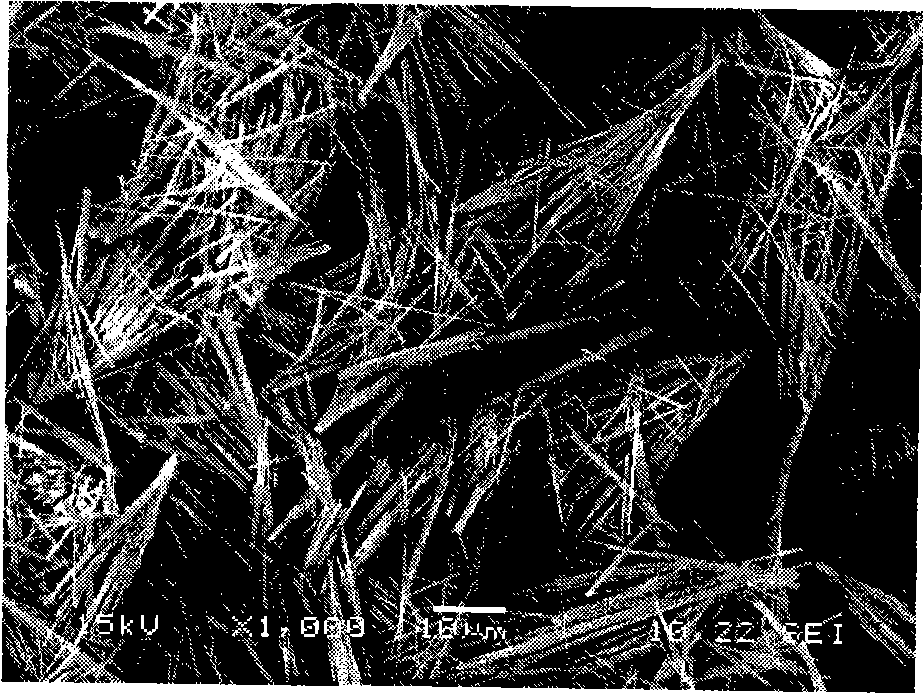

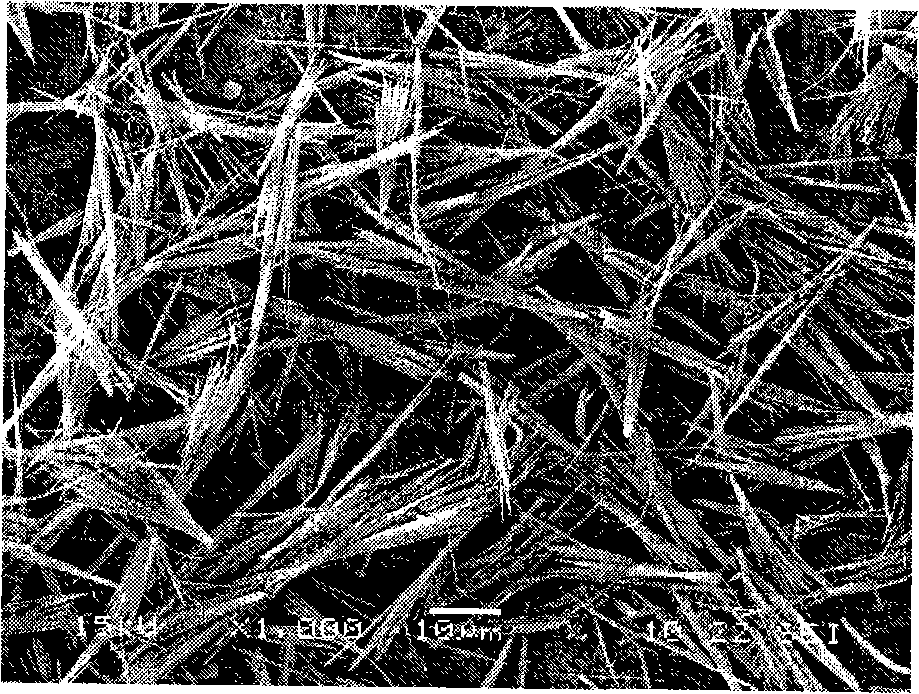

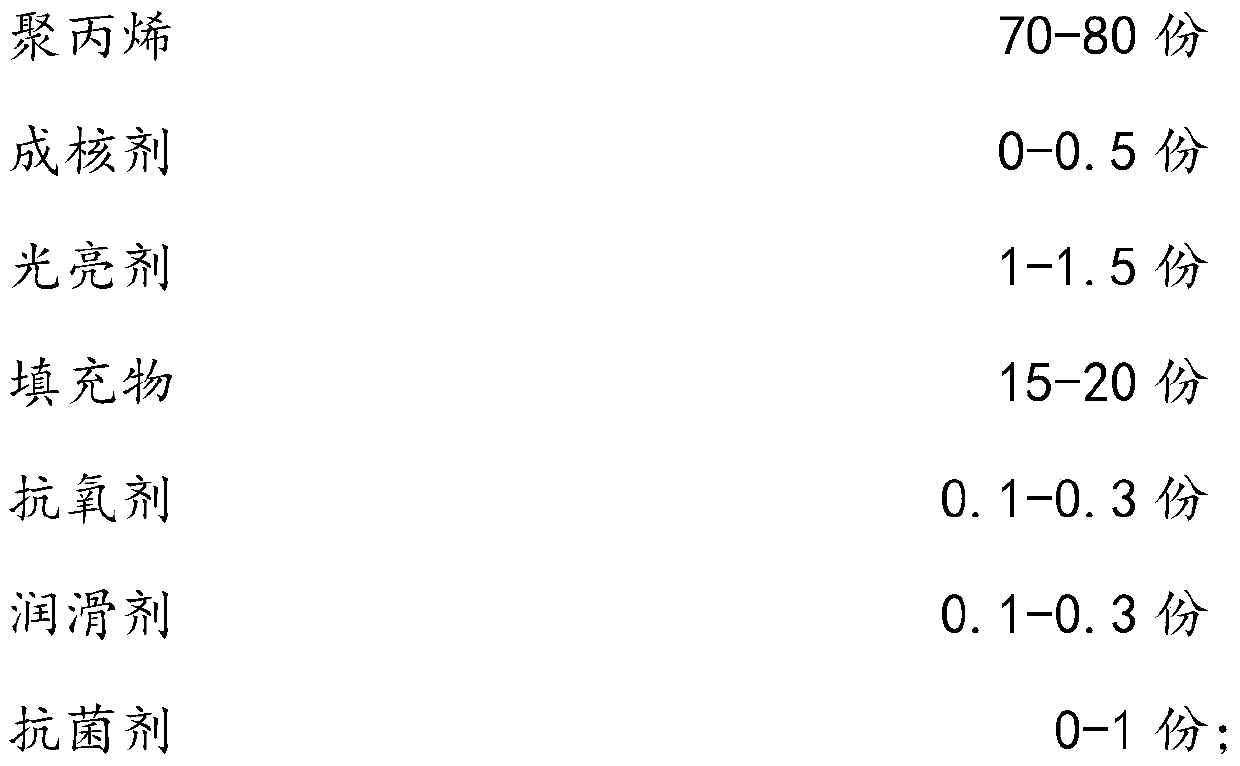

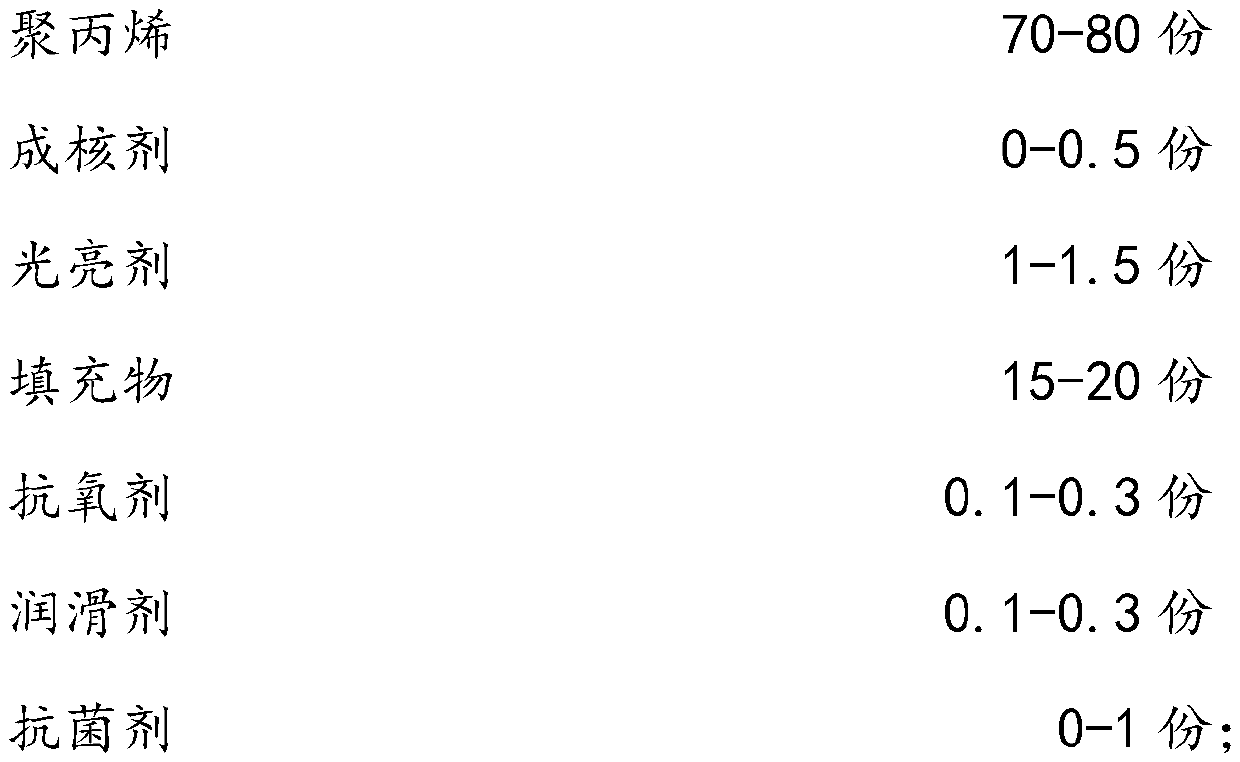

Polypropylene composite material with high gloss and low linear expansion coefficient and preparation method thereof

ActiveCN109721839AImprove gloss dropReduce the phenomenon of high coefficient of linear expansionPolymer scienceAntioxidant

The invention relates to the technical field of high polymer materials, and particularly relates to a polypropylene composite material with high gloss and low linear expansion coefficient and a preparation method thereof. The composite material is composed of the following raw materials in parts by mass: 70-80 parts of polypropylene, 0-0.5 part of a nucleating agent, 1-1.5 parts of a brightener, 15-20 parts of filler, 0.1-0.3 part of an antioxidant, 0.1-0.3 part of a lubricant and 0-1 part of an antibacterial agent; the mineral filler consists of whiskers, mica and nano montmorillonite, wherein the crystal whiskers consist of calcium carbonate whiskers, magnesium sulfate whiskers and basalt whisker. The provided polypropylene composite material with high gloss and low linear expansion coefficient has high material glossiness, the linear expansion coefficient of the polypropylene material can be effectively reduced, the material also has antibacterial performance, and meanwhile, the phenomenon that a polypropylene material in life shrinks seriously due to post-crystallization is avoided, and important practical benefits are achieved.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Whisker composite material for reinforcing automobile brake friction and a method for producing the same

