Modified molecular sieve for hydro-desulfurization as well as preparation and application thereof

A molecular sieve and modification technology, applied in molecular sieve catalysts, refined hydrocarbon oil, chemical instruments and methods, etc., can solve the problems of desulfurization activity decline, gasoline product octane number decrease, octane number loss, etc., to achieve high desulfurization, high Effect of desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

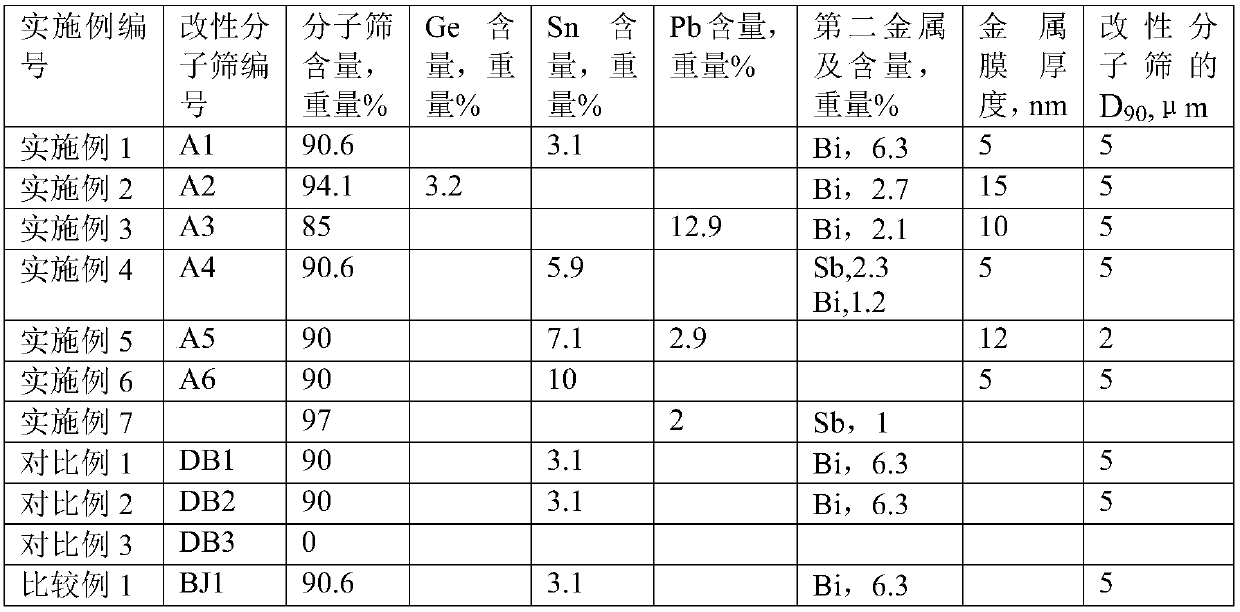

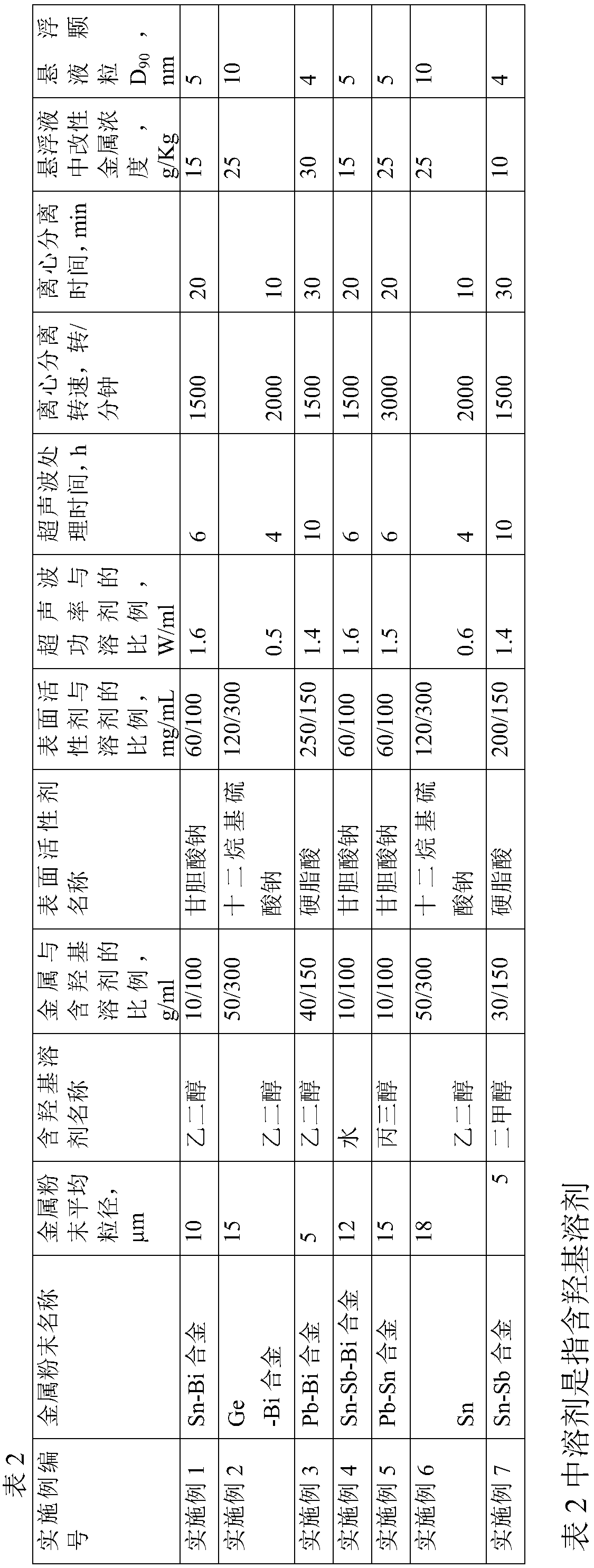

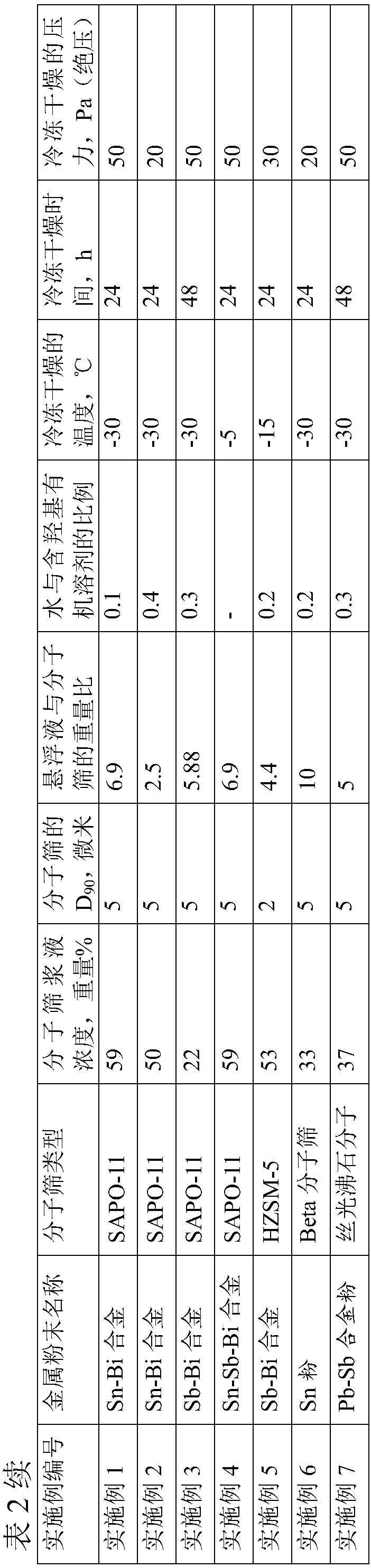

[0043] The preparation method of the modified molecular sieve provided by the invention comprises the steps of preparing a suspension and mixing the suspension with molecular sieve raw materials. The preparation method of the suspension includes: forming a mixture of metal powder, a hydroxyl-containing solvent and a surfactant, and treating it under ultrasonic waves to obtain a mixed liquid after ultrasonic treatment; wherein, during the ultrasonic treatment process, the fine particles are peeled off from the metal powder The metal particles are suspended in the solvent; the ultrasonic mixture separates the larger particles to obtain a suspension, which suspends fine particles containing modified metals. The metal powder can be an alloy powder containing multiple modified metals. Among them, there is no special requirement on the relative content of the metal powder (or metal powder or metal fine powder) and the hydroxyl-containing solvent, as long as the hydroxyl-containing s...

specific Embodiment approach

