MPP electrostatic tube of force and preparation method thereof

A power tube and raw material technology, applied in the field of MPP power tube and its preparation, can solve the problems of increasing product cost, unsatisfactory flame retardant effect, difficult to achieve, etc., and achieves the effect of good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

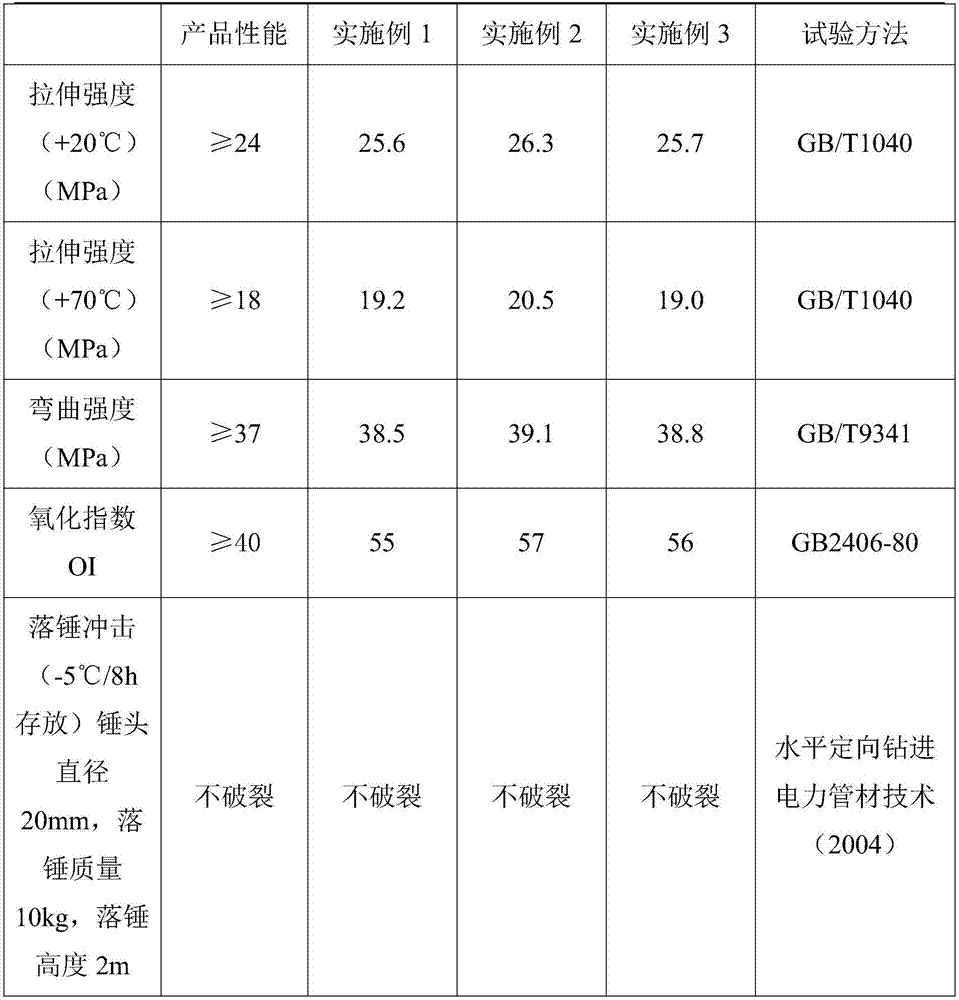

Examples

Embodiment 1

[0025] An MPP power pipe, calculated in parts by weight, includes the following raw materials:

[0026] 100 parts of MPP, 36 parts of light calcium carbonate, 12 parts of epoxidized soybean oil, 3.2 parts of isooctyl dithioglycolate di-n-octyltin, 7 parts of maleic anhydride grafted polypropylene PP-g-MAH, 7 parts of oxidized polyethylene wax , 7 parts of CPE resin, 5 parts of ethylene-propylene copolymer, 8 parts of graphene, 5 parts of modified whiskers, 13 parts of composite inorganic flame retardant, 2.4 parts of vinyltrimethoxysilane, polyisobutenyl succinyl 1.6 parts of amine, 0.8 part of antioxidant and 0.6 part of coloring agent; the percentage content of each component in the composite inorganic flame retardant is 22% of rare earth hydroxide, 50% of aluminum hydroxide, 20% of magnesium hydroxide and 8% of iron oxide %, the modified whiskers are surfactant-modified basic magnesium sulfate whiskers.

[0027] The modification method of the modified whiskers is: add 12 p...

Embodiment 2

[0030] An MPP power pipe, calculated in parts by weight, includes the following raw materials:

[0031] 100 parts of MPP, 25 parts of light calcium carbonate, 14 parts of epoxidized soybean oil, 2.4 parts of di-n-octyl tin dimercaptoacetate, 10 parts of maleic anhydride grafted polypropylene PP-g-MAH, 6 parts of oxidized polyethylene wax 10 parts of CPE resin, 4 parts of ethylene-propylene copolymer, 10 parts of graphene, 6 parts of modified whiskers, 15 parts of composite inorganic flame retardant, 1.5 parts of vinyltrimethoxysilane, polyisobutenyl succinyl 2 parts of imine, 0.5 part of antioxidant and 0.4 part of colorant; the percentage content of each component in the composite inorganic flame retardant is 16% of rare earth hydroxide, 50% of aluminum hydroxide, 30% of magnesium hydroxide and iron oxide 8%, the modified whiskers are surfactant-modified basic magnesium sulfate whiskers.

[0032] The modification method of the modified whiskers is: add 10 parts of basic magn...

Embodiment 3

[0035] An MPP power pipe, calculated in parts by weight, includes the following raw materials:

[0036] 100 parts of MPP, 45 parts of light calcium carbonate, 10 parts of epoxidized soybean oil, 4 parts of di-n-octyl tin dimercaptoacetate, 5 parts of maleic anhydride grafted polypropylene PP-g-MAH, 8 parts of oxidized polyethylene wax 5 parts, CPE resin 5 parts, ethylene-propylene copolymer 6 parts, graphene 5 parts, modified whisker 3 parts, composite inorganic flame retardant 10 parts, vinyltrimethoxysilane 3 parts, polyisobutenyl succinyl 1 part of imine, 1 part of antioxidant and 0.8 part of colorant; the percentage content of each component in the composite inorganic flame retardant is 22% of rare earth hydroxide, 30% of aluminum hydroxide, 40% of magnesium hydroxide and iron oxide 8%, the modified whiskers are surfactant-modified basic magnesium sulfate whiskers.

[0037]The modification method of the modified whiskers is: add 15 parts of basic magnesium sulfate whisker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com