Patents

Literature

80results about How to "Good for long-term operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined process method for producing clean diesel oil with low condensation point

ActiveCN103805258AGuaranteed yieldRealize comprehensive utilizationTreatment with hydrotreatment processesFractionationLiquid gas

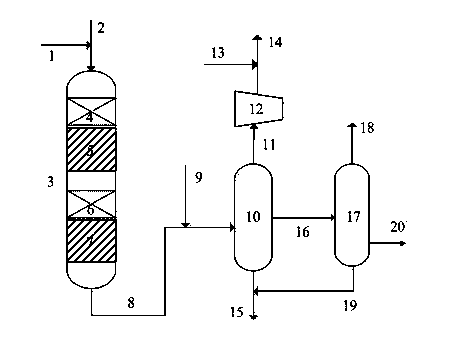

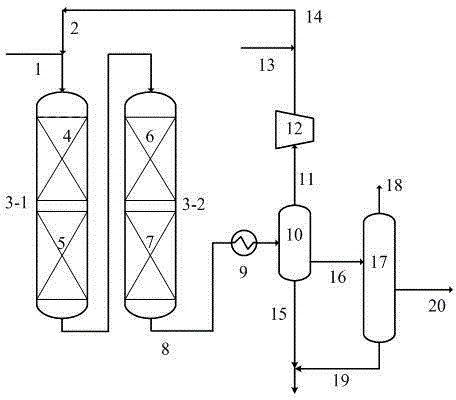

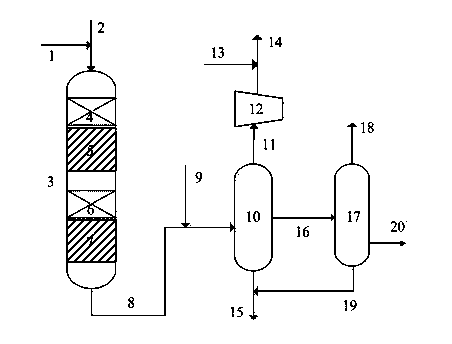

The invention discloses a combined process method for producing clean diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading catalyst bed layer, and a hydrodewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the clean diesel oil product with a low condensation point, and a few light naphtha and liquefied gas products. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-refining and hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

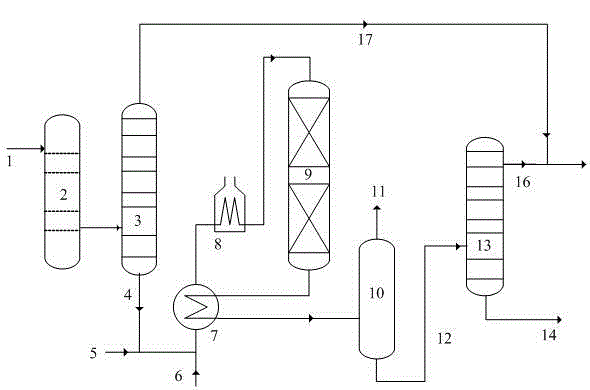

Mixed hydrogenation method for catalytic cracking gasoline and coking diesel oil

ActiveCN103059967AAvoid cokingExtended operating cycleTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a mixed hydrogenation method for catalytic cracking gasoline and coking diesel oil. The method comprises: subjecting FCC (fluid catalytic cracking) gasoline to alkali-free deodorization, making the deodorized catalytic gasoline enter a prefractionator to be fractionated into light gasoline and heavy gasoline; mixing the heavy gasoline with coking diesel oil, then performing hydrodesulfurization, separating the desulfurization product to obtain hydrogenated heavy gasoline and treated coking diesel oil, and blending the hydrogenated heavy gasoline with the light gasoline to obtain a clean gasoline product. According to the method provided in the invention, when the coking diesel oil and the heavy gasoline are mixed for hydrogenation, the nitride brought in by the coking diesel oil undergoes competitive adsorption at a catalyst hydrogenation center and causes poisoning of the hydrogenation center, thus reducing olefin hydrogenation selectivity and decreasing the octane number loss of hydrogenation. On the other hand, when the mixed feed flows through a heat exchanger and heating furnace, the raw materials are in a gas-liquid mixed phase in the heating furnace and the heat exchanger, so that a coke material can be dissolved and taken away, coking can be avoided in the heat exchanger and the heating furnace, and the operation cycle of the equipment can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

