Method for preparing basic magnesium sulfate whiskers by recycling mother liquor

A technology of magnesium sulfate whiskers and circulating mother liquor, applied in magnesium sulfate, chemical instruments and methods, single crystal growth and other directions, can solve problems such as complicated processes, and achieve the effects of high added value, good quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

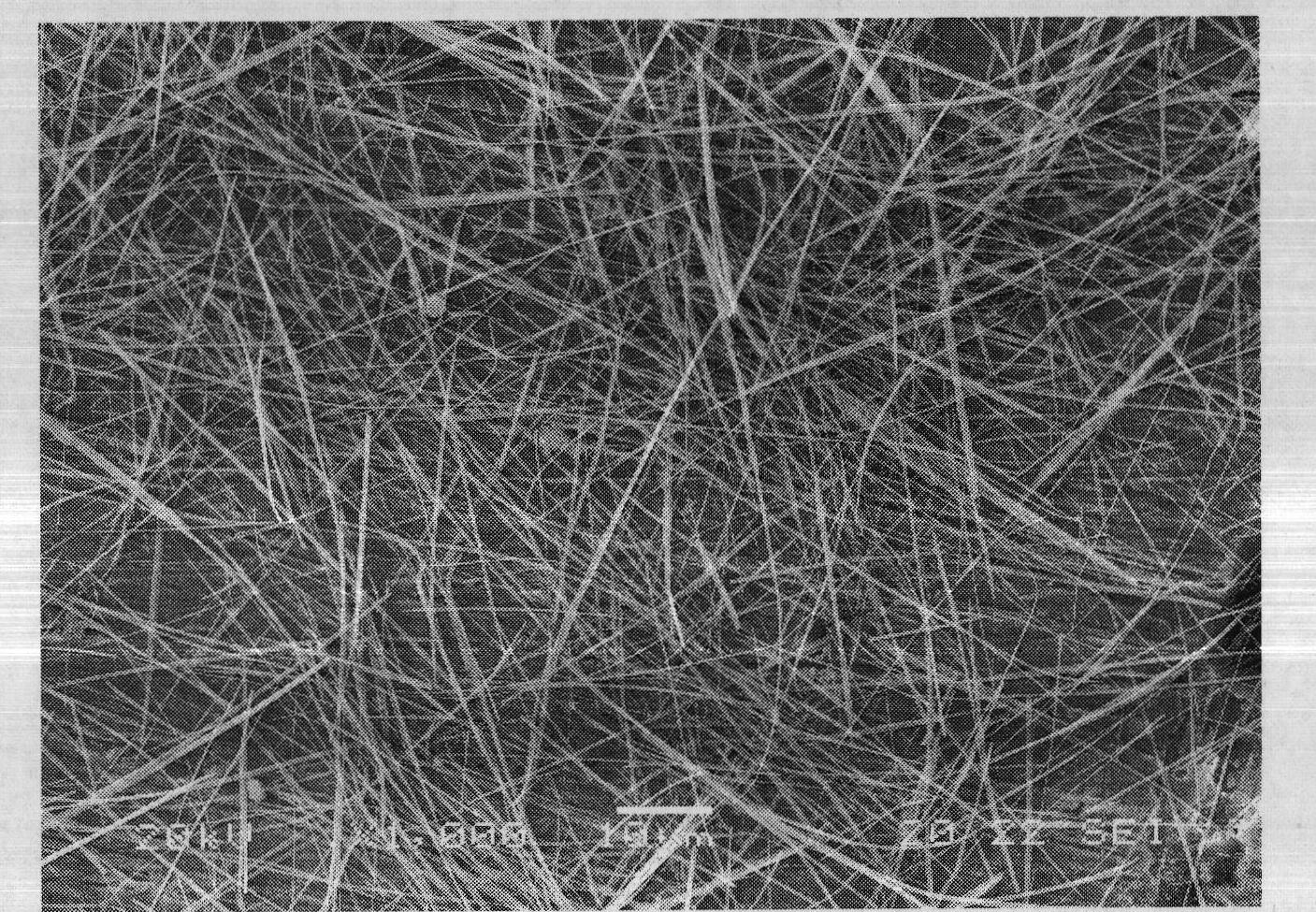

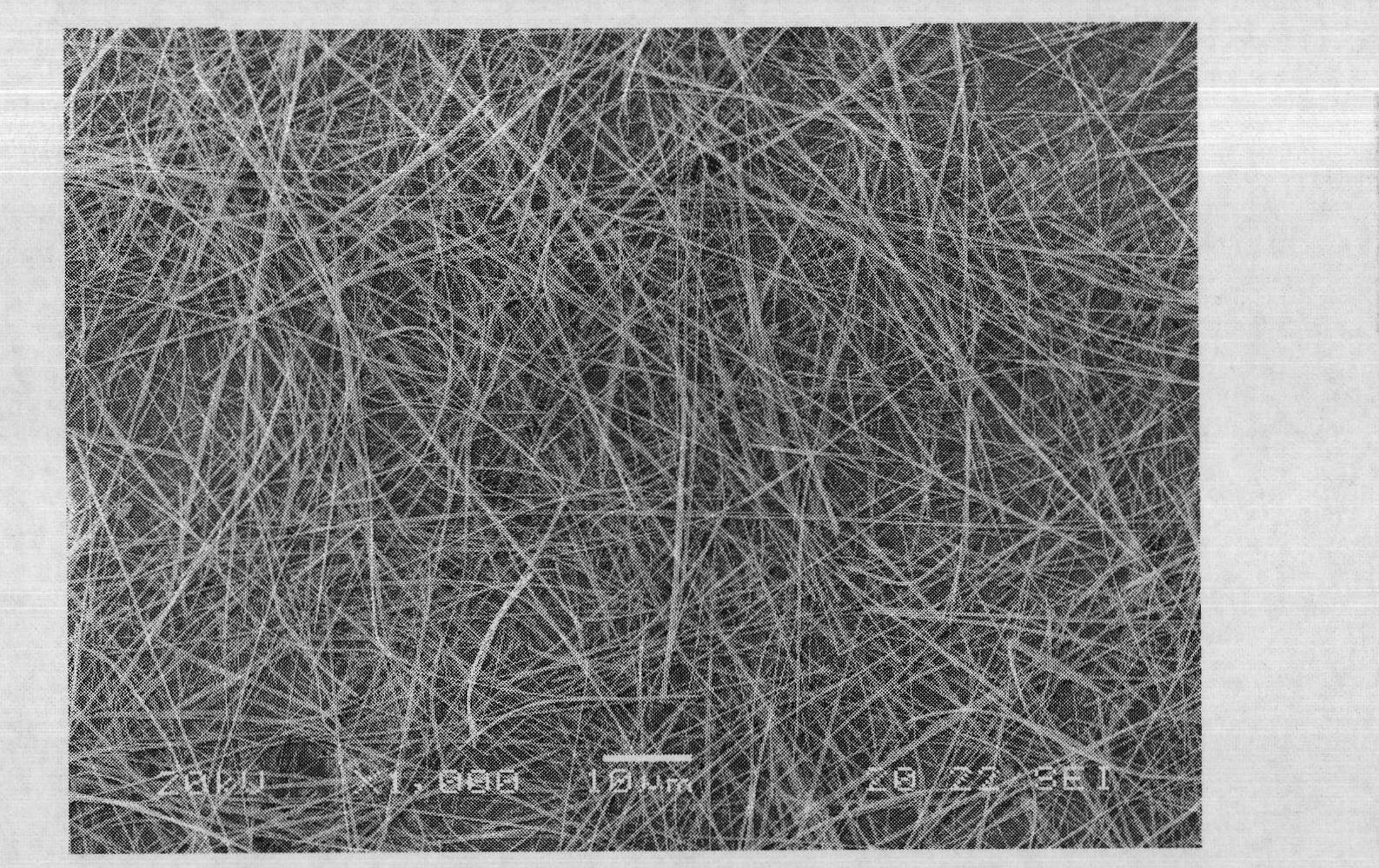

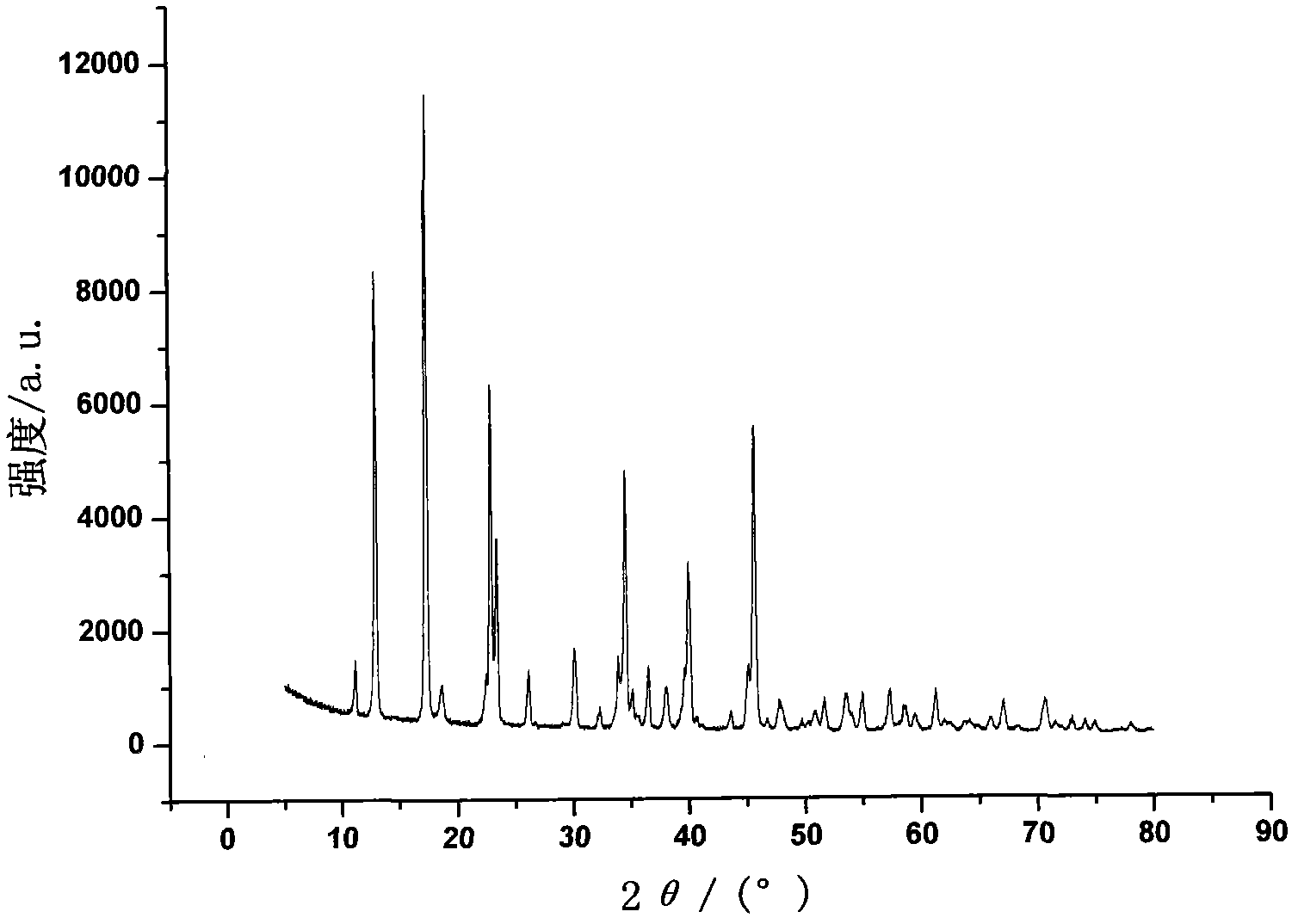

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of method of circulating mother liquor method to prepare basic magnesium sulfate whisker, comprises the following steps:

[0031] (1) 1700g of the mother liquor for the preparation of basic magnesium sulfate whiskers is taken, and concentrated to 650g by evaporation in a universal electric furnace. Now, the mother liquor contains 10.0% sodium sulfate mass fraction and 12.0% magnesium sulfate mass fraction.

[0032] Freeze and crystallize the concentrated mother liquor at -3°C in a low-temperature thermostat to precipitate sodium sulfate decahydrate; filter sodium sulfate decahydrate through a circulating water vacuum pump to obtain solid sodium sulfate decahydrate and filter the mother liquor.

