Patents

Literature

61results about How to "Increase isohydrocarbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

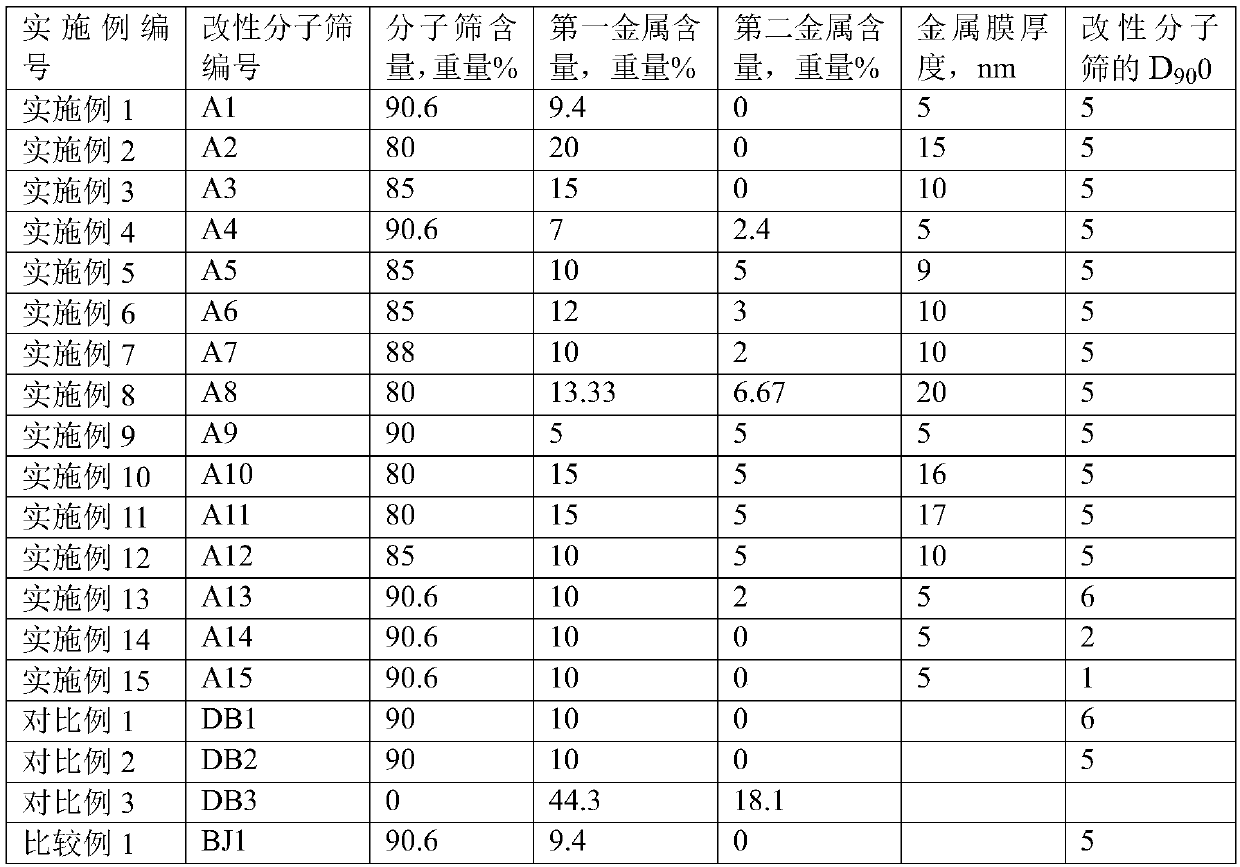

Catalyst for preparing gasoline by coupling naphtha and methanol and preparation method of catalyst

ActiveCN108080022AHigh yieldIncrease isohydrocarbon contentMolecular sieve catalystsHeterogenous catalyst chemical elementsChemistryMolecular sieve

