Backlight modular

A backlight module and back frame technology, applied in optics, nonlinear optics, instruments, etc., can solve problems affecting the brightness and uniformity of the backlight module, warping and deformation of reflectors, etc., to achieve the goal of improving brightness and uniformity and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above and other objects, features, and advantages of the present invention more clearly understood, a preferred embodiment is specifically cited below, and in conjunction with the accompanying drawings, the detailed description is as follows:

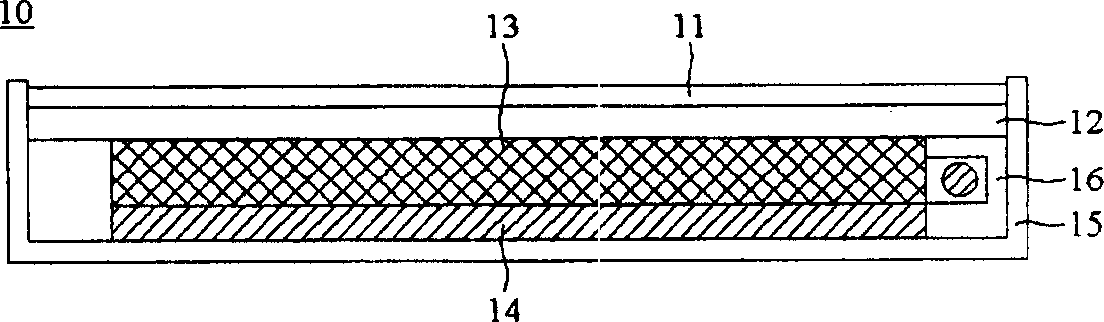

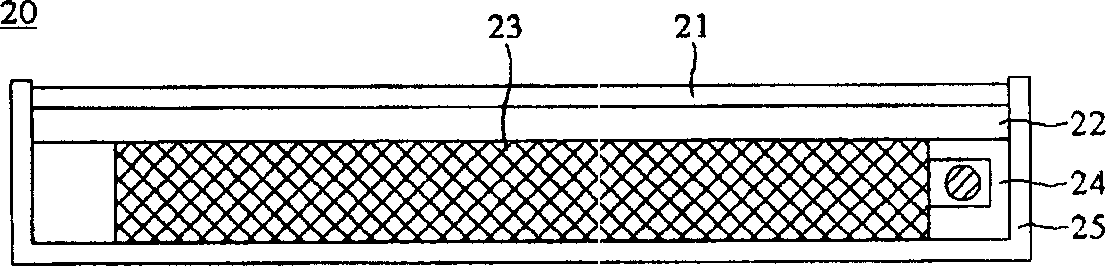

[0026] figure 2 It is a side view of a backlight module 20 in a preferred embodiment of the present invention. The backlight module 20 of the present invention includes a front frame 21, a set of optical films 22, a light guide plate 23, at least one lamp assembly 24 and a reflective The metal back frame 25 of inner surface. Wherein, the optical film 22 is disposed on the light guide plate 23 , and the optical film 22 and the light guide plate 23 are sequentially disposed in the metal back frame 25 . In addition, the lamp assembly 24 is located beside the light guide plate 23 . The appearance of the metal back frame 25 is similar to a box without a cover.

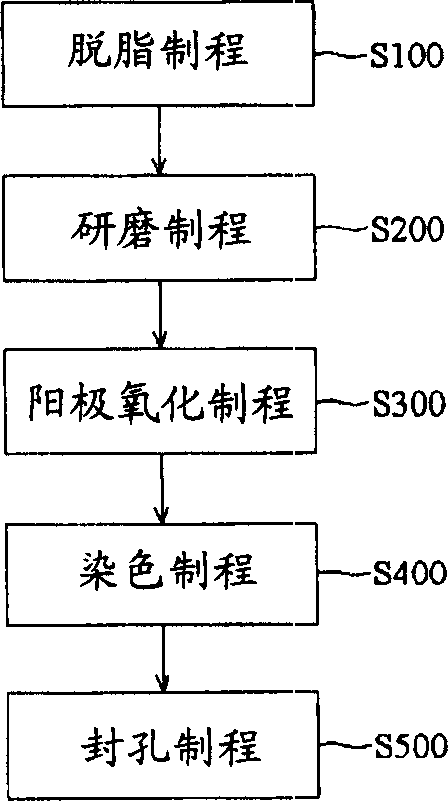

[0027] The manufacturing method of the metal bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com