Preparation of high length-diameter ratio magnesium hydroxide sulfate hydrate whisker

A magnesium sulfate whisker, high aspect ratio technology, applied in magnesium sulfate, chemical instruments and methods, single crystal growth and other directions, can solve the problems of complex process, uneven product morphology, limited technical industrial application, etc., and achieve cost The effect of low cost, high added value of products, and easy industrial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

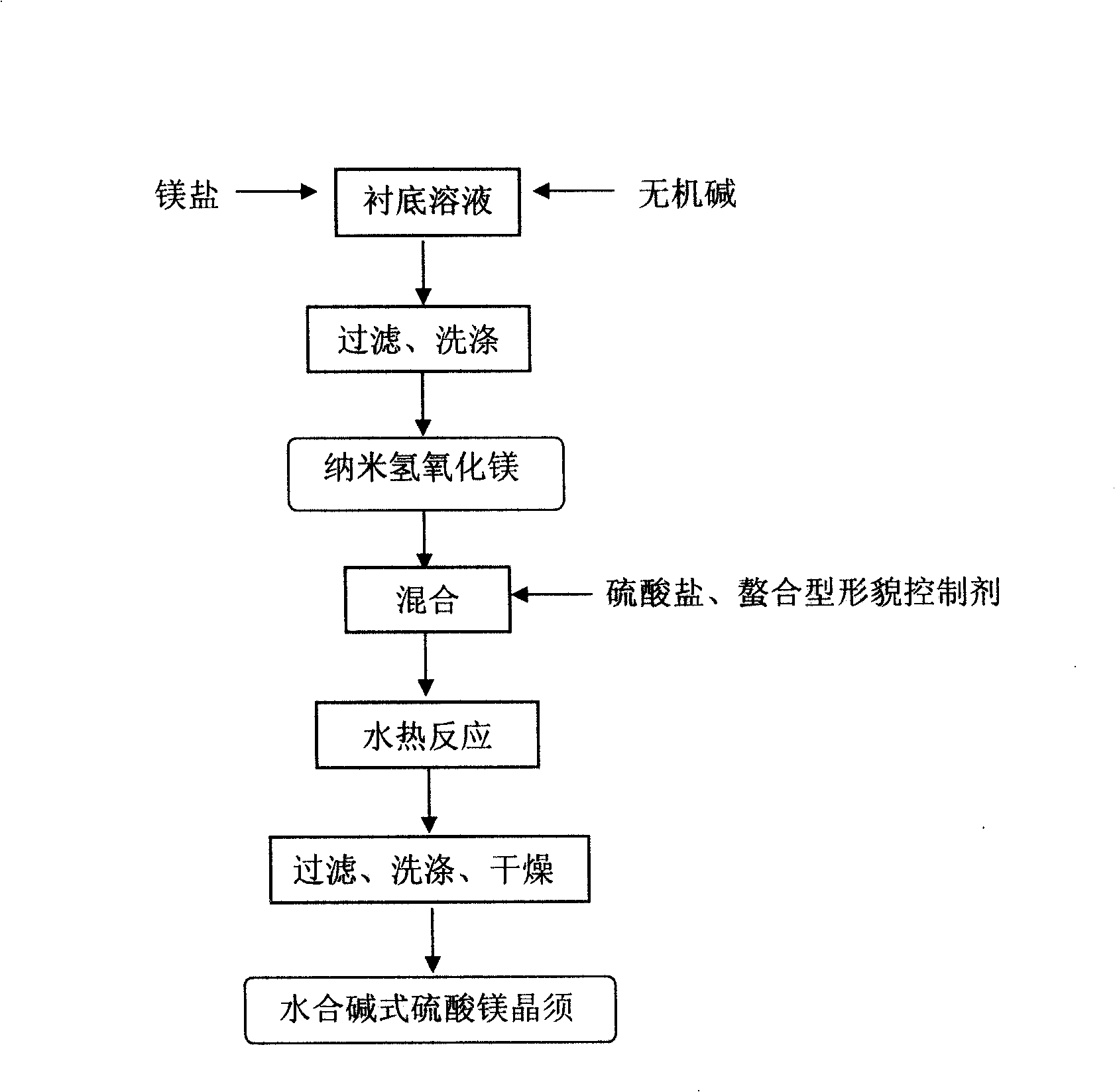

Method used

Image

Examples

Embodiment 1

[0025] Prepare 40 ml of 5 mol / L magnesium sulfate solution and 40 ml of 5 mol / L sodium hydroxide solution, inject the above solutions into 80 ml of deionized water at a speed of 1 ml / min at 10°C and 500 rpm stirring conditions , continue to react for 0.5 hours after the feeding is completed, and obtain a white milky slurry; after filtering and washing the above slurry, add it to a hydrothermal reactor containing 0.5 mol / liter of sodium sulfate and 0.005 mol / liter of sodium citrate to make a solid content rate of 25% (w / v) suspension, stir and disperse, then stir at 100°C at 500 rpm for 2 hours, then cool, filter, wash, and dry to obtain an average length of 50 μm, an average diameter of 0.25 μm, and an aspect ratio 200. Hydrated basic magnesium sulfate whiskers with a main content of 98%.

