Preparation method of organic high-polymer flocculant, and preparation method and application of inorganic-organic high-polymer composite coagulant

An organic polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of inorganic iron salt coagulant molecular weight, particle size, poor coagulation and bridging ability, etc., to achieve wide application range, settlement Good performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

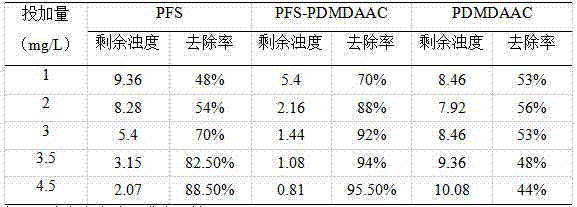

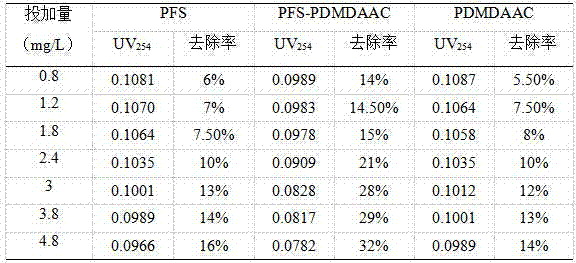

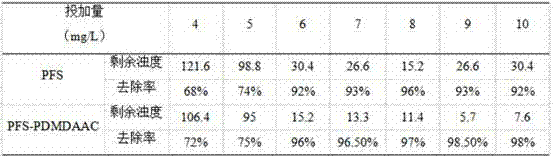

Examples

preparation example Construction

[0029] A preparation method of an inorganic-organic polymer composite coagulant, comprising the steps of:

[0030] 1) In the presence of an initiator and a chelating agent, the dimethyldiallylammonium chloride monomer is polymerized in the form of aqueous solution polymerization to obtain a colloidal solution of polydimethyldiallylammonium chloride ;

[0031] 2) heating and mixing the polyferric sulfate solution and the colloidal solution obtained in the previous step to obtain a colloidal mixed solution;

[0032] 3) Keep warm and disperse until the mixture forms a homogeneous system.

[0033] Preferably, in step 1), the polymerization is carried out in two stages: the first stage: heating to 45~65°C under stirring conditions, and reacting for 2~4 hours; the second stage stops stirring, and after raising the temperature to 55~70°C, keep warm Time 1~2h.

[0034] Preferably, in step 1), the mass ratio of the initiator to the chelating agent is (20-70):1.

[0035] Preferably,...

Embodiment 1

[0047] (1) Ammonium persulfate is used as the initiator to polymerize dimethyldiallyl ammonium chloride monomer in aqueous solution polymerization, which is carried out in two stages. In the first stage, dimethyldiallyl ammonium chloride with a mass concentration of 60% is adjusted The pH value of ammonium chloride monomer solution is 6, add initiator ammonium persulfate and metal chelating agent EDTA-4Na, heat and stir to 55°C, and continue stirring for 4h, the mass ratio of initiator ammonium persulfate and metal chelating agent EDTA-4Na 70:1, stop stirring in the second stage, heat up to 65°C, keep warm for 2 hours, prepare monomer conversion rate of 85%, intrinsic viscosity of 1.8dL / g organic polymer flocculant polydimethyldiallylammonium chloride colloidal solution.

[0048] (2) Heat the polyferric sulfate solution of 11% based on the mass fraction of total iron to 50~60°C under stirring conditions, add the colloidal solution obtained in step (1) to obtain a mixed solutio...

Embodiment 2

[0052] (1) Ammonium persulfate is used as the initiator to polymerize dimethyldiallyl ammonium chloride monomer in aqueous solution polymerization, which is carried out in two stages. In the first stage, dimethyldiallyl ammonium chloride with a mass concentration of 60% is adjusted The pH value of ammonium chloride monomer solution is 6, add initiator ammonium persulfate and metal chelating agent EDTA-4Na, heat and stir to 55°C, and continue stirring for 4h, the mass ratio of initiator ammonium persulfate and metal chelating agent EDTA-4Na 70:1, stop stirring in the second stage, heat up to 60°C, keep warm for 1h, prepare monomer conversion rate of 80%, intrinsic viscosity of 1.4dL / g organic polymer flocculant polydimethyldiallylammonium chloride colloidal solution.

[0053] (2) Heat the polyferric sulfate solution of 11% based on the mass fraction of total iron to 50~60°C under stirring conditions, add the colloidal solution obtained in step (1) to obtain a mixed solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com