Paint spraying method, paint spraying device, and paint spraying product of composite part

A technology for composite parts and products, which is applied in the fields of painting, painting equipment and painting products of composite parts, can solve problems such as increasing costs, increasing processes, and small area, and achieves the effects of improving yield and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

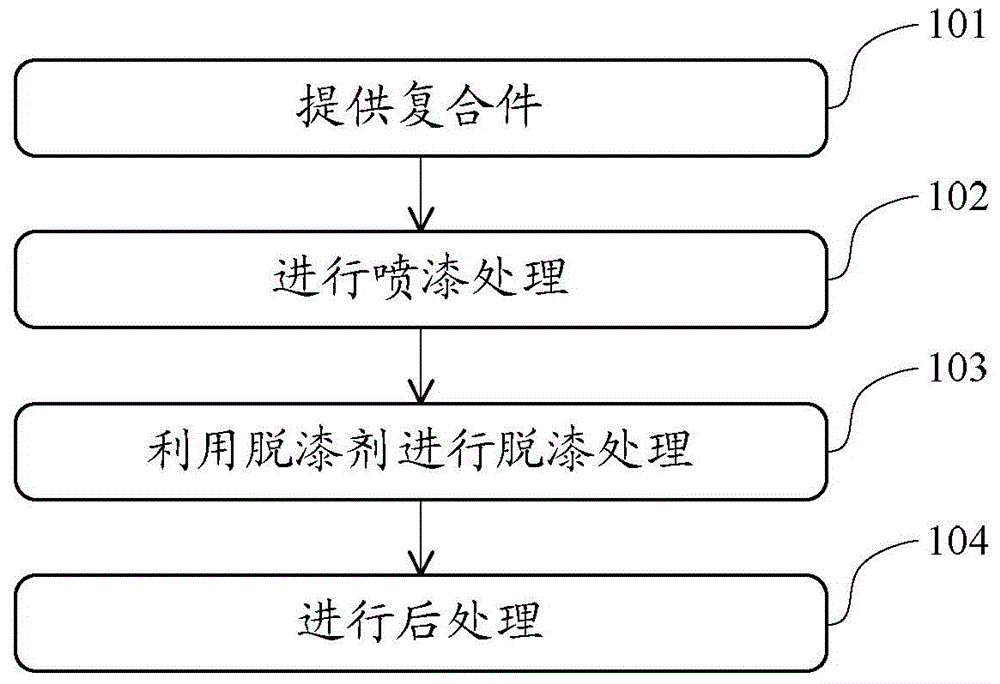

[0058] See attached to this application figure 1 , which shows a method for painting a composite part according to a first embodiment of the present invention. The method comprises the steps of:

[0059] Step 101: Provide a composite part including a plastic part and a non-plastic part.

[0060] Wherein, the material constituting the non-plastic part may be, for example, metal and / or inorganic non-metallic material.

[0061] Specifically, the metal may be: crystalline metal, amorphous metal (liquid metal), or crystalline-amorphous metal composite material. In a preferred embodiment, the crystalline metal may be: aluminum-based alloys, magnesium-based alloys, titanium-based alloys, iron-based alloys, and the like.

[0062] In addition, the inorganic non-metallic material may be: glass, oxide ceramics, carbide ceramics, composite compounds of oxide ceramics and / or composite compounds of carbide ceramics.

[0063] Furthermore, the composite part here can be used, for example,...

