High-mobility low-odor scratch-resistant automobile trim polypropylene material and preparation method thereof

A technology for polypropylene materials and automotive interiors, applied in the field of polymer modification processing, can solve the problems of not meeting the installation requirements of interior parts, affecting the durability and beauty of interiors, harmful and irritating odors, etc., and achieving a simple manufacturing process , low cost, and the effect of reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

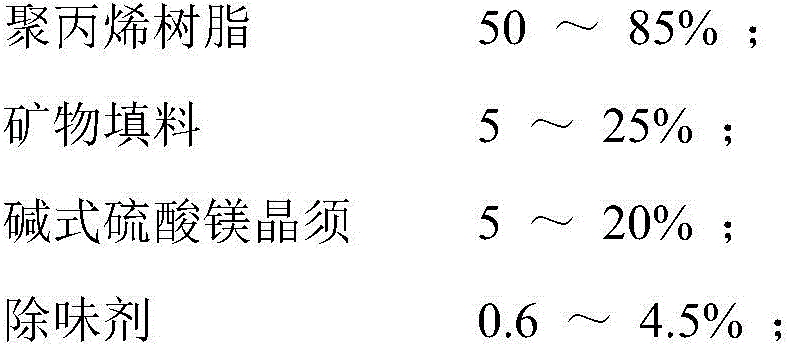

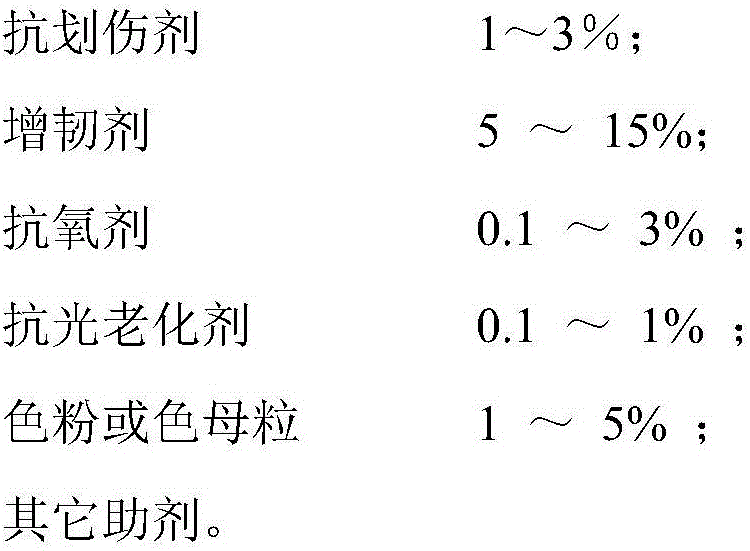

Method used

Image

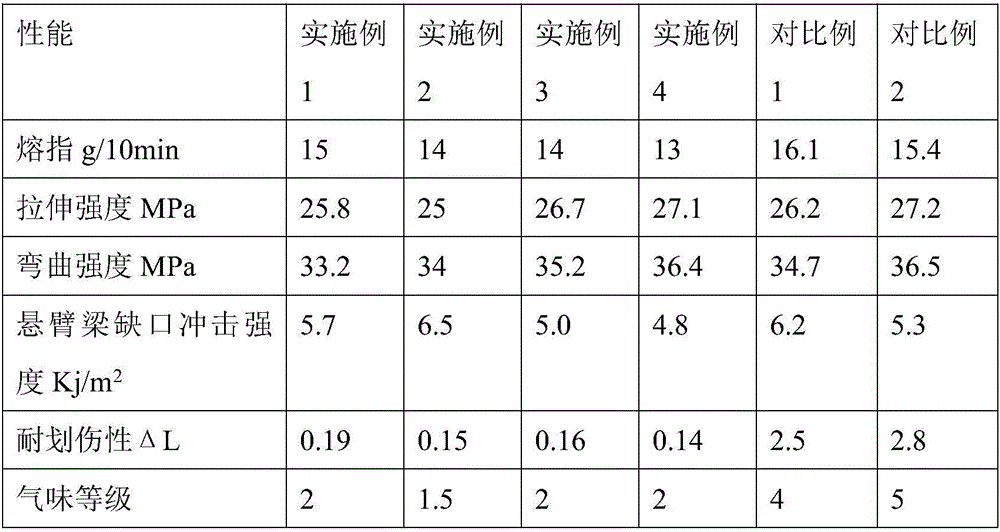

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment, the present invention is described in further detail:

[0030] In the composite material formulations of the examples and comparative examples, the polypropylene is the block copolymer polypropylene produced by Yangzi Petrochemical, whose trade name is M30-VH, or K9928 produced by Dushanzi Petrochemical. The mineral filler is 1500-mesh surface-active talcum powder with silicon content ≥ 58%. Described antioxidant is the mixture of main antioxidant and auxiliary antioxidant, specifically the phenolic antioxidant 1010 chemical name of Yabao Company is 3-(3,5 bis-tert-butyl-4-hydroxycyclohexyl) propane Ester, Yabao's phosphite antioxidant 168 is chemically named tris(2,4-di-tert-butylphenyl) phosphite, and the two are mixed at a weight ratio of 1:2. Described basic magnesium sulfate whisker is produced by Yingkou Visco Chemical Company, and its trade name is WS-1S2. The toughening agent is an ethylene-octene copolymer produced by Sab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com