Regular structure desulfurization catalyst and preparation method thereof, and sulfur-containing hydrocarbon desulfurization method

A technology of desulfurization catalyst and regular structure, which is applied in the field of desulfurization of sulfur-containing hydrocarbons. It can solve the problems of desulfurization activity and desulfurization stability, affect the implementation effect of desulfurization of sulfur-containing hydrocarbons, and reduce the octane number of gasoline products, so as to increase the stability of desulfurization. non-toxic, not easy to lose and aggregate, and improves the effect of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

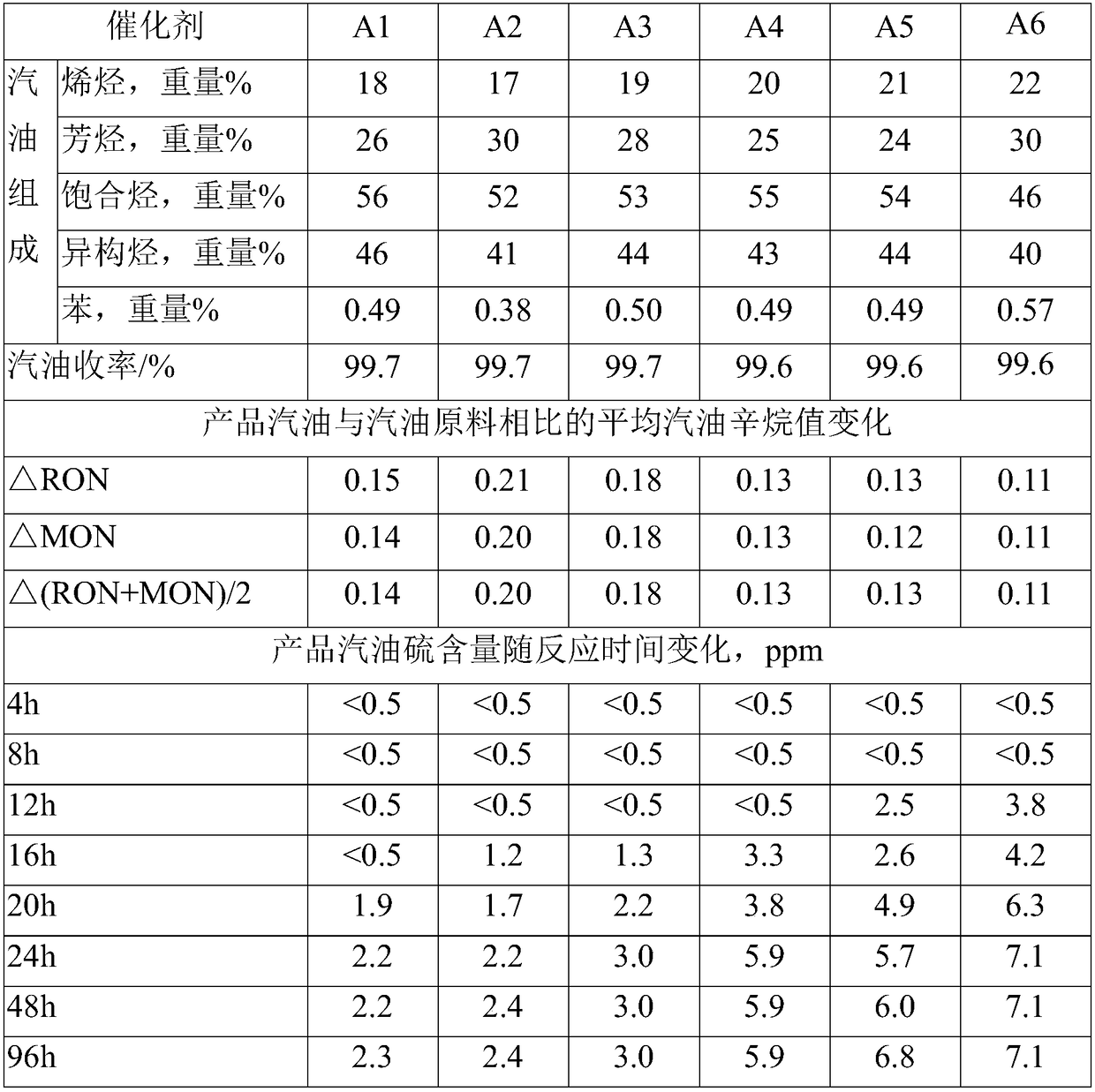

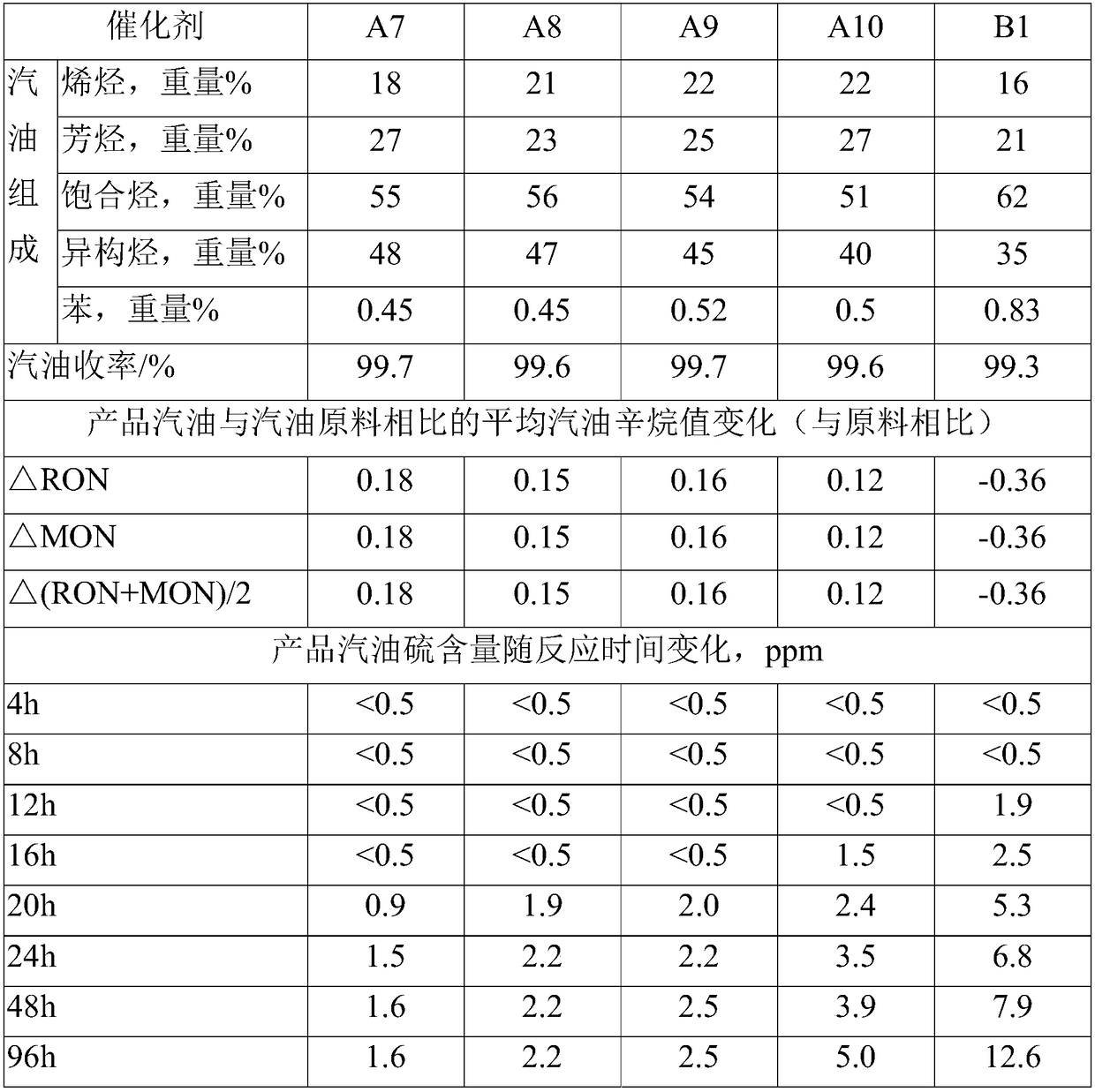

Examples

preparation example Construction

[0025] At the same time, the present invention also provides a method for preparing a desulfurization catalyst with a regular structure, the preparation method comprising the following steps: S1, a precursor of an oxide of at least one metal selected from groups IIA and IIB, optionally The rare earth oxide precursor and the non-aluminum binder precursor are mixed to prepare a matrix coating slurry; S2, coating the matrix coating slurry on a regular structure carrier, drying and firing to form a matrix coating slurry in the regular structure carrier Forming a matrix coating on the surface and / or the outer surface to obtain a catalyst carrier; S3, contacting the catalyst carrier with a transition metal precursor solution, drying and roasting to form a transition metal oxide on the matrix coating Material, obtain catalyst precursor; S4, described catalyst precursor in CH 4 / H 2 Reduction treatment is carried out under the atmosphere to reduce the transition metal oxide to form t...

Embodiment 1

[0062] This example is used to illustrate the regular structure desulfurization catalyst and its preparation method of the present invention.

