Preparation method of alkali type magnesium sulfate crystal whisker

A technology of magnesium sulfate whiskers and magnesium sulfate, applied in the direction of magnesium sulfate, chemical instruments and methods, single crystal growth, etc., can solve the problem of restricting the industrial production of basic magnesium sulfate whiskers, increasing process steps and raw material types, and being unsuitable for industrialization Production and other issues, to achieve the effect of saving resources, short preparation cycle, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

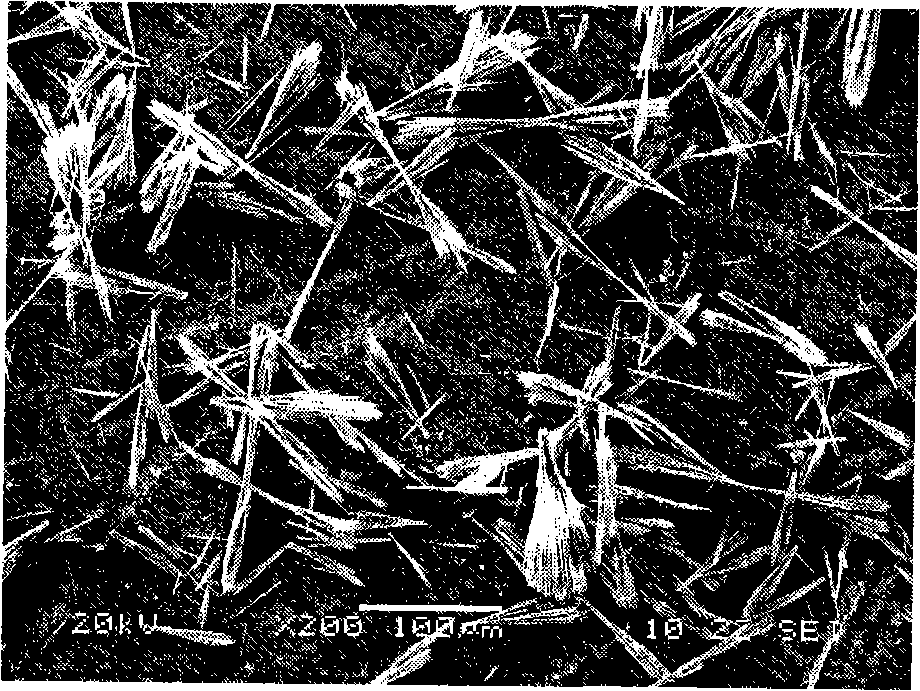

[0024] Embodiment 1, with MgSO 4 ·7H 2 O prepared 1.0mol L -1 1.4L of magnesium sulfate solution, at room temperature, 56g of sodium hydroxide solid was added to it under stirring, and stirred continuously to make it fully react to form a uniform magnesium hydroxide sol-magnesium sulfate mixed precursor. Transfer 1.4L of the reaction slurry prepared at room temperature to a 2L autoclave with a filling degree of 70%, perform hydrothermal reaction at 170°C for 10 hours, the initial stirring speed is about 450rpm, and adjust to 300rpm after constant temperature reaction for 3h. After the reaction was completed, it was allowed to cool naturally, and the reaction product was filtered to separate the solid from the liquid, and washed with distilled water until there was no sulfate ion. The whisker filter cake was dried at 80° C. for 1 h to obtain 61 g of the product. The microscopic appearance of the product is (one-way or two-way) fan-shaped bundle of fibers, the length of the t...

