Electronic product frame integrally-formed structural part and manufacturing method therefor

A technology for electronic products and forming structures, applied in electrical components, electrical equipment casings/cabinets/drawers, household components, etc., can solve the problem of inconsistent thermal expansion coefficient and shrinkage rate, mobile phone casings and screens are prone to fall, high carbon fiber product prices, etc. It can improve the toughness and poor impact resistance, avoid the weak strength of the whole machine, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

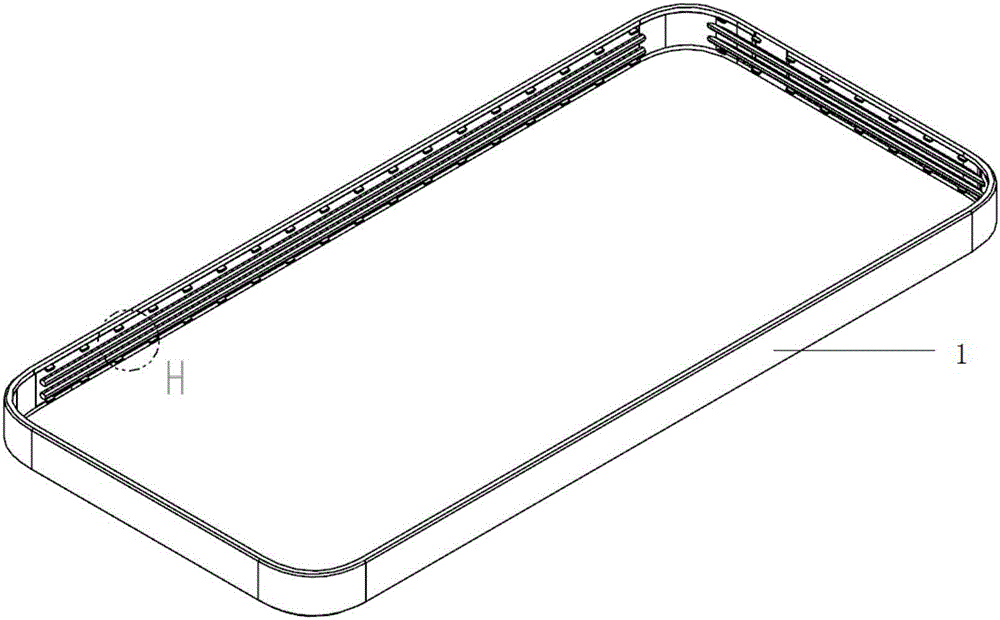

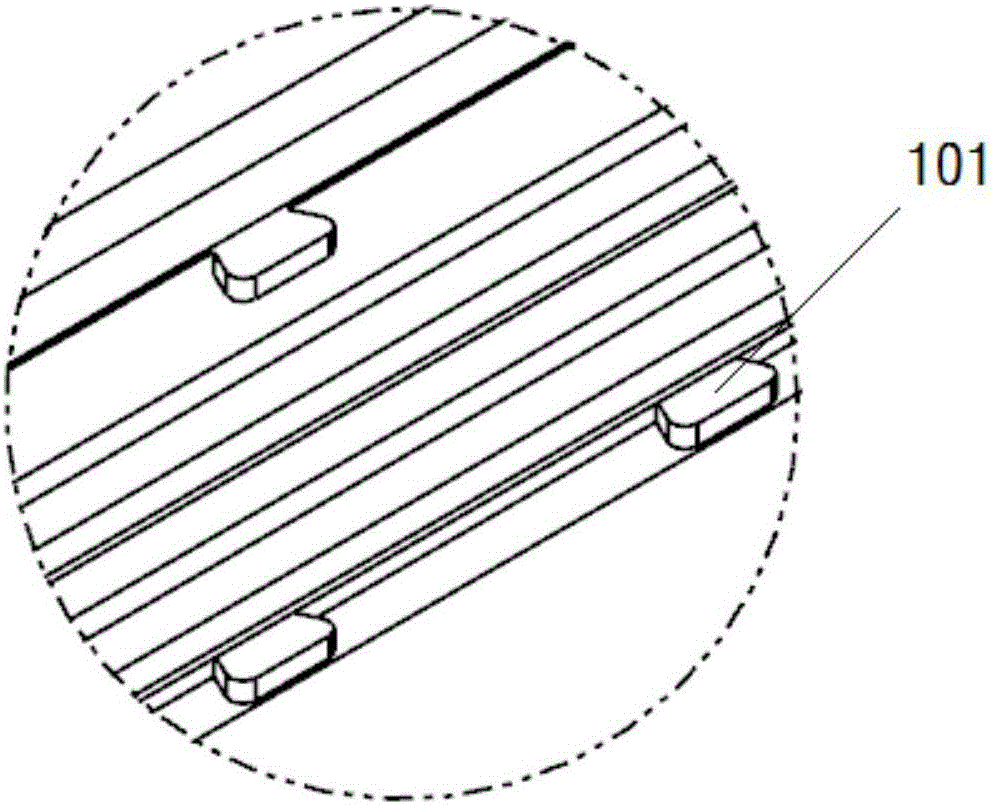