[0033] (2) Get 372mL of the filtered mother liquor obtained in step (1), add distilled water and MgSO 4 ·7H 2 O solid, dilute to a magnesium sulfate solution with a molar concentration of 0.8mol / L; then add NaOH solid according to the molar ratio of magnesiu...

Embodiment 2

[0036] Embodiment 2 A kind of method of circulating mother liquor method to prepare basic magnesium sulfate whisker, comprises the following steps:

[0037] (1) 1700g of the mother liquor for the preparation of basic magnesium sulfate whiskers is taken, and concentrated to 600g by evaporation in a universal electric furnace. Now, the mother liquor contains 10.8% sodium sulfate mass fraction and 13.5% magnesium sulfate mass fraction.

[0038] Freeze and crystallize the concentrated mother liquor at 0°C in a low-temperature thermostat to precipitate sodium sulfate decahydrate; filter sodium sulfate decahydrate through a circulating water vacuum pump to obtain solid sodium sulfate decahydrate and filter the mother liquor.

[0039] (2) Get 317mL of the filtered mother liquor obtained in step (1), add distilled water and MgSO 4 ·7H 2 O solid, dilute to a magnesium sulfate solution with a molar concentration of 0.8mol / L; then add NaOH solid according to the molar ratio of magnesium...

Embodiment 3

[0042] Embodiment 3 A kind of method of circulating mother liquor method to prepare basic magnesium sulfate whisker, comprises the following steps:

[0043] (1) 1800g of the mother liquor for the preparation of basic magnesium sulfate whiskers was taken, and concentrated to 610g by evaporation in a universal electric furnace. At this time, the mother liquor contained 12.0% of the sodium sulfate mass fraction and 14.0% of the magnesium sulfate mass fraction.

[0044] Freeze and crystallize the concentrated mother liquor at 3°C in a low-temperature thermostat to precipitate sodium sulfate decahydrate; filter sodium sulfate decahydrate through a circulating water vacuum pump to obtain solid sodium sulfate decahydrate and filter the mother liquor.

[0045] (2) Get 300mL of the filtered mother liquor obtained in step (1), add distilled water and MgSO 4 ·7H 2 O solid, dilute to a magnesium sulfate solution with a molar concentration of 1.1mol / L; then add NaOH solid according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com