Adhesive for veneering of artificial board and preparation method of adhesive

A veneer and board-making technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of easy dislocation, easy to stick to the plate, poor initial viscosity, etc., to increase hydrophobicity, prevent The effect of penetrating glue and improving initial viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of urea-formaldehyde resin 1

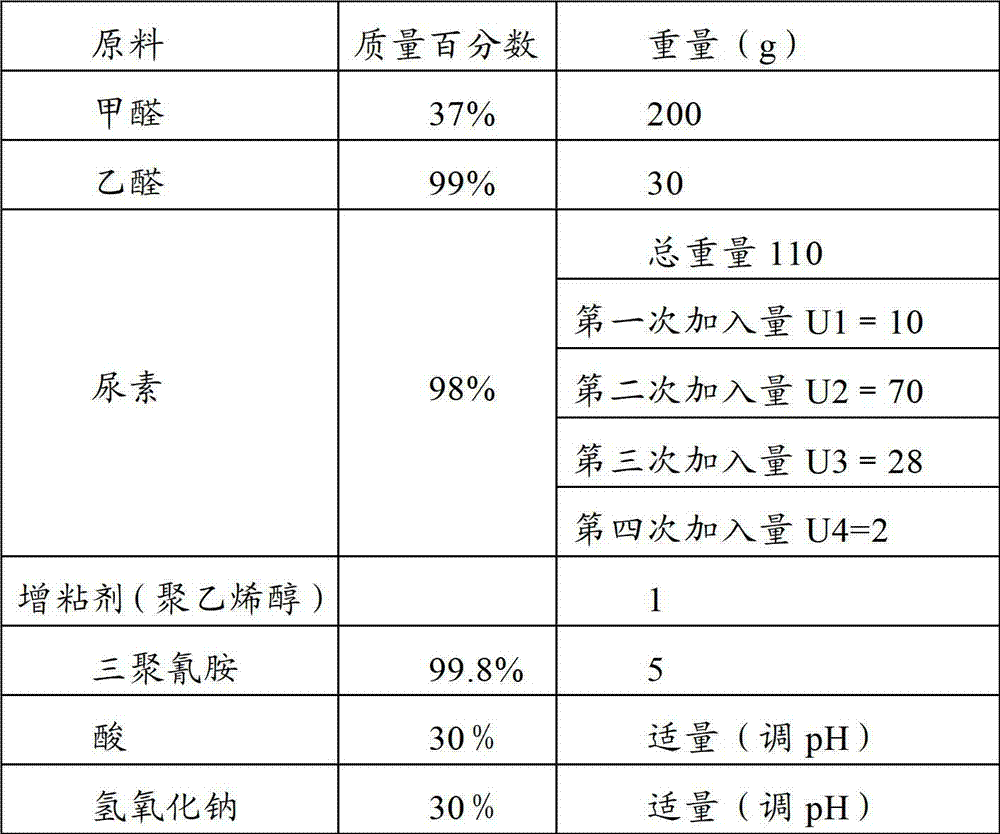

[0026] Raw material formula:

[0027]

[0028] Concrete reaction steps are as follows:

[0029] 1) Add formaldehyde to the reaction kettle one by one, adjust the pH to 9.0-11.0 with sodium hydroxide, then add acetaldehyde and the first batch of urea, heat up to 70-90°C, and keep warm for 60-120 minutes;

[0030] 2) Then lower the temperature to 40°C, adjust the pH to 7.0-9.5 with sodium hydroxide solution, add the second batch of urea, then raise the temperature to 75-95°C, and keep warm for 30-90 minutes;

[0031] 3) Adjust pH to 3-6, react to viscosity: apply -4 cups for 19s (30°C);

[0032] 4) Adjust the pH to 5-7, add the third batch of urea, control the temperature at 80-90°C, and react to viscosity: apply -4 cups for 23s (30°C);

[0033] 5) Adjust the pH to 7.0-7.5, add the fourth batch of urea and melamine, control the temperature at 75-80°C, keep warm for 10-40 minutes, and cool down;

[0034] 6...

