Surface flame-retardant wood-plastic composite material plate and preparation thereof

A wood-plastic composite material and board technology, which is applied in the field of surface flame-retardant wood-plastic composite material board and its preparation, can solve the problems of reduction, low whisker content, insignificant improvement effect, etc., and achieves high mechanical strength and flame retardant performance. Good, rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

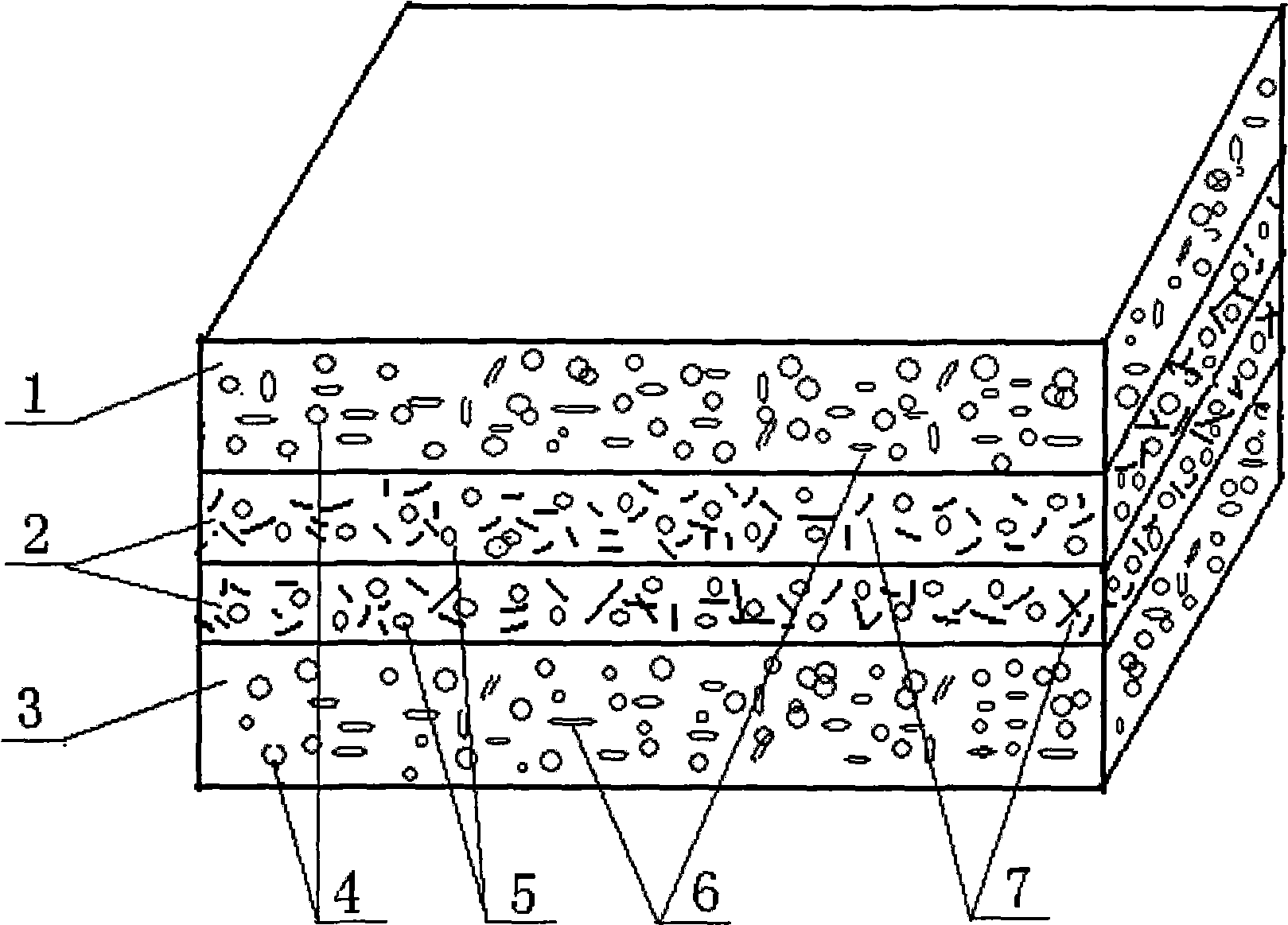

Image

Examples

Embodiment 1

[0027] Embodiment 1: A method for preparing a surface flame-retardant wood-plastic composite board, the preparation process of which is:

[0028] (1) Mix the silane coupling agent and water at a mass ratio of 1:1, weigh 1 g of the silane coupling agent and 1 g of water, and mix evenly, wherein water is the solvent; the silane coupling agent uses γ—(methacryloyl Oxy)propyltrimethoxysilane;

[0029] (2) The basic magnesium sulfate whiskers and the diluted silane coupling agent are in a mass ratio of 100:2, weigh 100g of basic magnesium sulfate whiskers and mix with the above-mentioned diluted silane coupling agent 2g, and mix them evenly at a temperature of 40°C. , vacuum-dried for 3 hours to make modified basic magnesium sulfate whiskers; the silane coupling agent adopts γ-(methacryloyloxy)propyltrimethoxysilane;

[0030] (3) Polyethylene plastic particles and modified basic magnesium sulfate whiskers are weighed in a mass ratio of 100:100, polyethylene plastic particles 100g,...

Embodiment 2

[0035] Embodiment 2: A method for preparing a surface flame-retardant wood-plastic composite board, the preparation process of which is:

[0036] (1) Mix the silane coupling agent and water at a mass ratio of 1:3, weigh 1 g of the silane coupling agent and 3 g of water, and mix evenly, wherein water is the solvent; the silane coupling agent uses γ—(methacryloyl Oxy)propyltrimethoxysilane;

[0037] (2) The basic magnesium sulfate whisker and the diluted silane coupling agent are in a mass ratio of 100:4, weigh 100g of the basic magnesium sulfate whisker and mix it with the above-mentioned diluted silane coupling agent 4g. , vacuum-dried for 4.5 hours to make modified basic magnesium sulfate whiskers; the silane coupling agent adopts γ-(methacryloyloxy)propyltrimethoxysilane;

[0038](3) The polystyrene plastic particles and the modified magnesium basic sulfate whiskers are weighed in a mass ratio of 100:110, and 100 g of the polystyrene plastic particles and 110 g of the modif...

Embodiment 3

[0043] Embodiment 3: A method for preparing a surface flame-retardant wood-plastic composite board, the preparation process of which is:

[0044] (1) Mix the silane coupling agent and water at a mass ratio of 1:5, weigh 1 g of the silane coupling agent and 5 g of water, and mix evenly, wherein water is the solvent; the silane coupling agent uses γ—(methacryloyl Oxy)propyltrimethoxysilane;

[0045] (2) The basic magnesium sulfate whisker and the diluted silane coupling agent are in a mass ratio of 100:6, weigh 100g of the basic magnesium sulfate whisker and mix it with the above-mentioned diluted silane coupling agent 6g. , vacuum-dried for 6 hours to make modified basic magnesium sulfate whiskers; the silane coupling agent adopts γ-(methacryloyloxy)propyltrimethoxysilane;

[0046] (3) Polypropylene plastic particles and modified basic magnesium sulfate whiskers are weighed in a mass ratio of 100:120, polypropylene plastic particles 100g, modified basic magnesium sulfate whisk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com