Device and method for preparing sulfur by means of carbothermic reduction of SO2

A SO2, carbothermic technology, applied in the preparation/purification of sulfur, chemical instruments and methods, sulfur compounds, etc., can solve the problem of the structure and parameters of the carbothermic reduction tower without a mature design, and achieve pressure reduction and stable operation. , the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

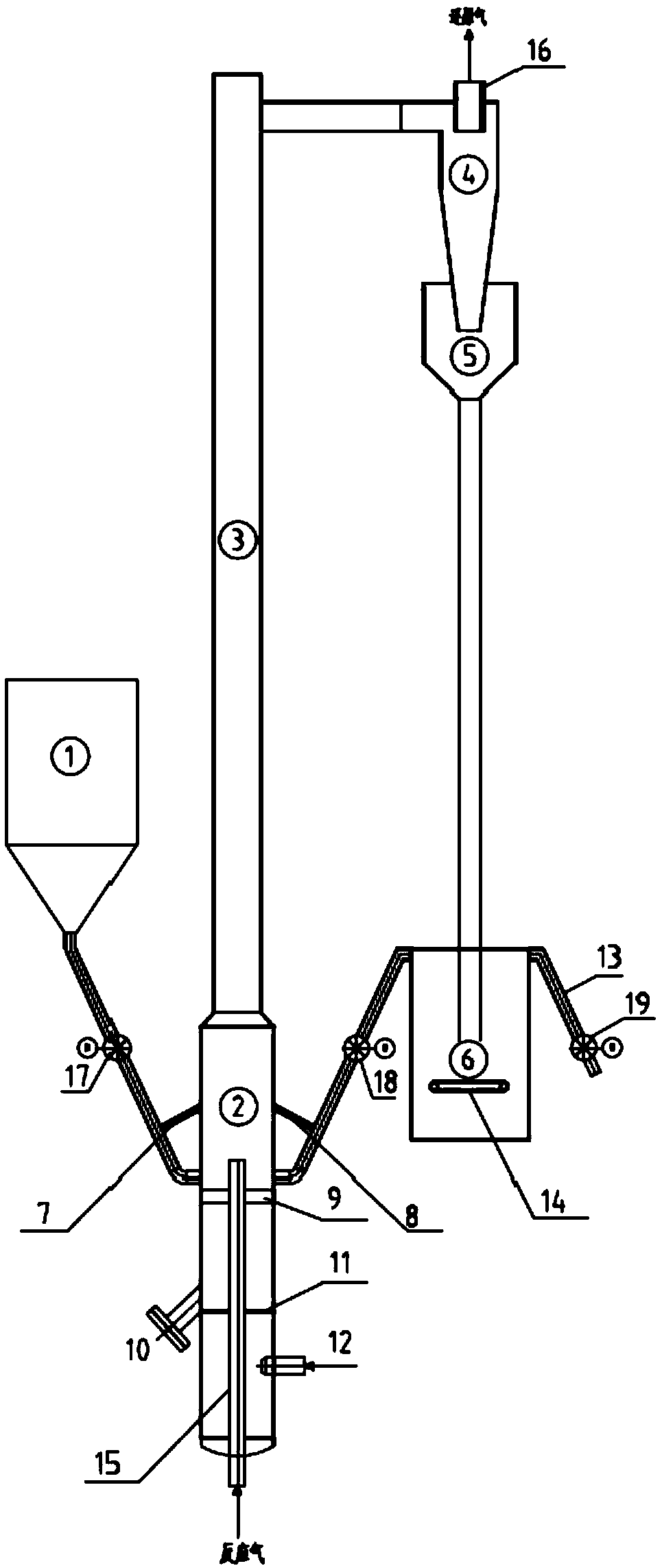

[0044] Carbothermal reduction of SO 2 The device for preparing sulfur includes silo 1, gas-solid mixing bin 2, carbothermic reduction tower 3, high temperature gas-solid separator 4, ash hopper 5, carbon-based reducing agent buffer tank 6, carbothermic reduction tower 3 from top to bottom It is the reaction section and gas-solid mixing silo 2. The silo 1 is connected to the material inlet of the gas-solid mixing silo 2. The top of the reaction section is provided with a reducing gas outlet, which is connected to the high-temperature gas-solid separator 4, ash hopper 5, and carbon-based reduction. The buffer tank 6, the carbon-based reducing agent buffer tank 6 is connected to the return port of the gas-solid mixing tank 2. The gas-solid mixing tank 2 is sequentially provided with a bracket 9, a distribution plate 11, and a supplemental gas inlet 12 from top to bottom. The inlet pipe 15 enters the gas-solid mixing bin 2 from the bottom of the gas-solid mixing bin 2, the bracket 9...

Embodiment 2

[0057] Carbothermal reduction of SO 2 The method for preparing sulfur, the specific steps are:

[0058] 1) The powdered carbon-based reducing agent is transported from the silo to the gas-solid mixing chamber, and the reactant gas enters the gas-solid mixing chamber from the reaction gas inlet pipe, and enters the upper part of the carbothermic reduction tower after being fully mixed with the powdered carbon-based reducing agent. Gas SO 2 The concentration is 10%;

[0059] 2) At the upper part of the carbothermic reduction tower, the gas velocity in the carbothermic reduction tower is 5m / s, the gas-solid contact time in the tower is 5s, the reaction temperature is 800℃, the C / S molar ratio is 50, the reaction gas and the powdered carbon-based reducing agent The reaction obtains reducing gas, and the reducing gas is N 2 , SO 2 , COS, H 2 S, CS 2 , CO, H 2 And CO 2 Mixture

[0060] 3) The reducing gas enters the high-temperature separator, and the powdery material carried in the reduc...

Embodiment 3

[0063] Carbothermal reduction of SO 2 The method for preparing sulfur, the specific steps are:

[0064] 1) The powdered carbon-based reducing agent is transported from the silo to the gas-solid mixing chamber, and the reactant gas enters the gas-solid mixing chamber from the reaction gas inlet pipe, and enters the upper part of the carbothermic reduction tower after being fully mixed with the powdered carbon-based reducing agent. Gas SO 2 The concentration is 15%;

[0065] 2) In the upper part of the carbothermic reduction tower, the gas velocity in the carbothermic reduction tower is 5m / s, the gas-solid contact time in the tower is 5s, the reaction temperature is 900℃, the C / S molar ratio is 60, the reaction gas and the powdered carbon-based reducing agent The reaction obtains reducing gas, and the reducing gas is N 2 , SO 2 , COS, H 2 S, CS 2 , CO, H 2 And CO 2 And other mixtures.

[0066] 3) The reducing gas enters the high-temperature separator, and the powdery material carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com