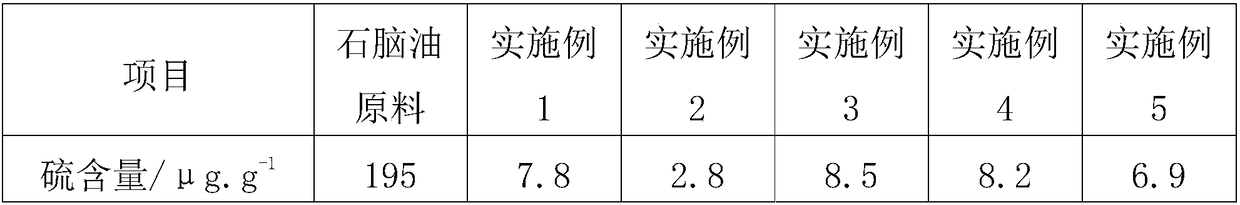

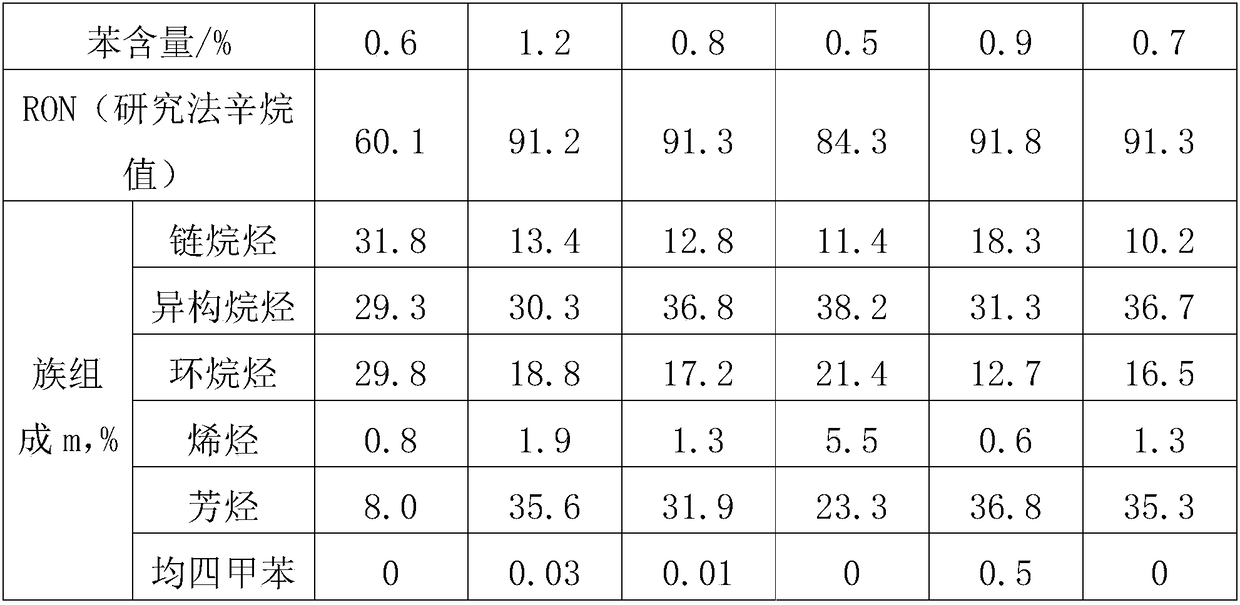

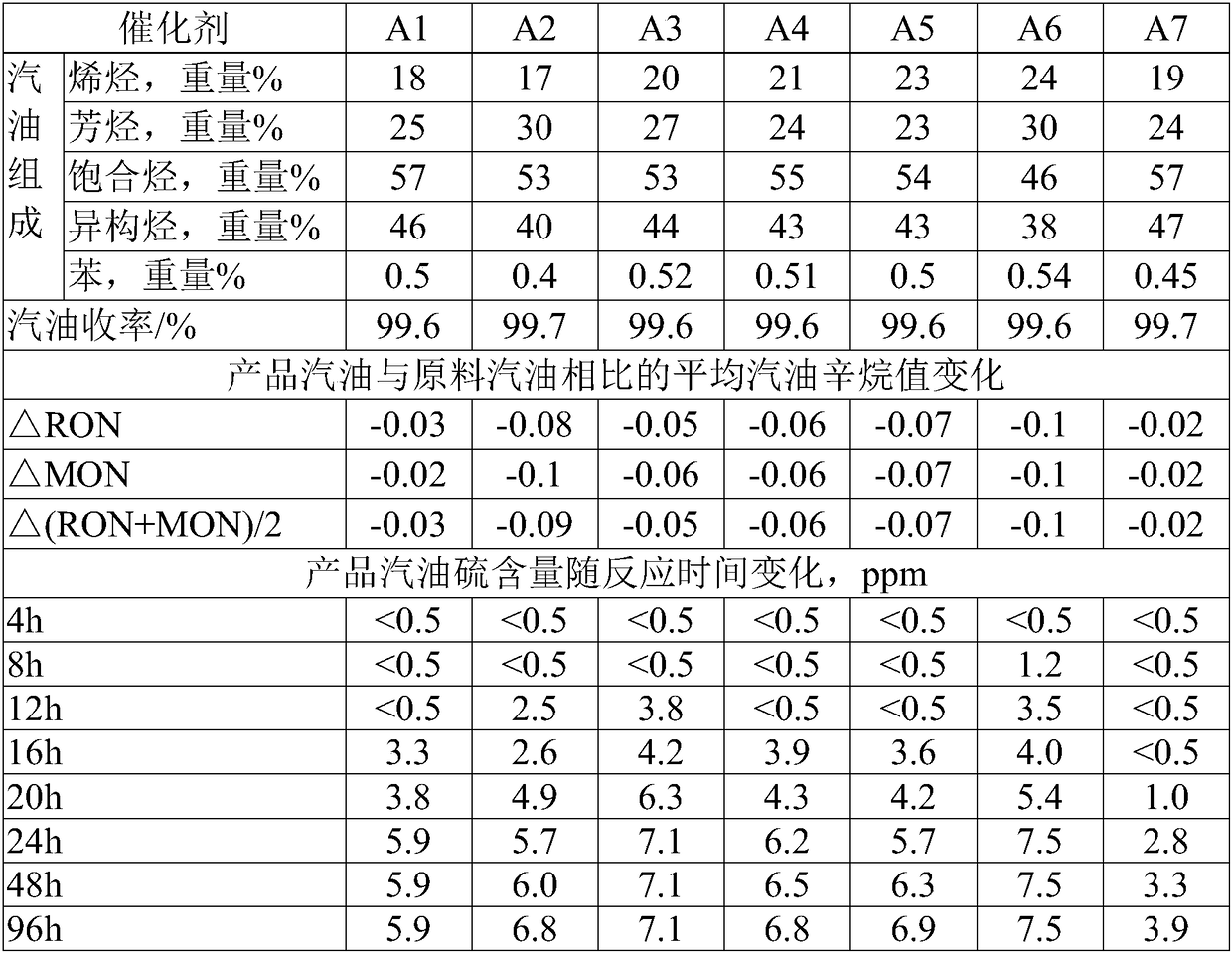

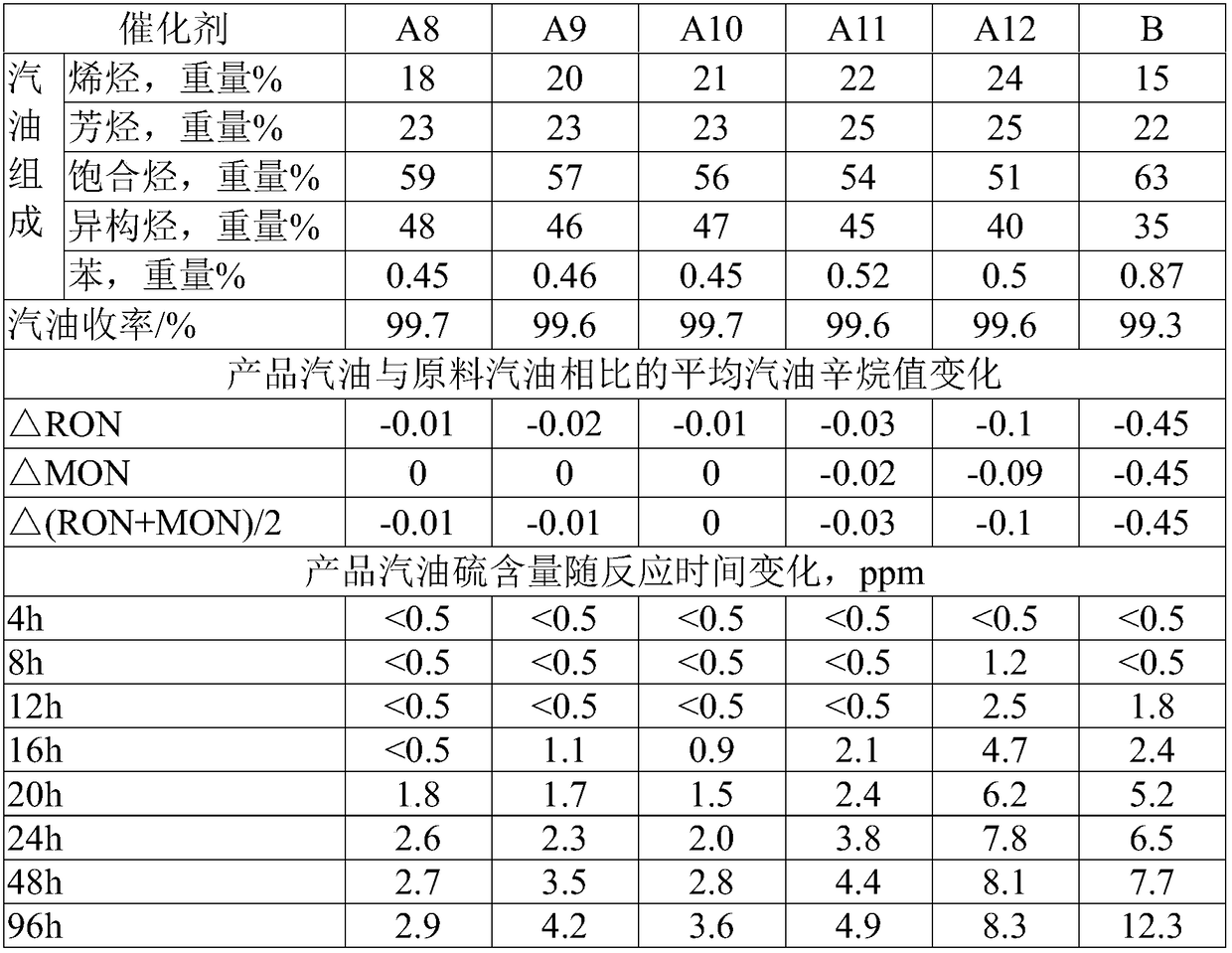

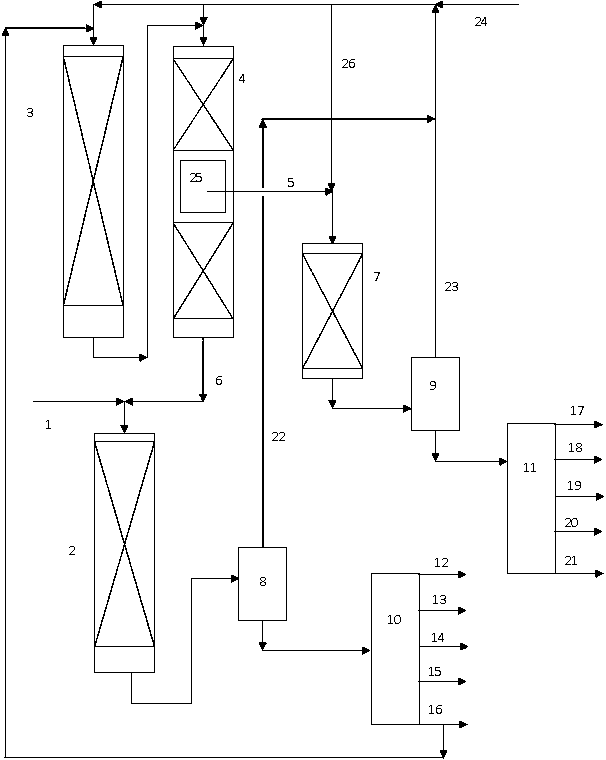

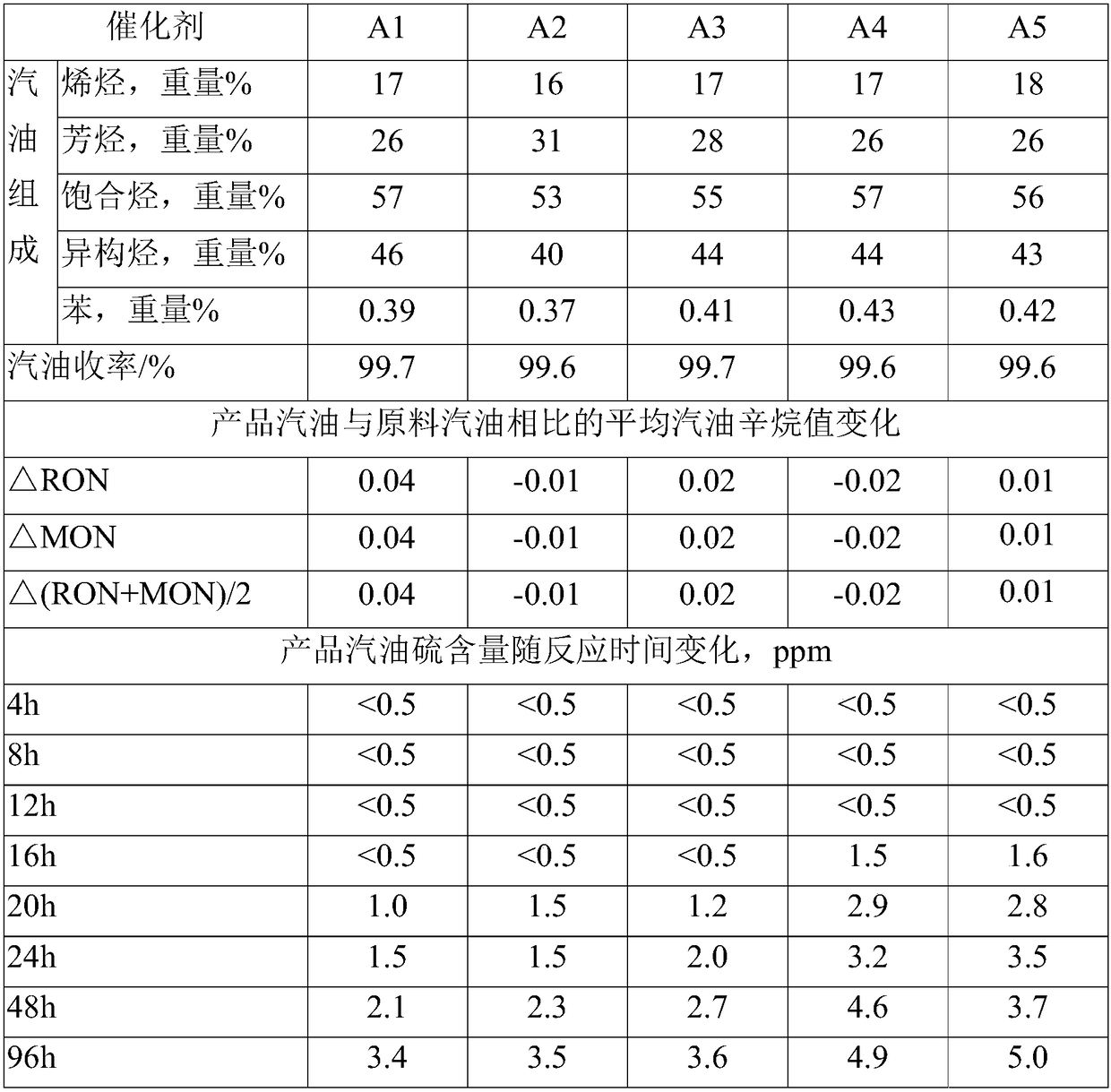

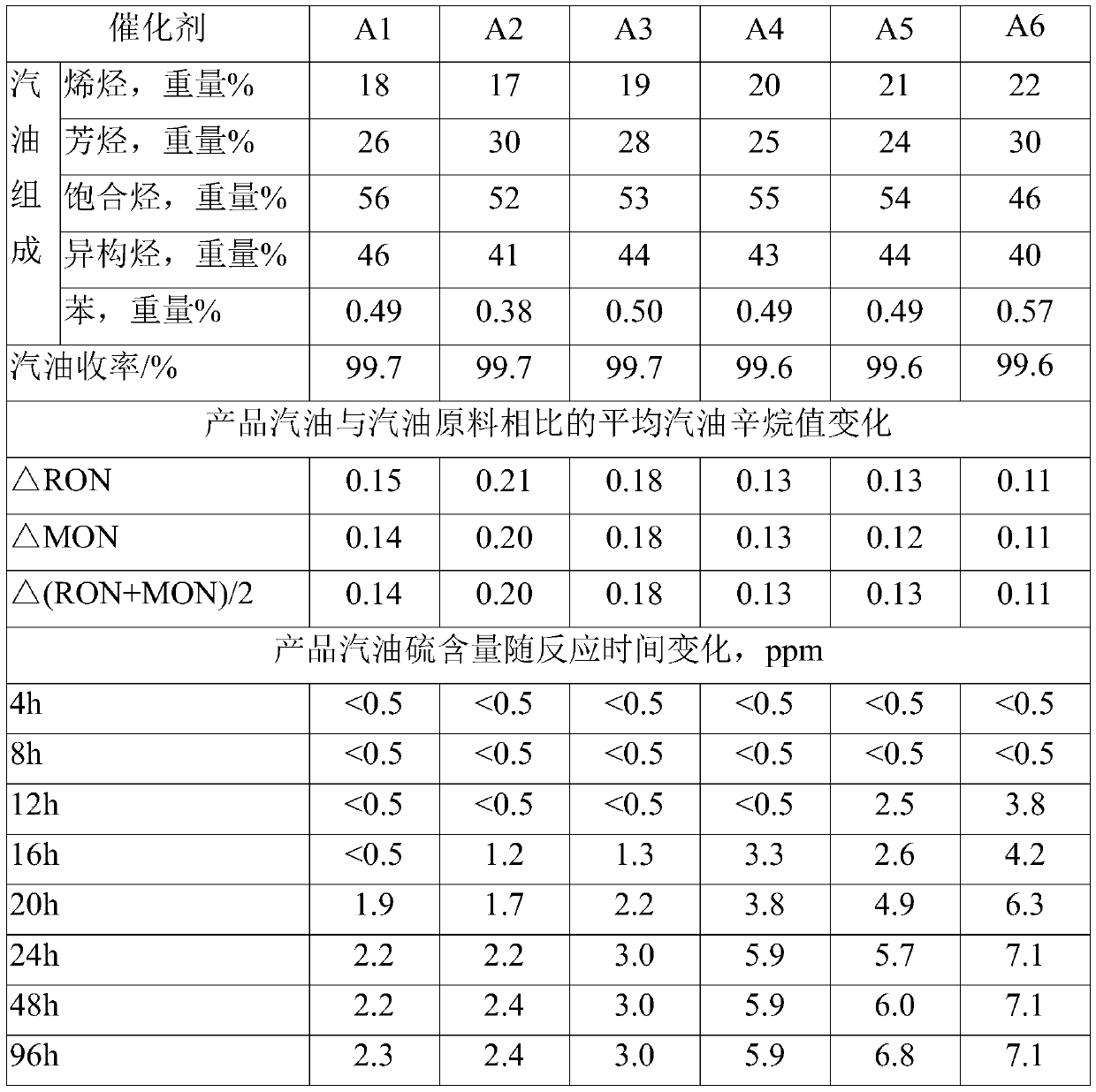

The invention relates to the technical field of catalysts, in particular to a catalyst for preparing gasoline by coupling naphtha and methanol and a preparation method of the catalyst. The catalyst isprepared from a component A, a component B and a component C, wherein the component A is prepared from a metal-modified small-grain HZSM-5 molecular sieve; the component B is prepared from one or more of a metal-modified HZSM-5 molecular sieve, an HZSM-22 molecular sieve, an HZSM-35 molecular sieve, an Hbeta zeolite molecular sieve and an H-type mordenite molecular sieve; the component C is prepared from a metal complex oxide. The catalyst provided by the invention has the functions of light hydrocarbon aromatization and methanol alkylation, and greatly reduces the content of durene; and thecatalyst provided by the invention has an isomerization function. and effectively increases the octane number of gasoline; and the catalyst provided by the invention has a desulfurization function, and effectively reduces the sulfur content of gasoline, so that the sulfur content of an obtained product is lower than 10ppm, and is up to the national V standard.

