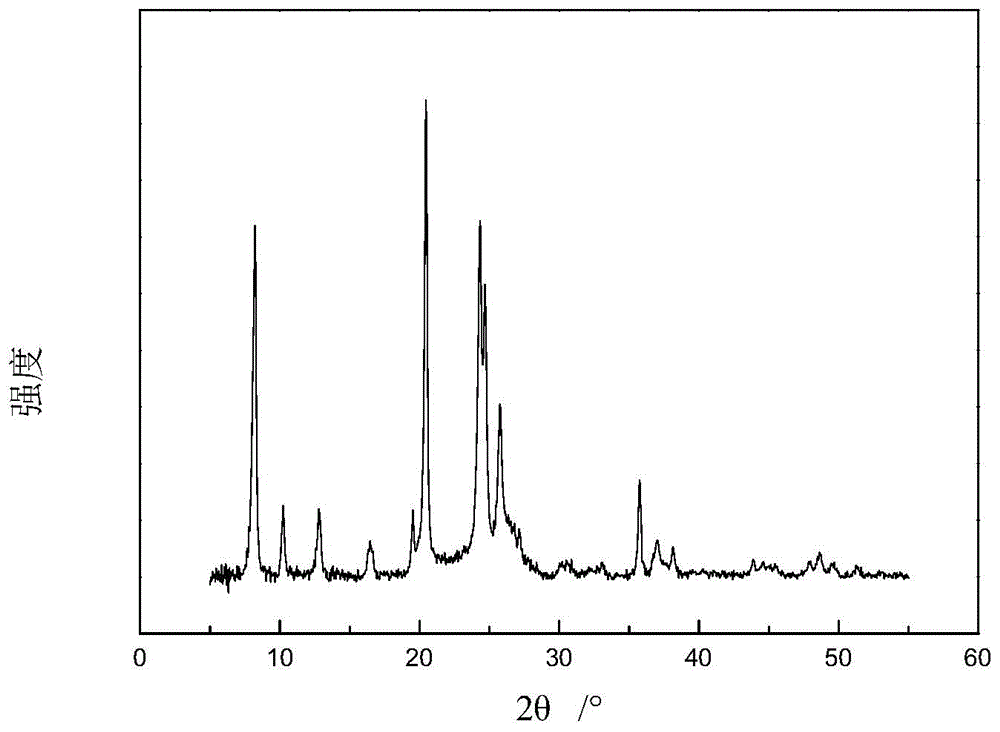

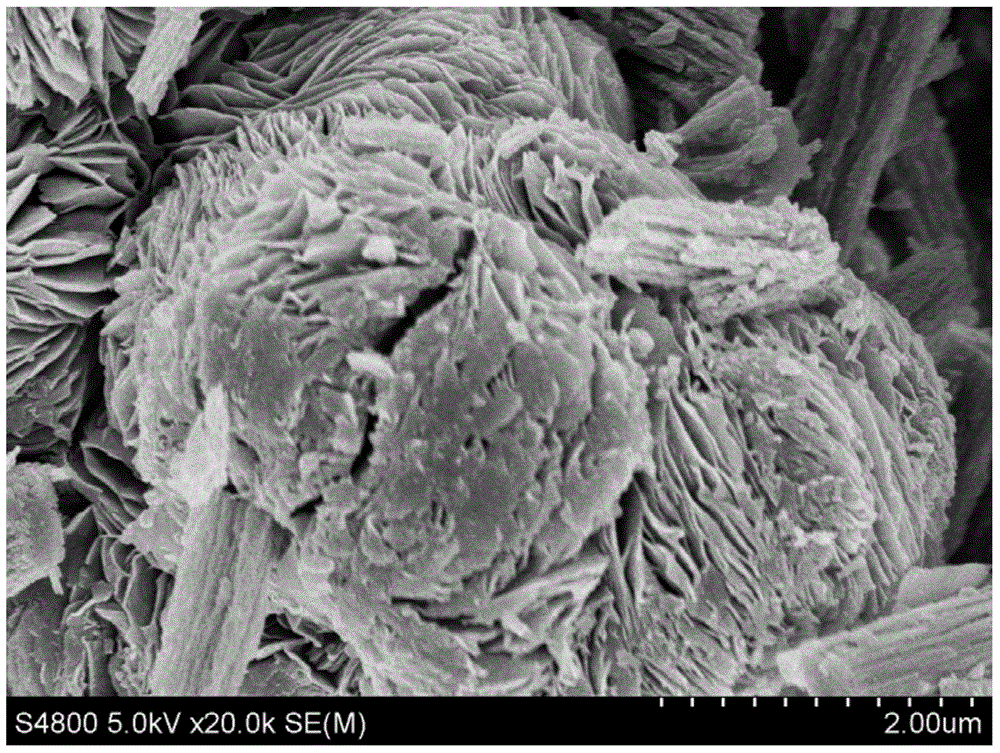

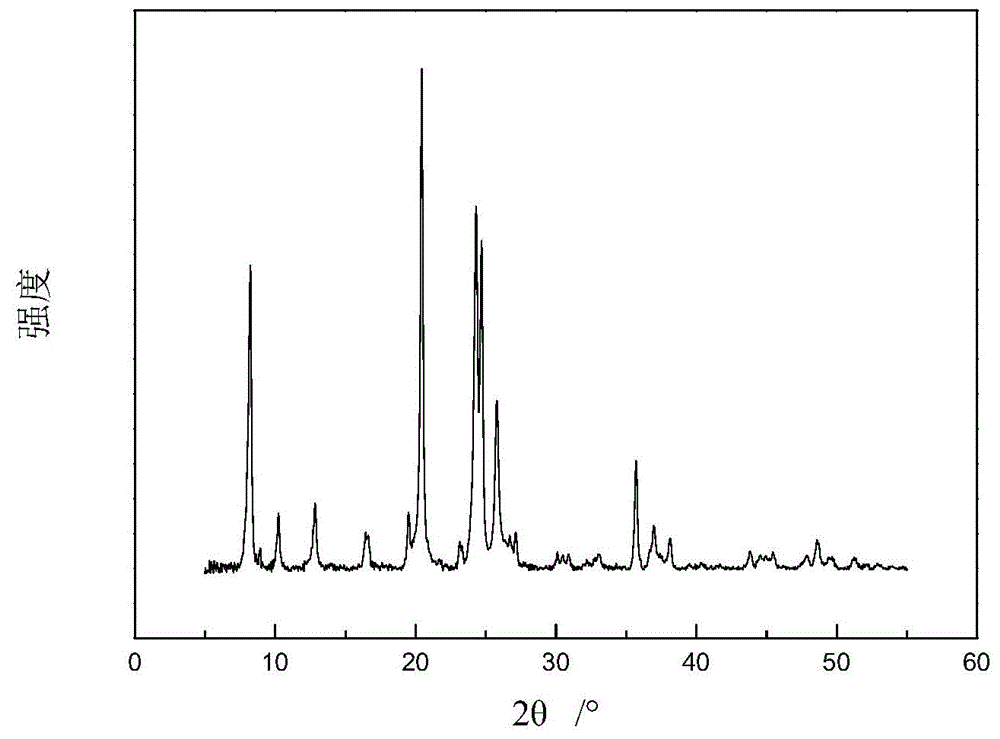

Preparation method of ZSM-22 molecular sieve nanosheet

A nanosheet and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of high cost and large amount of organic template agent, and achieve the effect of prolonging service life, improving catalytic activity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Specific embodiment one: The method for synthesizing ZSM-22 molecular sieve nanosheets by prefabricated seed crystal method in this embodiment is implemented according to the following steps:

[0031] 1. Preparation of prefabricated seed crystals:

[0032] a, take aluminum sulfate octadecahydrate, tetraethyl orthosilicate, 1,6 hexamethylenediamine, potassium hydroxide and deionized water as raw materials;

[0033] B, mixing the potassium hydroxide taken by step a with deionized water, dissolving to obtain an aqueous solution of potassium hydroxide, mixing the aluminum sulfate octadecanoate taken by step a with deionized water, and preparing an aqueous solution of aluminum sulfate after dissolving , mix the 1,6-hexamethylenediamine weighed in step a with deionized water, and dissolve to obtain an aqueous solution of 1,6-hexamethylenediamine, and mix the tetraethyl orthosilicate weighed in step a with deionized water to form a suspension liquid;

[0034] c. Add the alum...

specific Embodiment approach 2

[0047] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the tetraethyl orthosilicate described in step a in step one is replaced by SiO 2 The calculated mass fraction is 28%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the mass ratio of ethyl orthosilicate to deionized water described in step a in step 1 is 1: (3.1-5.0). Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com