Semi-conductive rubber part

A rubber part and semi-conductive technology, which is applied in the field of semi-conductive rubber parts, can solve the problems of easy condensation of toner, difficulty in electrification, and spheroidization of toner, so as to maintain the uniformity of electrical characteristics, suppress cracking, and prevent cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

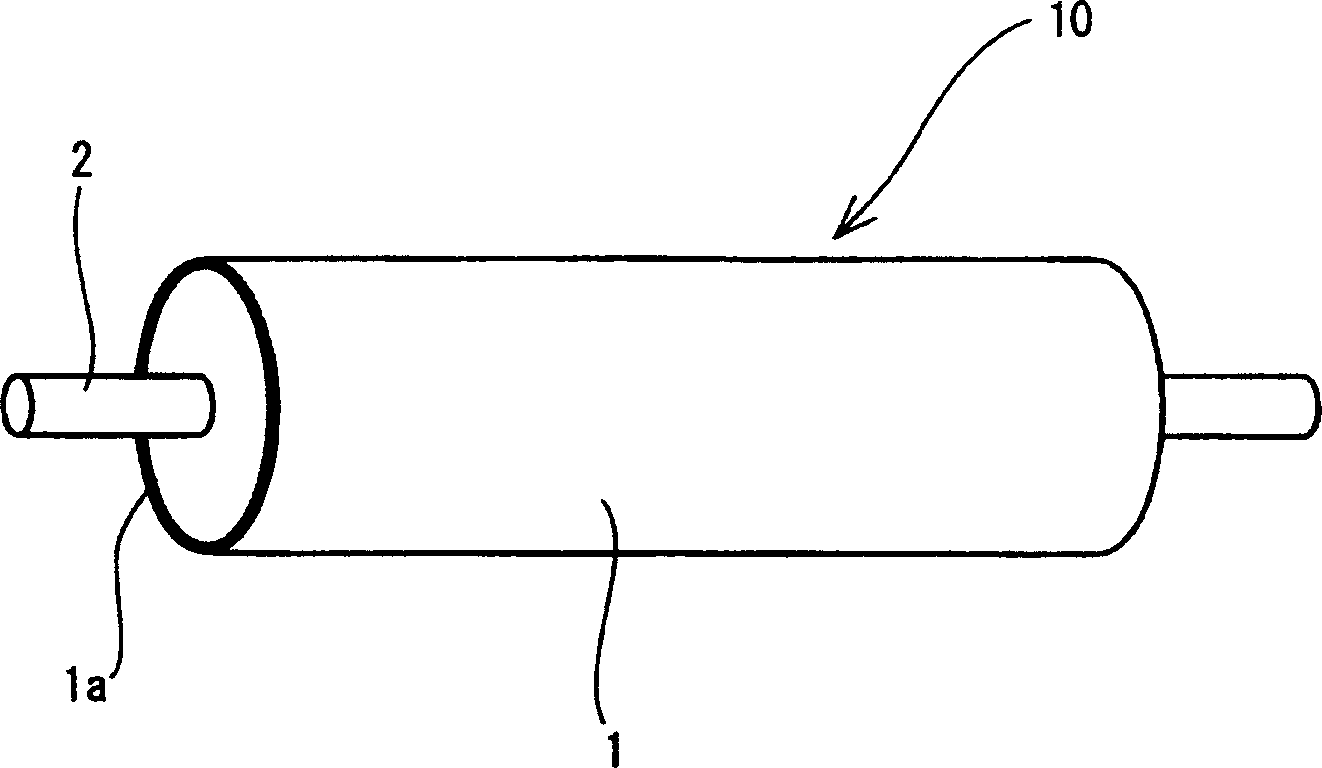

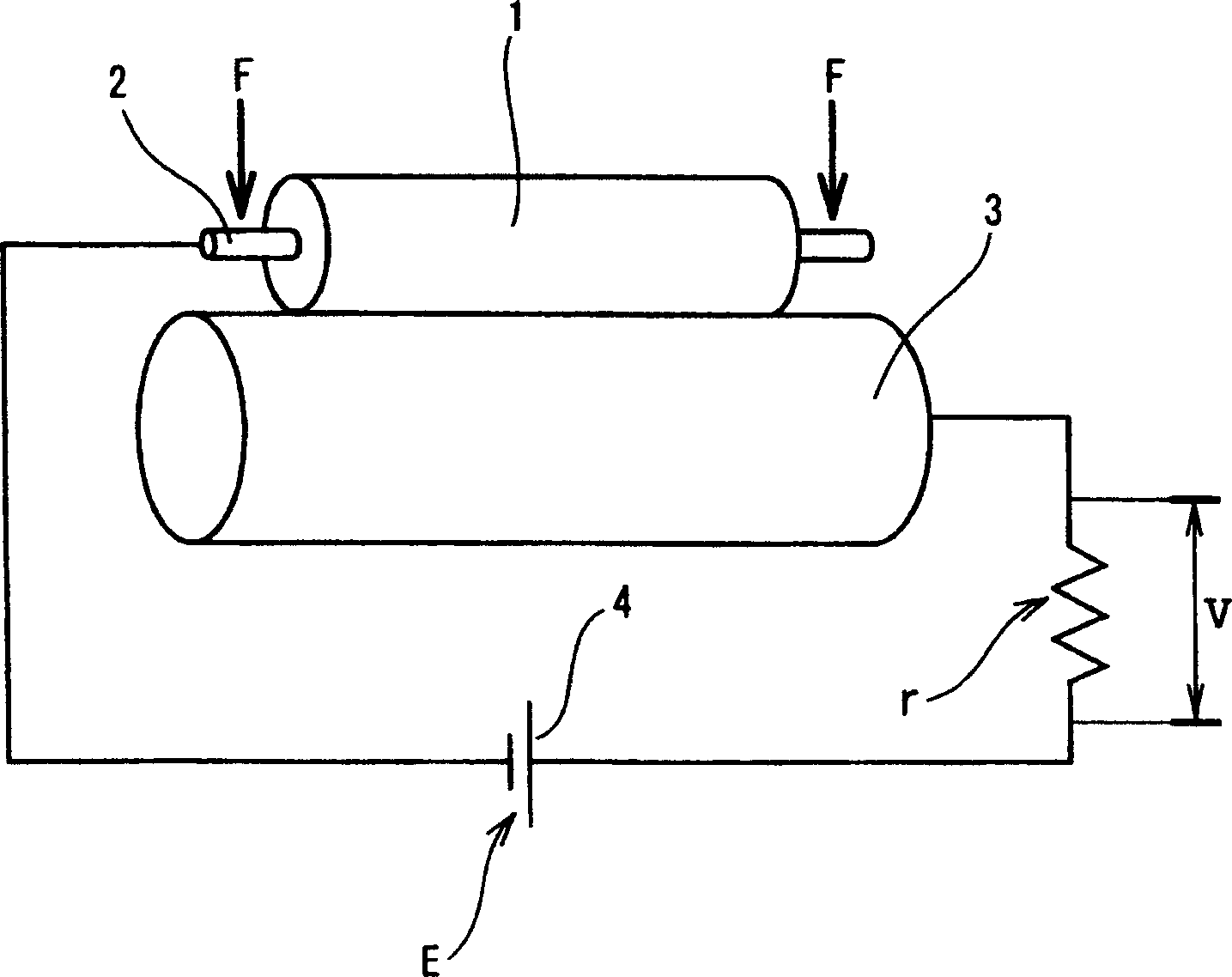

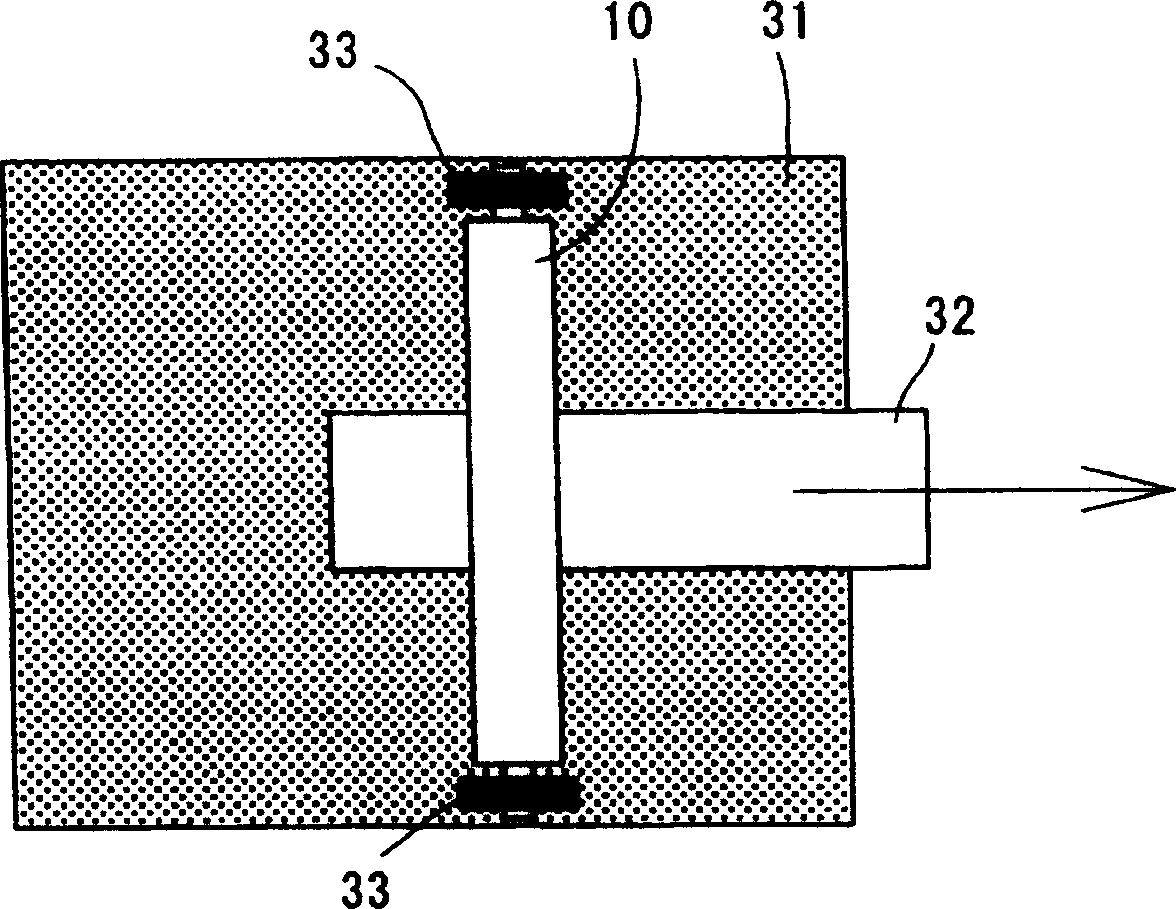

[0178] The rollers of Examples 1-6 and the rollers of Comparative Examples 1-3 composed of the semiconductive rubber member of the present invention were produced, and their characteristics were measured.

[0179] After kneading the additives listed in Tables 1 and 2 below with a Banbury mixer, they were extruded with an extruder and