Glove for grasping fine component

A technology for gloves and objects, applied in the field of gloves for grasping small objects, can solve problems such as dead space, inability to float or place small objects, and hindering the grasping of small objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

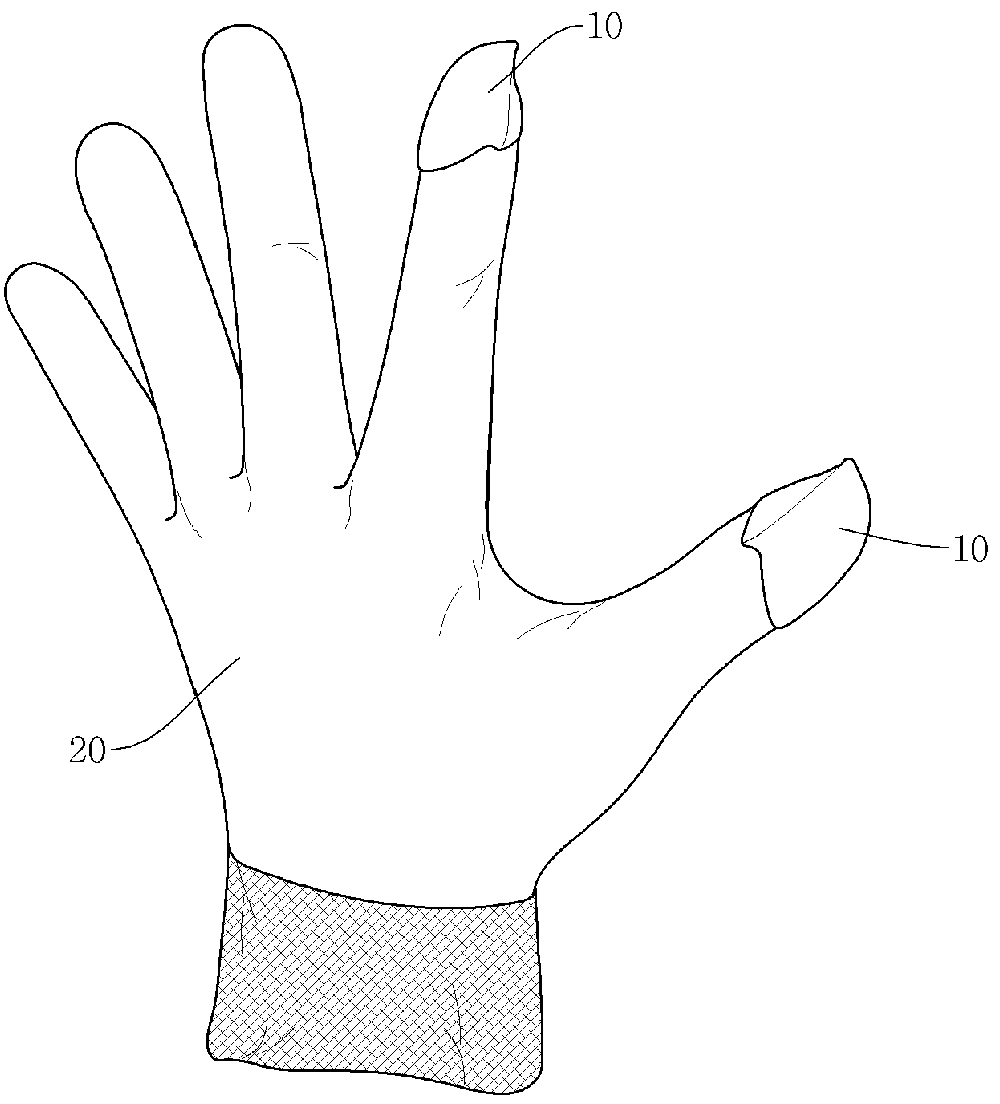

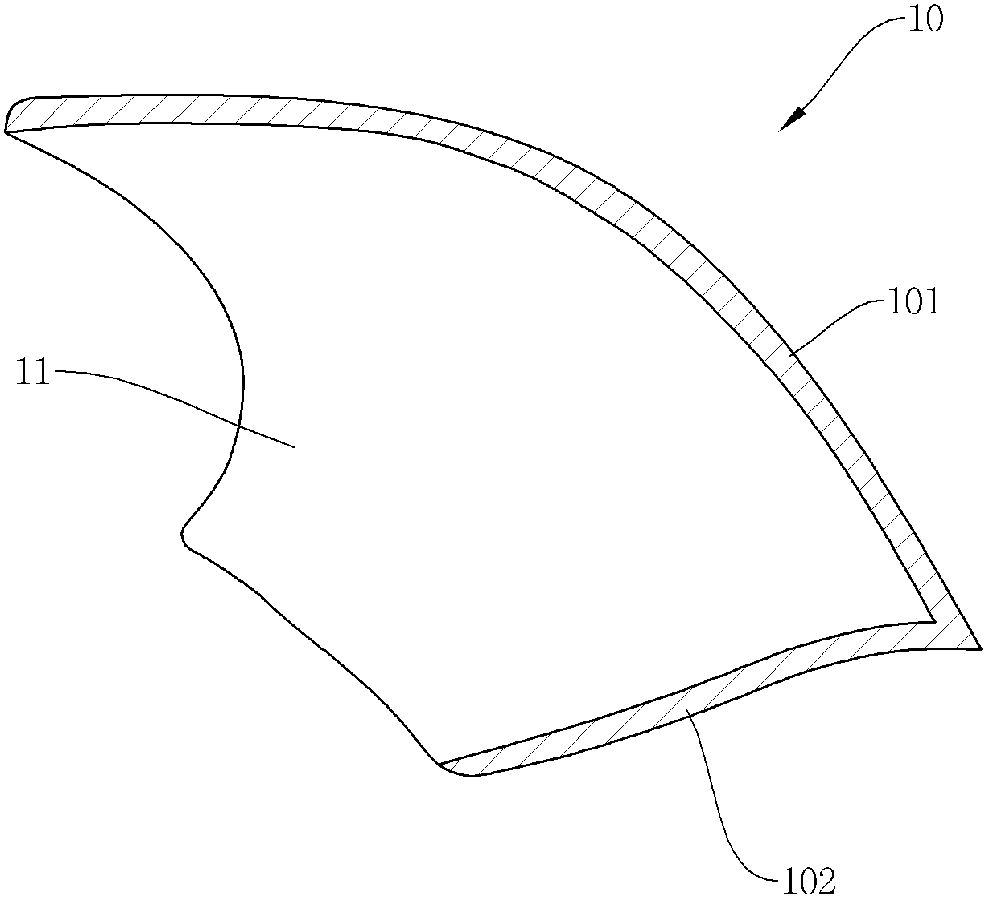

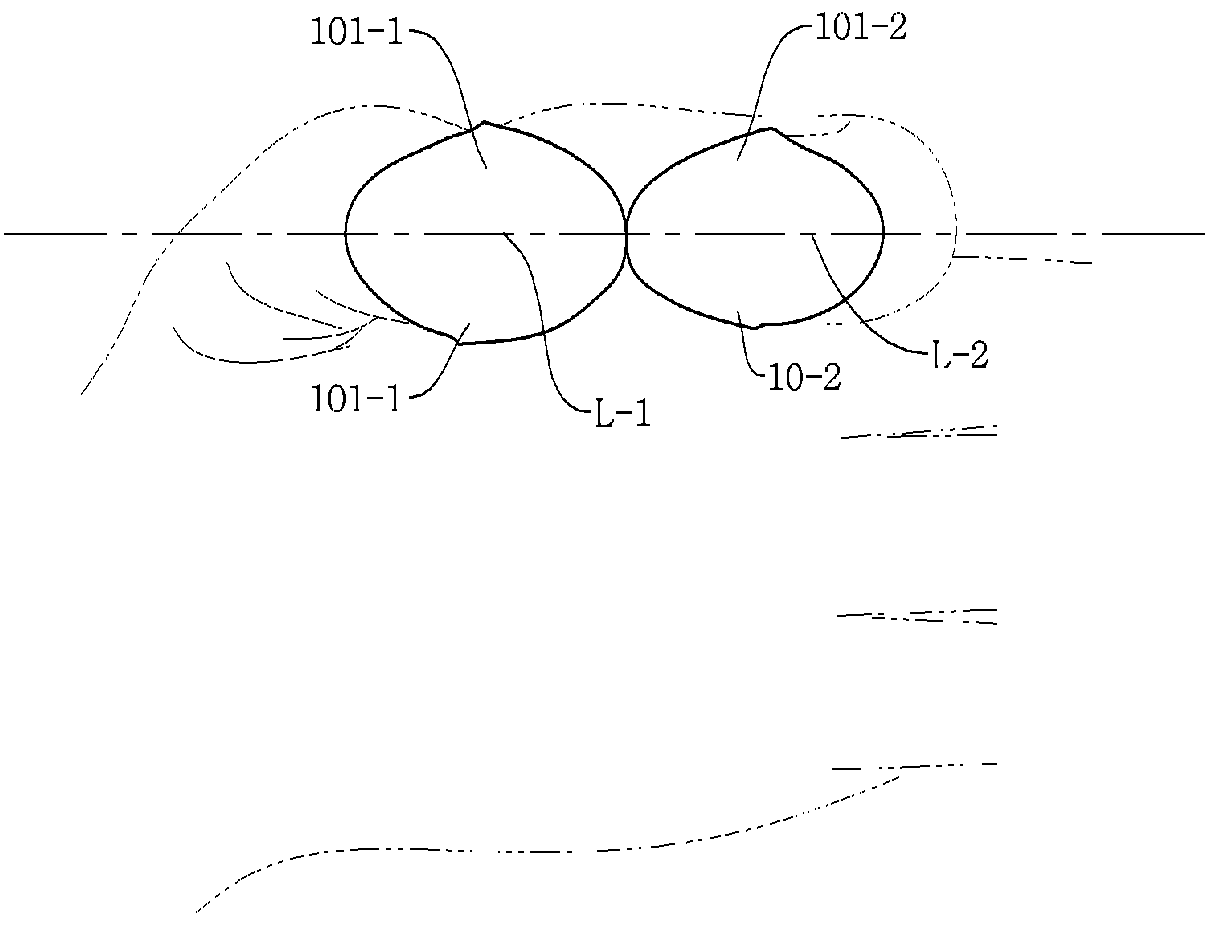

[0043] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Component elements that can be described using the same name in each figure are assigned the same figure symbol for convenience of description. figure 1 It is a perspective view of a glove for grasping small objects according to the first embodiment of the present invention, figure 2 yes figure 1 A cross-sectional view along line II' is shown.

[0044] see Figure 1 to Figure 2 , The glove for grasping small objects in this embodiment includes: a glove body, including a finger portion 20 wrapping fingers; and a fingertip portion 10 .

[0045] The fingertip portion 10 is formed at the end of the finger portion of the glove, and it includes a first layer 101 facing the back of the hand and a second layer 102 opposite to the first layer 101. The first layer 101 and the second layer 102 are in the The fronts are joined together to form a structure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com