[0054] The present invention provides a specific implementation of the preparation method of the modified molecular sieve, which includes the following steps: uniformly mixing the metal powder and the hydroxyl-containing solvent, and then using a specific ultrasonic power of 50-250W / (100g hydroxyl-containing solvent), preferably 100-150W / (100g hydroxyl-containing solvent) under the power of ultrasonic treatment for 4 to 10 hours, such as 5 to 8 hours, and then the ultrasonic mixture is centrifuged at 1200 to 3000 rpm, preferably 1500 to 2500 rpm, and the suspension is obtained after separation liquid; then put the molecular sieve solid powder or the molecular sieve slurry containing the molecular sieve solid powder into the obtained suspension, disperse evenly, and freeze-dry to prepare the modified molecular sieve. The average particle diameter of the metal fine powder is less than 20 microns, preferably 1-15 microns or 3-18 microns; the D of the molecular sieve solid powder...

Embodiment 1

[0067] This example is used to illustrate the modified molecular sieve of the present invention and its preparation method.

[0068] First, add 10g of Sn-Bi alloy powder (the average particle size of Sn-Bi alloy powder is 10 microns, and the weight ratio of Sn to Bi is 0.5:1) and 100ml of ethylene glycol (Sinopharm Group, purity AR) into a 200ml jar. , mix well, then add 60mg of surfactant sodium glycocholate (purity AR, source: Nanjing Pars Biotechnology Co., Ltd); Ultrasonic treatment for 6h (frequency 40KHz); centrifuge the ultrasonicated liquid at 1500r / min for 20min in a centrifuge, take out the supernatant (i.e. suspension) with a straw, the concentration of the modified metal in the suspension is 15g / Kg ,D 90 is 5nm;

[0069] 14.5 grams (on a dry basis) of SAPO-11 molecular sieve powder (Si: Al: P molar ratio = 1: 9: 10, D 90 =14 microns, relative crystallinity 91%, industrial grade, product of Qilu Branch of Sinopec Catalyst Co., Ltd., the same below), mixed with 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com