Owner:SINOPEC ENG GRP CO LTD

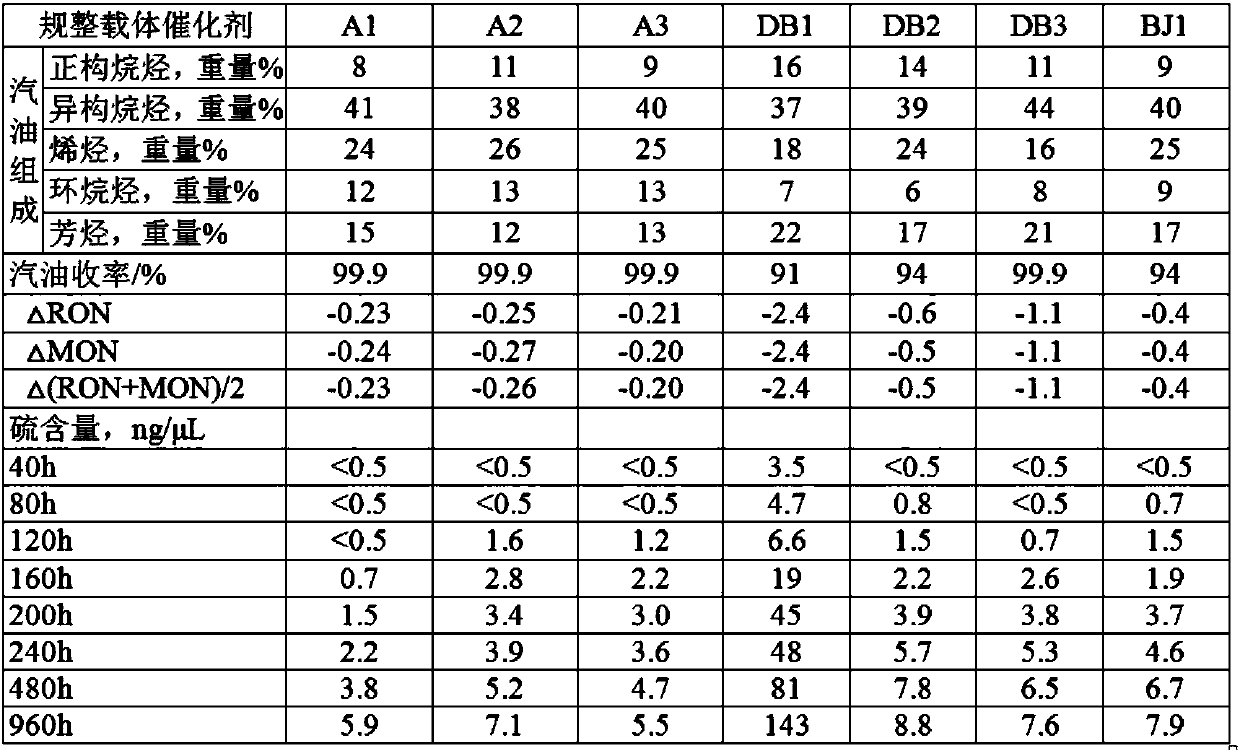

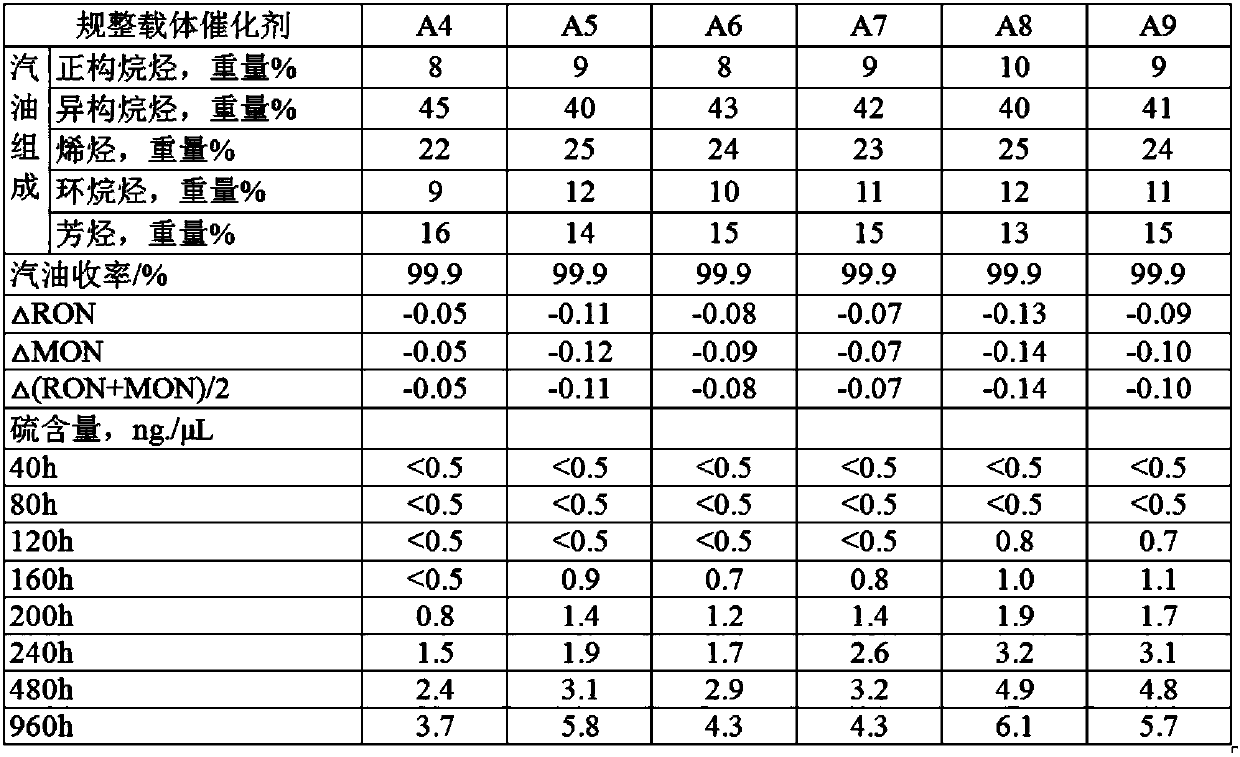

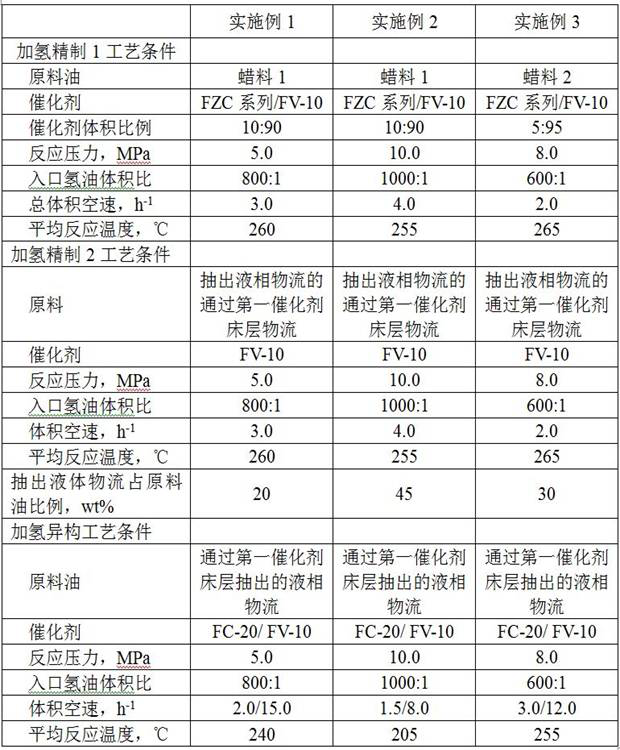

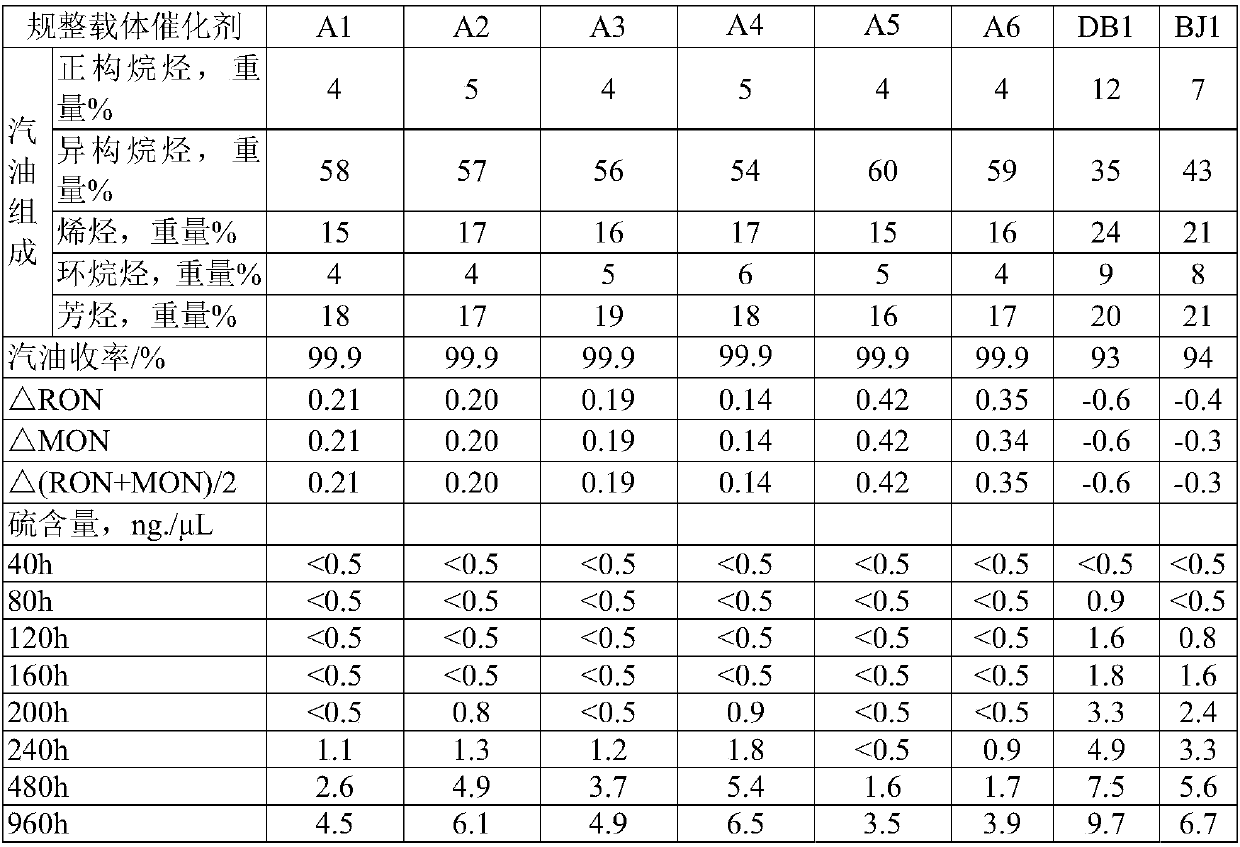

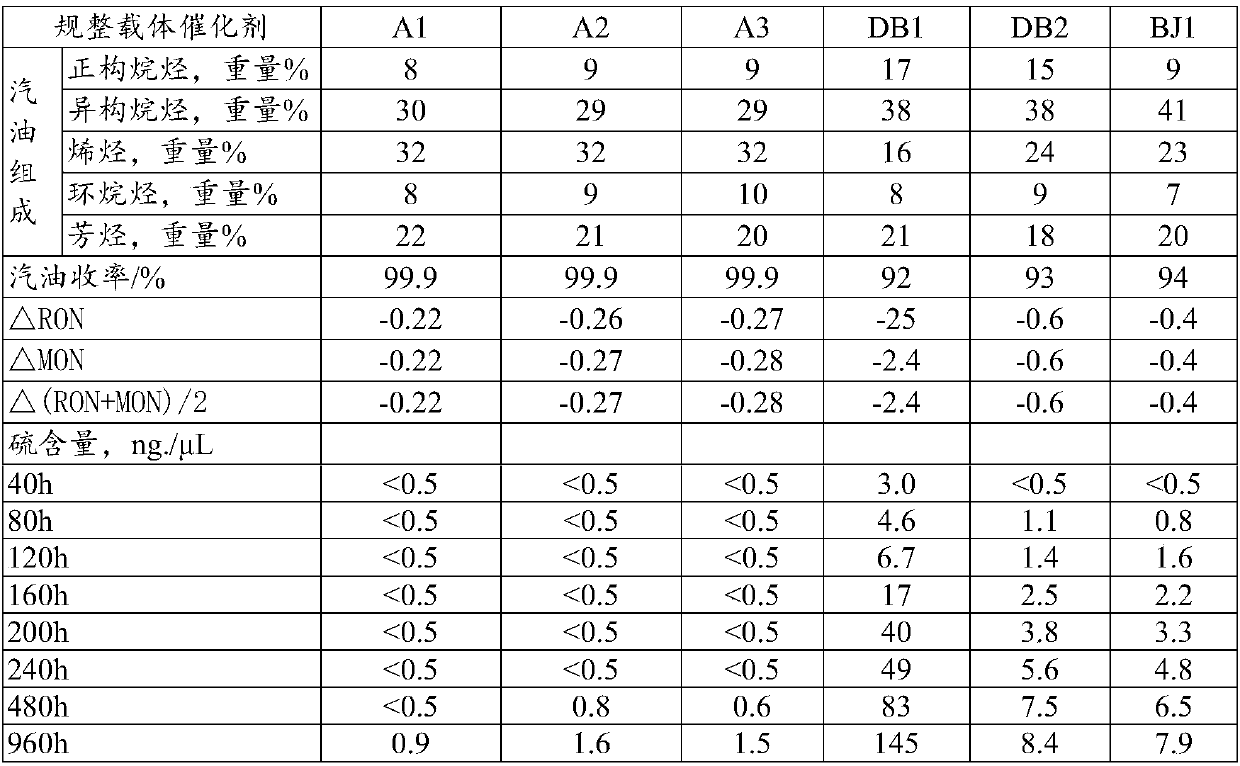

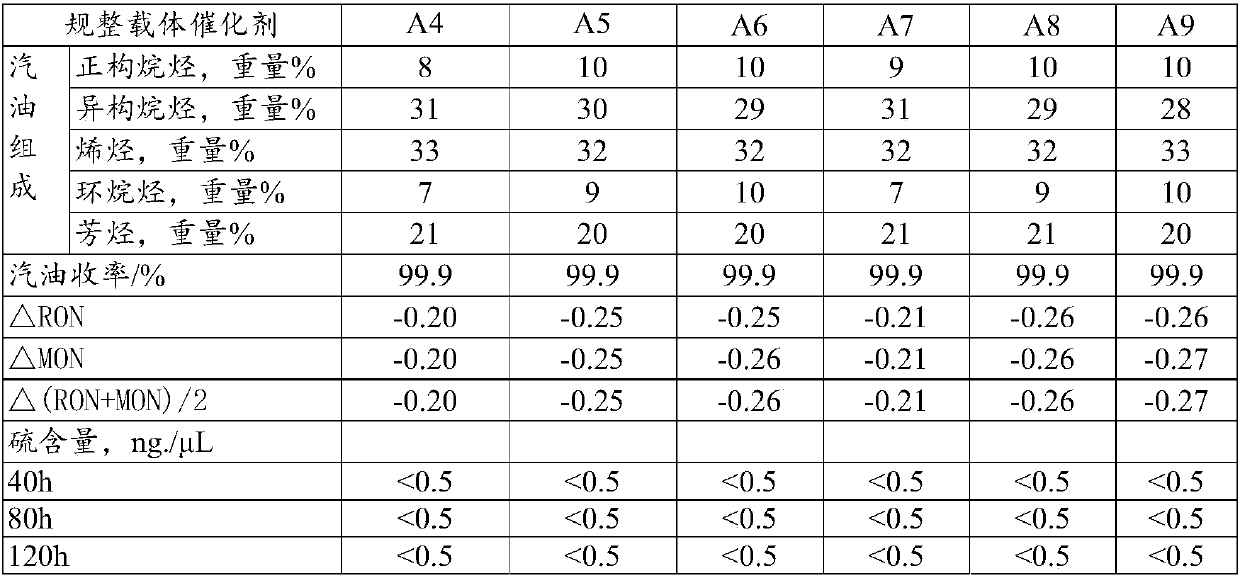

Regular structure desulfurization catalyst and preparation method thereof, and sulfur-containing hydrocarbon desulfurization method

ActiveCN108404946AHigh desulfurization activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatment productsTransition metal carbidesActive component

The invention discloses a regular structure desulfurization catalyst and a preparation method thereof, and a sulfur-containing hydrocarbon desulfurization method. The catalyst comprises a regular structure carrier and an active component coating distributed on the inner surface and / or outer surface of the regular structure carrier, wherein the active component coating comprises, by weight, 5-70 wt% of a transition metal carbide and 30-95 wt% of a matrix, and the matrix comprises, by weight, 5-35 wt% of alumina, 5-35 wt% of a silica source, and 30-90 wt% of the oxide of at least a metal selected from group IIA and group IIB. The catalyst of the present invention has good desulfurization activity and good desulfurization stability, and can improve the octane number of the desulfurized oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

