Whisker modified polypropylene (PP) composite material and preparation method thereof

A composite material and polypropylene technology, applied in the polymer field, can solve the problems of warping and deformation of parts, restricting the wide application of whisker-modified polypropylene materials, and having a large difference in shrinkage rate, so as to avoid warping and deformation, and achieve good results. Rigidity and toughness, the effect of meeting dimensional assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with specific examples.

[0030] The models of nucleating agents in Examples 1-5 are Milliken Company HPN-20E, HPN-04E, HPN-68L. The antioxidant is selected from antioxidant 1076, antioxidant 168 or antioxidant 3114; the light stabilizer is selected from light stabilizer UV-3808 or light stabilizer UV-703; the ultraviolet absorber is ultraviolet absorber UV-2908.

[0031] In the embodiment, the twin-screw extruder is selected to be provided with two vacuuming places, one of which is located between the conveying section and the melting section, and the other is located in the metering section. The screw aspect ratio of the twin-screw extruder is 40-50:1, the screw speed is 200-500r / min, and the temperature of the twin-screw extruder is 190-230°C.

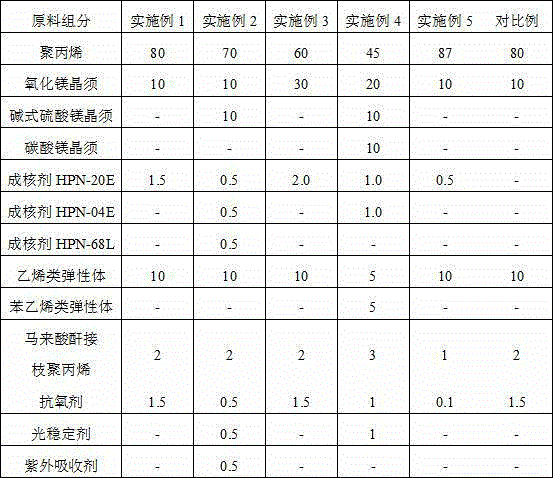

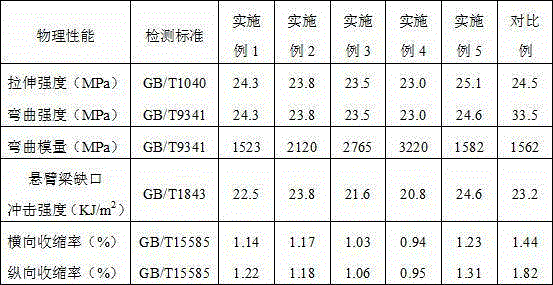

[0032] According to the whisker-modified polypropylene composite material in each embodiment in the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com