High-stability modified Y-type molecular sieve for high production of isomerized C4 and preparation method of high-stability modified Y-type molecular sieve

A molecular sieve and modification technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, refined hydrocarbon oil, etc., can solve the problems of inability to effectively increase the content of isomeric hydrocarbons in gasoline, poor thermal and hydrothermal stability of Y molecular sieve, and low zeolite crystallization retention etc. to achieve the effects of high stability, high crystallinity and low coke selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

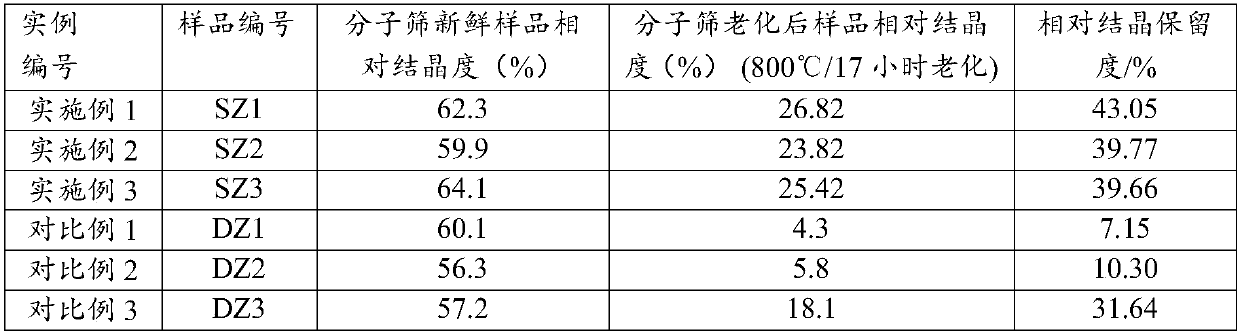

Examples

Embodiment approach

[0032] The preparation method of the modified Y-type molecular sieve provided by the invention, a kind of embodiment comprises the following steps:

[0033] (1) NaY molecular sieve (also known as NaY zeolite) is contacted with a mixed solution of soluble calcium salt and rare earth salt for ion exchange reaction, filtered and washed to obtain calcium and rare earth conventional unit cell size Y type with reduced sodium oxide content Molecular sieve; the ion exchange is usually exchanged for 30 to 120 minutes at a temperature of 15 to 95° C., preferably 65 to 95° C.;

[0034] (2) Calcium-containing and rare earth-containing conventional Y-type molecular sieves with a reduced sodium oxide content are calcined for 4.5-7 hours at a temperature of 350-480° C. in an atmosphere containing 30-90% by volume of water vapor, and dried, Obtaining a Y-type molecular sieve with a reduced unit cell constant whose water content is less than 1% by weight; the unit cell constant of the Y-type m...

Embodiment 1

[0043] Get 2000 grams of NaY molecular sieves (on a dry basis) and add to 20 liters of decationized aqueous solution and stir to make it evenly mixed, and add 345ml of Ca(NO 3 ) 2 solution (concentration of the solution in terms of CaO is 248g / L), then add 300ml of RE (NO 3 ) 3 Solution (rare earth solution concentration is RE 2 o 3 Calculated as 319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a unit cell constant of 2.471nm, a sodium oxide content of 6.6% by weight, and calcium oxide based on CaO. Content 4.9% by weight, with RE 2 o 3 A Y-type molecular sieve with a total rare earth content of 4.4% by weight is then roasted for 6 hours at a temperature of 390° C. in an atmosphere containing 50 volume percent water vapor and 50 volume percent air to obtain a Y-type molecular sieve with a unit cell constant of 2.455 nm. After that, carry out Drying process, so that its water content is les...

Embodiment 2

[0046] Get 2000 grams of NaY molecular sieves (on a dry basis) and add them to 25 liters of decationized aqueous solution and stir to make them evenly mixed. Add 368ml of CaCl 2 solution (concentration of solution in terms of CaO: 248g / L), 400ml of RECl 3 solution (in RE 2 o 3 The calculated solution concentration is: 319g / L), stirred, heated up to 90-95°C, kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a unit cell constant of 2.471nm and a sodium oxide content of 5.2% by weight %, Calcium content in terms of CaO is 8.7% by weight, in terms of RE 2 o 3 A Y-type molecular sieve with a total rare earth content of 5.7% by weight is then calcined at a temperature of 450°C and 80% water vapor for 5.5 hours to obtain a Y-type molecular sieve with a unit cell constant of 2.461nm, and then dried to reduce its water content at 1 wt%, then follow SiCl 4 : Y-type zeolite = 0.6:1 weight ratio, feed SiCl vaporized by heating 4 The gas was rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com