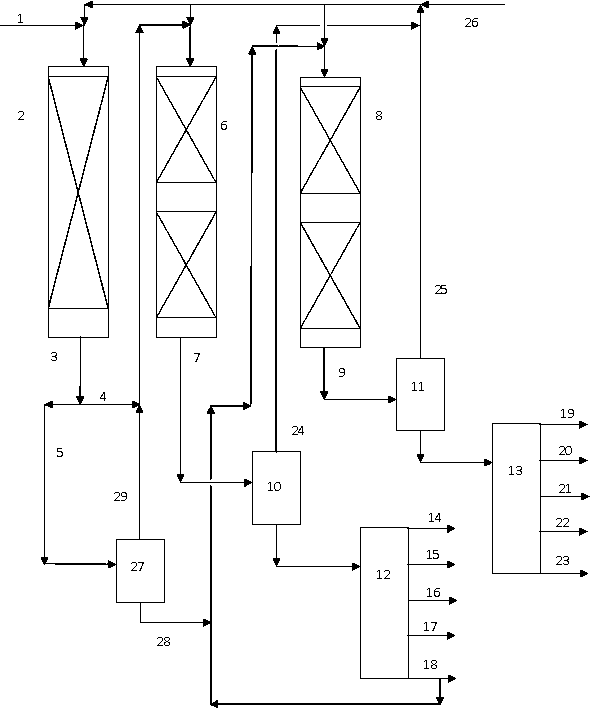

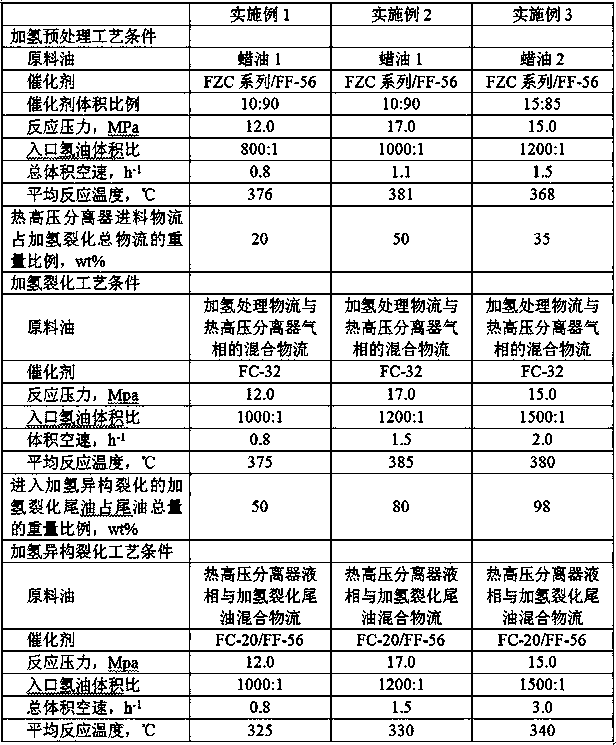

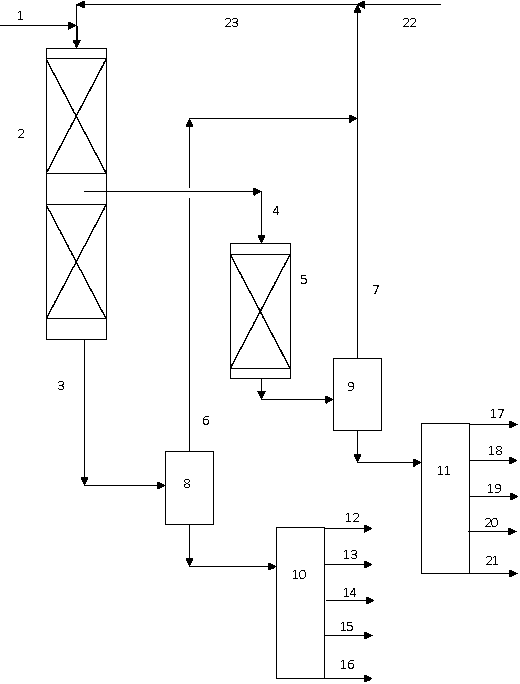

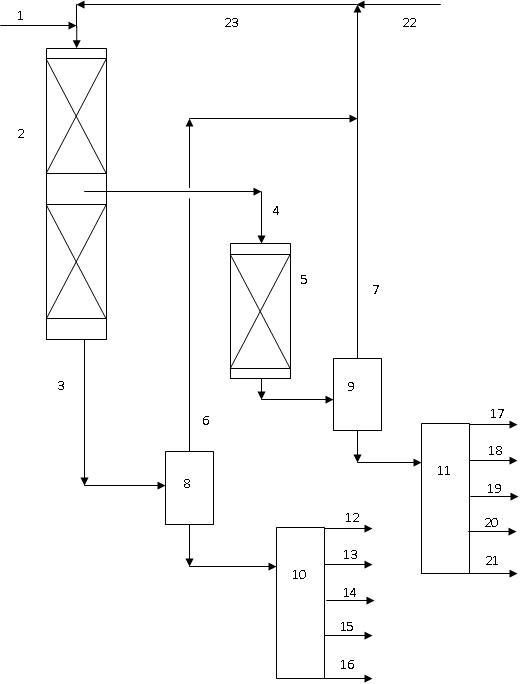

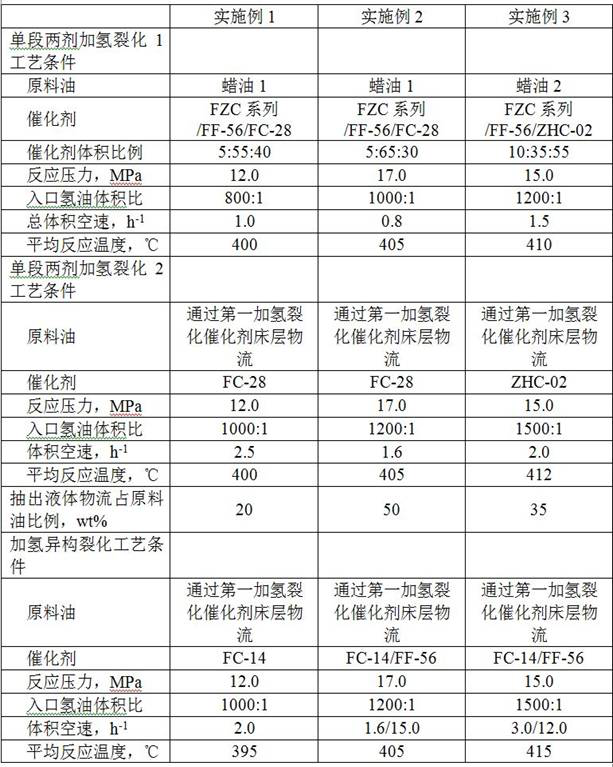

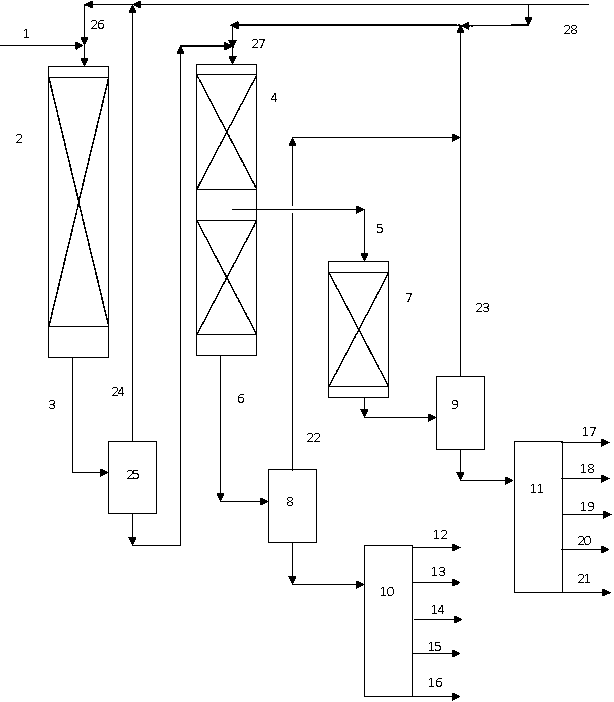

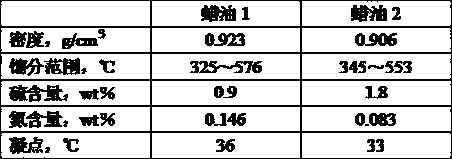

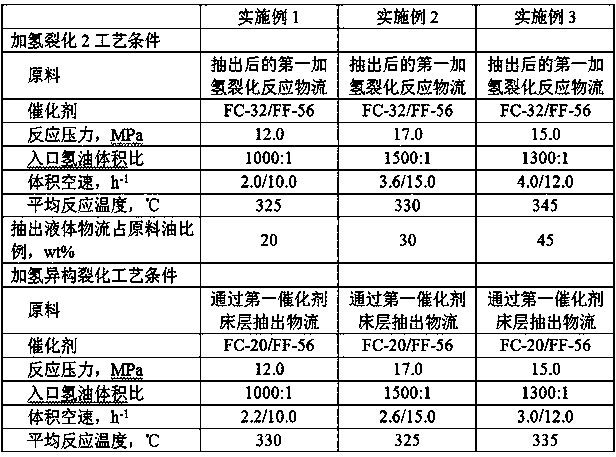

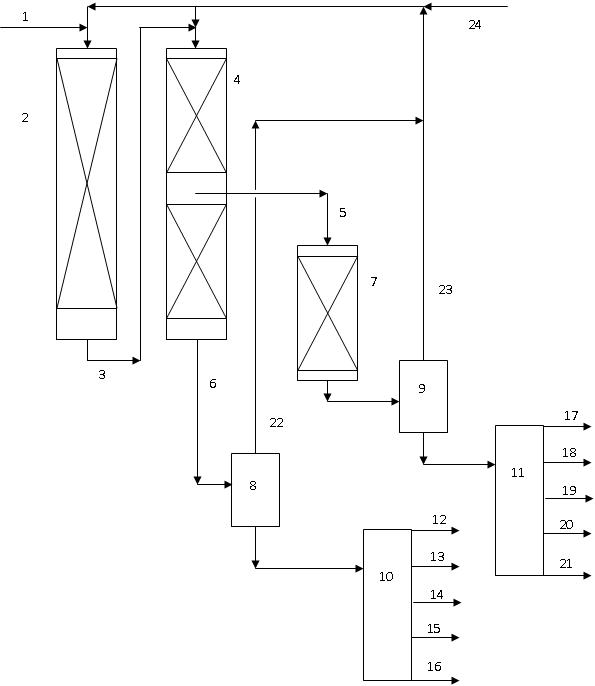

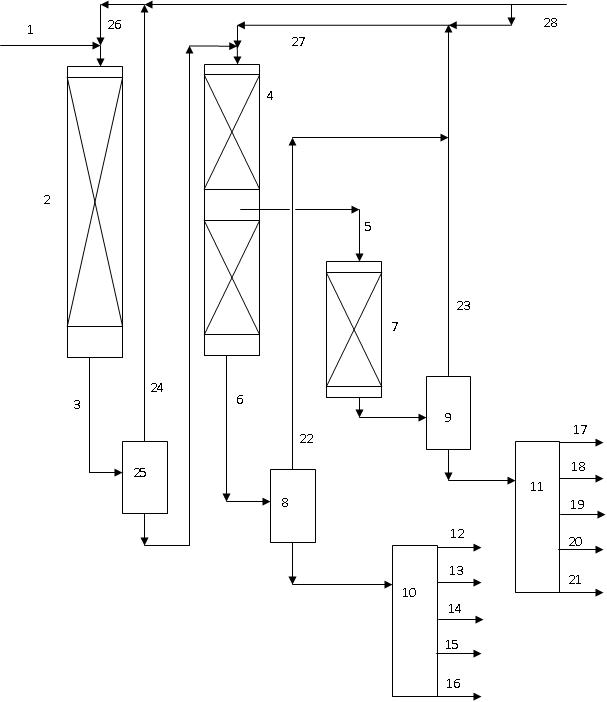

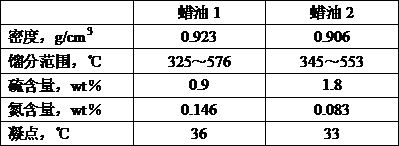

Flexible reverse-sequence hydrocracking process

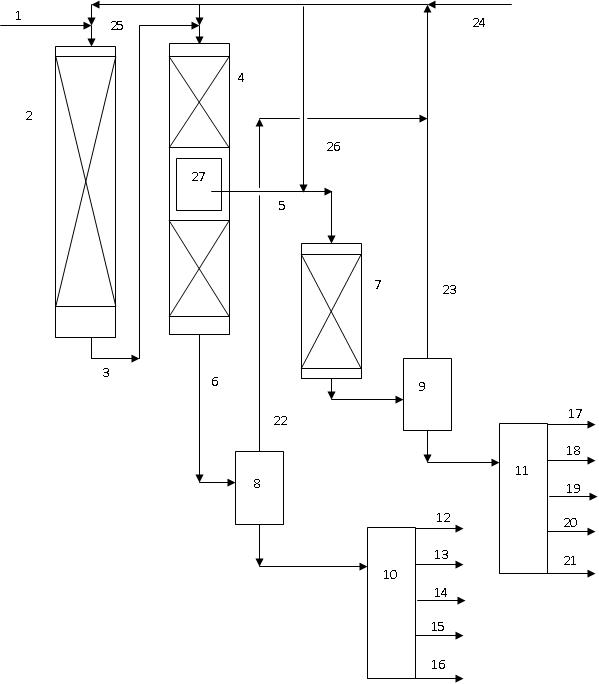

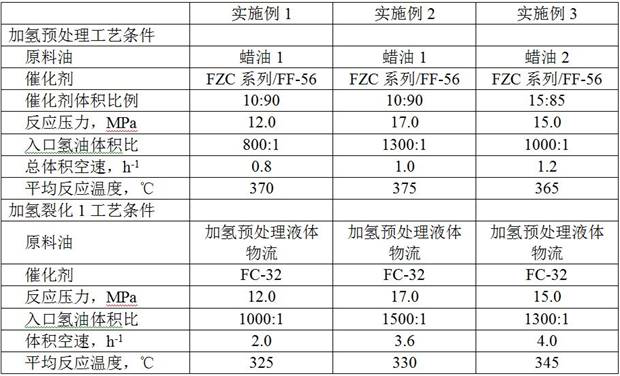

ActiveCN109988623AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

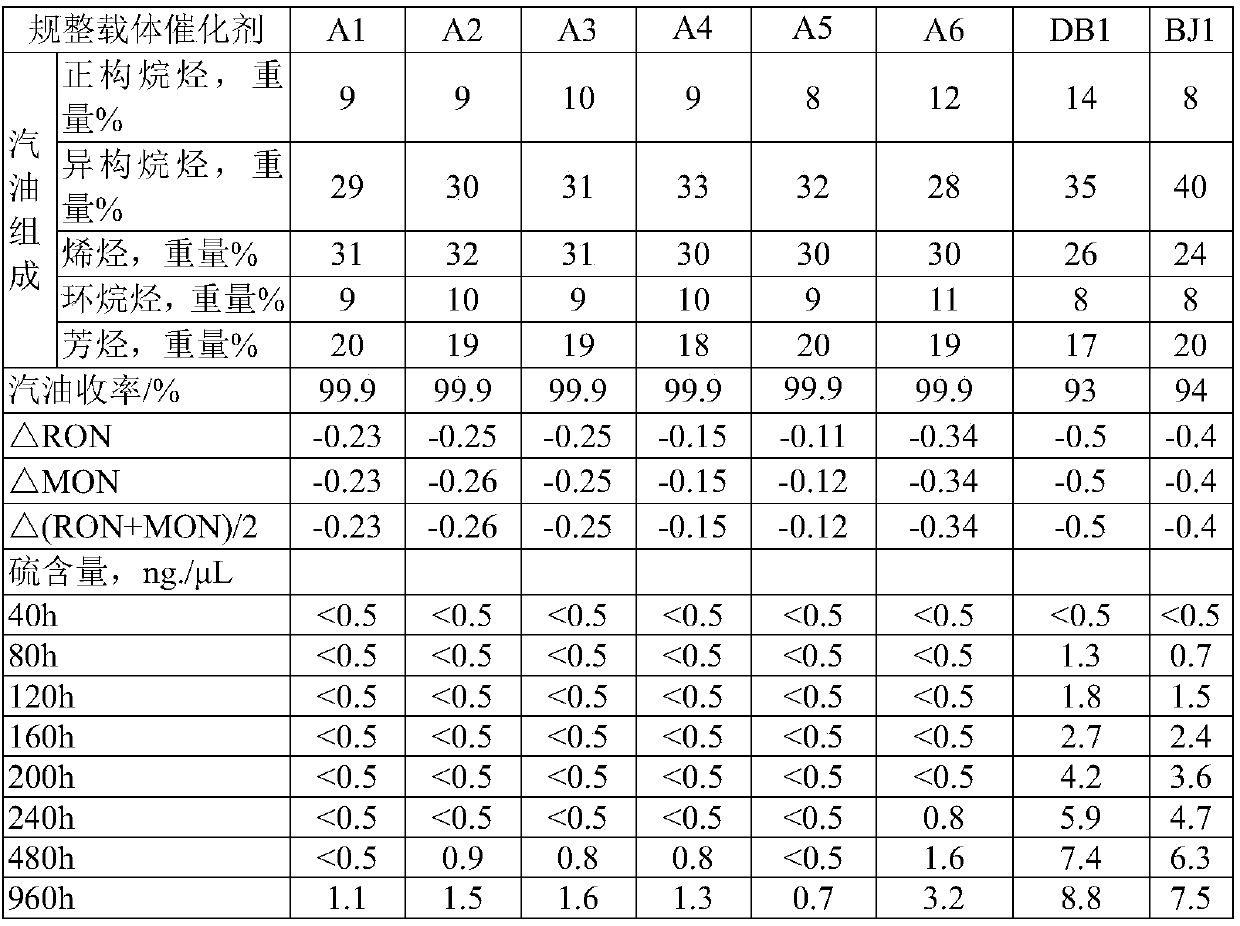

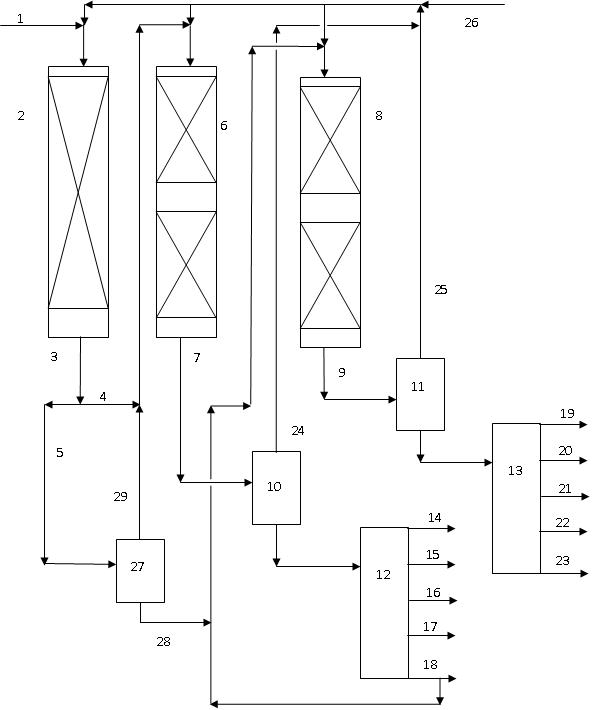

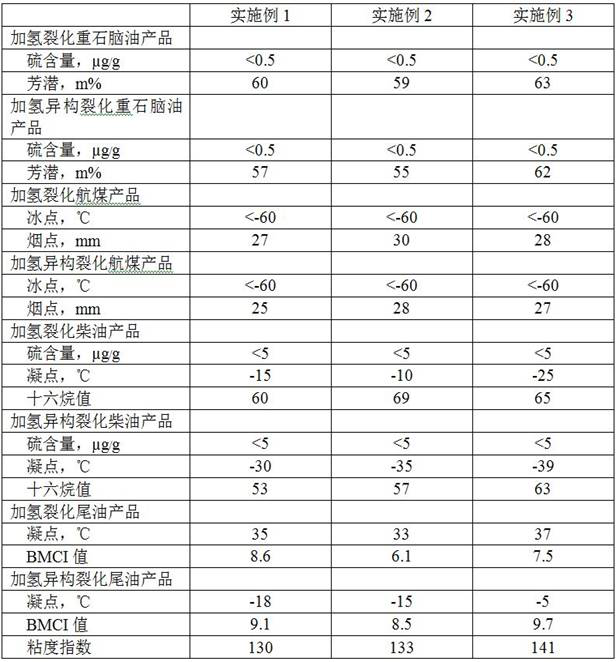

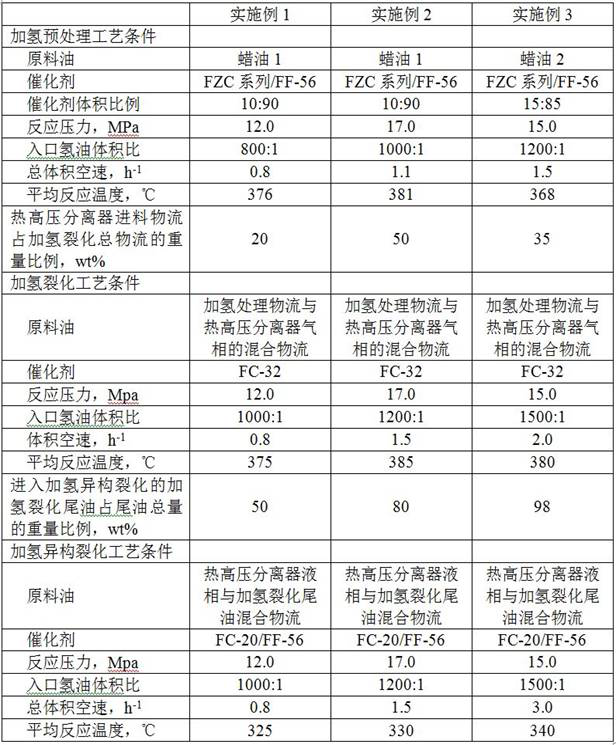

The invention discloses a flexible reverse-sequence hydrocracking process. The process comprises the following steps: mixing wax oil raw oil with a hydrocracked material; carrying out hydrogenation pretreatment; carrying out separation fractionation on the hydrogenation pretreated material flow to obtain gas, distillate oil and tail oil; carrying out hydrocracking pretreatment on the obtained tailoil, allowing the tail oil to pass through a first hydrocracking catalyst bed layer in a hydrocracking reactor to obtain a material, and dividing the obtained material into two streams; separating one material stream in a separator, extracting the obtained liquid phase out of the hydrocracking reactor, and subjecting the liquid phase to an isomerization cracking reaction in a hydroisomerization cracking reactor; allowing the other material stream to flow downward to pass through a second hydrocracking catalyst bed layer; and carrying out gas-liquid separation and fractionation on a hydroisomerization cracking reaction product to obtain hydroisomerization cracked naphtha, aviation kerosene, diesel oil and tail oil products. The invention provides the hydrocracking process for simultaneously producing more than two different-specification light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular structure desulfurization catalyst and preparation method thereof, and sulfur-containing hydrocarbon desulfurization method

