Ethylene oligomerization method

A technology of ethylene oligomerization and ethyl, which is applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of expensive aluminoxane and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

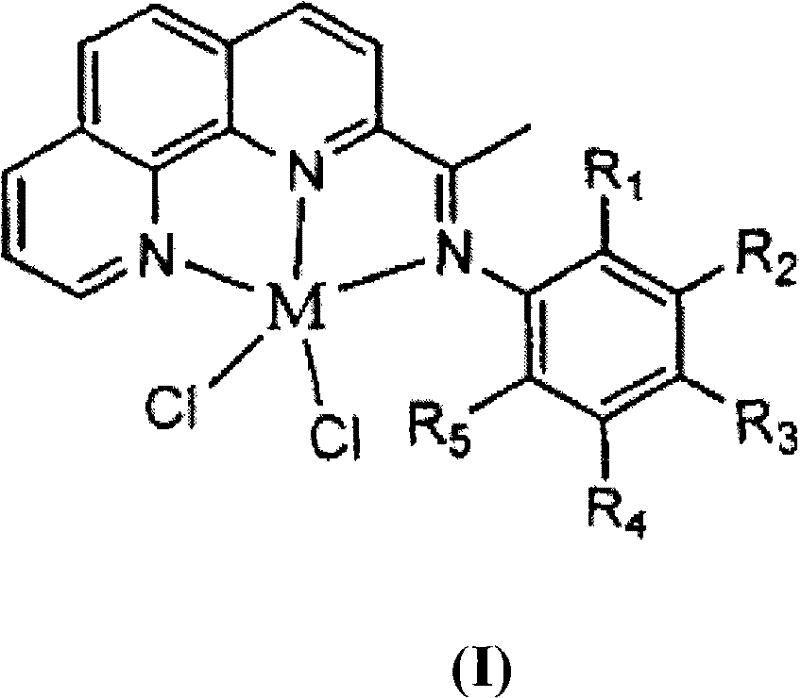

Method used

Image

Examples

Embodiment 1

[0082] 1. Preparation of the main catalyst

[0083] 2-Acetyl-1,10-phenanthroline (0.4445g, 2mmol) and 2,6-diethylaniline (0.4175g, 2.8mmol) were added 40mg p-toluenesulfonic acid as catalyst and 2g was added Molecular sieve was used as dehydrating agent, refluxed in 30ml of ethanol for 1 day, filtered to remove solvent toluene, the residue was dissolved and supported with dichloromethane, overbased alumina column, rinsed with petroleum ether / ethyl acetate (4:1) , the second fraction is the product, and the solvent is removed to obtain a yellow solid, which is a ligand of 2-acetyl-1,10-phenanthroline (2,6-diethylaniline), and the yield is 0.6 g and the yield is 84%. . NMR analysis: 1 H NMR (300MHz, CDCl 3 ): δ9.25 (dd, J=3.0Hz, 1H); 8.80 (d, J=8.3Hz, 1H); 8.35 (d, J=8.3Hz, 1H); 8.27 (dd, J=7.8Hz, 1H) ); 7.86(s, 2H); 7.66(m, 1H); 7.15(d, J=7.6Hz, 2H); 6.96(t, J=7.5Hz, 1H); 2.58(s, 3H, CH) 3 ); 2.43 (m, 4H, CH 2 CH 3 ); 1.16(t, J=7.5Hz, 6H, CH 2 CH 3 ). Elemental Analy...