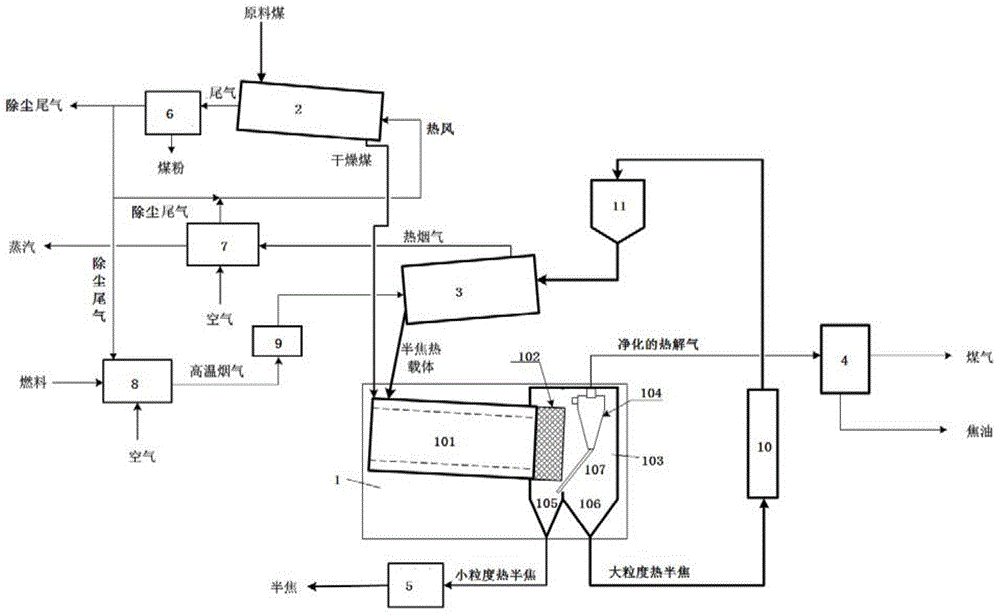

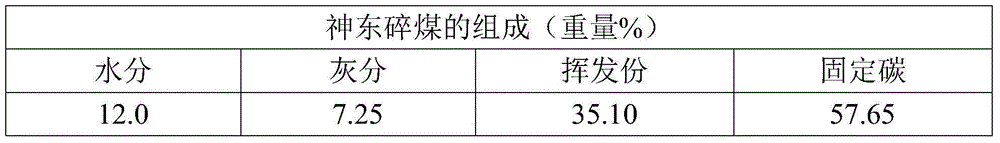

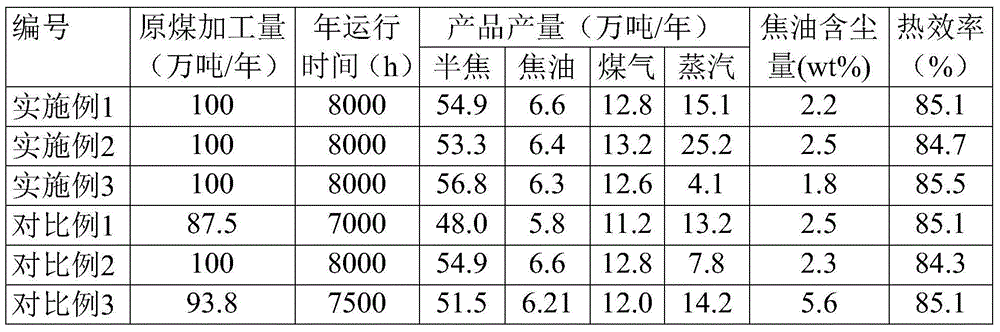

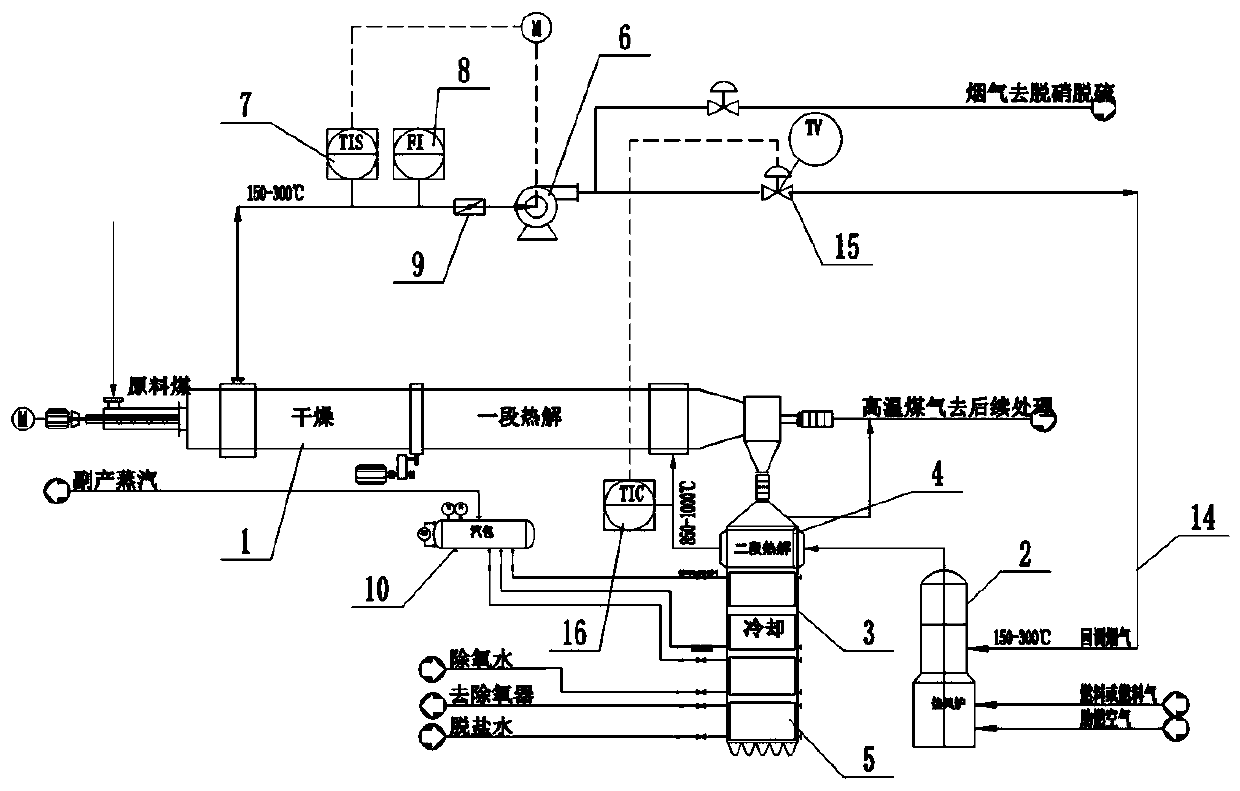

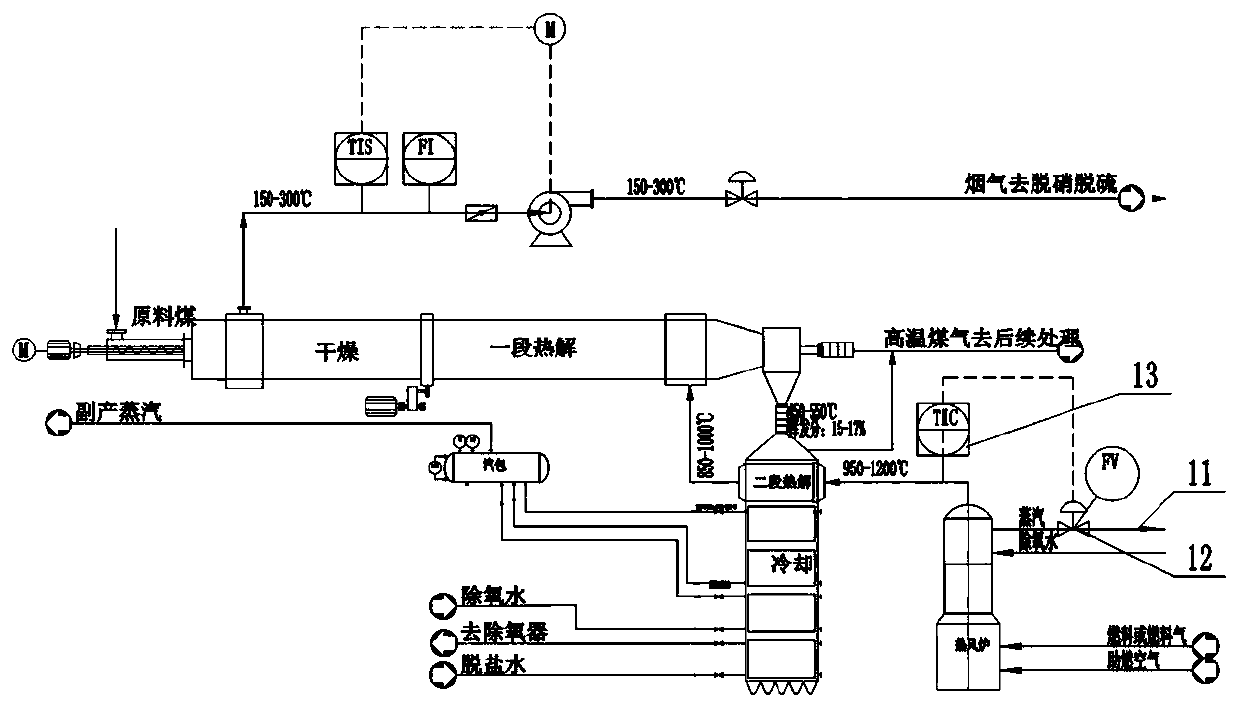

Pyrolysis system for pyrolysis of broken coal, and device and method for producing semicoke, tar and coal gas by pyrolysis of broken coal

ActiveCN104152162AAvoid condensationIncrease productionDirect heating destructive distillationSpecial form destructive distillationThermodynamicsSolid particle

The invention discloses a pyrolysis system for pyrolysis of broken coal, and a device and a method for producing semicoke, tar and coal gas by pyrolysis of broken coal. The pyrolysis system comprises a pyrolyzer, a particle size classifier, a distributing cabin, a cyclone separator, a small hopper, a large hopper and a discharge tube, wherein the pyrolyzer, the distributing cabin, the small hopper and the large hopper are tightly connected; the small hopper and the large hopper are connected below the distributing cabin; the particle size classifier is connected to the outlet of the pyrolyzer and is arranged inside the distributing cabin; the cyclone separator is arranged inside the distributing cabin, and used for separating pyrolysis gas discharged by the pyrolyzer to obtain solid particles and purified pyrolysis gas. The device comprises the pyrolysis system. The tar obtained by adopting the method is high in yield and high in quality, the coal gas is high in effective components and high in heating value, the yield of the semicoke is improved, the whole energy efficiency is high, and the device can run within a long period.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

