Low-density and high-rigidity polypropylene composite material and preparation method of low-density and high-rigidity polypropylene composite material

A technology of composite materials and polypropylene, applied in the field of polymers, can solve the problems that cannot meet the requirements of parts, actual design, and the requirements of lightweight automotive materials, etc., and achieve the effect of improving rigidity, good rigidity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

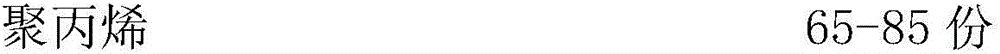

Method used

Image

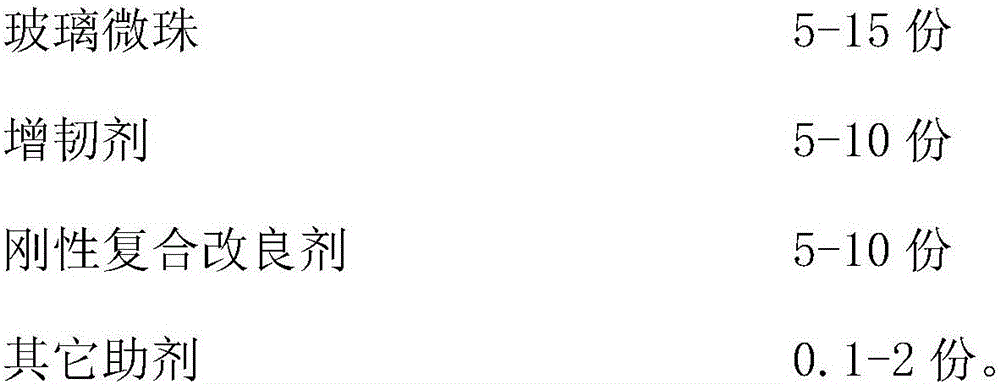

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments.

[0025] The glass beads in Examples 1-5 are IM16K hollow glass beads resistant to shearing and breaking produced by 3M Company; the rigid composite improver is purchased from a domestic trader, and the original supply is Toray Corporation of Japan; the toughening agent is selected from ethylene- Butene polymer, ethylene-octene polymer, ethylene-propylene polymer, or a mixture of two or more; other additives include antioxidants, light stabilizers, scratch-resistant agents, antistatic agents or coloring agent.

[0026] The twin-screw extruder used in the embodiment of the present invention has two vacuum locations, one of which is located at the end of the conveying section and the beginning of the melting section; the other is located at the metering section. The screw aspect ratio of the twin-screw extruder is 40-50:1, the screw speed is 200-500r / min, and the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com