Composite reinforcing agent and PC/PBT alloy, and applications of composite reinforcing agent and PC/PBT alloy

A reinforcing agent and alloy technology, which is applied in the field of plastic alloys, can solve the problems of poor material fluidity, increase the start-stop response time of the nozzle, and affect the forming accuracy, etc., and achieve the effects of improving low-temperature impact performance, improving mechanical properties, and improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

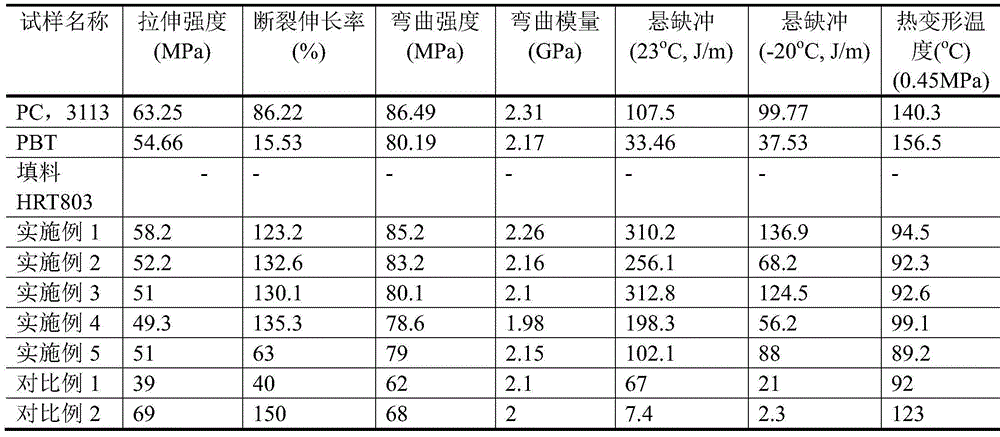

Examples

Embodiment 1

[0043] Preparation of composite reinforcing agent

[0044] Accurately weigh 30-70 parts of carboxylated styrene-butadiene rubber, preferably 50 parts; accurately weigh 70-30 parts of basic magnesium sulfate whiskers, preferably 50 parts; under the mixing of a high-speed heating mixer, when the mixing temperature reaches 50 degrees, 1-3 parts of silane coupling agent are added to obtain a composite reinforcing agent after they are fully blended in a mixer.

Embodiment 2

[0046] Preparation of PC / PBT alloy material

[0047] Accurately weigh the PC material of 70 mass parts, the PBT material of 30 mass parts, the composite reinforcing agent of 5 mass parts, the sodium dihydrogen phosphate of 0.25 mass parts, the light stabilizer 622 parts of 0.3 mass parts; Ethylene glycol, the antioxidant 1010 of 0.3 mass parts, the shell layer-PMMA core layer-cross-linked polybutadiene rubber of 12 mass parts; Add in the high-speed stirrer, motor speed 1300 rev / mins, mix at room temperature Take it out after 2 minutes, put the mixed material into the hopper of Ф18 twin-screw extruder, melt, extrude, cool, and granulate to make PC / PBT for FDM. Among them, the temperature of the twin-screw extruder from the first section to the sixth section is controlled at 230°C, 240°C, 250°C, 255°C, 255°C, 260°C, the head temperature is 255°C, and the screw speed is 350°C. rpm. The cooling water temperature is 20-40°C.

[0048] Example 2

[0049] Preparation of PC / PBT all...

Embodiment 3

[0052] Preparation of PC / PBT alloy material

[0053] Accurately weigh 40 parts by mass of PC material, 60 parts by mass of PBT material, 10 parts by mass of composite reinforcing agent, 0.5 parts by mass of sodium dihydrogen phosphate, 0.3 parts by mass of light stabilizer 622, and 0.3 parts by mass of polyethylene Diol, 0.3 parts by mass of antioxidant 1010, 16 parts by mass of shell layer-polymethyl methacrylate core layer-crosslinked polybutyl acrylate material. Sample preparation is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com