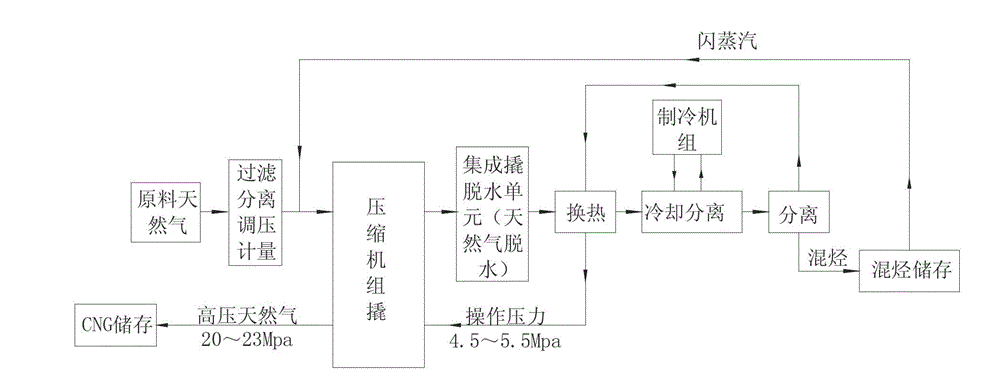

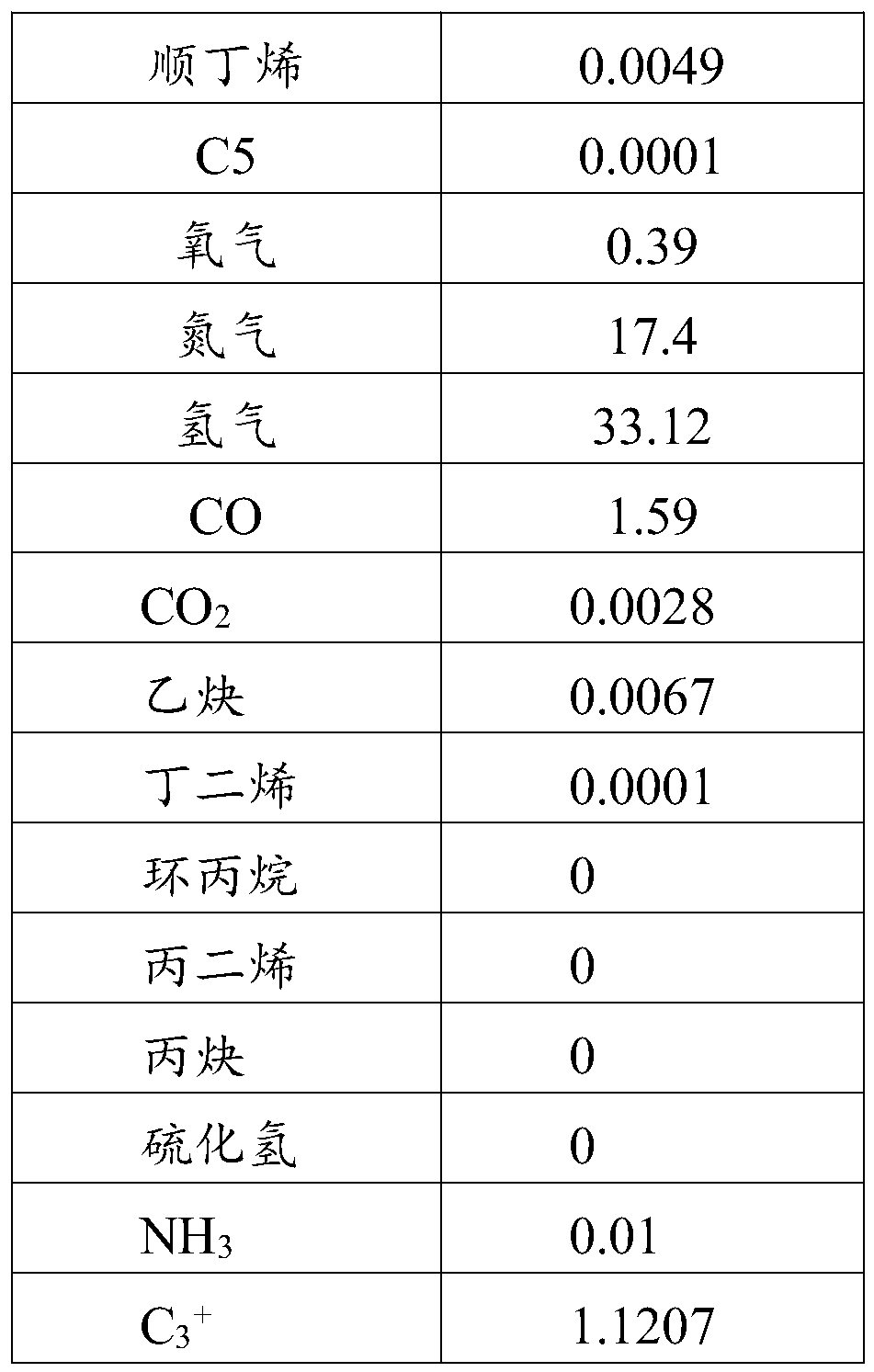

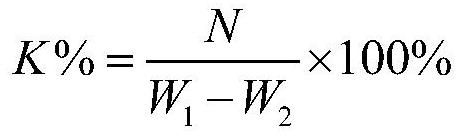

Natural gas recovery process

InactiveCN103146450AGood for long-term operationImprove reliabilityGaseous fuelsCompressed natural gasRecuperator