ActiveCN108404951AHigh desulfurization activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatment productsActive componentRare earth

The invention discloses a regular structure desulfurization catalyst and a preparation method thereof, and a sulfur-containing hydrocarbon desulfurization method. The catalyst comprises a regular structure carrier and an active component coating distributed on the inner surface and / or outer surface of the regular structure carrier, wherein the active component coating comprises, by weight, 5-70 wt% of a transition metal nitride and 30-95 wt% of a matrix, and the matrix comprises, by weight, 5-35 wt% of alumina, 0.5-10 wt% of a rare earth oxide, and 60-90 wt% of the oxide of at least a metal selected from group IIA and group IIB. The catalyst of the present invention has good desulfurization activity and good desulfurization stability, and can improve the octane number of the desulfurized oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

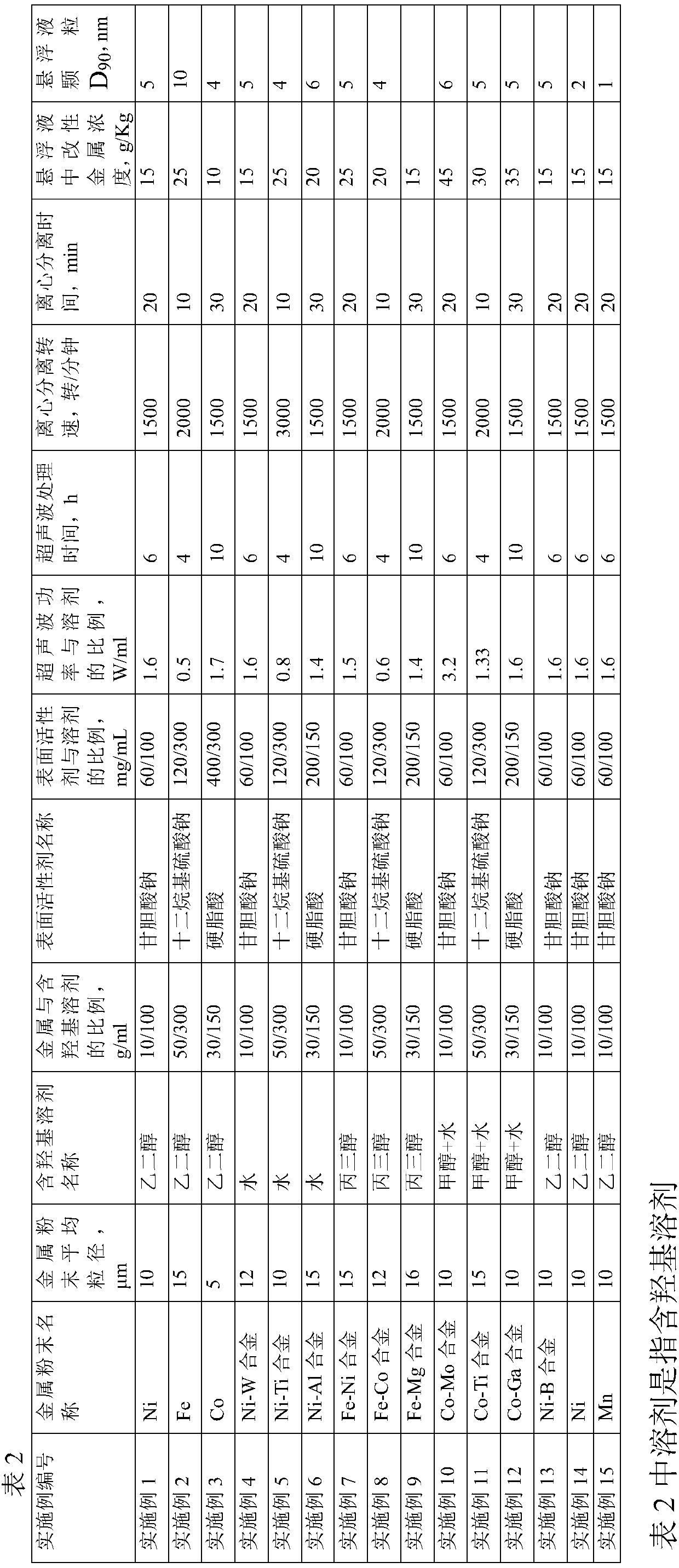

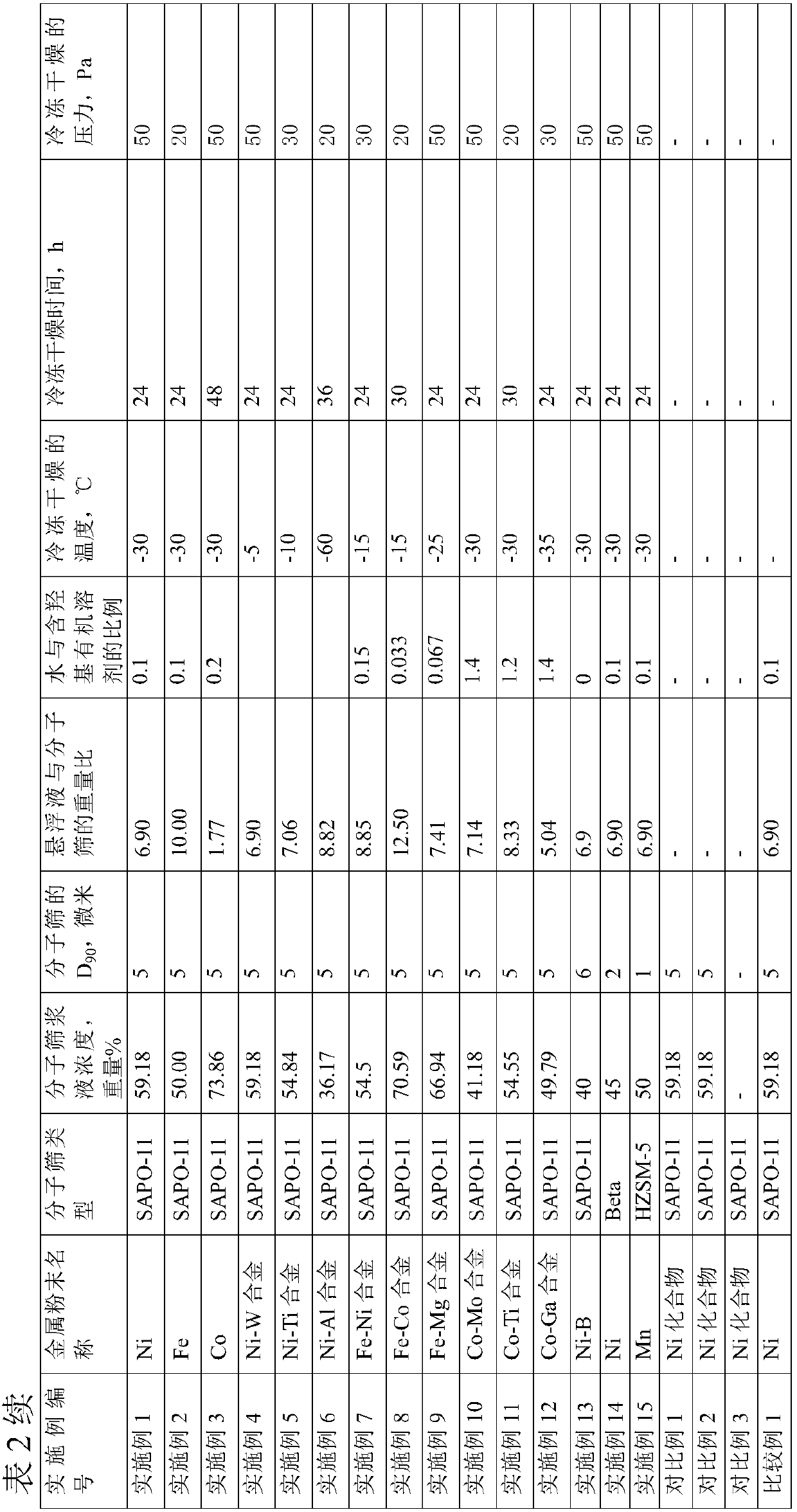

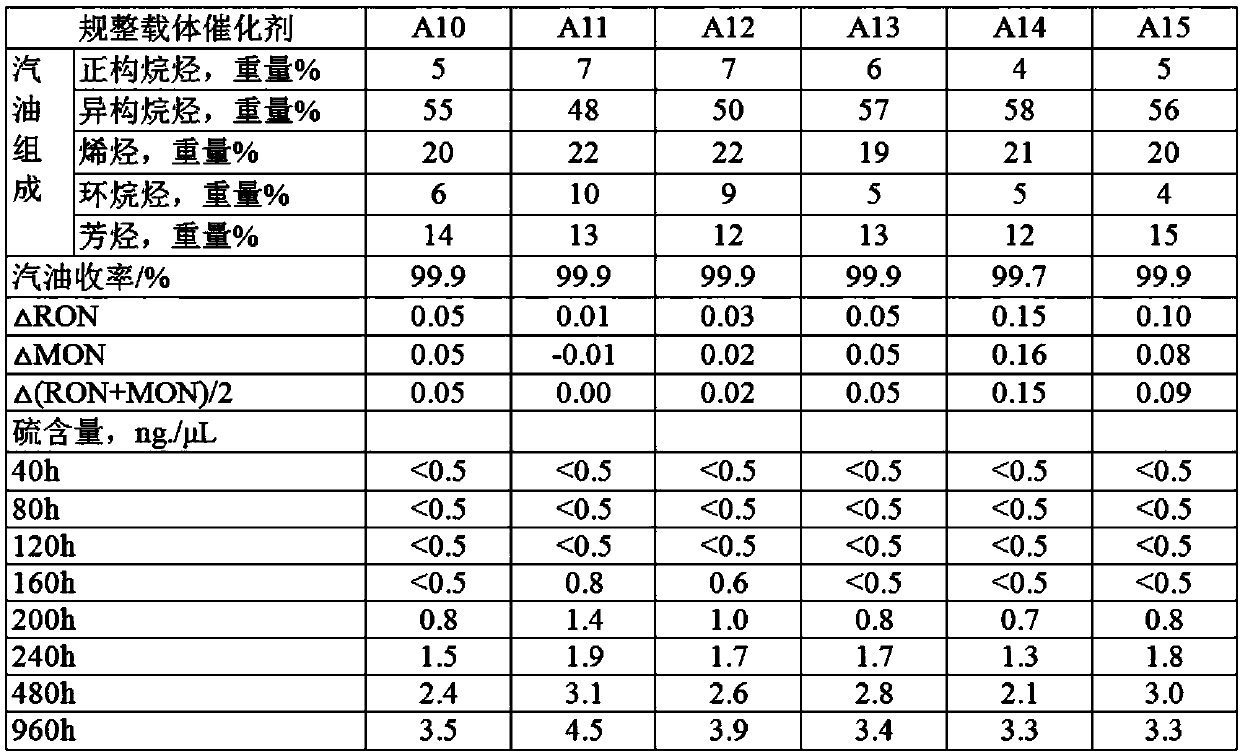

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

PendingCN111085187AHigh activityHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsPtru catalystActive agent

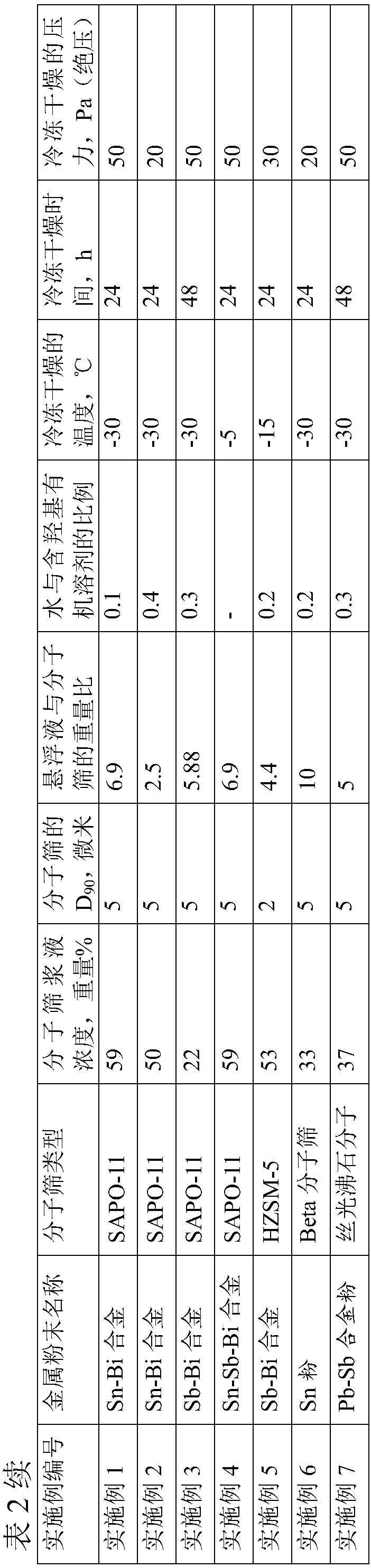

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the surface of the regular carrier, wherein the active coating comprises a matrix containing IIA and IIB group metal oxides and a modified metal film attached to the outer surfaceof the matrix, the modified metal film comprises a modified metal, and the modified metal comprises one or more of Cr, Mo and W. The preparation method comprises the following steps: forming a mixturefrom metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; after the ultrasonic treatment, separating the mixed solution to obtain suspension; contacting the suspension with matrix particles, carrying out freeze drying to obtain matrix particles containing a modified metal film, andcoating the regular carrier with the matrix particles containing the modified metal film to obtain the regular carrier catalyst. The catalyst is used for hydrocarbon hydro-desulfurization, has high desulfurization activity and good stability, and can reduce the octane number loss of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for producing lubricant base oil

ActiveCN109988620AFlexible Hydrocracking ProcessFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking process for producing lubricant base oil. A material obtained after a wax oil raw material is subjected to hydrogenation pretreatment is divided into two parts; a part of the material is separated by a hot high-pressure separator to obtain a liquid phase, and the liquid phase is mixed with hydrogen and then passes through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; the other part of the material is mixed with a gas phase obtained by hot high-pressure separation and hydrocracking tail oil and then passes through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; a hydrocracking reaction product and a hydroisomerization cracking reaction product are subjectedto gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications; and the hydrocracking tail oil is partially or completely circulatedinto the isomerization cracking reactor. The process provided by the invention can be used for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially producing high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified molecular sieve for hydro-desulfurization as well as preparation and application thereof

