Short-flow high-efficiency spinning machine used for producing multicomponent yarn

A short process and spinning machine technology, applied in the field of textile processing, can solve the problems of frequent doffing tube changes, affecting the appearance of fabrics, and increasing the number of yarn joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

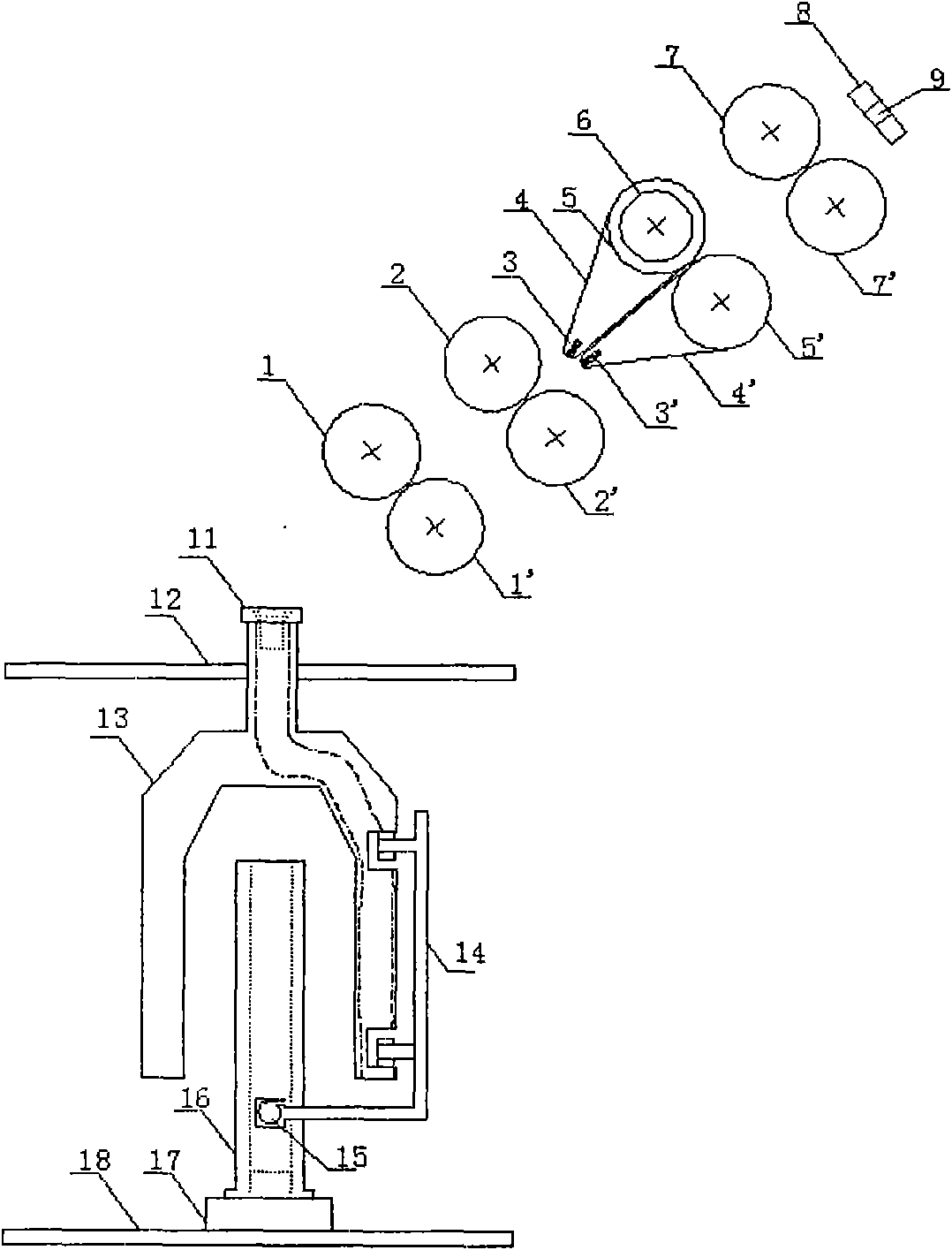

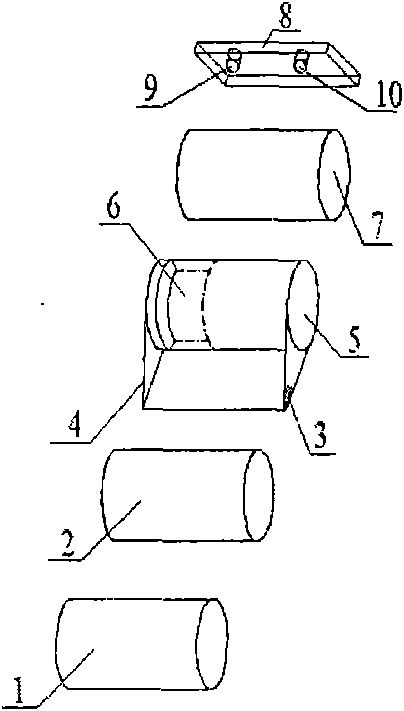

Embodiment 1

[0032] See figure 2 In the middle of one side of the third top roller 5 of the spinning machine, a positioning annular groove 6 with a width of 12 mm and a depth of 3 mm is opened, and a positioning yarn feeding hole 9 with a diameter of 10 mm and a positioning yarn feeding hole 9 with a diameter of 10 mm are opened on the positioning yarn feeding device 8. Aperture is the yarn feeding hole 10 of 10mm, and positioning yarn feeding hole 9 and yarn feeding hole 10 are on the same horizontal line. The axis of the positioning yarn feeding hole 9 is collinear with the center line of the positioning annular groove 6, and the yarn feeding hole 10 is positioned at the side of the positioning yarn feeding hole 9. Setting the center distance of the second roller 2' and the back roller 7' is 102mm, and setting the second roller 2' and the third roller 5' center distance is 45mm. Fix the flyer 13 on the upper dragon shaft 12 through the bearing, install a plurality of grooved annular fa...

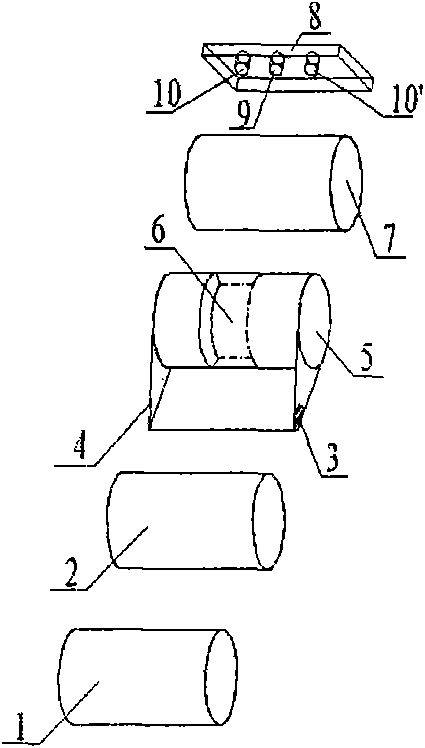

Embodiment 2

[0037] See image 3 In the middle part of the third top roller 5 of the spinning machine, a width of 10 mm and a depth of 3.5 mm are opened to position the annular groove 6. On the positioning yarn feeding device 8, a positioning yarn feeding hole 9 and a yarn feeding