The invention provides a whisker composite material for reinforcing automobile brake friction and a method for producing the same, wherein the composite friction material consists of basic magneislum whisker, pyrophyllite power, phenol resin, copper powder, graphite powder, aluminium oxide and zine stearate, as raw materials; the producing method comprises raw material pretreatment, raw material mixing, hot press molding and cooling. The invention achieves the phenol resin reinforcement by the basic magneislum whisker [MgSO4.5MgO.8H2O] with excellent low cost, selects the pyrophyllite [Al4Si8O20OH4] as the filler for the assorted fiber brake friction material, the concerted coupling function of a substrate, the whister and the filler can be exerted according to the addition of a friction reinforcing agent, and an antiwear agent, thereby the novel automobile brake composite material has advantages of good heat resistance, moderate coefficient of friction, small wear rate, well heat fade resistance, good brake effect and low cost.

Owner:FUZHOU UNIV

Efficient flame-retardant and smoke-suppressant agent for wood-based composite material and preparation method thereof

ActiveCN105295405AInhibitionEfficient flame retardant effectNon-macromolecular adhesive additivesWood impregnation detailsMontmorilloniteMagnesium Sulfate whiskers

The invention discloses an efficient flame-retardant and smoke-suppressant agent for a wood-based composite material and a preparation method thereof. The efficient flame-retardant and smoke-suppressant agent is prepared from 55-65 parts of inrumescent flame retardant, 2-6 parts of organic montmorillonite, 15-25 parts of nano-metal hydroxide and 10-20 parts of magnesium sulfate whisker. The preparation method includes the following steps that 1, the inrumescent flame retardant is synthesized and prepared; 2, the organic montmorillonite is synthesized and prepared; 3, the nano-metal hydroxide and the magnesium sulfate whisker are prepared; 4, the efficient flame-retardant and smoke-suppressant agent is prepared. The adopted raw materials including the inrumescent flame retardant, the organic montmorillonite, the nano-metal hydroxide and the magnesium sulfate whisker achieve multiple synergistic flame-retardant effects including synergistic flame retardant of the inrumescent flame retardant and the organic montmorillonite (the inrumescent flame retardant-nano synergy) and synergistic flame retardant of the organic montmorillonite and the nano-metal hydroxide (nano-nano synergy); the advantages of being high in flame-retardant, environment-friendly and smoke-suppressant efficiency, low in smoke and poison and the like. The technology is simple, industrialization is easy, and cleanliness and non-pollution can be achieved.

Owner:贵州恒力源林业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com