Embodiment 2

[0036] Embodiment 2: the preparation of urea-formaldehyde resin 2

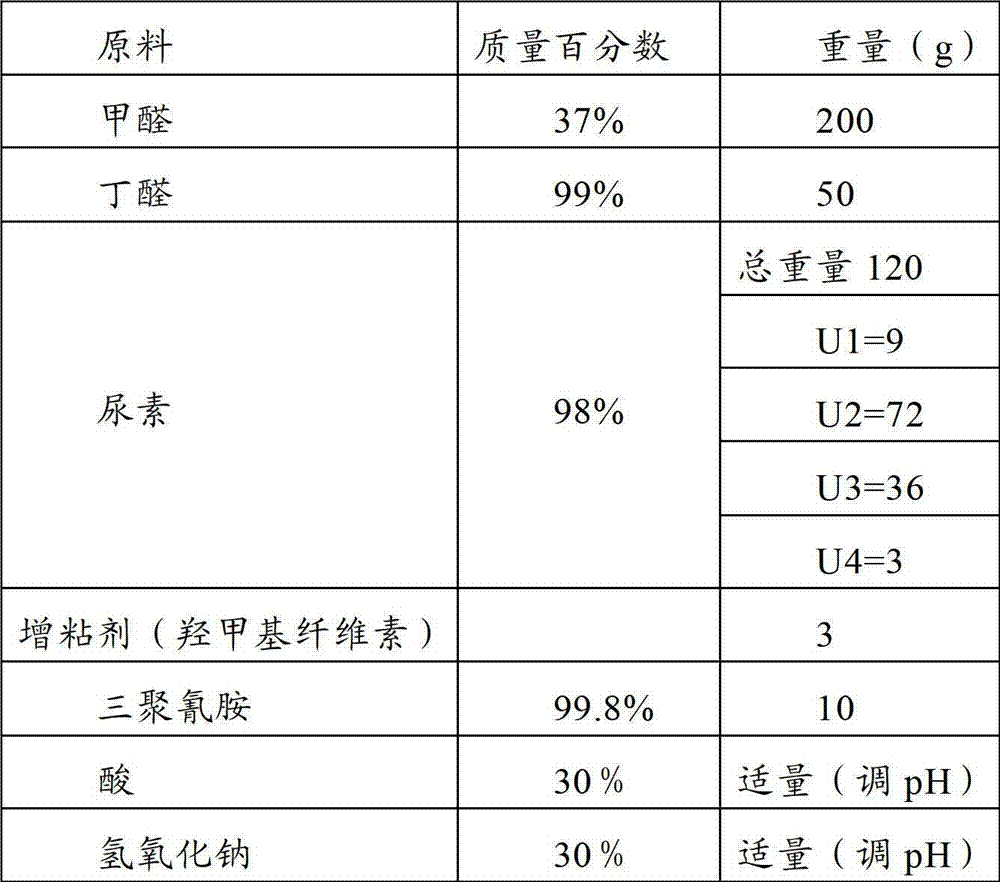

[0037] Raw material formula:

[0038]

[0039] Concrete reaction steps are as follows:

[0040] 1) Add formaldehyde to the reaction kettle one by one, adjust the pH to 9.0-11.0 with sodium hydroxide, then add butyraldehyde and the first batch of urea, raise the temperature to 70-90°C, and keep it warm for 60-120 minutes;

[0041] 2) Then lower the temperature to 40°C, adjust the pH to 7.0-9.5 with sodium hydroxide solution, add the second batch of urea, then raise the temperature to 75-95°C, and keep warm for 30-90 minutes;

[0042] 3) Adjust pH to 3-6, react to viscosity: apply -4 cups for 20s (30°C);

[0043] 4) Adjust the pH to 5-7, add the third batch of urea, control the temperature at 80-90°C, and react to viscosity: apply -4 cups for 24s (30°C);

[0044] 5) Adjust the pH to 7.0-7.5, add the fourth batch of urea and melamine, control the temperature at 75-80°C, keep warm for 10-40 minutes, and cool...