[0046] refer to Figure 1 to Figure 1 4. In one embodiment, an electronic product frame integrally formed structural part, including a carbon fiber sheet outer frame 1 made of carbon fiber sheet and a metal inner frame 2 made of metal, the carbon fiber sheet The outer frame 1 and the metal inner frame 2 are integrally formed by injection molding carbon fiber resin composite material 3 .

[0047]In a preferred embodiment, the carbon fiber sheet is made of a plurality of single-layer carbon fiber cloths impregnated with resin and superposed by hot pressing.

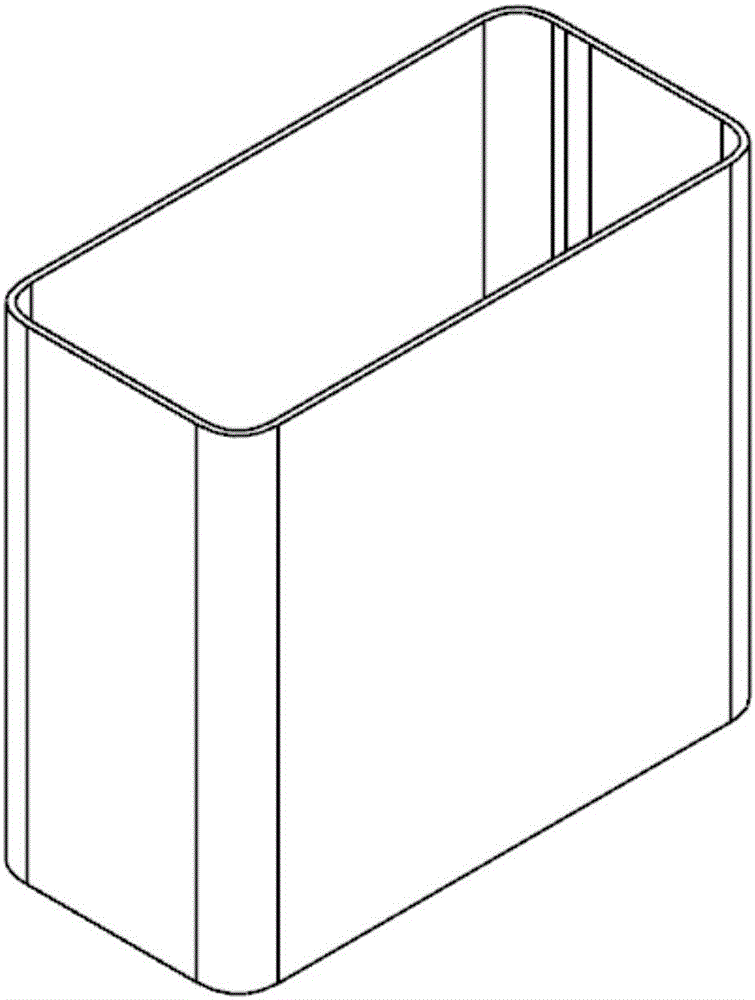

[0048] In a preferred embodiment, the carbon fiber sheet is thermocompressed and solidified into a cylindrical shape, and the carbon fiber sheet outer frame 1 is an annular carbon fiber substrate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com