PendingCN111085262AHigh desulfurization activityHigh desulfurization rateMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveActive agent

The invention discloses a modified molecular sieve for hydro-desulfurization as well as preparation and application thereof. The modified molecular sieve comprises a molecular sieve and a modifying metal film positioned on the outer surface of molecular sieve particles, wherein the modifying metal film contains one or more first modifying metals selected from Fe, Co, Ni and Mn and optional B. Thepreparation method of the modified molecular sieve comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonic treatment to obtain suspension, mixing the suspension with a molecular sieve, and carrying out freeze-drying to obtain the modified molecular sieve. The modified molecular weight is used for hydro-desulfurization of sulfur-containing hydrocarbons, has high activity and stability, can obviously reduce the olefin content, increase the iso-hydrocarbon content and increase the octane number of gasoline when used for gasoline desulfurization, and has a high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular structure desulfurization catalyst and preparation method thereof, and sulfur-containing hydrocarbon desulfurization method

ActiveCN108404945AHigh desulfurization activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentTransition metal carbidesActive component

The invention discloses a regular structure desulfurization catalyst and a preparation method thereof, and a sulfur-containing hydrocarbon desulfurization method. The catalyst comprises a regular structure carrier and an active component coating distributed on the inner surface and / or outer surface of the regular structure carrier, wherein the active component coating comprises, by weight, 5-70 wt% of a transition metal carbide and 30-95 wt% of a matrix, and the matrix comprises, by weight, 5-35 wt% of a non-aluminum binder, 0.5-10 wt% of a rare earth oxide, and 60-90 wt% of the oxide of at least a metal selected from group IIA and group IIB. The catalyst of the present invention has good desulfurization activity and good desulfurization stability, and can improve the octane number of thedesulfurized oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

PendingCN111085258AHigh activityHigh desulfurization activityMolecular sieve catalystsHydrocarbon oils refiningPtru catalystFreeze-drying

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the outer surface of the regular carrier, the active coating comprises a IIA and IIB group metal oxide-containing matrix, a molecular sieve and a modified metal film, and the modified metal film comprises nickel and one or more rare earth metals selected from lanthanum, cerium, praseodymium and neodymium. The preparation method comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonic treatment to obtain suspension; contacting the suspension with matrix particles and / or molecular sieve particles or particles containing a matrix and a molecular sieve, carrying out freeze-drying, and then coating on a regular carrier. The catalyst can be used for hydro-desulfurization of hydrocarbon fuel, has the characteristics of high activity and good stability, is used for gasoline desulfurization, and can increase the octane number of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

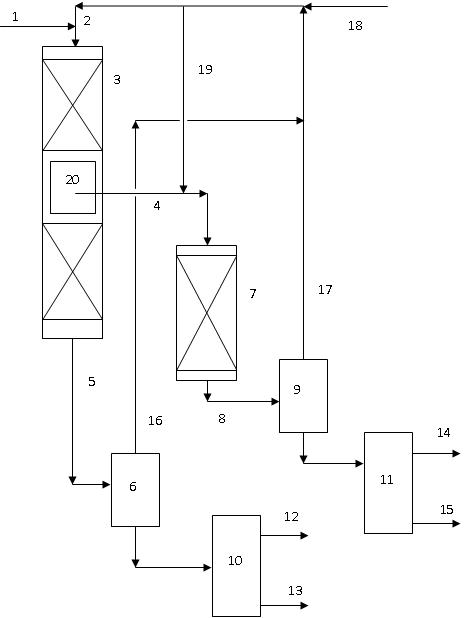

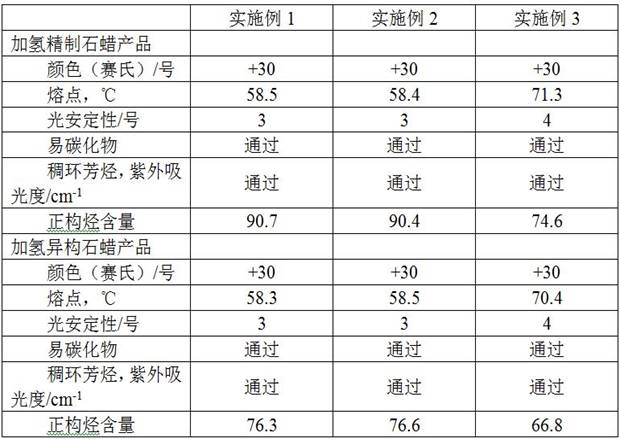

Flexible paraffin liquid phase hydrogenation process

ActiveCN109988608AEffective distributionFlexible productionPetroleum wax refiningTreatment with hydrotreatment processesParaffin waxIsomerization

The invention discloses a flexible paraffin liquid phase hydrogenation process. A paraffin raw material and circulating oil enter a liquid-phase hydrofining reactor under a liquid-phase hydrogenationcondition; the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the liquid-phase hydrofining reactor from the middle of the bed layer, and fed into a liquid-phase hydroisomerization reactor for isomerization reaction; the other material stream continues flowing downward to pass through a lower hydrofining catalystbed layer; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain paraffin products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two paraffin products with different specifications on one set of liquid-phase hydrogenation process equipment for the first time, heat carried by a part of hydrofined materials can be fully utilized, and coupling operation of the liquid-phase hydrofining reactor and the liquid-phase hydroisomerization reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible vaseline hydrogenation process

ActiveCN109988597AEffective distributionFlexible productionHydrocarbon oils treatmentIsomerizationVapor–liquid separator

The invention discloses a flexible vaseline hydrogenation process. A vaseline raw material enters a hydrofining reactor, and the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is separated by a gas-liquid separator arranged in the middle of the bed layer, and the obtained liquid is extracted out of the hydrofining reactor and mixedwith hydrogen and then enters a hydroisomerization reactor to be subjected to an isomerization reaction; the other material stream is a mixture stream of gas in the reactor and a residual liquid after extraction, and the mixture stream flows downwards through a hydrofining catalyst bed layer at the lower part; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are respectively subjected to gas-liquid separation and fractionation to obtain vaseline products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two vaseline products with different specifications on a set of hydrogenation process equipment for the first time, heat carried by part of hydrofined materials can be fully utilized, and coupling operation of the hydrofining reactor and the hydroisomerization reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

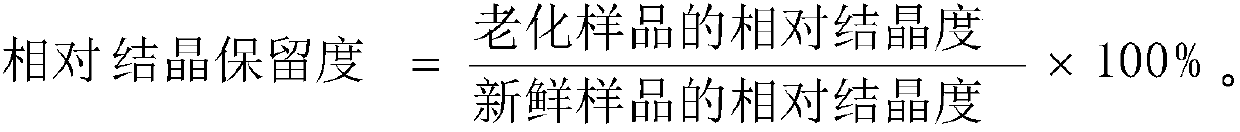

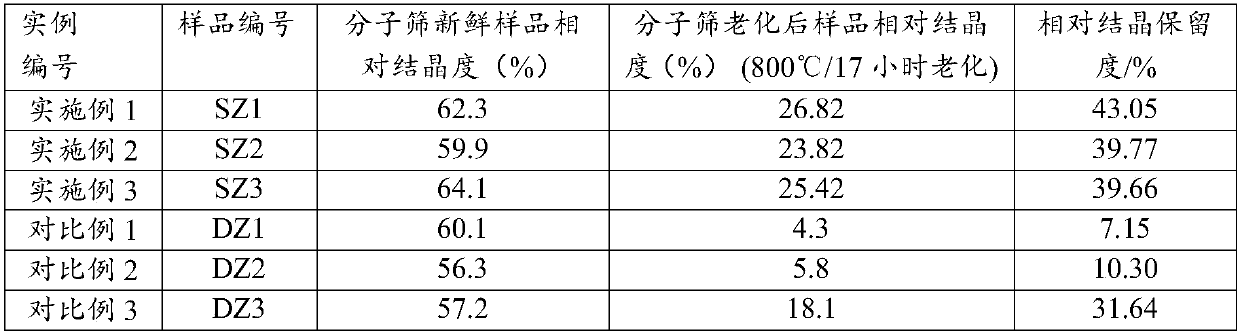

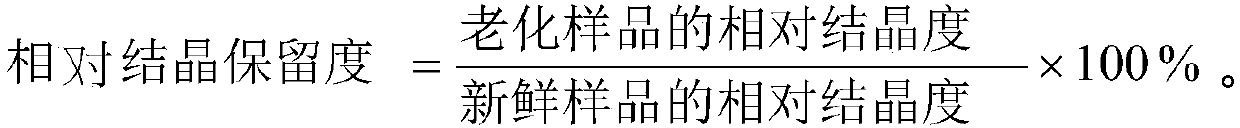

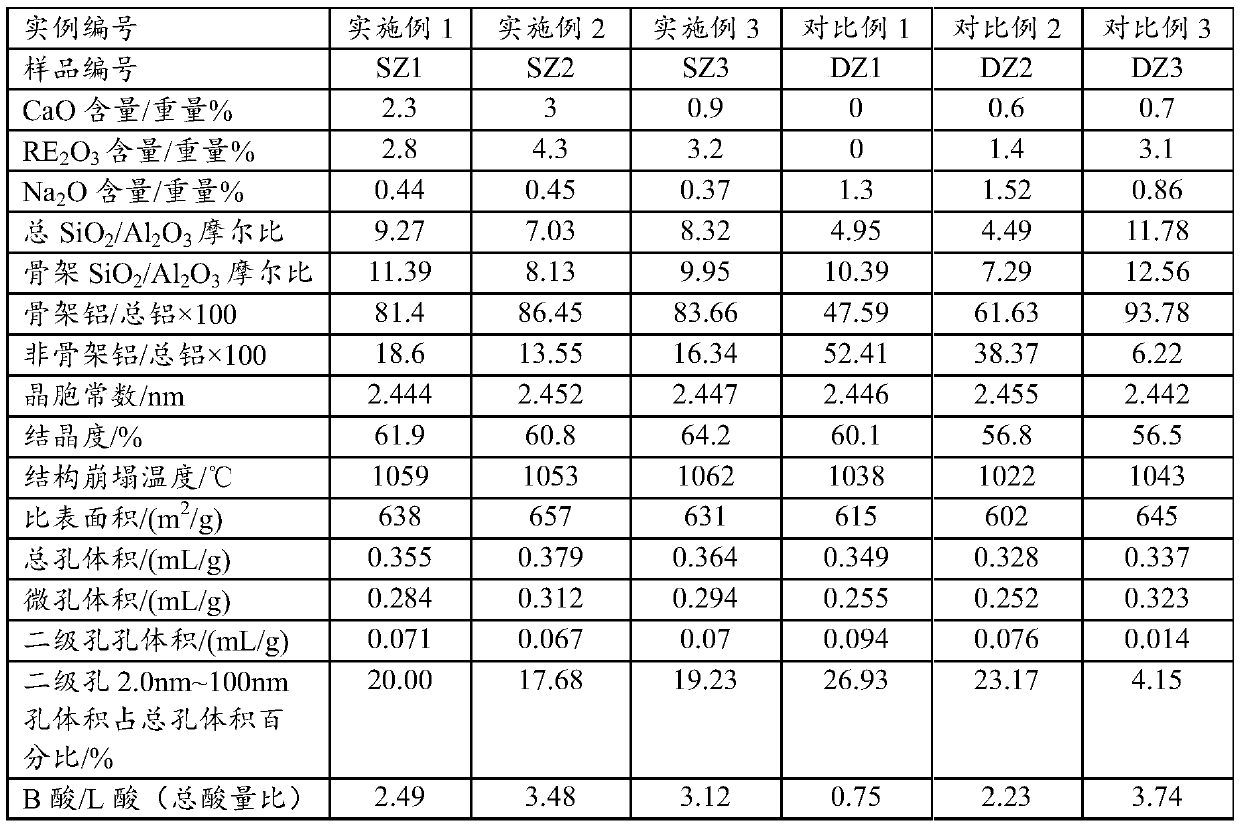

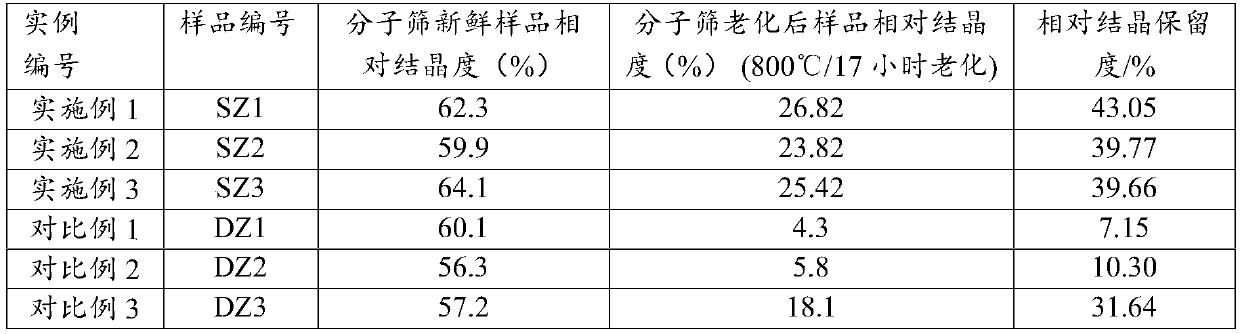

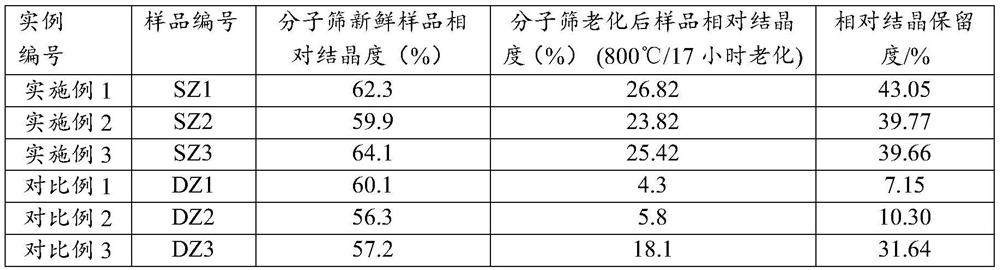

High-stability modified Y-type molecular sieve for high production of isomerized C4 and preparation method of high-stability modified Y-type molecular sieve

ActiveCN110652999AHigh thermal and hydrothermal stabilityHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePhysical chemistry

The invention discloses a high-stability modified Y-type molecular sieve for high production of isomerized C4 and a preparation method of the high-stability modified Y-type molecular sieve. The CaO content of the modified Y-type molecular sieve is 0.3-4 wt%, the RE2O3 content is 2 to 7 wt%; the content of Na2O is 0.1 to 0.5 wt%; the total pore volume is 0.33 mL / g to 0.39 mL / g; the pore volume of the secondary pores of 2-100nm accounts for 10-25% of the total pore volume; the lattice constant is 2.440-2.455 nm, the content of non-framework aluminum accounts for not more than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of the amount of acid B to the amount of acid L measured by a pyridine adsorption infrared method at 200 DEG C is not lower than 2.30. The preparation method comprises the steps of ion exchange, modification treatment under certain temperature and water vapor conditions and reaction with silicon tetrachloride. The modified Y-type molecular sieve has higher heavy oil conversion activity, lower coke selectivity, higher gasoline yield and isomeric C4 yield, and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking method for producing lubricant base oil