no. 2 approach

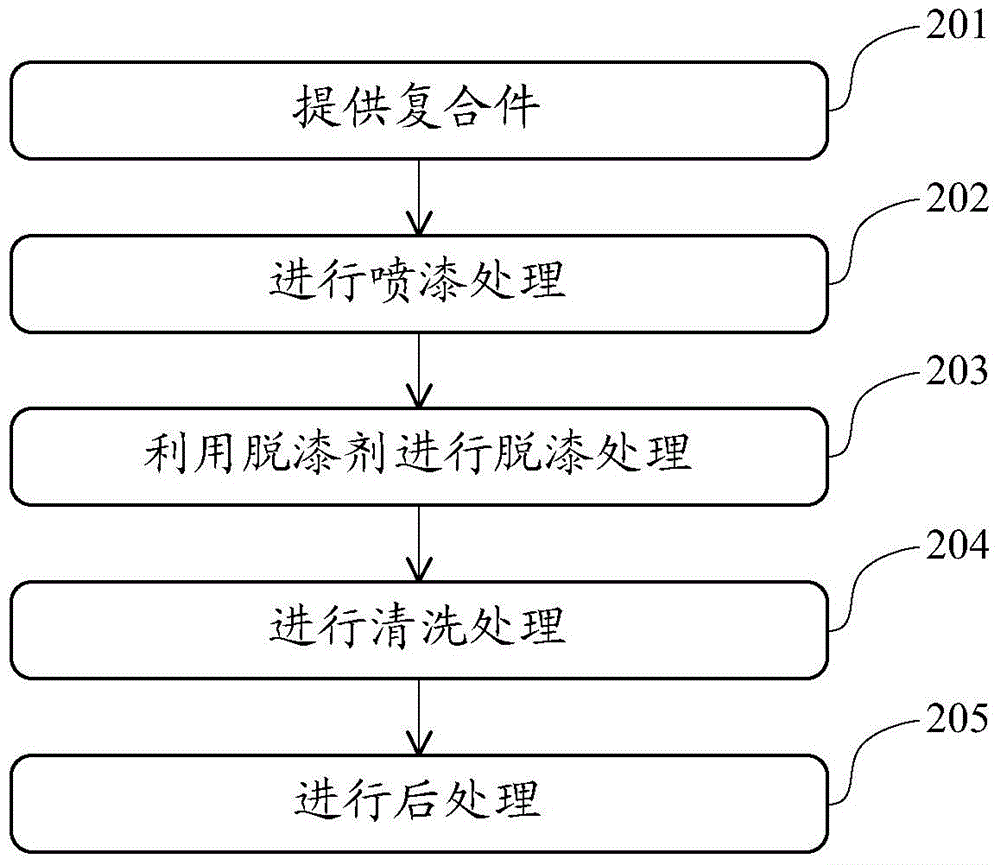

[0096] See attached to this application figure 2 , which shows a method for painting a composite part according to a second embodiment of the present invention. The method comprises the steps of:

[0097] Step 201: Provide a composite part including a non-plastic part and a plastic part.

[0098] Step 202: Carry out painting treatment on the surface of the composite part.

[0099] Step 203: Perform paint removal treatment on the composite part.

[0100] Step 204: Cleaning the composite part.

[0101] After stripping the composite part, an additional cleaning treatment can further remove residues on the composite part, such as residual paint and paint stripper on overpainted areas.

[0102] The cleaning treatment can be carried out in various appropriate ways, for example, ultrasonically cleaning the composite, wiping the composite with a dust-free cloth and / or blowing and cleaning the composite with a pressurized airflow, etc. The various cleaning methods mentioned abov...

no. 3 approach

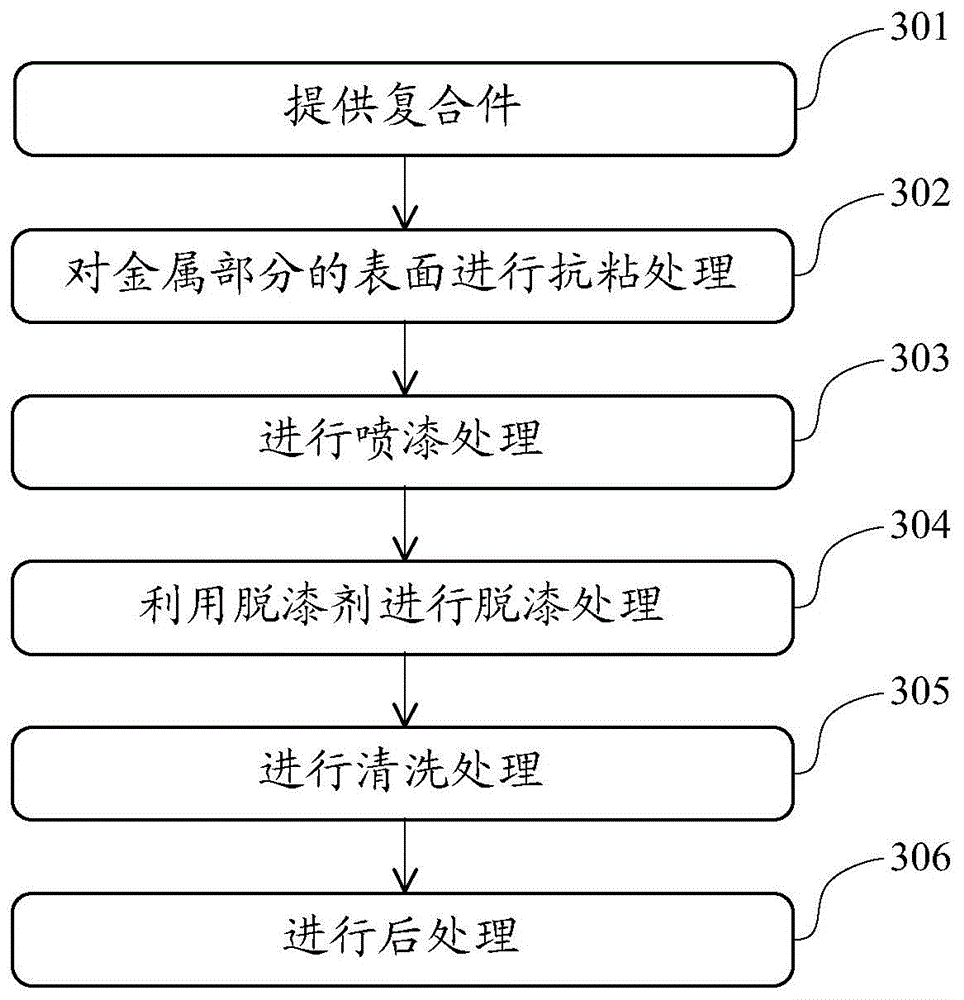

[0108] See attached to this application image 3, which shows a method for painting a composite part according to a third embodiment of the present invention. The method comprises the steps of:

[0109] Step 301: Provide a composite part including a non-plastic part and a plastic part.

[0110] Step 302: Anti-adhesive treatment is performed on the surface of the non-plastic part of the composite part.

[0111] The anti-adhesive treatment can be realized by coating the surface of the non-plastic part of the composite part with an anti-fouling film layer. Preferably, the anti-adhesive treatment can be achieved by coating the surface with a micro-nano antifouling film layer. More preferably, the micro-nano antifouling film layer can be coated by spray coating or PVD plating. The micro-nano antifouling film layer can make the non-plastic part exhibit the texture characteristics of the material of the non-plastic part while having an anti-adhesive effect.

[0112] In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com