Embodiment 2

[0027] Prepare 40 milliliters of 0.5 mol / liter magnesium chloride solution, 40 milliliters of 0.5 mol / liter potassium hydroxide solution, and inject the above solution into 200 milliliters of 1 mol / liter at a speed of 10 milliliters / minute at 90°C and 50 rpm stirring conditions Potassium sulfate solution, continue to react for 2 hours after the feeding is completed, and obtain a white milky slurry; filter and wash the above slurry and add it to a hydrothermal reactor containing 5 mol / L potassium sulfate and 0.0001 mol / L potassium tartrate to make a solid containing A suspension with a rate of 1% (w / v), stirred and dispersed, then stirred at a constant temperature of 50 rpm at 250°C for 20 hours, then cooled, filtered, washed, and dried to obtain an average length of 500 μm, an average diameter of 1 μm, and a long diameter Hydrated basic magnesium sulfate whiskers with a ratio of 500 and a main content of 99.5%.

Embodiment 3

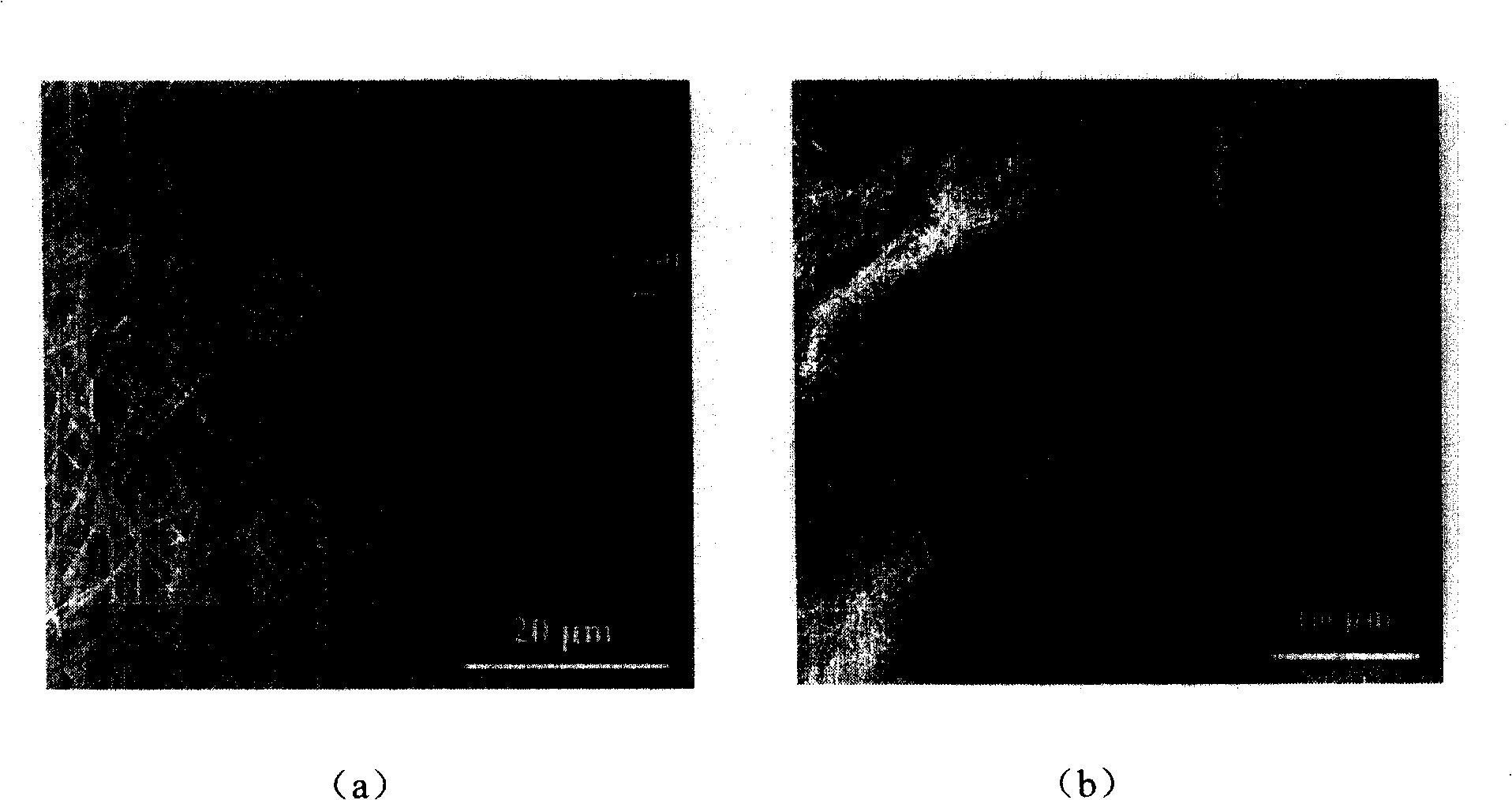

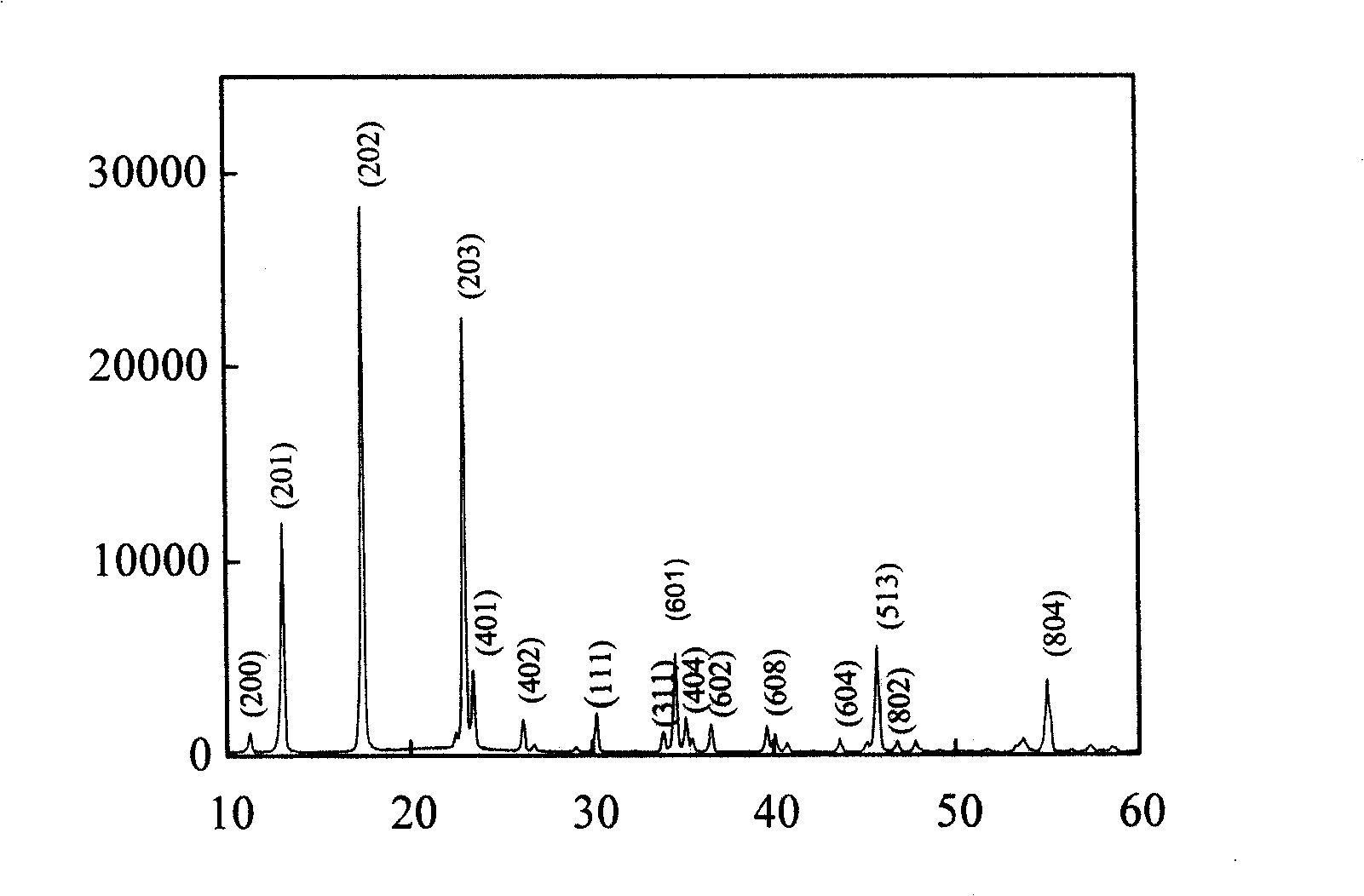

[0029] Prepare 40 milliliters of 1 mol / liter magnesium sulfate solution, 40 milliliters of 5 mol / liter ammonia solution, and inject the above solution into 400 milliliters of 0.5 mol / liter chlorine at a speed of 5 milliliters / minute at 25°C and 200 rev / min stirring conditions. Potassium chloride solution, continue to react for 1 hour after the feeding is completed, and obtain a white milky slurry; add the above-mentioned slurry to a hydrothermal reactor containing 2 mol / liter of magnesium sulfate and 0.0004 mol / liter of ethylenediammonium tetraacetic acid after filtering and washing. Form a suspension with a solid content rate of 15% (w / v), stir and disperse, then stir at 180°C at a constant temperature of 100 rpm for 6 hours, then cool, filter, wash, and dry to obtain an average length of 160 μm and an average diameter of 0.08 Hydrated basic magnesium sulfate whiskers with μm, aspect ratio of 2000, and main content of 98.5%. figure 1 are the topography images of hydrothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com