New method of rapid synthesis of basic bitter salt

A magnesium sulfate whisker and basic technology, which is applied in the field of inorganic chemical material preparation, can solve problems such as limiting the large-scale industrial application of basic magnesium sulfate whiskers, and achieves improving the hydrothermal reaction rate, reducing process energy consumption and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

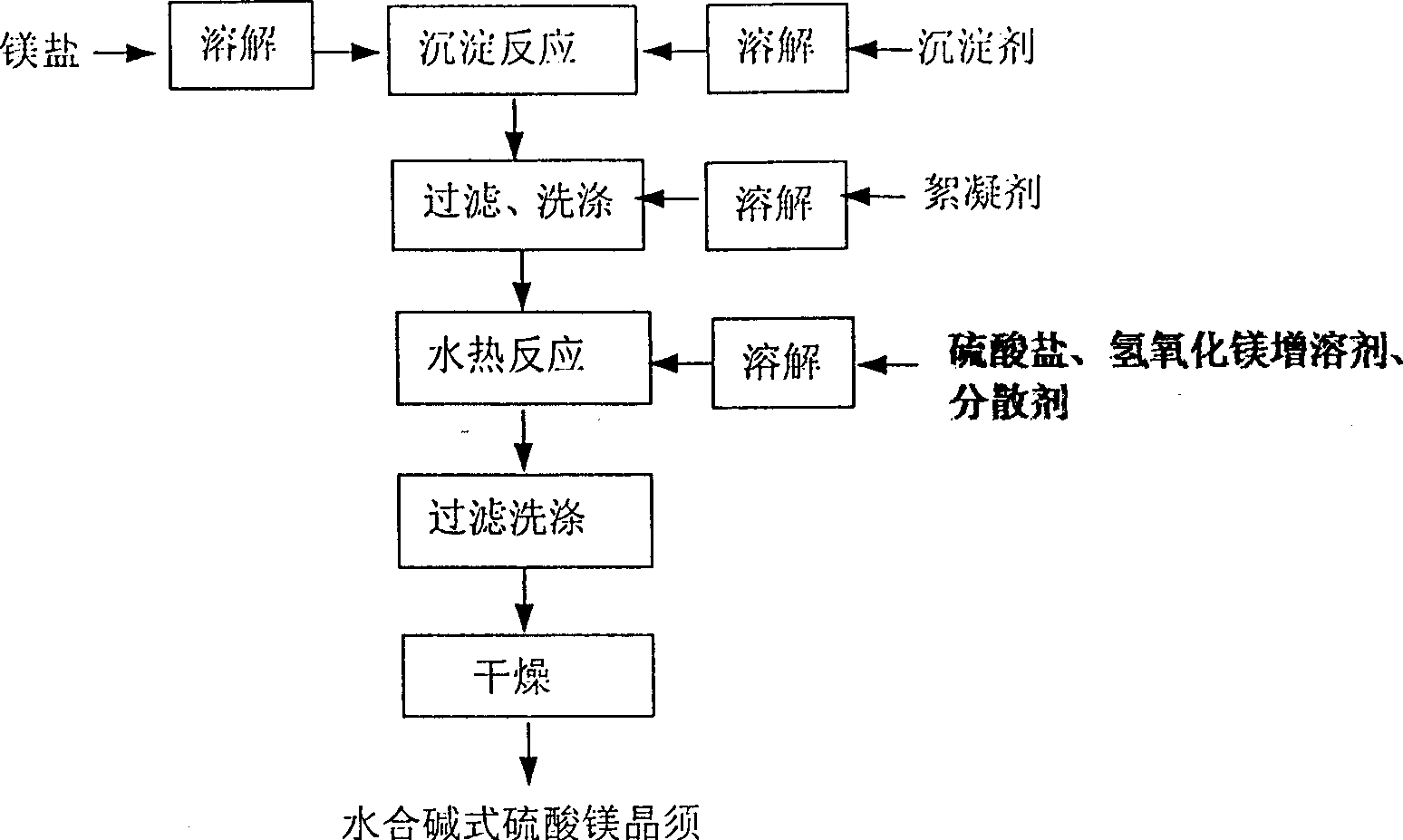

[0026] The present invention is a kind of preparation method of hydrated basic magnesium sulfate whisker, take the inorganic water-soluble magnesium salt (magnesium chloride, magnesium sulfate) from the high-magnesium brine by-product of sea and lake salt chemical industry as main raw material, in precipitating agent (hydrogen Sodium oxide, potassium hydroxide, ammonium hydroxide) and stirring state (200-700rpm) at 25-90 ° C for precipitation reaction to generate a highly dispersed nano-magnesium hydroxide precursor suspension with an average particle size of 10-100 nanometers; Add a small amount of flocculant (polyacrylamide, starch, polyaluminum sulfate) to the above suspension to improve the solid-liquid separation effect, and resuspend the obtained solid in a solution containing sulfate (sodium sulfate, potassium sulfate, ammonium sulfate, Magnesium sulfate), magnesium hydroxide solubilizer (sulfuric acid, nitric acid, ethylenediaminetetraacetic acid, oxalic acid) and dispe...

