Method for directly synthesizing basic magnesium sulfate whiskers by brine

A magnesium sulfate whisker and bittern technology, which is applied in the field of inorganic material preparation, can solve the problems of high raw material cost, unsuitability for industrial production, complex process, etc., and achieve low raw material price, high product purity and yield, and simple process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

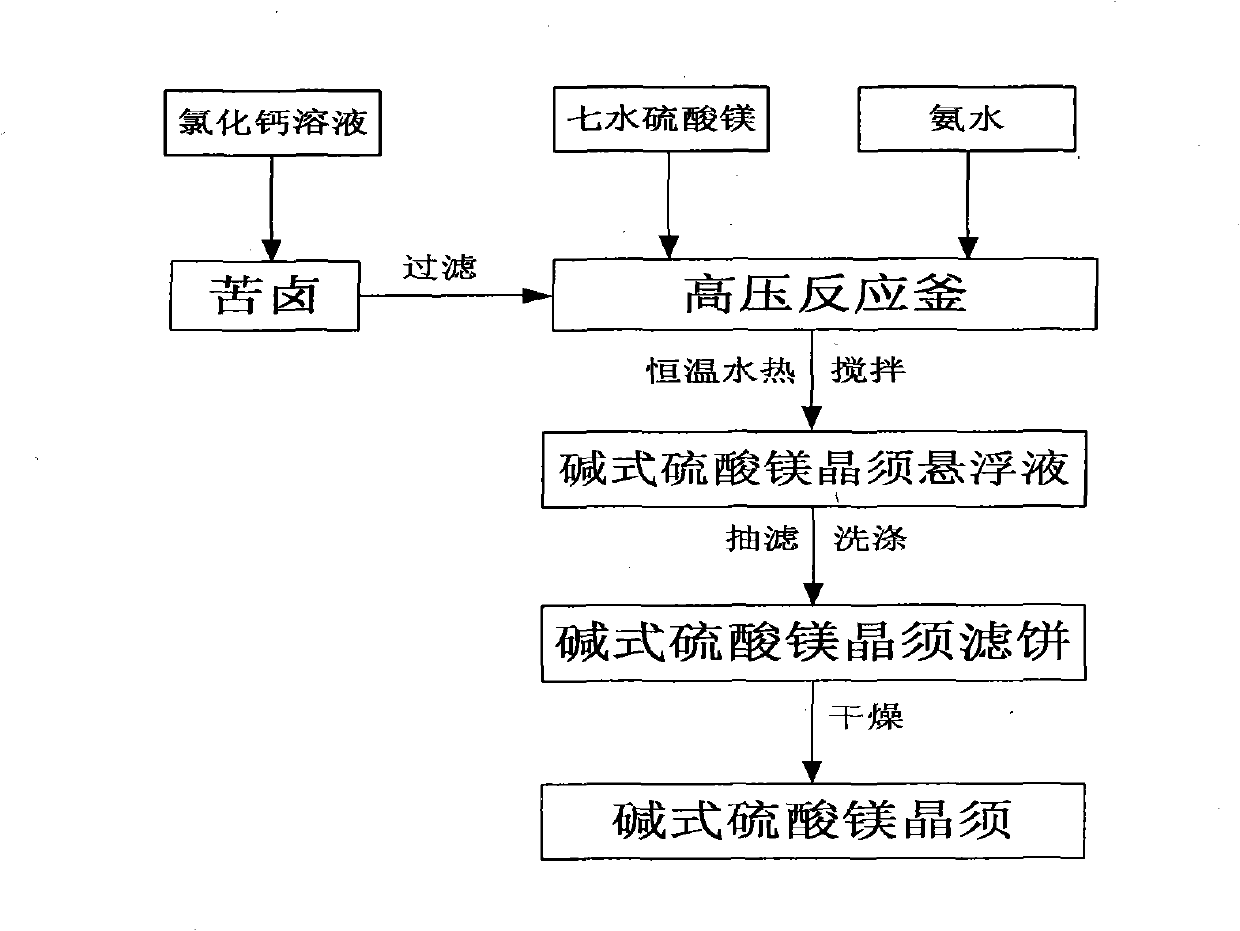

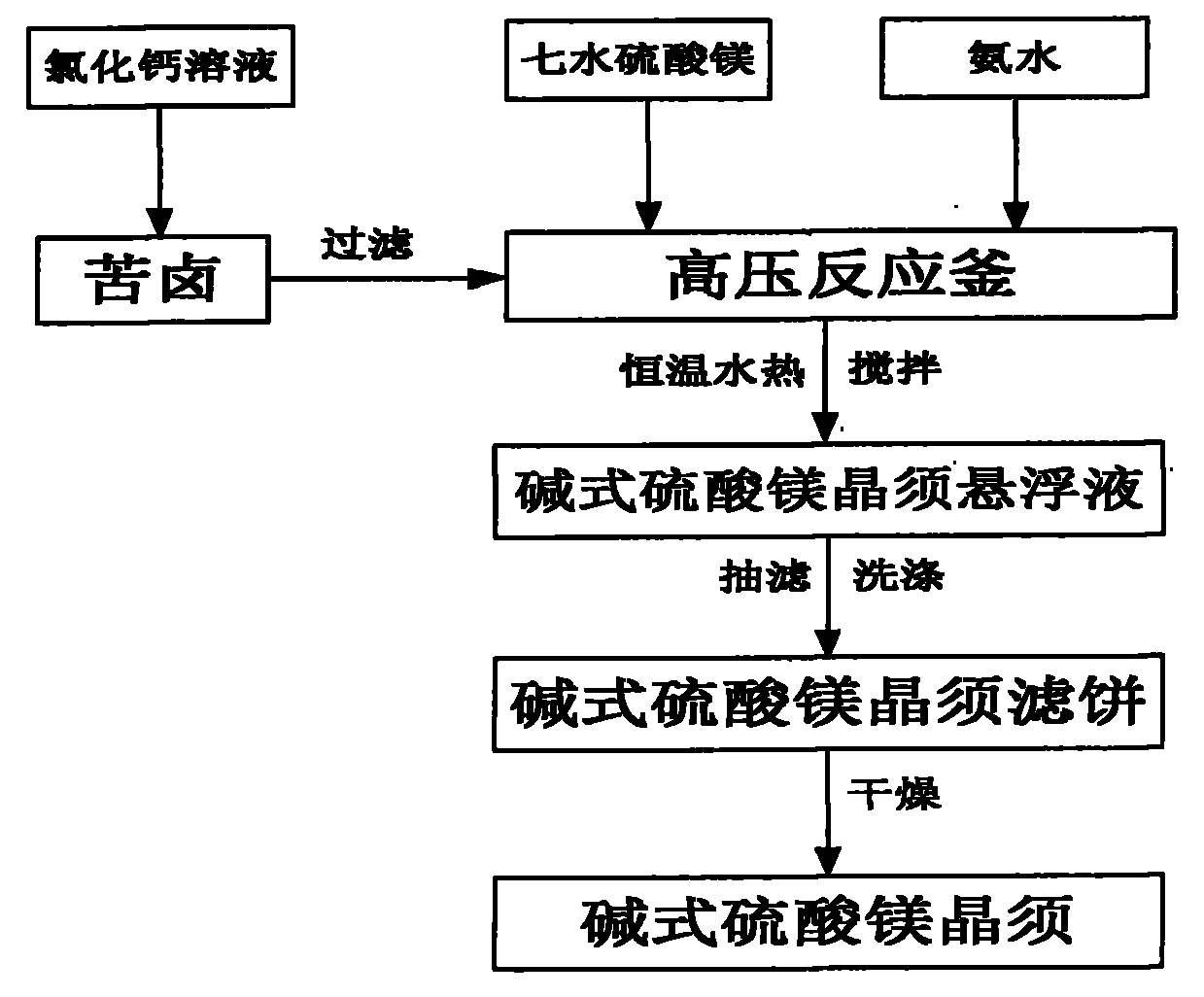

Method used

Image

Examples

Embodiment 1

[0028] Take 2 liters of bittern, analyze to get SO 4 2- It is 58.06g / L, that is, a total of 1.21 moles of SO 4 2- , add 2.42L of 0.5mol / L calcium chloride solution, add 1.21 moles of calcium chloride in total, stir for 10 minutes, filter, and analyze to get Mg 2+ 18.23g / L, SO 4 2- It is 2.98g / L. Measure 1 liter of pretreated bittern and place it in a 3-liter high-pressure reactor, and use 2 times the magnesium ion (Mg) in the pretreated bittern 2+ ) Molar weight adds ammoniacal liquor (25%, m / m) namely 212.68g, with 2 times of magnesium ion (Mg 2+ ) molar amount of magnesium sulfate heptahydrate (98.13%, m / m) was added, namely 380.84g. Start stirring at 300 rpm, and raise the temperature to 160°C. Stop heating, continue stirring, constant temperature hydrothermal reaction for 8 hours, stop constant temperature. Then cool naturally to room temperature, move the basic magnesium sulfate whisker suspension prepared in the autoclave out of the autoclave, separate the solid...

Embodiment 2

