Method for recycling chloride ions in wastewater

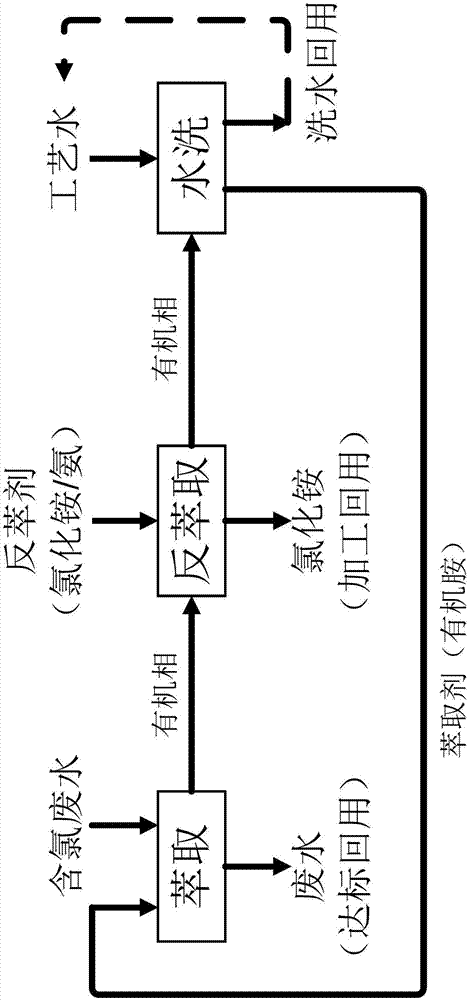

A chlorine ion and wastewater technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of difficult application of desulfurization system, immature recovery and utilization technology of small amount of ozone chlorine gas, etc., and achieve expansion Application fields, promotion of efficient utilization, and effect of reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

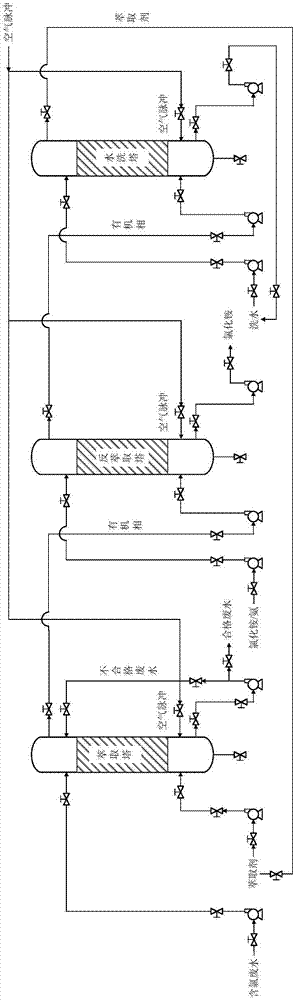

Embodiment 1

[0035] Chlorine-containing wastewater was selected from the desulfurization wastewater of a thermal power plant in Guizhou. After pretreatment, the ion-containing chloride ion content was 23606 mg / kg. The extraction-reextraction system sets the pulse frequency of the pulse sieve plate column to 3Hz, and the pulse amplitude to 5mm. During the extraction process, triethanolamine is used as the extraction agent, the volume ratio of the organic phase to the aqueous phase is 1.1:1, and sulfonated kerosene (not the scientific name, sulfonated kerosene is also It is called No. 260 solvent oil and No. 260 special kerosene-type solvent oil, which are usually sulfonated kerosene and are the most commonly used diluent in the extraction process. Solvent oil is determined according to its 98% distillation temperature or dry point (100% distillation temperature ) to classify, the distillation range of No. 260 solvent oil is 195~260°C.) as the diluent, the volume ratio of sulfonated kerosene ...

Embodiment 2

[0037] Chlorine-containing wastewater was selected from a high-alumina fly ash industrial demonstration base in Inner Mongolia that produced high-concentration chlorine-containing wastewater during the production of white carbon black by hydrochloric acid method. After pretreatment, the ion-containing chloride ion content was 8352 mg / kg.

[0038] In the extraction-reextraction system, the pulse frequency of the pulse sieve plate column is set at 3 Hz, and the pulse amplitude is 5 mm. During the extraction process, polyacrylamide is used as the extraction agent, the volume ratio of the organic phase to the aqueous phase is 1.5:1, and No. 5 paint solvent oil (not the scientific name, paint And cleaning forever solvent oil is a category of solvent oil, the distillation range is 140 ~ 200 ℃, No. 5 is a brand of paint and cleaning forever solvent oil. Solvent oil is based on its 98% distillation temperature or dry point (100% distillation According to the product distillation range,...

Embodiment 3

[0040] Chlorine-containing wastewater is selected from a chlor-alkali chemical plant in Chongqing, and its ion-containing chloride ion content after pretreatment is 650mg / kg. In the extraction-stripping system, the pulse frequency of the pulse sieve plate column is set at 2 Hz, and the pulse amplitude is 2.5 mm. During the extraction process, triethanolamine is used as the extraction agent, the volume ratio of the organic phase to the aqueous phase is 1:1, and sulfonated kerosene is used as the diluent. The volume ratio of triethanolamine and triethanolamine is 30%, and at 20°C, extract for 10 minutes; in the stripping process, the ammonia / ammonium chloride mixed solution is the stripping agent, the mass concentration of ammonia water is 8%, the mass concentration of ammonium chloride solution is 25%, and the ammonia The excess coefficient of the product is 0.25. At 40°C, back-extract for 30 minutes; during the regeneration and washing process of the organic phase, wash with wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com