Anion-cation co-doped lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., to achieve the effects of inhibiting oxygen release, increasing cycle ratio, and reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to the general chemical formula (Mn 0.526 Ni 0.421 co 0.053 )CO 3 The precursor 1g powder of the lithium-rich manganese cathode material is mixed with 0.04744g potassium acetate CH3COOK, 0.006108g lithium chloride LiCl and 0.4326g lithium carbonate Li 2 CO 3 Mix evenly, heat up to 500°C at a rate of 2°C / min in an air atmosphere, hold for 5 hours, then raise the temperature to 880°C at a rate of 1°C / min, hold for 15 hours, and cool naturally to room temperature to obtain anion-cation co-doped modification Lithium-rich manganese-based cathode material (chemical formula: Li 1.155 K 0.045 mn 0.421 Ni 0.337 co 0.042 o 1.987 Cl 0.013 ).

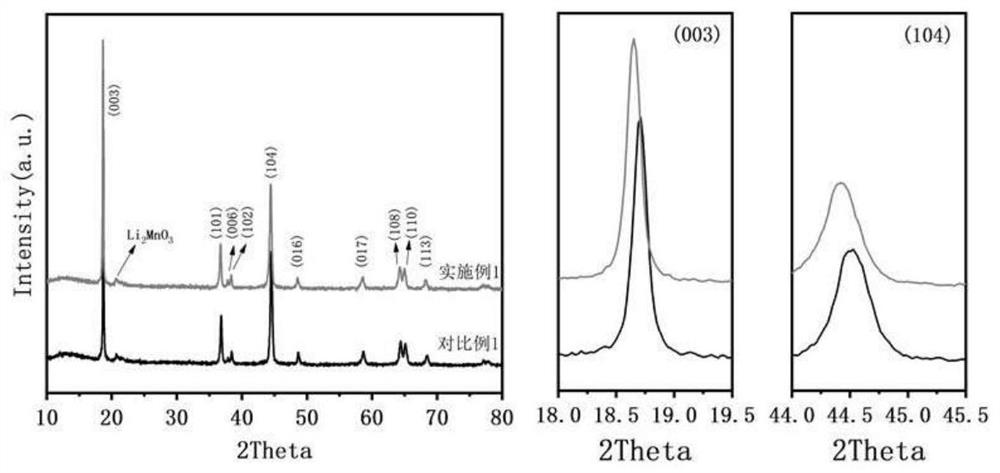

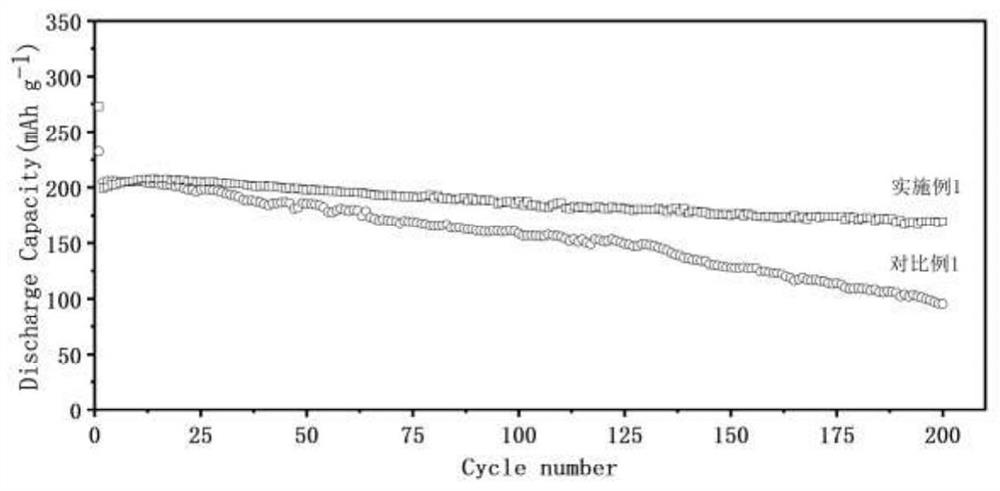

[0027] The X-ray diffractometer results of the positive electrode material prepared by the above method are as follows: figure 1 As shown in the figure, it can be seen that the material conforms to the crystal peak of lithium-rich materials, which conforms to α~NaFeO 2 structure, and there is no impurity peak, indicati...

