Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polymers, can solve the problems of affecting product assembly and appearance, high shrinkage of high-crystalline PP, lack of oil-resistant properties, etc., to increase self-cleaning ability, improve oil resistance, The effect of good surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

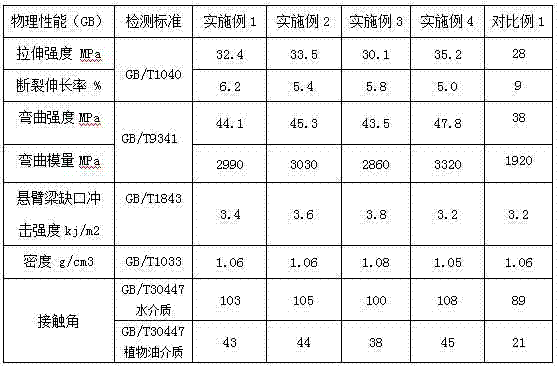

Examples

Embodiment 1

[0040] 75 parts of random copolymerized polypropylene resin

[0041] Barium sulfate 10 parts

[0042] Magnesium Sulfate Whiskers 10 parts

[0043] Fluoride perfluoropolyether oil 0.5 parts

[0044] Antioxidant 1010 0.2 parts

[0045] Nucleating agent NA-11 0.15 parts

[0046] Nucleating agent WBG-Ⅱ 0.15 parts

[0047] Lubricant calcium stearate 0.5 parts

[0048] Surface brightener TAF 0.8 parts

[0049] The specific preparation method is as follows:

[0050] (1) Adding barium sulfate, antioxidant and lubricant together is that temperature is 65 ℃ and is led in the mixer that has nitrogen protection and mixes for 5 minutes;

[0051] (2) Add polypropylene, magnesium sulfate whiskers, fluoride, nucleating agent and other additives, and continue mixing for 5 minutes;

[0052](3) Under the protection of nitrogen, put the mixed material in step (2) into a parallel twin-screw extruder to melt, extrude and granulate to obtain an anti-oil pollution reinforced high-gloss polypr...

Embodiment 2

[0054] Random copolymerization polypropylene resin 50 parts

[0055] Homopolypropylene 30 parts

[0056] Barium sulfate 10 parts

[0057] Magnesium Sulfate Whiskers 10 parts

[0058] Fluoride polytetrafluoroethylene 0.5 parts

[0059] Antioxidant 168 0.2 parts

[0060] Nucleating agent NA-11 0.1 parts

[0061] Lubricant zinc stearate 0.5 part

[0062] Lubricant PE wax 0.5 parts

[0063] The specific preparation method is as follows:

[0064] (1) adding barium sulfate, antioxidant and lubricant together into a mixer with a temperature of 65-75° C. and passing through nitrogen protection to mix for 10 minutes;

[0065] (2) Add polypropylene, magnesium sulfate whiskers, fluoride, nucleating agent and other additives, and continue mixing for 2 minutes;

[0066] (3) Under the protection of nitrogen, put the mixed material in step (2) into a parallel twin-screw extruder to melt, extrude and granulate to obtain an anti-oil pollution reinforced high-gloss polypropylene composi...

Embodiment 3

[0068] Random copolymerization polypropylene resin 78 parts

[0069] Barium sulfate 14 parts

[0070] Magnesium Sulfate Whiskers 6 parts

[0071] Fluoride perfluoropolyether oil 0.2 parts

[0072] Antioxidant 1010 0.2 parts

[0073] Antioxidant 168 0.2 parts

[0074] Nucleating agent NA-11 0.2 parts

[0075] Nucleating agent WBG-Ⅱ 0.1 parts

[0076] Lubricant PE wax 0.8 parts

[0077] Surface brightener TAF 1 part

[0078] The specific preparation method is as follows:

[0079] (1) adding barium sulfate, antioxidant and lubricant together into a mixer with a temperature of 65-75°C and nitrogen protection and mixing for 8 minutes;

[0080] (2) Add polypropylene, magnesium sulfate whiskers, fluoride, nucleating agent and other additives, and continue mixing for 3 minutes;

[0081] (3) Under the protection of nitrogen, put the mixed material in step (2) into a parallel twin-screw extruder to melt, extrude and granulate to obtain an anti-oil pollution reinforced high-glos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com