[0063] (1) Preparation of substrate coating slurry:

[0064] Mix 1.01kg of nano-zinc oxide powder (Beijing Chemical Plant, containing 1.0kg of zinc oxide on a dry basis) and 1L of deionized water, and wet ball mill to obtain slurry A (mixture particle size d 900.356kg of zirconium tetrachloride (Beijing Chemical Plant, analytically pure, 0.188kg in terms of zirconia) was slowly added to the nitric acid solution of 3.1kg of concentration 10% by weight until the solution pH value was 2, and Stir slowly to avoid the precipitation of zirconia crystals, and obtain a colorless and transparent zirconium sol; add 0.0625 kg of lanthanum oxide (Sinopharm Group, analytically pure, containing 0.062 kg on a dry basis) to the aforementioned zirconium sol, stir and mix evenly, and then add 25% by weight dropwise Ammonia solution until the pH value i...

Embodiment 2

[0074] This example is used to illustrate the regular structure desulfurization catalyst and its preparation method of the present invention.

[0075] (1) Preparation of substrate coating slurry:

[0076] Mix 1.01kg of nano-zinc oxide powder (Beijing Chemical Plant, containing 1.0kg on a dry basis of zinc oxide) and 1L deionized water, and wet ball mill (mixture particle size d 90 8 μm), to obtain slurry A; 1.19kg of titanium tetrachloride (Beijing Chemical Plant, analytically pure, 0.5kg in terms of titanium oxide) was slowly added to 0.76kg of 25% by weight ammonia solution to the pH of the solution 0.322 kg of cerium nitrate (Beijing Chemical Plant, analytically pure, 0.17 kg in terms of cerium oxide) was added to the aforementioned titanium sol, stirred and mixed After uniformity, 25% by weight of ammonia solution was added dropwise until the pH value was greater than 10 to form a cerium-titanium sol to obtain slurry B; the slurry A and slurry B obtained above were mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com