Embodiment 2

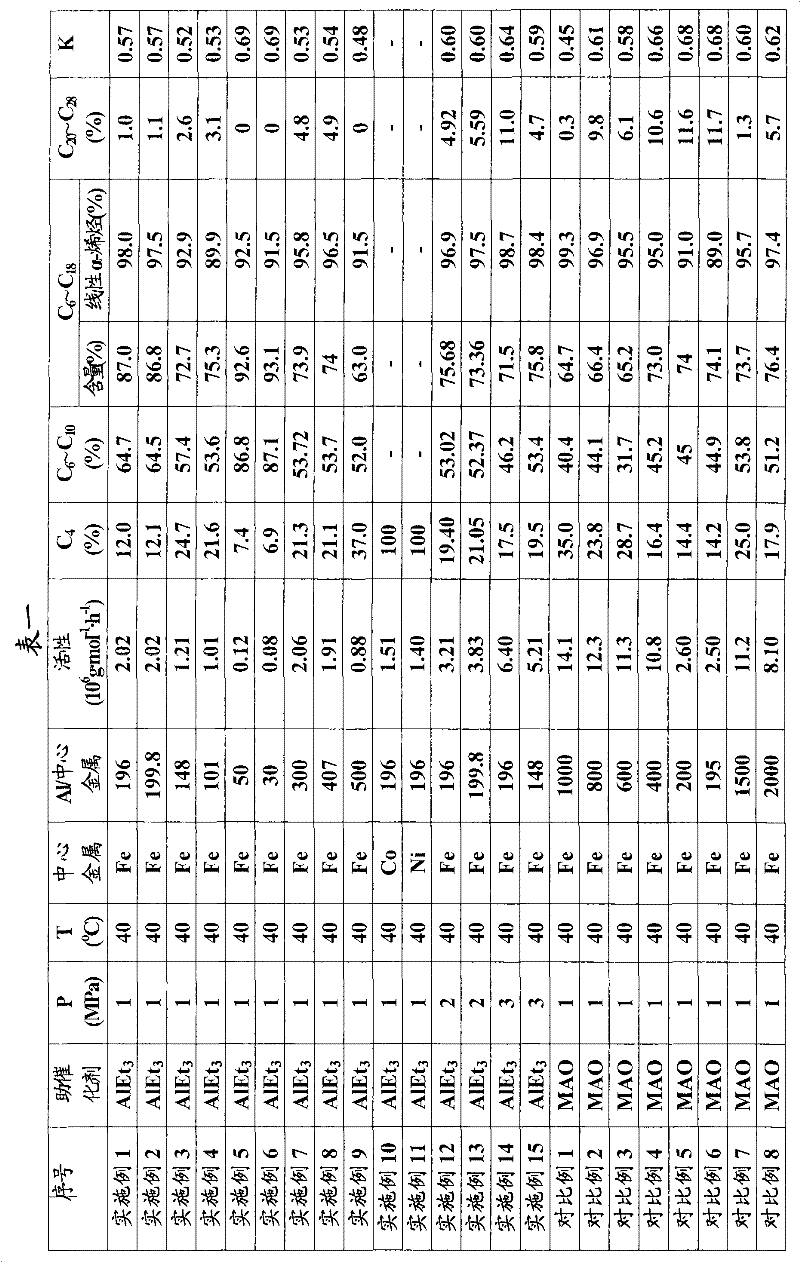

[0088] Adopt the main catalyst prepared in Example 1, the cocatalyst is triethylaluminum to carry out ethylene oligomerization, and the difference from Example 1 is: the consumption of triethylaluminum toluene solution is 0.54ml (concentration is 0.74mol / l) , so that Al / Fe=199.8. At 40 °C, the ethylene pressure of 1 MPa was maintained, and the reaction was stirred for 30 min. Take out a small amount of the mixture with a syringe and neutralize it with 5% dilute hydrochloric acid for GC analysis: the oligomerization activity is 2.02 × 10 6 g·mol -1 ·h -1 , the oligomer content is C 4 12.1%, C 6 ~C 10 64.5%, C 6 ~C 18 86.8% (including 97.5% of linear alpha-olefins), C 20 ~C 28 1.1%, K value 0.57. The remaining mixture was neutralized with 5% hydrochloric acid in acidified ethanol, and no polymer was obtained. The analysis results are shown in Table 1.

Embodiment 3

[0090] Adopt the main catalyst prepared in Example 1, the cocatalyst is triethylaluminum to carry out ethylene oligomerization, and the difference from Example 1 is: the consumption of triethylaluminum toluene solution is 0.4ml (concentration is 0.74mol / l) , so that Al / Fe=148. At 40 °C, the ethylene pressure of 1 MPa was maintained, and the reaction was stirred for 30 min. Take out a small amount of the mixture with a syringe and neutralize it with 5% dilute hydrochloric acid for GC analysis: the oligomerization activity is 1.21 × 10 6 g·mol -1 ·h -1 , the oligomer content is C 4 24.7%, C 6 ~C 10 57.4%, C 6 ~C 18 72.7% (including 92.9% of linear alpha-olefins), C 20 ~C 28 2.6%, K value 0.52. The remaining mixture was neutralized with 5% hydrochloric acid in acidified ethanol, and no polymer was obtained. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com