ActiveCN109988642AHigh normal hydrocarbon contentHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking method for producing lubricant base oil. The method includes dividing a wax oil raw material subjected to hydrogenation pretreatment into two parts; separating one part of the material by a hot high-pressure separator to obtain a gas phase and a liquid phase; mixing the other part of the material with the gas phase obtained by hot high-pressure separation and circulating hydrogen, and allowing the mixture to pass through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; mixing the liquid phase obtained by hot high-pressureseparation with hydrocracking tail oil and circulating hydrogen, and allowing the mixture to pass through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; respectively carrying out gas-liquid separation and fractionation on a hydrocracking reaction product and a hydroisomerization cracking reaction product to obtain distillate oil and tailoil products with different specifications; and partially or completely circulating the hydrocracking tail oil to an isomerization cracking reactor. The invention provides the flexible hydrocrackingmethod for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on a set of hydrogenation process equipment for the first time, especially high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN110653001AHigh hydrothermal stabilityHigh conversion activity of heavy oilCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The catalytic cracking catalyst comprises a modified Y-type molecular sieve, an alumina binder and clay; according to the modified Y-type molecular sieve, the CaO content of the modified Y-type molecular sieve is 0.3-4% by weight, the RE2O3 content is 2 to 7 wt%, the content of sodium oxide is 0.1 wt%-0.5 wt%, the total pore volume is 0.33 mL / g to 0.39 mL / g, the pore volume of secondary pores withthe pore diameter of 2nm-100nm of the modified Y-type molecular sieve accounts for 10%-25% of the total pore volume, the lattice constant is 2.440 to 2.455nm, the content of non-framework aluminum inthe modified Y-type molecular sieve is not higher than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of the amount of acid B to the amount of acid L is not lower than 2.30. The catalytic cracking catalyst has the advantages of higher heavy oil conversion activity, lower coke selectivity, higher gasoline yield, higher isomeric C4 yield and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

InactiveCN111085206AHigh activityHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsPtru catalystActive agent

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the surface of the regular carrier, wherein the active coating comprises a heat-resistant inorganic oxide matrix and a modified metal film, the modified metal film comprises a modified metal, and the modified metal is one or more of Fe, Co, Ni, Mn, Ti, Zr, V, Ge, Pb, Sn, Sb and Bi. The preparation method comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonictreatment to obtain suspension; contacting the suspension with matrix particles, carrying out freeze drying so as to obtain matrix particles containing a modified metal film, and then coating the regular carrier with the matrix particles containing the modified metal film so as to obtain the regular carrier catalyst. The catalyst is high in desulfurization activity, good in stability and high inproduct yield, is used for gasoline desulfurization and is small in octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible paraffin hydrogenation process

ActiveCN109988637BEffective distributionFlexible productionPetroleum wax refiningTreatment with hydrotreatment processesParaffin waxPtru catalyst

The invention discloses a flexible paraffin hydrogenation process. The paraffin wax raw material enters the hydrofining reactor, and the material after passing through the upper hydrofining catalyst bed is divided into two streams; one stream of material passes through the gas-liquid separator installed in the middle of the bed, and the separated liquid is drawn out of the refining reactor and mixed with hydrogen into the The hydroisomerization reactor carries out the isomerization reaction; the other material is the gas in the reactor and the remaining liquid mixture flow after extraction, and the mixture flow continues to flow down through the lower hydrofinishing catalyst bed; the resulting hydrofinishing reaction The material and the hydroisomerization reaction material are subjected to gas-liquid separation and fractionation respectively to obtain paraffin products of different specifications. The present invention provides a hydrogenation process for the simultaneous production of two or more paraffin products of different specifications on a set of hydrogenation process equipment for the first time, which can make full use of the heat carried by part of the hydrogenation refining material to realize the hydrogenation refining reactor and hydrogenation process. Coupling operation of hydroisomerization reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

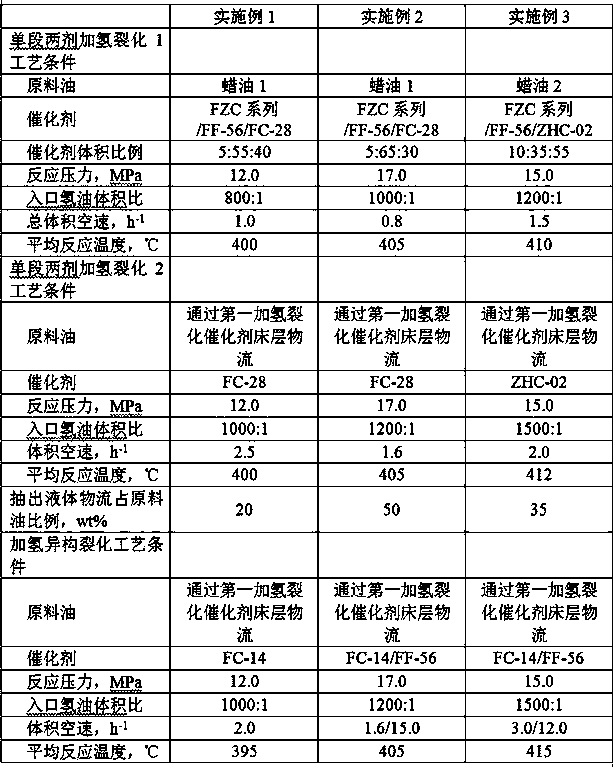

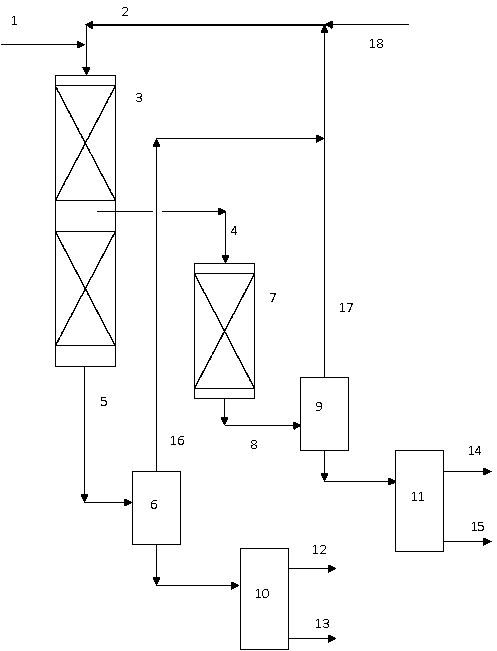

A flexible single-stage two-catalyst hydrocracking process

ActiveCN109988618AFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystIsomerization

The invention discloses a flexible single-stage two-catalyst hydrocracking process. A wax oil raw material and hydrogen are mixed and then enter a single-stage two-catalyst hydrocracking reactor, andthe material passing through an upper hydrogenation pretreatment catalyst bed layer and a single-stage hydrocracking catalyst bed layer is divided into two streams; one material stream is extracted out of the single-stage reactor from the middle of the bed layers, enters a hydroisomerization cracking reactor and subjected to isomerization cracking reaction; the other material stream flows downwards through a single-stage hydrocracking catalyst bed layer at the lower part; and a single-stage hydrocracking reaction product and a hydroisomerization cracking reaction product are respectively separated and fractionated to obtain distillate oil and tail oil products with different specifications. The invention provides the process for simultaneously producing more than two types of light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on a set of hydrogenation process equipment. In the process, heat carried by part of cracked materials can be fully utilized, and coupling operation of the single-stage two-catalyst hydrocracking reactor and the hydroisomerization cracking reactor is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

InactiveCN111085256AHigh activityHigh desulfurization activityMolecular sieve catalystsHydrocarbon oils refiningPtru catalystActive agent

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The catalyst comprises a regular carrier and an active coating attachedto the outer surface of the regular carrier, the active coating comprises a IIA and IIB group metal oxide-containing matrix, a molecular sieve and a modified metal film, the modified metal film comprises a modified metal, and the modified metal comprises one or more of Cr, Mo and W. The preparation method comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonic treatment to obtain suspension; contacting the suspension with matrix particles and / or molecular sieve particles or particles containing a matrix and a molecular sieve, freeze-drying, and then coating on a regular carrier. The catalyst can be used for hydro-desulfurization of hydrocarbon fuel, has the characteristics of high activity and good stability, is used for gasoline desulfurization, and can increase the octane number of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular structure desulfurization catalyst, preparation method thereof, and method for desulfurization of sulfur-containing hydrocarbons

ActiveCN108404952BHigh desulfurization activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentPtru catalystPhysical chemistry

The invention discloses a regular structure desulfurization catalyst, a preparation method thereof and a method for desulfurizing sulfur-containing hydrocarbons. The catalyst includes a regular structure carrier and an active component coating distributed on the inner surface and / or outer surface of the regular structure carrier; Based on the total weight of the active component coating, the active component coating contains 5 to 70% by weight of transition metal nitride and 30 to 95% by weight of the matrix; based on the total weight of the matrix , the matrix contains 70 to 90% by weight of an oxide of at least one metal selected from groups IIA and IIB and 10 to 30% by weight of silicon oxide. The catalyst has good desulfurization activity and desulfurization stability, and can increase the octane number of desulfurized oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

