Composite reinforced modified polypropylene composition for vehicle parts, and preparation method thereof

A polypropylene composition and composite reinforcement technology, applied in the field of polypropylene composition, can solve the problems of poor fluidity, impact strength and other mechanical properties, inconvenience, and weak structural strength of polypropylene composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

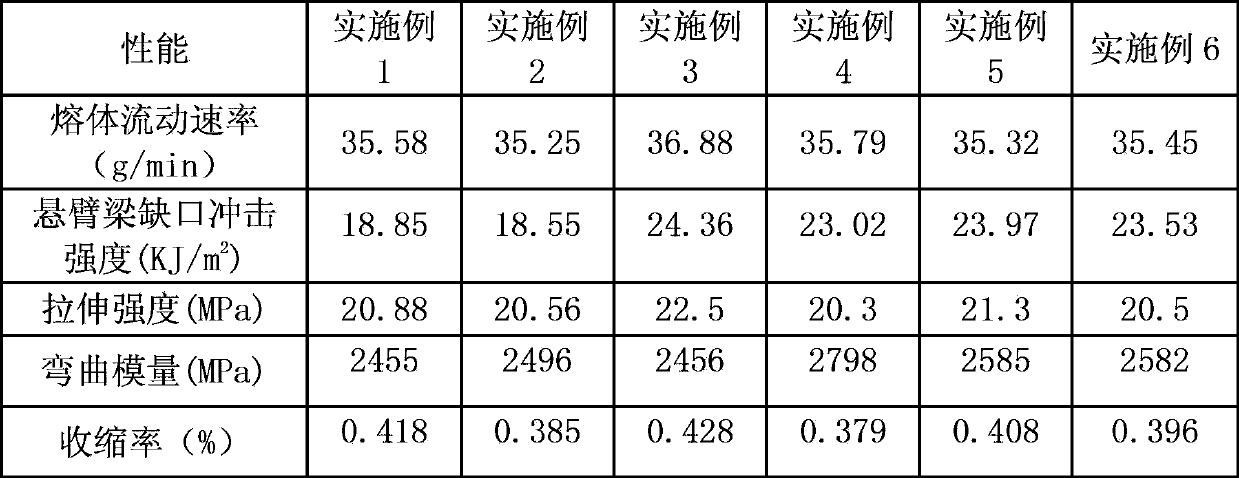

Examples

Embodiment 1

[0044] A composite reinforced modified polypropylene material for automobile parts, its composition and the weight percentage of each composition are as follows:

[0045] Polypropylene resin (PP) 60.6%,

[0046] Polyolefin Elastomer 17%,

[0047] Talc 16%,

[0048] Magnesium Sulfate Whiskers 6%,

[0049] Antioxidant 0.2%,

[0050] Processing aid 0.2%,

[0051] Among them: polypropylene resin (PP), the brand is BX3920, produced by SK Company of South Korea; polyolefin elastomer, the brand is DF640, produced by Mitsui Corporation of Japan; the inorganic filler is basic magnesium sulfate whisker, the brand is WS-1S, produced by Produced by Wesker Chemical Co., Ltd. in Yingkou City, Liaoning; talcum powder is commercially available; the antioxidant is IRGANOX 1010, produced by Swiss Ciba Fine Chemical Company; the processing aid is plastic processing aid EBS, produced by Zibo Zhoucun Lubo Chemical Co., Ltd. Ltd. production.

[0052] In the present embodiment, the inorganic f...

Embodiment 2

[0059] In the present embodiment, except that the inorganic filler adopts talcum powder 12% and magnesium sulfate whisker 10%, all the other are the same as embodiment 1.

Embodiment 3

[0061] In this example, except for 18% of polyolefin elastomer, 15% of talcum powder and 6% of magnesium sulfate whiskers as inorganic fillers, the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com