Embodiment 2

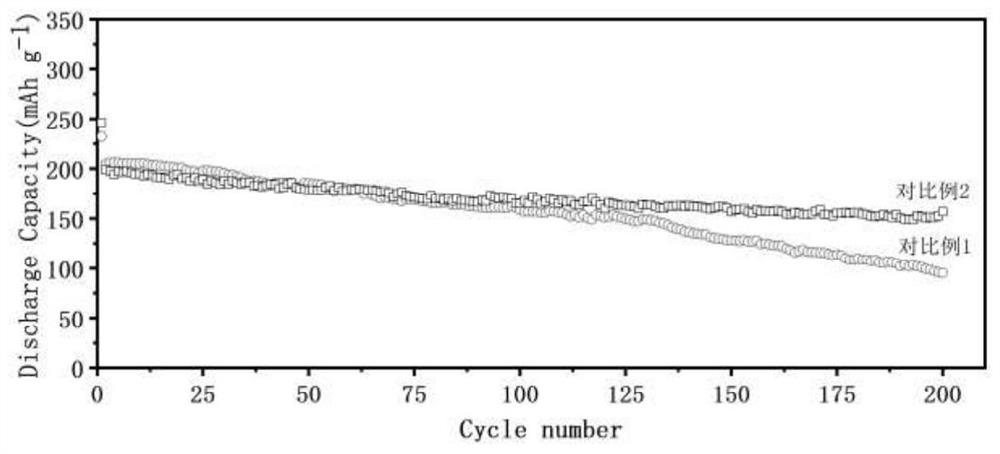

[0030] According to the general chemical formula (Mn 0.526 Ni 0.368 co 0.105 )CO 3 1g powder of the precursor of the lithium-rich manganese cathode material and 0.03668g rubidium carbonate Rb 2CO 3 , 0.013847g nickel bromide NiBr and 0.4293g lithium carbonate Li 2 CO 3 Mix evenly, heat up to 500°C at a rate of 2°C / min in an air atmosphere, hold for 5 hours, then raise the temperature to 900°C at a rate of 1°C / min, hold for 15 hours, and cool naturally to room temperature. That is, the anion-cation co-doped modified lithium-rich manganese-based positive electrode material (Li 1.185 Rb 0.015 mn 0.421 Ni 0.29 5 co 0.084 o 1.983 Br 0.017 ). According to the battery test conditions of Example 1, the first-cycle efficiency of the battery of the material of this example is 80%, the capacity retention rate after 100 cycles is 87%, and the average voltage retention rate is 93%.

Embodiment 3

[0032] According to the general chemical formula (Mn 0.526 Ni 0.316 co 0.158 )CO 3 The precursor of lithium-rich manganese cathode material and 0.00702g cesium carbonate Cs 2 CO 3 , 0.0058735g lithium iodide LiI and 0.4932g lithium carbonate Li 2 CO 3 Mix evenly, heat up to 500°C at a rate of 2°C / min in an air atmosphere, hold for 5 hours, then raise the temperature to 880°C at a rate of 1°C / min, hold for 15 hours, and cool to room temperature naturally. That is, the anion-cation co-doped modified lithium-rich manganese-based positive electrode material (Li 1.198 Cs 0.002 mn 0.421 Ni 0.253 co 0.12 6 o 1.996 I 0.004 ). According to the battery test conditions of Example 1, the first cycle efficiency of the battery of the material of this example is 83%, the capacity retention rate after 100 cycles is 90%, and the average voltage retention rate is 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com