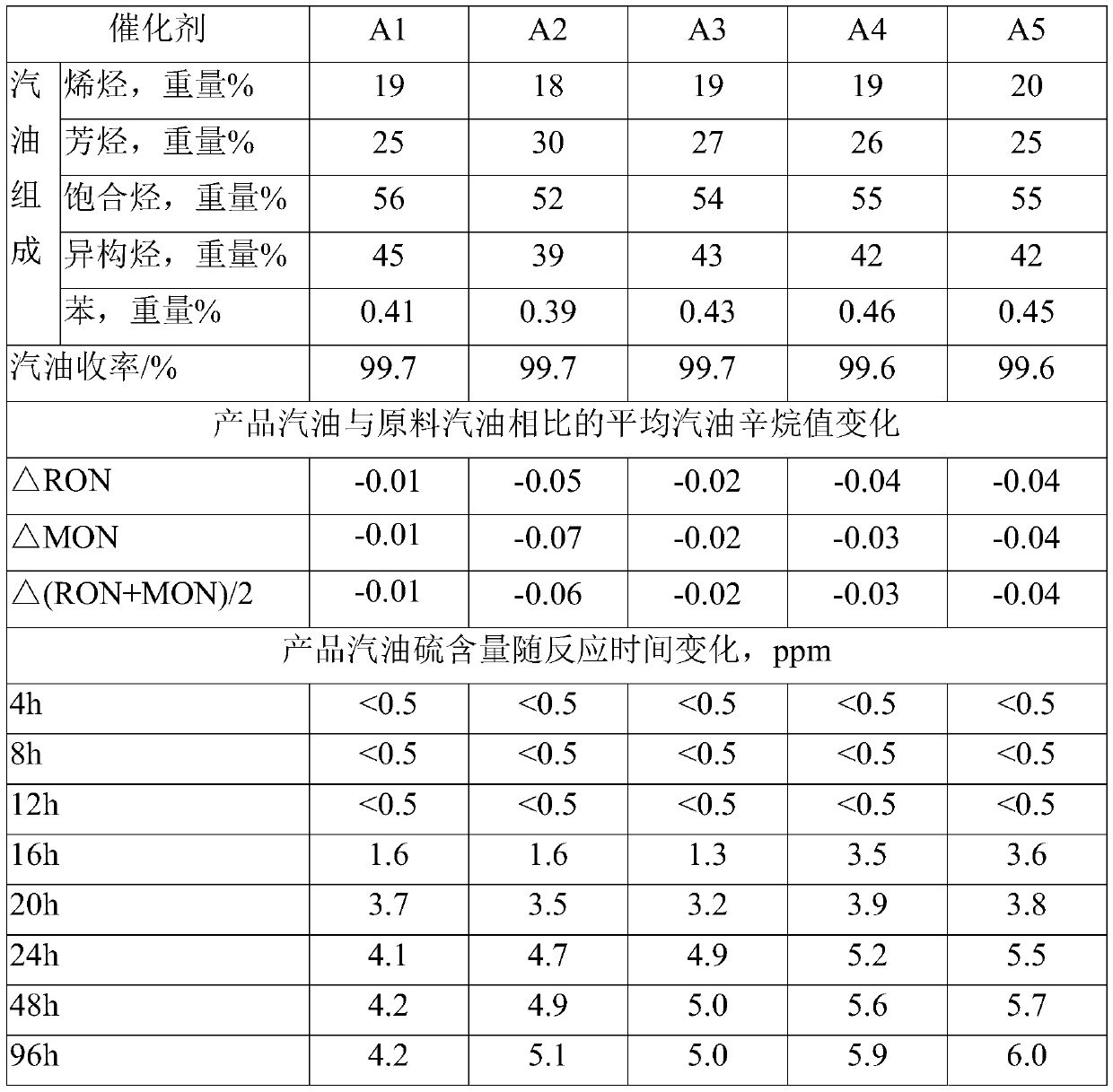

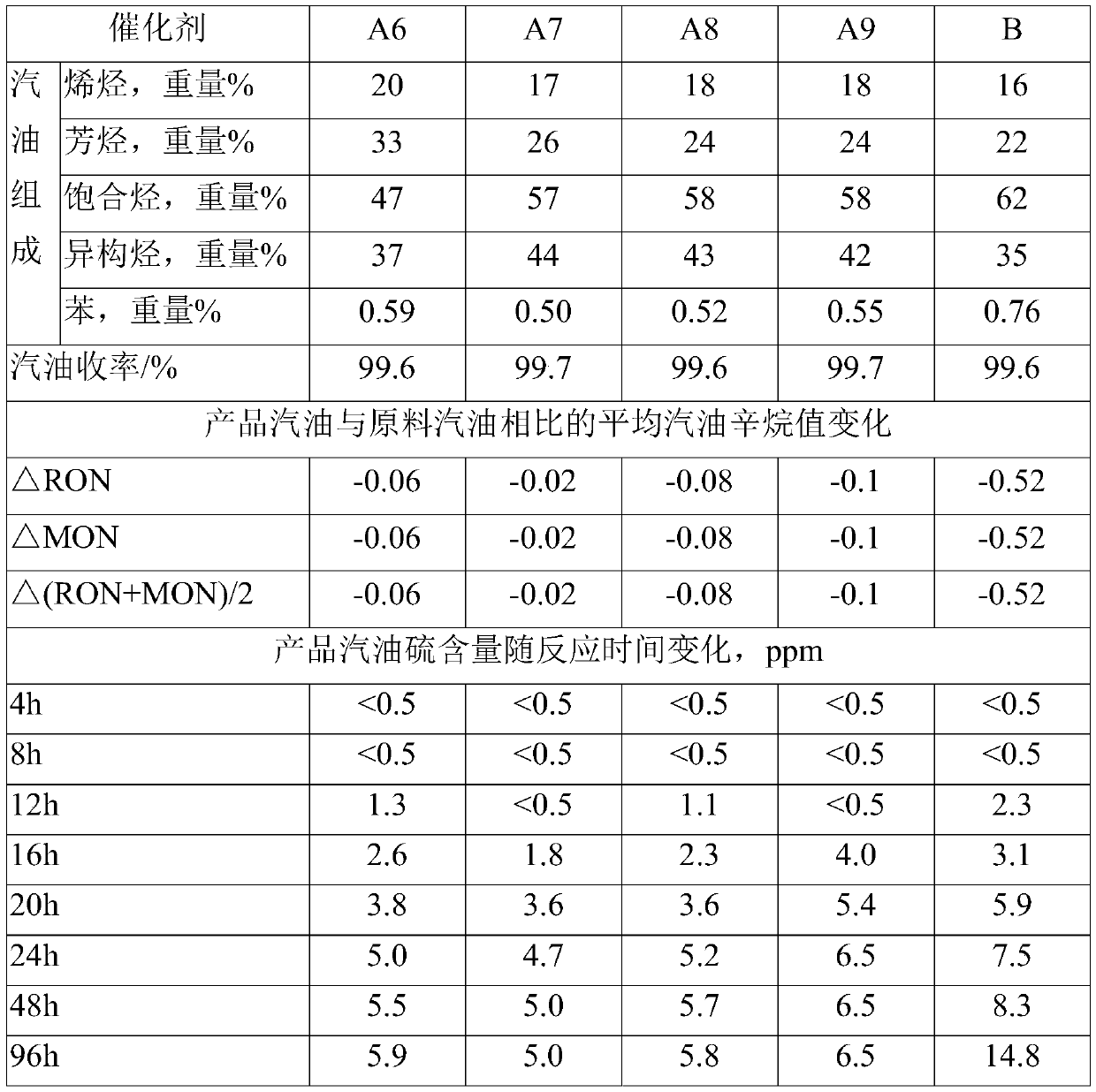

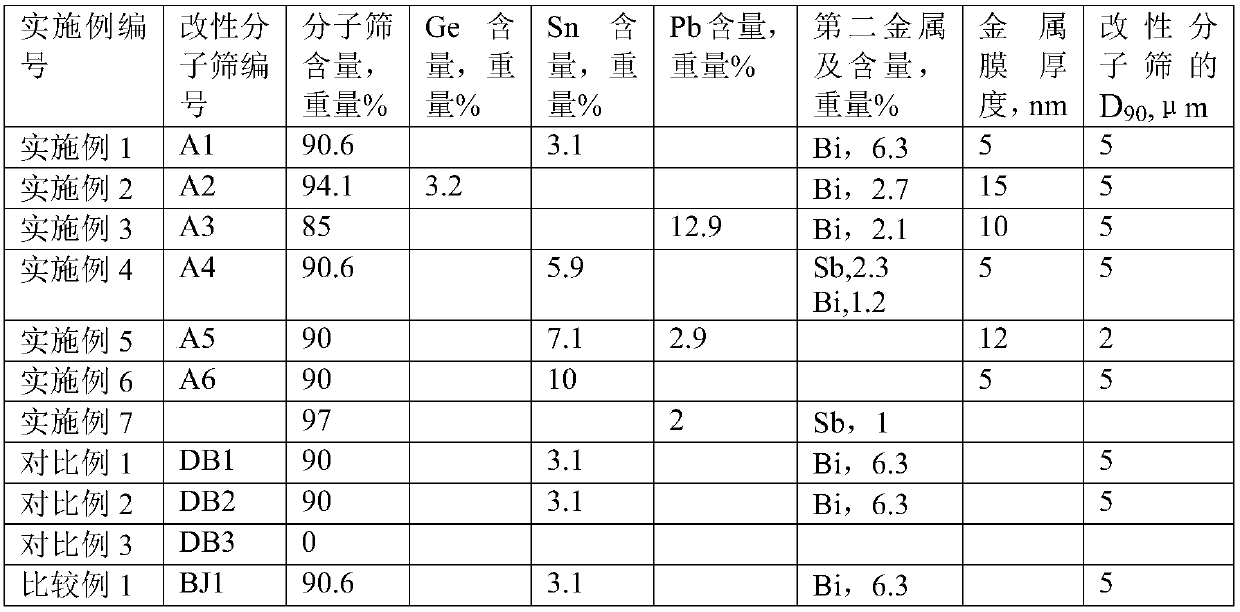

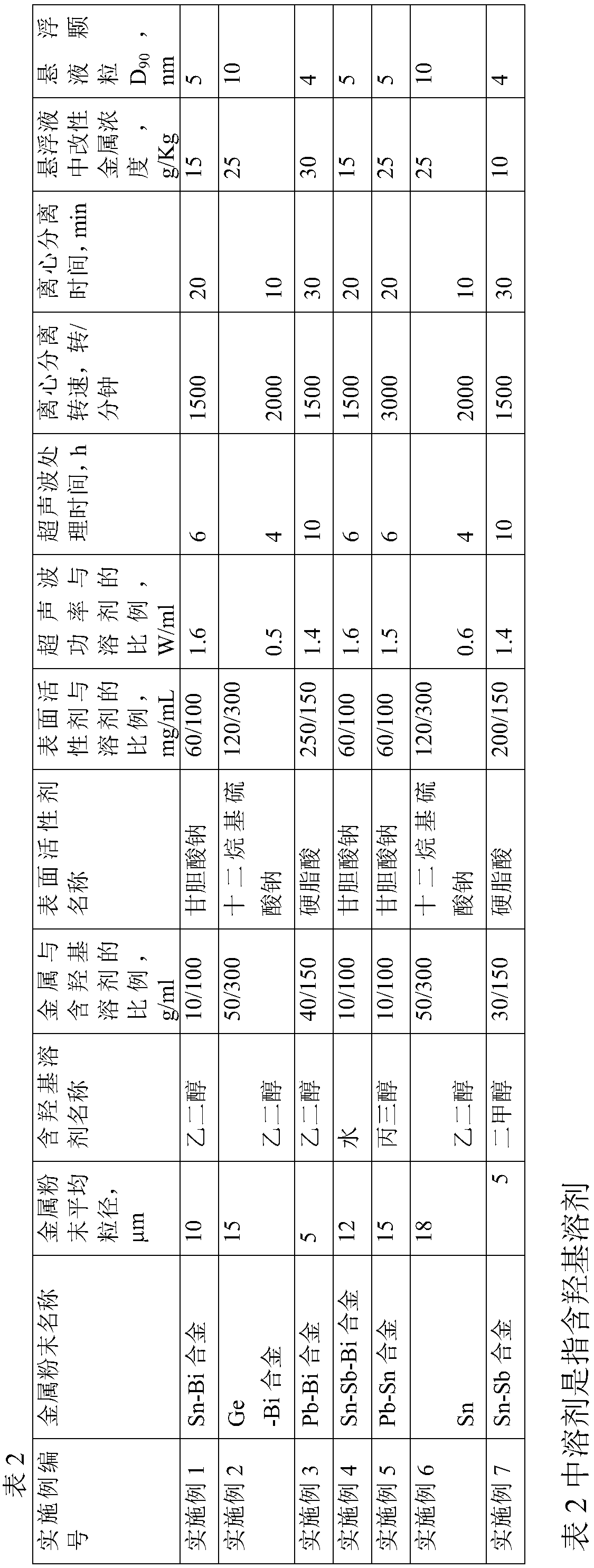

Modified molecular sieve for hydro-desulfurization as well as preparation and application thereof

PendingCN111085261AHigh desulfurization activityHigh desulfurization rateMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveActive agent

The invention relates to a modified molecular sieve for hydro-desulfurization and preparation and application thereof. The modified molecular sieve comprises a molecular sieve and a modifying metal film, and the modifying metal film is located on the outer surface of molecular sieve particles; wherein the modifying metal film contains a modifying metal, the modifying metal comprises a first metaland an optional second metal, the first metal is one or more of Ge, Sn and Pb, and the second metal is Bi and / or Sb and / or Ga. The preparation method comprises the following steps: forming a mixturefrom metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonic treatment to obtain suspension, mixing the suspension with a molecular sieve, and carrying out freeze-drying to obtain the modified molecular sieve. The modified molecular sieve can be used for hydro-desulfurization of sulfur-containing hydrocarbons, has the characteristics of high desulfurization activity, high stability and good selectivity, is used for gasoline desulfurization, and can improve the octane number of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for the production of lube base stocks

ActiveCN109988642BFlexible productionFang QiangaoTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a flexible hydrocracking method for producing lubricating oil base oil. The wax oil raw material after hydrogenation pretreatment is divided into two parts; one part of the material is separated by a hot high-pressure separator to obtain a gas phase and a liquid phase, and the other part of the material is mixed with a hot high-fraction gas phase and circulating hydrogen and passed through a hydrogenation system containing a Y-type molecular sieve. Cracking catalyst bed; after the hot high-resolution liquid phase is mixed with hydrocracking tail oil and circulating hydrogen, it passes through the hydroisomerization cracking catalyst bed containing isomerization cracking type molecular sieve; hydrocracking reaction product and hydroisomerization cracking The reaction products are subjected to gas-liquid separation and fractionation respectively to obtain distillate oil and tail oil of different specifications, and part or all of the hydrocracking tail oil is recycled into the isomerization cracking reactor. The present invention provides for the first time a flexible hydrocracking method for simultaneously producing two or more different specifications of naphtha, aviation fuel, diesel oil, and tail oil products, especially high-quality lubricating oil base oil, on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible single-stage two-agent hydrocracking process

ActiveCN109988618BFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsNaphtha

The invention discloses a flexible single-stage two-agent hydrocracking process. The wax oil raw material is mixed with hydrogen and enters the single-stage two-component hydrocracking reactor. The material after passing through the upper hydrogenation pretreatment catalyst and the single-stage hydrocracking catalyst bed is divided into two streams; one stream of material is drawn out from the middle of the bed. stage reactor, enters the hydroisomerization cracking reactor for isomerization cracking reaction; another stream of material continues to flow down through the lower single-stage hydrocracking catalyst bed; the single-stage hydrocracking reaction material and hydroisomerization cracking The reaction materials are separated and fractionated separately to obtain distillate oil and tail oil products of different specifications. The invention provides a single-stage two-dose hydrocracking process for simultaneously producing two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil, and tail oil products on a set of hydrogenation process equipment, which can fully Using the heat carried by part of the cracked material, the coupling operation of the single-stage two-component hydrocracking reactor and the hydroisomerization cracking reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

InactiveCN111085213AHigh activityHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsActive agentSurface-active agents

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the surface of the regular carrier, wherein the active coating comprises a matrix containing IIA and IIB group metal oxides and a modified metal film attached to the outer surfaceof the matrix, the modified metal film comprises a modified metal, and the modified metal is one or more of Fe, Co, Ni, Mn, Ti, Zr, V, Ge, Pb, Sn, Sb and Bi. The preparation method comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after ultrasonic treatment to obtain suspension; contacting the suspension with matrix particles, carrying out freeze drying to obtain matrix particles containing amodified metal film, and coating the regular carrier with the matrix particles containing the modified metal film to obtain the regular carrier catalyst. The catalyst is used for hydrocarbon hydro-desulfurization, has high desulfurization activity and good stability, and can reduce the octane number loss of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible Hydrocracking Process

ActiveCN109988621BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible hydrocracking process. After hydrogenation pretreatment, the wax oil raw material enters the hydrocracking reactor, and the material after passing through the first hydrocracking catalyst bed is divided into two streams; one stream of material is separated, and the obtained liquid is pumped out of the hydrocracking reactor and mixed with hydrogen Then enter the hydroisomerization cracking reactor for isomerization cracking reaction; another stream of material mixture continues to flow downward through the second hydrocracking catalyst bed; the obtained hydrocracking reaction product and hydroisomerization cracking reaction product respectively Carry out gas-liquid separation and fractionation to obtain naphtha, jet fuel, diesel and tail oil products of different specifications. The present invention provides for the first time a hydrocracking process for simultaneous production of two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel, and tail oil products on a set of hydrogenation process equipment, which can make full use of partial cracking The heat carried by the material realizes the coupled operation of the hydrocracking reactor and the hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of highly stable modified Y-type molecular sieve with high yield isomerism C4 and preparation method thereof

ActiveCN110652999BHigh thermal and hydrothermal stabilityHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePhysical chemistry

A highly stable modified Y-type molecular sieve that is prolific in isomeric C4 and its preparation method. The CaO content of the modified Y-type molecular sieve is 0.3 to 4% by weight, RE 2 O 3 Content is 2~7% by weight, Na 2 The O content is 0.1~0.5% by weight, the total pore volume is 0.33~0.39mL / g, the pore volume of the secondary pores of 2~100nm accounts for 10~25% of the total pore volume, and the unit cell constant is 2.440~2.455nm. The proportion of skeleton aluminum content in the total aluminum content is not higher than 20%, the lattice collapse temperature is not lower than 1050°C, and the ratio of B acid amount to L acid amount measured at 200°C using the pyridine adsorption infrared method is not lower than 2.30. The preparation method includes the steps of ion exchange, modification treatment under certain temperature and water vapor conditions, and reaction with silicon tetrachloride. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity, higher gasoline yield, isomeric C4 yield, and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible two-stage hydrocracking process

ActiveCN109988626AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxIsomerization

The invention discloses a flexible two-stage hydrocracking process. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a separation system, an obtained liquid phase without impurities enters a hydrocracking reactor containing a reduction state hydrocracking catalyst, and an obtained first hydrocracked material is divided into two streams; one material stream is extracted out of the hydrocracking reactor through the middle of a bed layer and enters an isomerization cracking reactor containing a reduction state hydroisomerization cracking catalyst for reaction; theother material stream flows through a hydrocracking catalyst bed layer at the lower part; and an obtained hydrocracking reaction material and an obtained hydroisomerization cracking reaction materialare subjected to gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications. The invention provides the hydrocracking process forsimultaneously producing more than two distillate oil and tail oil products with different specifications on one set of hydrogenation equipment for the first time, heat carried by part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydroisomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process

ActiveCN109988640BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible hydrocracking process. After the wax oil raw material is pretreated by hydrogenation, it enters the hydrocracking reactor, and the material passing through the upper hydrocracking catalyst bed is divided into two strands; one strand of material is extracted from the hydrocracking reactor through the middle of the bed, and enters the hydrocracking reactor. The isomerization cracking reactor carries out the isomerization cracking reaction; another stream of material continues to flow downward through the lower hydrocracking catalyst bed; the obtained hydrocracking reaction material and hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively Get different specifications of naphtha, jet fuel, diesel and tail oil products. The present invention provides for the first time a hydrocracking process for simultaneously producing two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil, and tail oil products on a set of hydrogenation process equipment, which can make full use of partial cracking The heat carried by the material realizes the coupled operation of the hydrocracking reactor and the hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible vaseline hydrogenation process

ActiveCN109988619AEffective distributionFlexible productionTreatment with hydrotreatment processesIsomerizationStream flow

The invention discloses a flexible vaseline hydrogenation process. A vaseline raw material enters a hydrofining reactor, and the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the hydrofining reactor through the middle of the bed layer and enters a hydroisomerization reactor for isomerization reaction; the othermaterial stream flows downwards through a hydrofining catalyst bed layer at the lower part; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain vaseline products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two vaseline products with different specifications on a set of hydrogenation process equipment for the first time, heat carried by part of hydrofined materials can be fully utilized, and coupling operation of the hydrofining reactor and the hydroisomerization reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible two-stage hydrocracking process

ActiveCN109988607BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a combined process of hydrotreating and hydrocracking. The wax oil raw material passes through the first hydrogenation pretreatment catalyst bed, and the obtained material is divided into two streams; one stream of material is drawn out of the hydrogenation pretreatment reactor through the middle of the bed, and mixed with LCO to pass through the hydrotreatment reactor, and the hydrotreatment stream Carry out gas-liquid separation and fractional distillation to obtain catalytic cracking raw materials; another stream of material continues to pass through the second hydrogenation pretreatment catalyst bed, and the hydrogenation pretreatment stream passes through the hydrocracking catalyst bed for hydrocracking reaction, and the obtained hydrocracking reaction The material is subjected to gas-liquid separation and fractional distillation to obtain hydrocracking products such as naphtha, jet fuel, diesel oil and tail oil. The present invention provides for the first time a combined hydrogenation process for simultaneous production of hydrocracking light products and catalytic cracking raw materials on a set of hydrogenation process equipment, which can make full use of the heat carried by the hydrogenation pretreatment material to realize hydrogenation pretreatment Coupling operation of treatment reactor and hydrotreating reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regular structure desulfurization catalyst and preparation method thereof and method for desulfurization of sulfur-containing hydrocarbons

ActiveCN108404945BHigh desulfurization activityImprove stabilityPhysical/chemical process catalystsHydrocarbon oils treatmentTransition metal carbidesPtru catalyst

The invention discloses a regular structure desulfurization catalyst and a preparation method thereof, and a sulfur-containing hydrocarbon desulfurization method. The catalyst comprises a regular structure carrier and an active component coating distributed on the inner surface and / or outer surface of the regular structure carrier, wherein the active component coating comprises, by weight, 5-70 wt% of a transition metal carbide and 30-95 wt% of a matrix, and the matrix comprises, by weight, 5-35 wt% of a non-aluminum binder, 0.5-10 wt% of a rare earth oxide, and 60-90 wt% of the oxide of at least a metal selected from group IIA and group IIB. The catalyst of the present invention has good desulfurization activity and good desulfurization stability, and can improve the octane number of thedesulfurized oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com