Embodiment 1

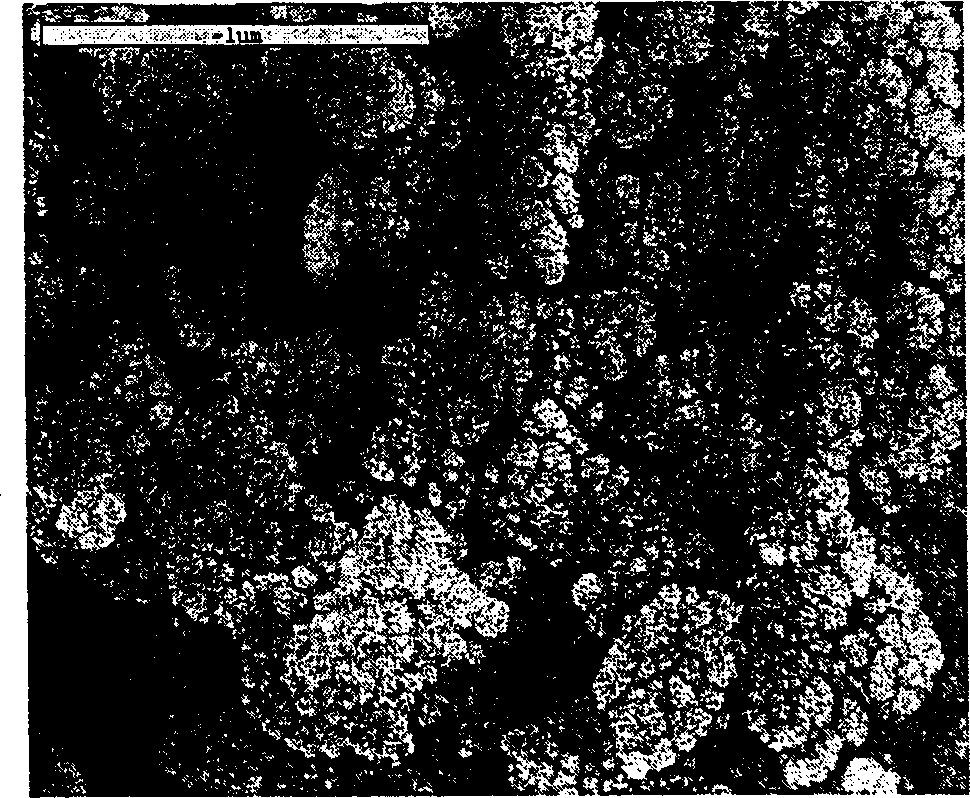

[0035] Prepare 30% (w / v) magnesium chloride solution 100ml, 20% (w / v) potassium hydroxide solution 100ml, 0.1% (w / v) polyacrylamide solution 5ml, hydrothermal reaction solution (containing 30% sodium sulfate, 20% sulfuric acid and 10% sodium hexametaphosphate) 100ml. The magnesium chloride solution was added to the potassium hydroxide solution at 25° C. under stirring (800 rpm), and the magnesium chloride addition rate was 30 ml / min. After the feeding was completed, a magnesium hydroxide precursor suspension with an average particle diameter of 10 nanometers was prepared. The polyacrylamide solution was added into the obtained suspension, stirred for 10 minutes, and then allowed to settle for 30 minutes. Cool the resulting suspension, filter it, wash it with deionized water for 3 times, put it into the hydrothermal reaction solution, stir (300rpm) and disperse it for 30 minutes, then place it in a high-pressure hydrothermal reaction kettle, and set it in a stirring state (700...

Embodiment 2

[0037] Prepare 10% (w / v) magnesium sulfate solution 100ml, 5% (w / v) sodium hydroxide solution 100ml, 1% (w / v) starch solution 5ml, hydrothermal reaction solution (containing 10% potassium sulfate, 5 % nitric acid and 1% sodium hexametaphosphate) 100ml. The magnesium sulfate solution was added to the sodium hydroxide solution at 40° C. under stirring (500 rpm), and the magnesium sulfate addition rate was 15 ml / min. After the feeding is completed, a highly dispersed magnesium hydroxide precursor suspension with an average particle diameter of 60 nanometers is obtained. The starch solution was added into the resulting suspension, stirred for 10 minutes and then left to settle for 30 minutes. Cool the resulting suspension, filter it, wash it with deionized water for 3 times, put it into the hydrothermal reaction solution, stir (300rpm) and disperse it for 30 minutes, then place it in a high-pressure reactor, and conduct hydrothermal treatment at 200°C under stirring (200rpm) 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com