[0030] Take 2 liters of bittern, analyze to get SO 4 2- It is 55.22g / L, that is, a total of 1.15 moles of SO 4 2- , add 2.3 L of 0.5mol / L calcium chloride solution, add 1.15 moles of calcium chloride in total, stir for 10 minutes, filter, and analyze to get Mg 2+ 17.28g / L, SO 4 2- It is 2.36g / L. Measure bittern after 1 liter of pretreatment and place it in 3 liters of high-pressure reactors, with 2.1 times of magnesium ion (Mg 2+ ) Molar weight adds ammoniacal liquor (25%, m / m) namely 211.68g, with 2.4 times of magnesium ion (Mg 2+ ) molar amount of magnesium sulfate heptahydrate (98.13%, m / m) that is 433.19g was added. Turn on stirring at 400 rpm, and raise the temperature to 150°C. Stop heating, continue stirring, constant temperature hydrothermal reaction for 6 hours, stop constant temperature. Then cool naturally to room temperature, move the basic magnesium sulfate whisker suspension prepared in the autoclave out of the autoclave, separate the solid from the liqu...

Embodiment 3

[0032] Take 2 liters of bittern, analyze to get SO 4 2- It is 57.21g / L, that is, 1.19 moles of SO 4 2- , add 2.38L of 0.5mol / L calcium chloride solution, add 1.19 moles of calcium chloride in total, stir for 10 minutes, filter, and analyze, Mg 2+ 17.92g / L, SO 4 2- It is 3.02g / L. Measure 1 liter of pretreatment bittern and be placed in 3 liters of pressure reactors, with 2.15 times the magnesium ion (Mg in the pretreatment bittern) 2+ ) Molar weight adds ammoniacal liquor (25%, m / m) i.e. 224.75g, with 2.6 times the magnesium ion (Mg in the pretreatment bittern) 2+ ) molar amount of magnesium sulfate heptahydrate (98.13%, m / m) was added, namely 486.67g. Turn on stirring at 450 rpm, and raise the temperature to 170°C. Stop heating, continue stirring, constant temperature hydrothermal reaction for 5 hours, stop constant temperature. Then cool naturally to room temperature, move the basic magnesium sulfate whisker suspension prepared in the autoclave out of the autoclave, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com