Enhanced toughened halogen-free flame-retardant polypropylene mixture and preparation method thereof

A flame-retardant polypropylene, reinforcement and toughening technology, applied in the flame-retardant field of halogen-free flame-retardant polypropylene mixture, modified resin, can solve the problems of low flame-retardant efficiency, large surface polarity, large amount of addition, etc., to achieve comprehensive Effects of improved performance, ease of handling, and increased compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

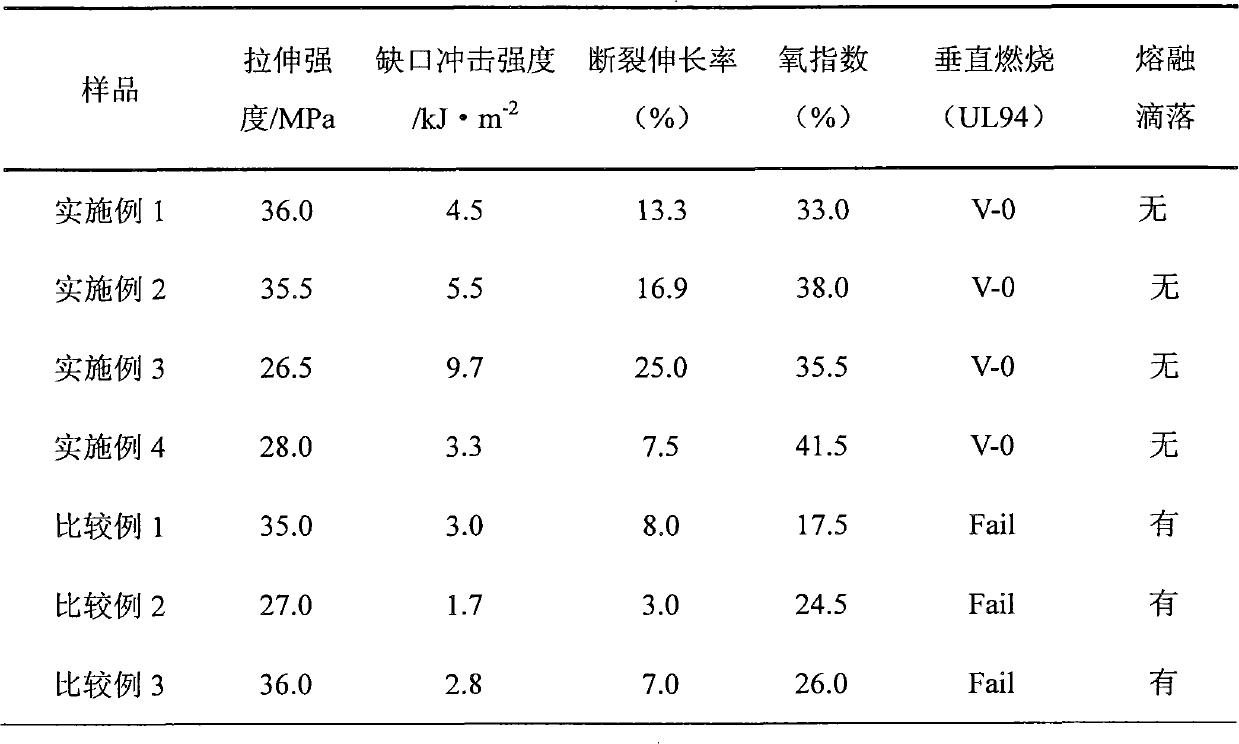

Examples

Embodiment 1

[0032] 0.5 parts by mass of silane coupling agent (KH-560, Jiangxi Xinghuo Chemical Plant) was diluted with 20 parts by mass of dehydrated alcohol (analytical grade, Donghong Chemical Plant, Guangzhou), and mixed with 100 parts by mass of basic magnesium sulfate whiskers ( MHSH, grade WS-1S, average length 10-60 μm, diameter less than 10 μm, Shandong Yingkou Wesker Chemical Co., Ltd.) at 400 rpm high-speed mixer (JYHG-100W, Shenzhen Jiayuan Kechuang Plastic Machinery Co., Ltd.) mixed in medium for 30 minutes, and baked in an oven (model LG1008, Shanghai Experimental Instrument Factory) at 80° C. for 6 hours to obtain modified basic magnesium sulfate whiskers (m-MHSH).

[0033] Add 100 parts by mass of polypropylene (PP, brand T30S, melt index of 3.0g / 10min, China Petroleum & Chemical Corporation Maoming Branch) to an open double-roller heat refiner with a roll temperature of 170°C, 10 parts by mass of ethylene- Vinyl acetate copolymer (EVA, brand name EVA14-2, vinyl acetate (V...

Embodiment 2

[0037]After 3 parts by mass of silane coupling agent (KH-560, Jiangxi Xinghuo Chemical Plant) was diluted with 30 parts by mass of dehydrated alcohol (analytical grade, Donghong Chemical Plant, Guangzhou), mixed with 100 parts by mass of basic magnesium sulfate whiskers ( MHSH, grade WS-1S, average length 10-60 μm, diameter less than 10 μm, Shandong Yingkou Wesker Chemical Co., Ltd.) at 800 rpm high-speed mixer (JYHG-100W, Shenzhen Jiayuan Kechuang Plastic Machinery Co., Ltd.) Mix in medium for 15 minutes, bake in an oven (model LG1008, Shanghai Experimental Instrument Factory) at 100° C. for 4 hours to obtain modified basic magnesium sulfate whiskers (m-MHSH).

[0038] Add 100 parts by mass of polypropylene (PP, brand T30S, melt index of 3.0g / 10min, China Petroleum & Chemical Corporation Maoming Branch) to an open double-roller heat refiner with a roll temperature of 180°C, 20 parts by mass of ethylene- 1-octene copolymer (POE, trade mark DF610, melt index is 1.2g / 10min, Mits...

Embodiment 3

[0041] Dilute 2 parts by mass of titanate coupling agent (NXT-401, Guangzhou Baoxin Chemical Materials Co., Ltd.) with 30 parts by mass of absolute ethanol (analytical grade, Guangzhou Donghong Chemical Factory), and mix with 100 parts by mass of alkali Magnesium sulfate whiskers (MHSH, grade WS-1S, average length 10-60 μm, diameter less than 10 μm, Shandong Yingkou Wesker Chemical Co., Ltd.) in a high-speed mixer (JYHG-100W, Shenzhen Jiayuan Branch) at 600 rpm Chuang Plastic Machinery Co., Ltd.) for 20 minutes, and baked in an oven at 90°C for 5 hours to obtain modified basic magnesium sulfate whiskers (m-MHSH).

[0042] Add 100 parts by mass of polypropylene (PP, brand T30S, melt index 3.0g / 10min, China Petroleum & Chemical Corporation Maoming Branch) to an open double-roller heat refiner with a roll temperature of 170°C, and 40 parts by mass of the linear low Density polyethylene (LLDPE, brand name DFDA-7042, melt index is 2.0g / 10min, Maoming Branch of China Petroleum and C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com