Low formaldehyde resin adhesive for decorative impregnating paper and preparation method thereof

A technology of formaldehyde resin and production method, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of easy cracking of the adhesive layer, negative effects, and resistance to strong alkali erosion, etc., and achieve The effect of reducing the release of free formaldehyde, adding less, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0029] Below, in conjunction with specific embodiment, the present invention is described further:

[0030] The low-formaldehyde resin adhesive for decorative adhesive film paper described in the present embodiment comprises following raw materials: concentration is 3000Kg of formaldehyde 3000Kg of 37%, urea 2000 Kg of concentration 98%, 75 Kg of compound auxiliary agent; Compound auxiliary agent is made of 15 Kg curing agent , 40 Kg cross-linking agent and 20 Kg strengthening agent. The molar ratio of formaldehyde to urea, F / U=1.13.

[0031] The curing agent is hexamethylenetetramine. Its function: improve the curing speed and adequacy of the resin, more effectively shield the release of formaldehyde, and prolong the service life of low-aldehyde environmentally friendly glue.

[0032] The crosslinking agent is methacrylic acid. Its function: it can improve the cross-linked structure of the resin during the reaction process.

[0033] The reinforcing agent is white carbon b...

specific Embodiment 2

[0045] The difference between the low-formaldehyde resin adhesive for decorative adhesive film paper described in this embodiment and specific embodiment 1 is: the addition amount of composite auxiliary agent is 50 Kg; and 15 Kg enhancer composition. Others are the same as in Example 1.

[0046] The difference between the production method of the low-formaldehyde resin adhesive for decorative film paper described in this example and the specific example 1 is that in step 2), the addition amount of the first batch of compounding additives is 22.5Kg. In step 7), the amount of the second batch of compound additives added is 27.5Kg. Others are the same as in Example 1.

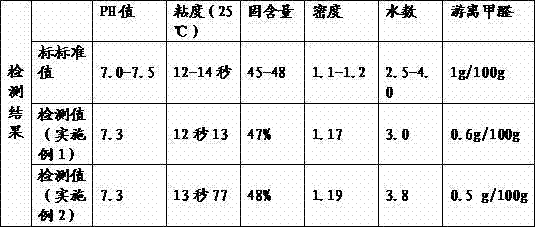

[0047] Table 1 The main performance parameter table of the resin adhesive described in embodiment 1 and 2

[0048]

[0049] It can be seen from Table 1 that the impregnated film paper produced by this process is 0.4mg / L, which is much higher than the national standard to ensure that the formaldehyde emission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com