processed into a tubular shape with an outer diameter of φ18 mm and an inner diameter of φ9.5 mm. This tube was mounted on a shaft for vulcanization, vulcanized in a vulcanization tank at 160°C for 1 hour, then mounted on a shaft of φ10 mm coated with a conductive adhesive, and bonded in a furnace at 160°C. Then, the end was shaped, laterally ground with a cylinder grinder, and mirror-polished as finish grinding, and ground to a predetermined surface roughness at φ16 mm (tolerance 0.05).

[0180] After washing the surface of the roller with water, except for Comparative Example 2, it was irradiated with ultraviolet rays to form an oxide layer on t...

Embodiment 7 and comparative example 4

[0231] Use the added materials shown in Table 3 to make a rubber sheet with a thickness of 3mm from an unvulcanized rubber roller, wind it on the vulcanization shaft in the die, pressurize and vulcanize it into a tubular shape with an outer diameter of φ18mm and an inner diameter of φ12.5mm, and then install it on the The φ14mm shaft coated with the conductive adhesive was bonded in a furnace at 160°C. Then, shape the end, use a cylindrical grinder for transverse grinding, and use mirror grinding as fine grinding, and grind to a specified surface roughness with φ16mm (tolerance 0.05).

[0232] In Example 7 and Comparative Example 4, the same materials as in Examples 1-6 and Comparative Examples 1-3 were used. However, "シススト3" produced by Tokai Carbon Co., Ltd. was used as the conductive carbon black.

[0233] With respect to the thus-produced semiconductive rubber rollers of Example 7 and Comparative Example 4, the roller resistance when 500 V was applied was measured, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com