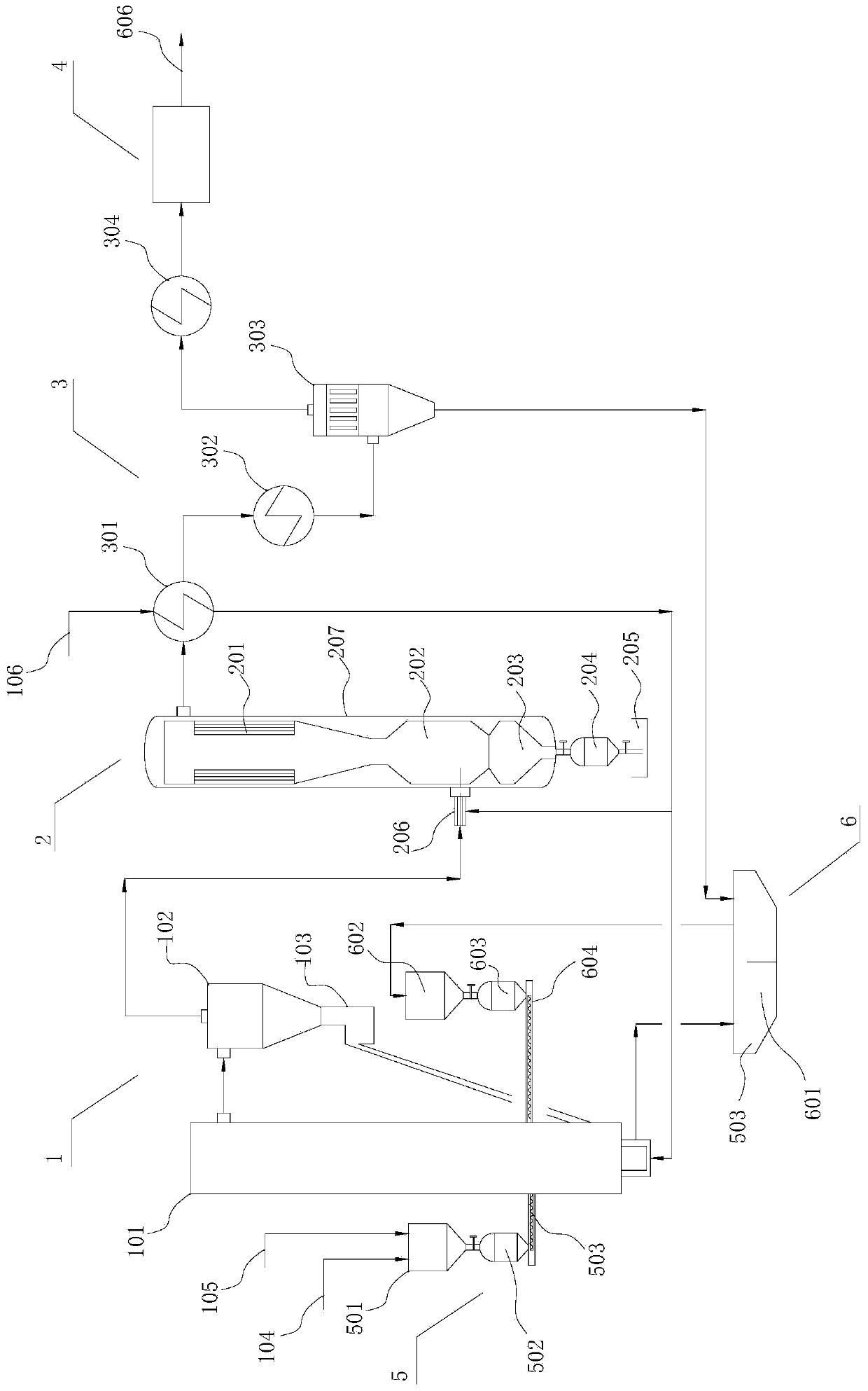

System and method for gasifying and melting solid wastes

A technology of gasification melting and garbage, which is applied in the direction of granular/powdered fuel gasification, chemical industry, and the manufacture of combustible gas, etc. Material and other problems, to achieve the effect of improving operation stability, high gasification and melting temperature, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] The solid waste gasification melting system and method of this embodiment adopts oily sludge as the raw material of solid waste, and the basic production process is the same as that of Embodiment 1. River sand mixture, ratio 30:70), to improve the degree of vitrification of waste residue after gasification of oily sludge, so that it can form a stable glass body after gasification and melting reaction. In addition, the gasification agent is a mixed gas of pure oxygen and water vapor, and the weight ratio of pure oxygen and water vapor is 1.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com