hole 10 and a feeding hole 10 are opened. The yarn hole 10' is positioned on the same horizontal line as the yarn feeding hole 9, the yarn feeding hole 10 and the yarn feeding hole 10', and their apertures are 10mm. The axis of the positioning yarn feeding hole 9 is collinear with the center line of the positioning annular groove 6, and the yarn feeding hole 10 and the yarn feeding hole 10' are positioned at both sides of the positioning yarn feeding hole 9 respectively. Setting the center distance of the second roller 2' and the back roller 7' is 115mm, and setting the second roller 2' and the third roller 5' center distance is 55mm. Fix the flyer 13 on the upper shaft 12 through the bearing, install the inner ...

Embodiment 3

[0041] See Figure 4 On both sides of the third top roller 5 of the spinning machine, a positioning annular groove 6 and a positioning annular groove 6' with a width of 8 mm and a depth of 4 mm are opened respectively, and two positioning yarn feeding devices are provided on the positioning yarn feeding device 8. Hole 9 and 9 ' and a yarn feeding hole 10, positioning yarn feeding hole 9 and 9 ' and yarn feeding hole 10 are on the same horizontal line, and their apertures are 10mm. The axis of positioning yarn feeding hole 9 and positioning yarn feeding hole 9' is collinear with the midline of positioning annular groove 6 and 6' respectively, and yarn feeding hole 10 is positioned in the middle of positioning yarn feeding hole 9 and positioning yarn feeding hole 9'. Setting the center distance of the second roller 2' and the back roller 7' is 114mm, and setting the second roller 2' and the third roller 5' center distance is 40mm. Fix the flyer 13 on the upper shaft 12 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com