Preparation methods of high-viscosity polytrimethylene terephthalate and copolyester thereof

A kind of technology of polytrimethylene terephthalate, trimethylene phthalate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

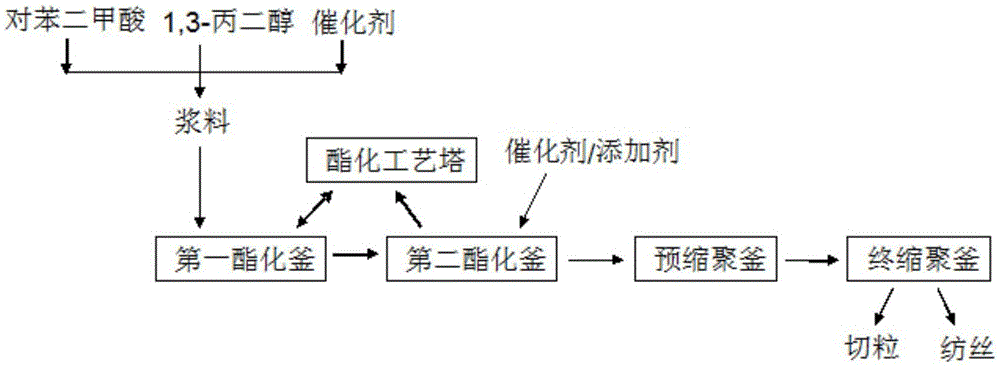

[0030] On the one hand, the invention provides a kind of preparation method of high-viscosity polytrimethylene terephthalate, figure 1 A schematic flow chart of the preparation method is shown. Such as figure 1 Shown, this preparation method comprises the steps:

[0031] Mixing step: prepare a slurry made of terephthalic acid and 1,3-propanediol at 40-60°C under normal pressure;

[0032] Primary esterification step: the slurry is continuously transported to the first esterification tank for primary esterification to obtain the first esterified product;

[0033] Secondary esterification step: transporting the first esterified product into a second esterification tank for secondary esterification to obtain a second esterified product;

[0034] Pre-condensation step: the second esterified product is continuously transported into a pre-condensation tank for polycondensation, and small molecules are removed to obtain a polytrimethylene terephthalate prepolymer;

[0035] Final p...

Embodiment 1

[0046] Prepare terephthalic acid and 1,3-propanediol in a molar ratio of 1:1.4 to form a slurry, and then continuously send it to the first esterification tank at a flow rate of 475kg / h for an esterification reaction at an absolute pressure of 140kPa At a temperature of 240° C., 0.1 kg / h of tetrabutyl titanate was continuously added and kept for 2 hours to obtain the first esterified product. Then the first esterification product enters the second esterification tank for secondary esterification reaction, and stays for 1 hour at an absolute pressure of 80 kPa and a temperature of 250° C. to obtain the second esterification product. Then the second esterified product is continuously sent into the pre-condensation tank for polycondensation reaction, and 0.1kg / h tetrabutyl titanate is added at the same time, and the temperature is raised to 260°C, and the vacuum degree is 2kPa, and the by-product is released for 30 minutes. obtained prepolymer. Finally, the prepolymer enters the...

Embodiment 2

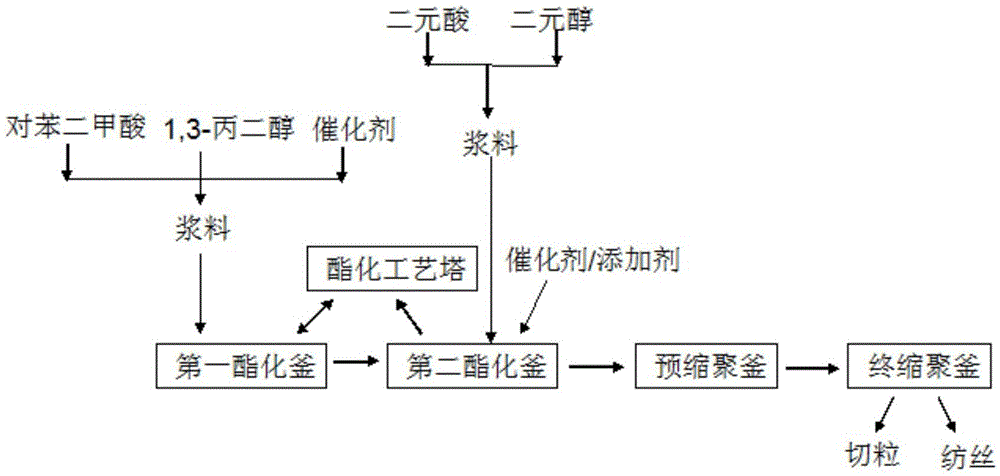

[0048] Add 350kg / h terephthalic acid, 350kg / h succinic acid and 800kg / h 1,3-propanediol into the slurry tank continuously to make a slurry, and then continuously send it to the first esterification tank for an esterification reaction , at an absolute pressure of 60kPa and a temperature of 240°C, add 0.4kg / h tetrabutyl titanate, stay for 4h, remove by-product water, and obtain the first esterified product. Then the first esterified product enters the second esterification tank for the second esterification reaction. Under the absolute pressure of 40kPa and the temperature of 240°C, it stays for 2 hours to remove by-product water to obtain the second esterified product. Then the second esterified product enters the pre-condensation tank for polycondensation reaction, and at the same time, 0.1kg / h tetrabutyl titanate is added, and the temperature is raised to 260°C, and the vacuum degree is 3kPa, and it stays for 120min to remove by-products and obtain pre-polymerization things. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com