Embodiment 3

[0047] Embodiment 3: the preparation of urea-formaldehyde resin 3

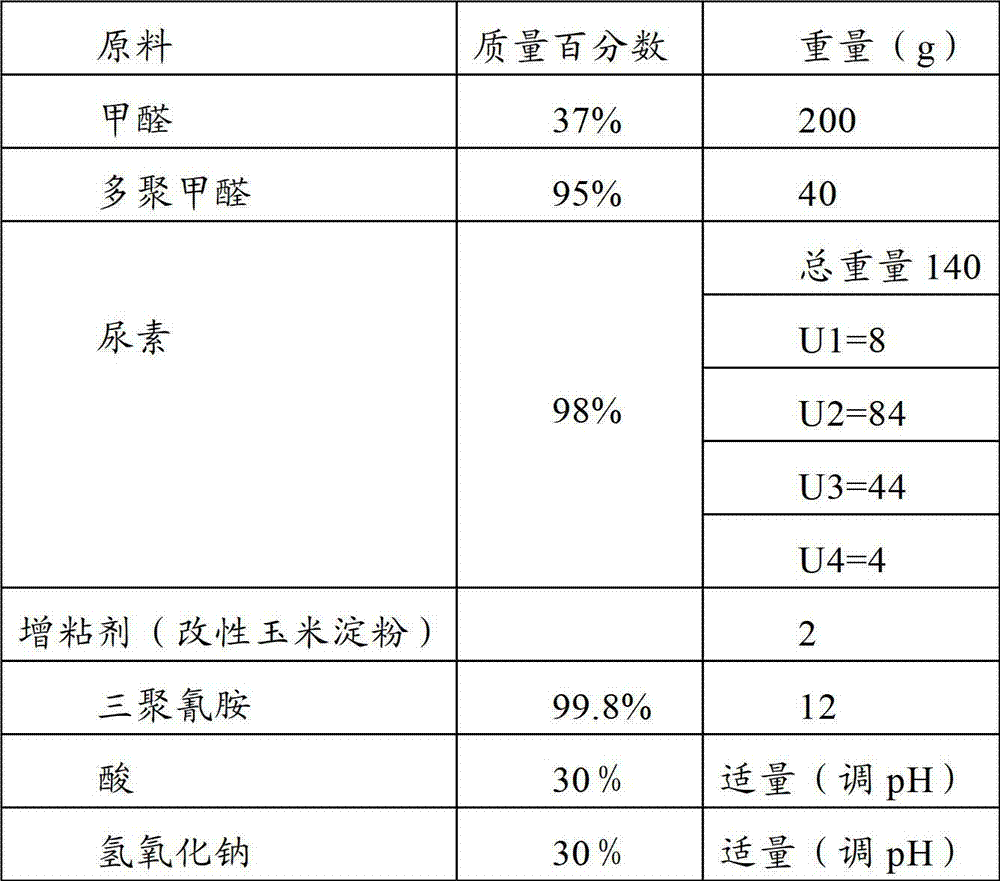

[0048] Raw material formula:

[0049]

[0050] Concrete reaction steps are as follows:

[0051] 1) Add formaldehyde to the reaction kettle one by one, adjust the pH to 9.0-11.0 with sodium hydroxide, then add paraformaldehyde and the first batch of urea, heat up to 70-90°C, and keep warm for 60-120 minutes;

[0052] 2) Then lower the temperature to 40°C, adjust the pH to 7.0-9.5 with sodium hydroxide solution, add the second batch of urea, then raise the temperature to 75-95°C, and keep warm for 30-90 minutes;

[0053] 3) Adjust pH to 3-6, react to viscosity: apply -4 cups for 21s (30°C);

[0054] 4) Adjust the pH to 5-7, add the third batch of urea, control the temperature at 80-90°C, and react to viscosity: Tu-4 cups for 26s (30°C);

[0055] 5) Adjust the pH to 7.0-7.5, add the fourth batch of urea and melamine, control the temperature at 75-80°C, keep warm for 10-40 minutes, and cool down;

[0056] 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com