Low-density super-matte bionic polypropylene composite and preparation method thereof

A technology of ultra-matt bionic and composite materials, which is applied in the field of low-density ultra-matt bionic polypropylene composite materials and its preparation, can solve the problems of strong plastic feeling and harsh touch, achieve good rigidity and toughness, and improve rigidity , the effect of meeting the size and assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

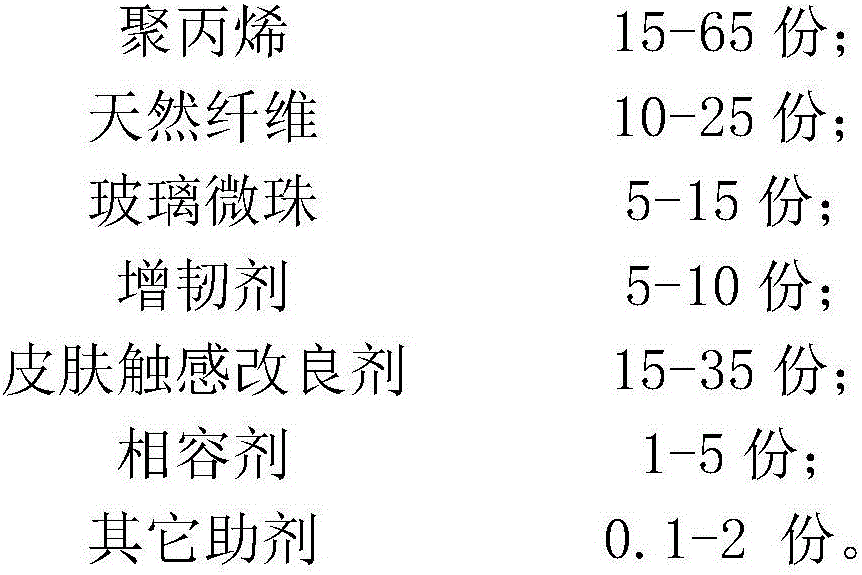

Method used

Image

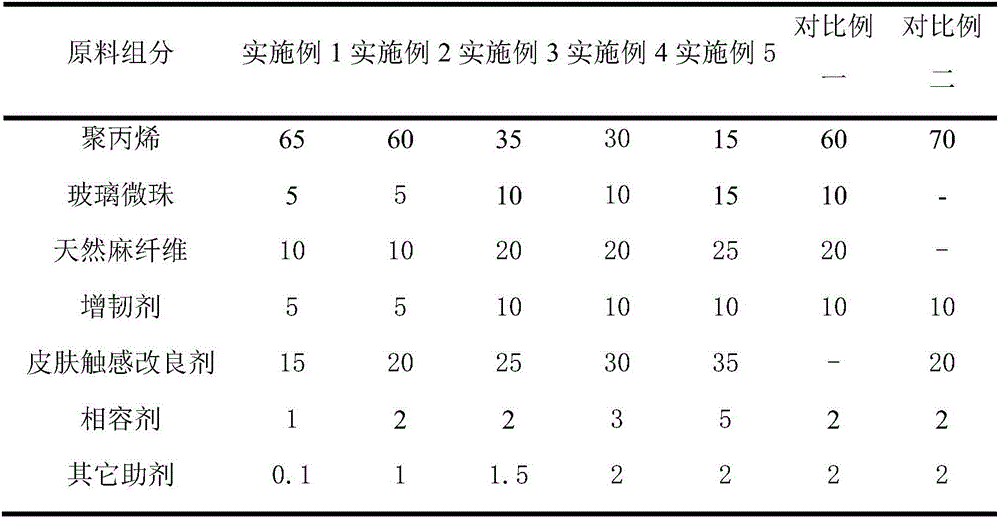

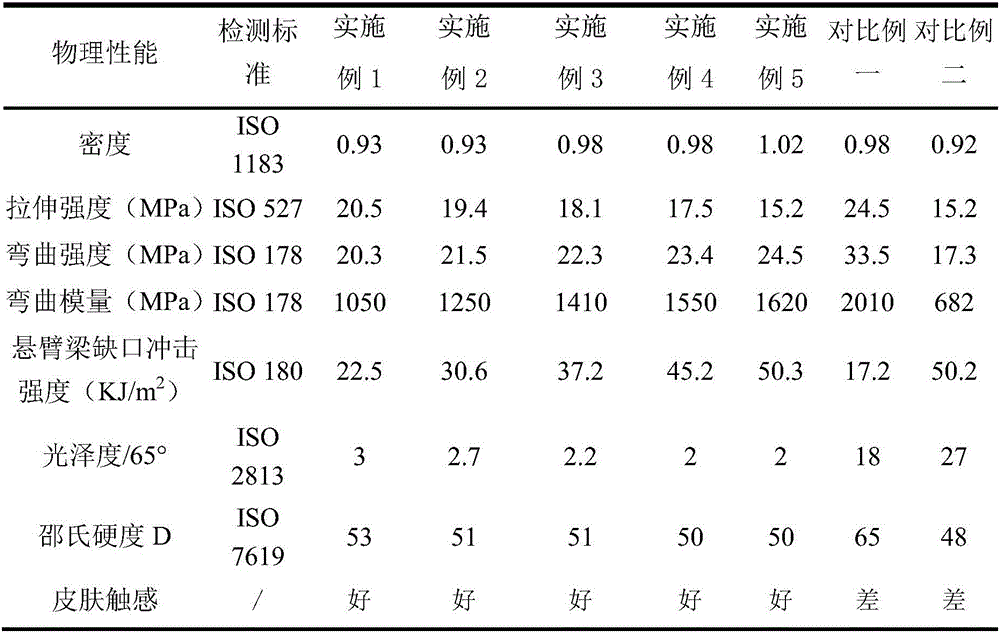

Examples

preparation example Construction

[0034] Concrete preparation method comprises the following steps:

[0035] (1) Weigh the raw materials according to the parts by weight of the prepared raw materials, add polypropylene, toughening agent, and skin touch modifier to the mixer, mix at 800-1500r / min for 3-15 minutes, and then add Compatibilizer and other additives, continue mixing at 800-1500r / min for 3-15 minutes;

[0036] (2) Add the material fully mixed in the step (1) into a twin-screw extruder for melting, add natural fibers and hollow glass microspheres at the side feeding port of the extruder, melt and mix under the protection of nitrogen, and finally pass through the double-screw extruder Extruded by a screw extruder, granulated and shaped to produce a low-density ultra-matt biomimetic polypropylene composite material.

[0037] If functional auxiliary agents such as scratch-resistant agents, antistatic agents, and colorants are added to the preparation components of the present invention to make the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com