Operation lever structure

一种操作杆、连杆的技术,应用在控制构件、直线运动轴、仪器等方向,能够解决辊轴难顺畅运动、危及操作杆操作性能等问题,达到提高操作性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

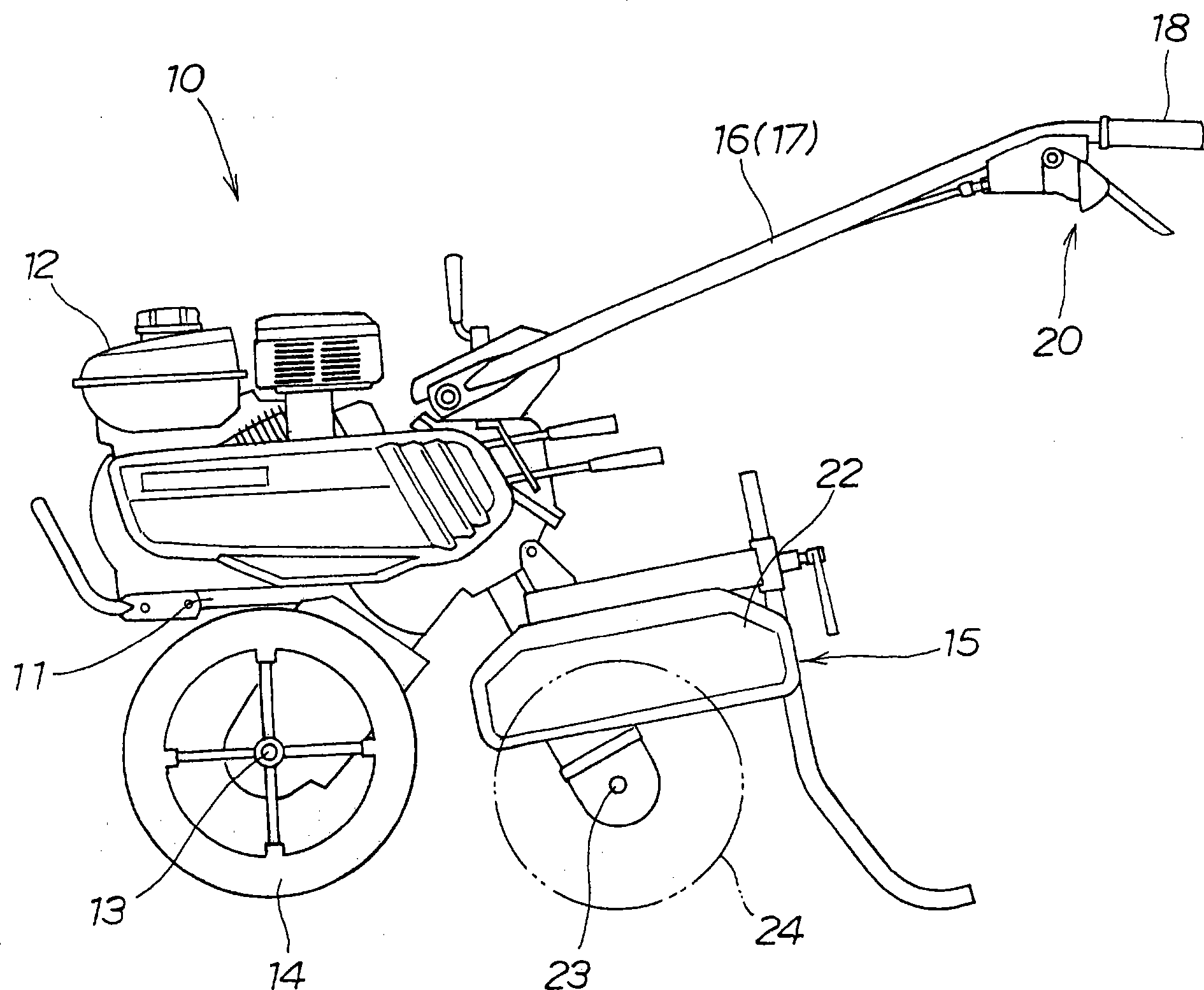

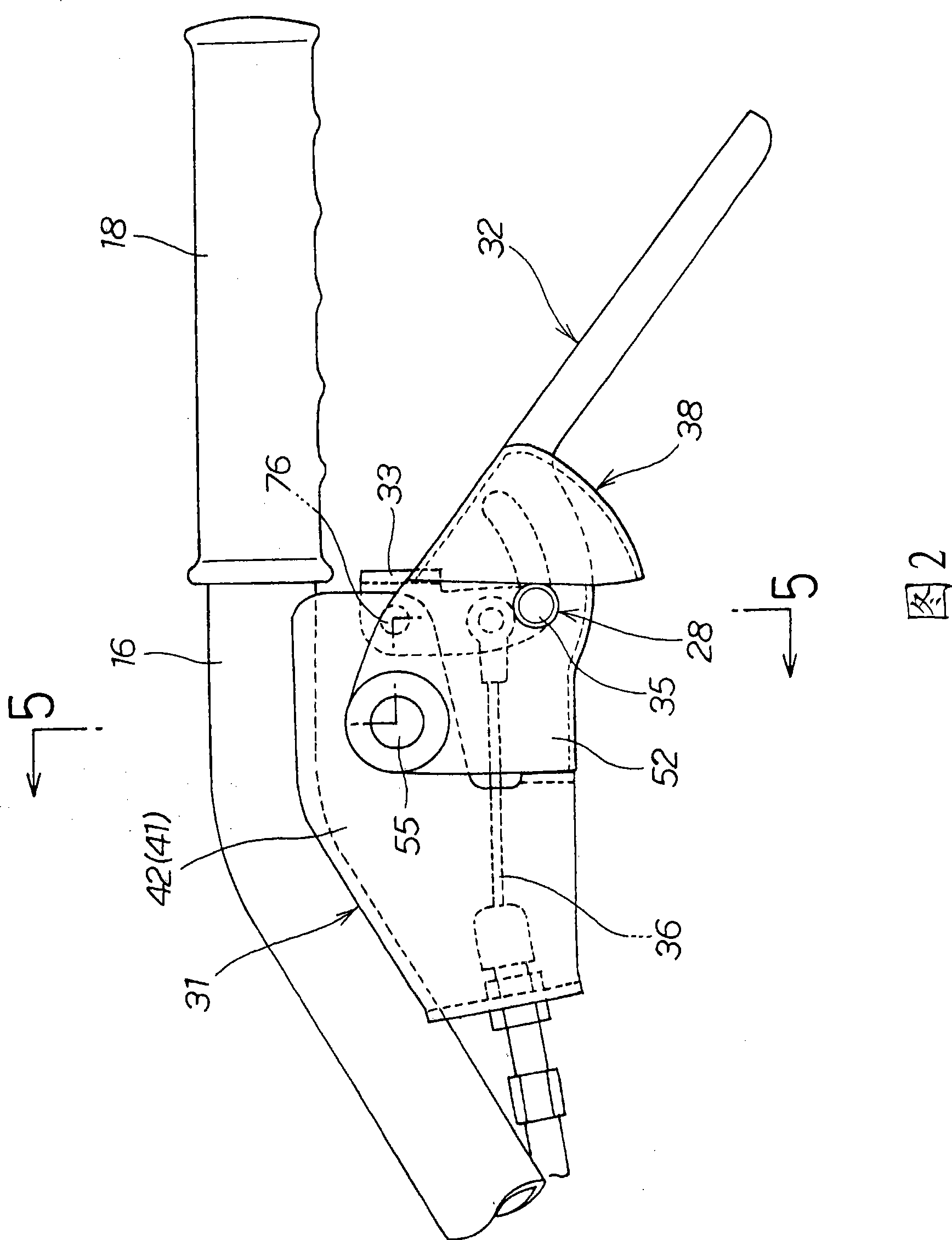

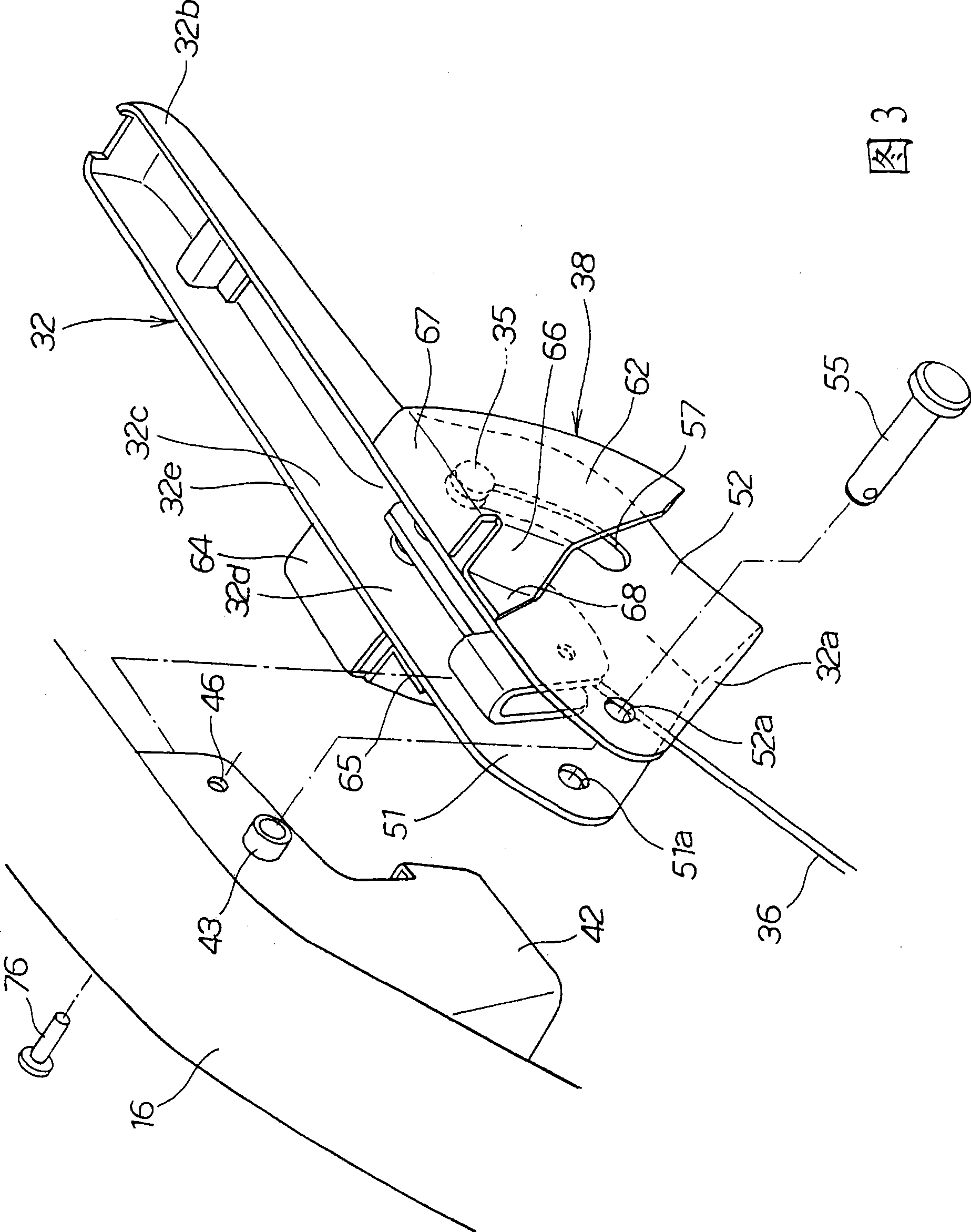

[0026] The following describes a walking-type power tillage machine as an embodiment of the working machine according to the present invention.

[0027] Such as figure 1 As shown, the walking work machine 10 includes: an engine 12, which is installed on the upper part of the machine body 11; left and right wheels 14, which are arranged on the lower end of the machine body 11 through an axle 13; and a tillage device 15 which is arranged on the machine body. 11; the left and right handles 16, 17, which are arranged at the rear of the machine body 11; and the operating lever structure 20, which is arranged near the left grip 18 of the left handle 16.

[0028] The farming device 15 includes: a farming cover 22 attached to the rear of the machine body 11 so as to be able to move up and down; a farming claw 24 provided on a rotating shaft 23 under the farming cover 22; and a power transmission part (not shown) ), which is used to transmit the rotation of the engine 12 to the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com