Embodiment 2

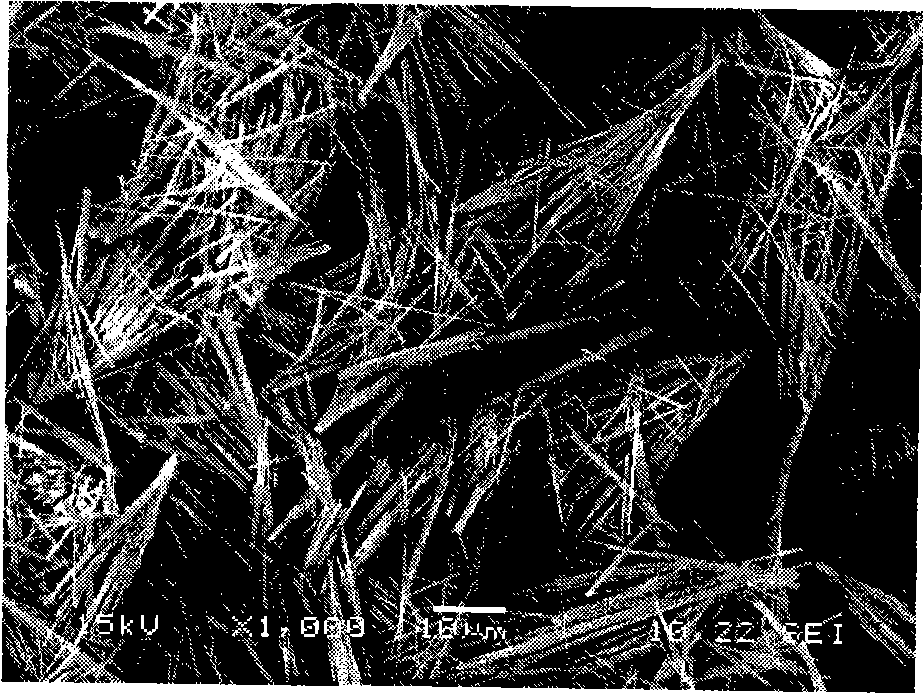

[0025] Embodiment 2, with MgSO 4 ·7H 2 O prepared 2.5mol L -1 1.45 L of magnesium sulfate solution, at room temperature, 181 g of solid sodium hydroxide was added therein under stirring, and stirred continuously to make it fully react to form a uniform mixed precursor of magnesium hydroxide sol-magnesium sulfate. 1.6 L of the reaction slurry prepared at room temperature was transferred to a 2 L autoclave with a filling degree of 80%, and the hydrothermal reaction was carried out at 170° C. for 10 hours with a stirring intensity of 500 rpm. After the reaction was completed, it was allowed to cool naturally, and the reaction product was filtered to separate the solid from the liquid, and washed with distilled water until there was no sulfate ion. The whisker filter cake was dried at 80°C for 4 hours to obtain 195g of the product. The microscopic appearance of the product is partly fan-shaped bundle-like fibers, and partly dispersed whiskers are formed, with a diameter of abou...

Embodiment 3

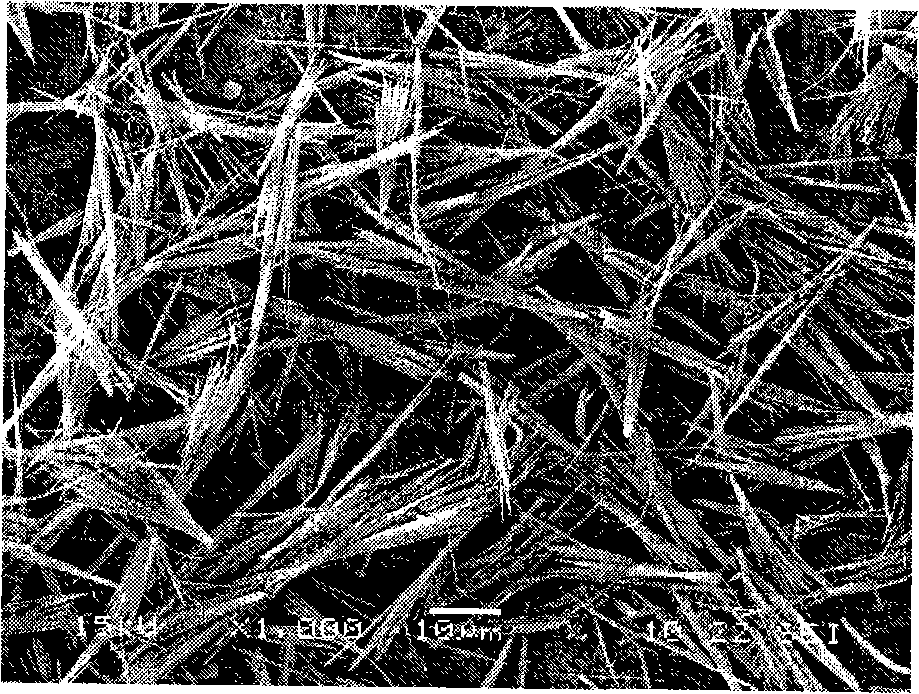

[0026] Embodiment 3, with MgSO 4 ·7H 2 O prepared 2.0mol L -1 1.5 L of magnesium sulfate solution, at room temperature, add 150 g of solid sodium hydroxide to it under stirring, and keep stirring to make it fully react to form a uniform magnesium hydroxide sol-magnesium sulfate mixed precursor. 1.6L of the reaction slurry prepared at room temperature was transferred to a 2L autoclave with a filling degree of 80%, and the hydrothermal reaction was carried out at 170° C. for 10 hours, and the stirring intensity was 500-600 rpm. After the reaction was completed, it was allowed to cool naturally, and the reaction product was filtered to separate the solid from the liquid, and washed with distilled water until there was no sulfate ion. The whisker filter cake was dried at 80° C. for 4 hours to obtain 155 g of the product. The microscopic appearance of the product is (two-way or one-way) fan-shaped bundle fibers, the length of the two-way fan-shaped bundle fibers is about 40-50 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com