The invention discloses a natural gas recovery process. The light hydrocarbon recovery rate can be improved, and energy consumption can be reduced by the natural gas recovery process. The process comprises the following steps of separating and filtering the material gas by a separator and a filter orderly, entering into a compressor to compress, air cooling, and then separating a part of water and heavy hydrocarbon through the separator; deeply dewatering through a dehydration unit until the moisture is smaller than 10ppm; filtering, pre-cooling to -10 DEG C through a heat exchanger, cooling to -35 DEG C by a refrigerator, then cooling and separating, and reheating the separated mixed hydrocarbon to normal temperature through the heat exchanger and then conveying to a mixed hydrocarbon storage tank; returning the separated gas to the heat exchanger to exchange heat; reheating the gas to the normal temperature, and then entering a CNG (compressed natural gas) to compress and store. By adopting the process, the material gas with low air pressure and unstable storage quantity can be collected; and the natural gas recovery process is high in recovery rate, low in recovery cost, simple in recovery equipment, simple and convenient to operate, and low in energy consumption.

Owner:四川金科深冷设备工程有限公司

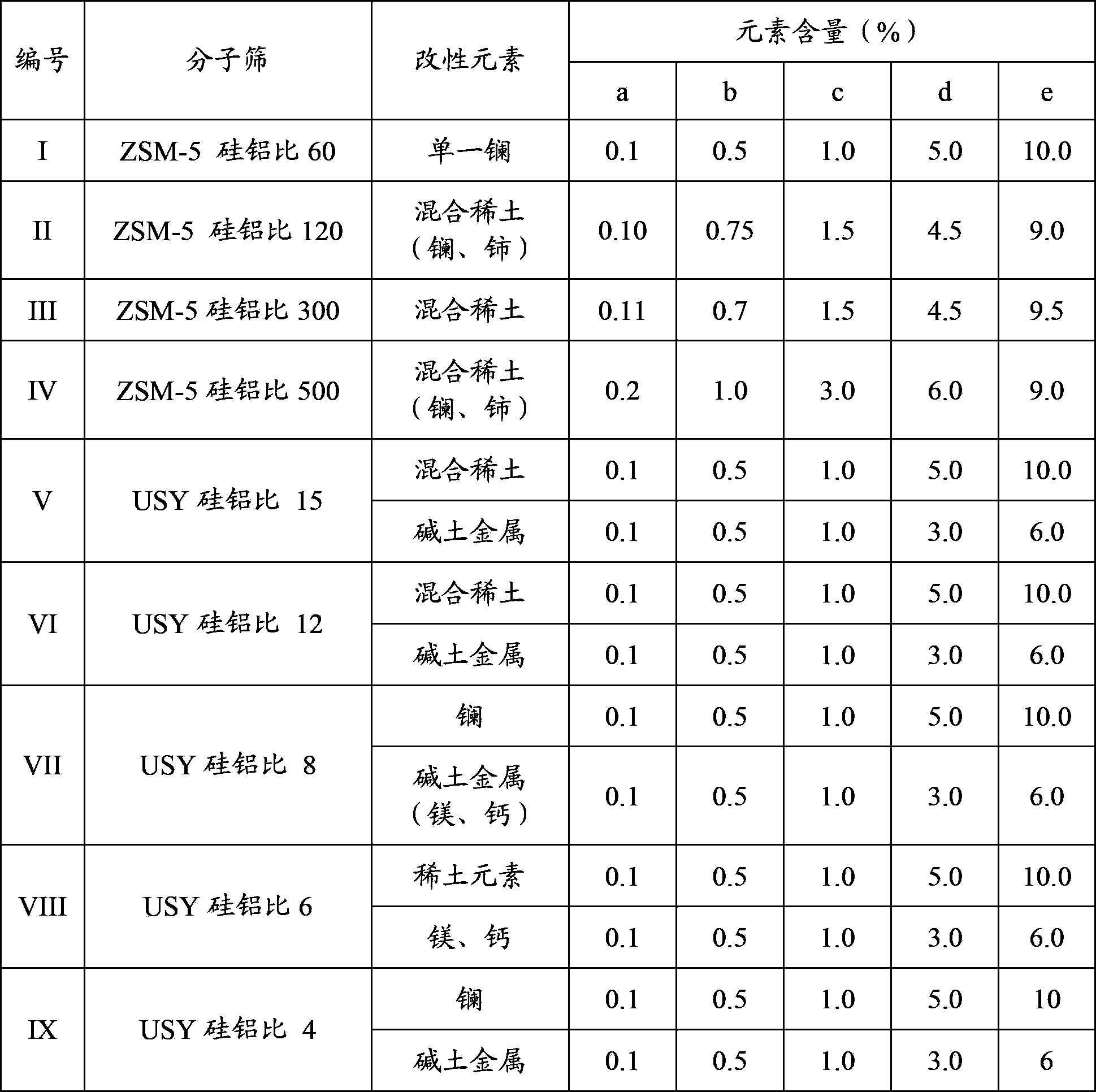

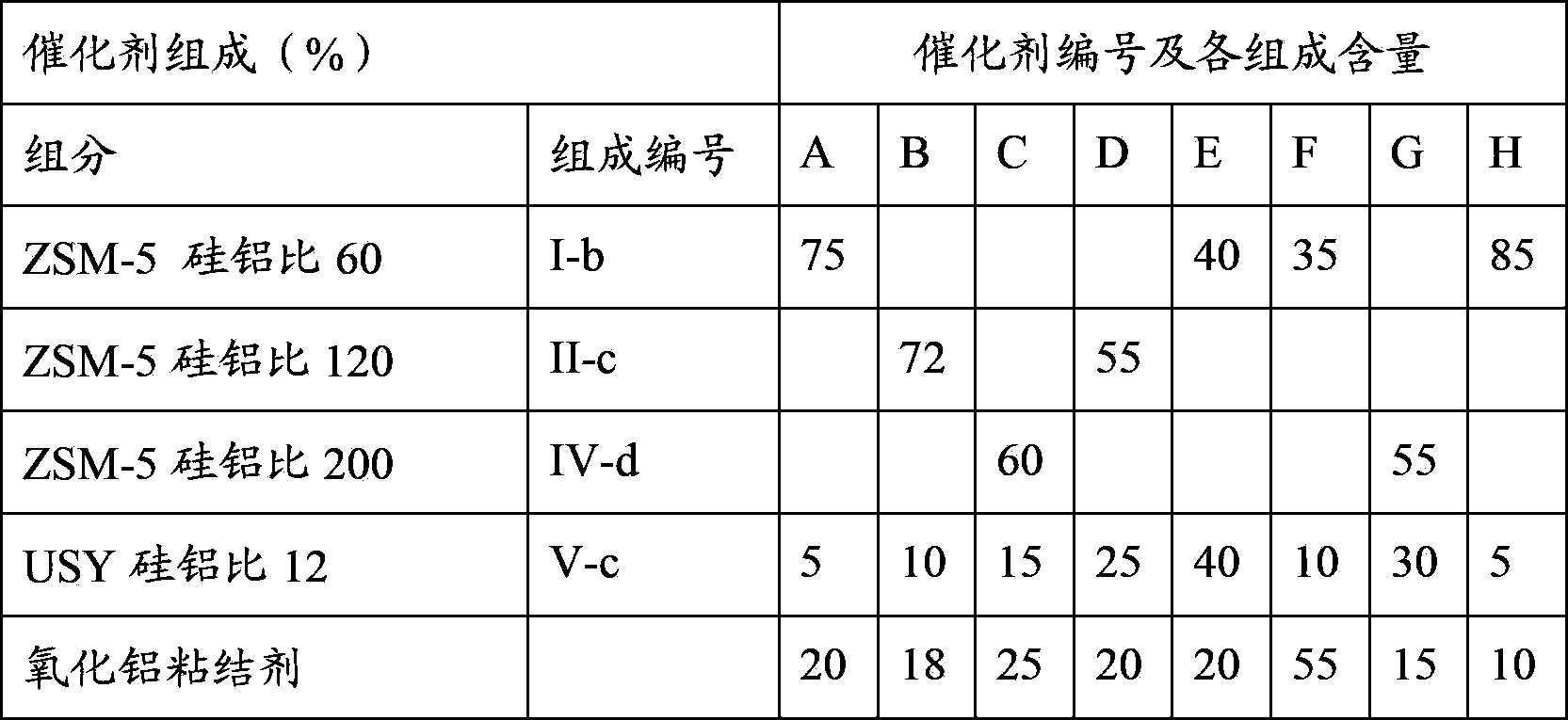

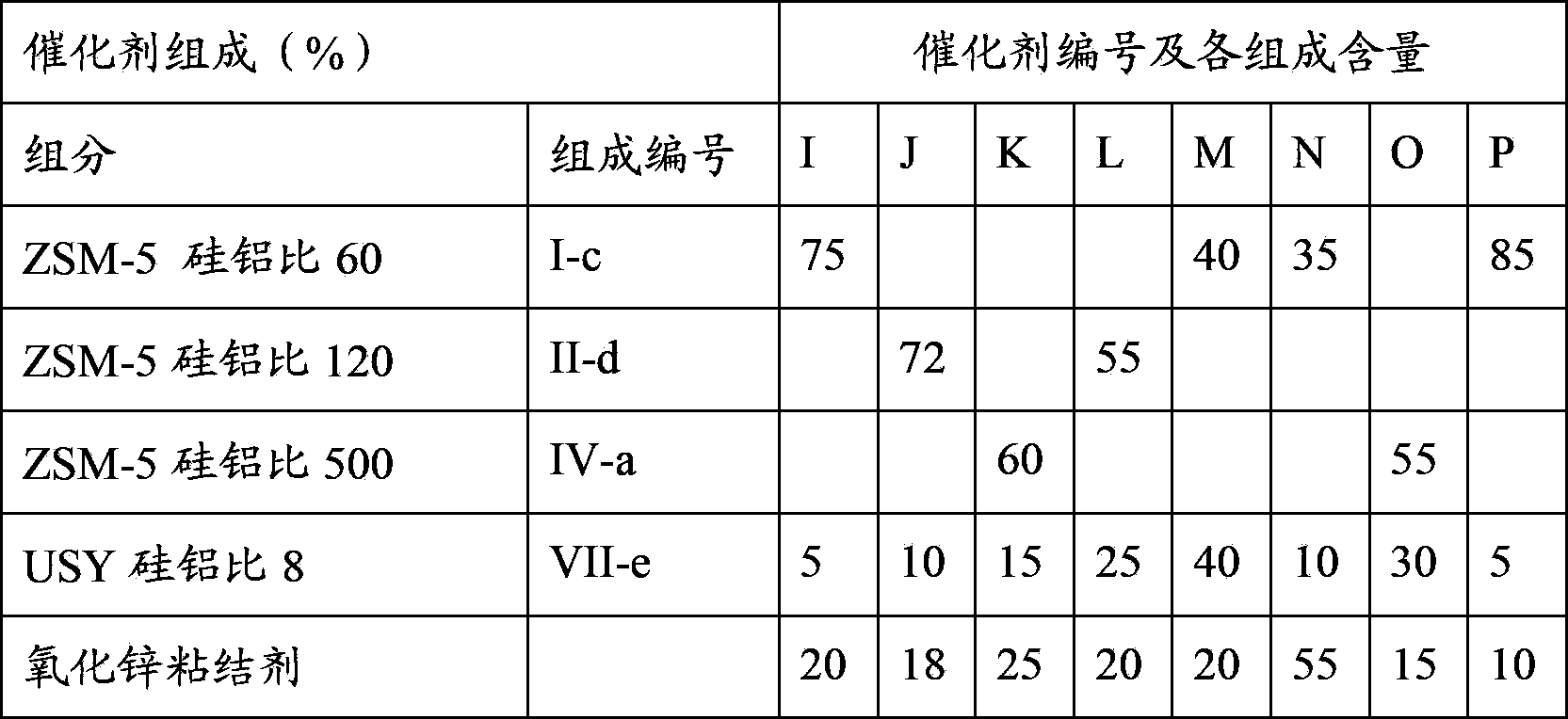

Catalyst for preparing ethylbenzene by reacting ethylene with benzene, and preparation method and application of catalyst

ActiveCN103801389AReduce manufacturing costReduce pollutionMolecular sieve catalystsHydrocarbonsMolecular sieveRare earth

The invention discloses a catalyst for preparing ethylbenzene by reacting ethylene with benzene. The catalyst comprises a modified ZSM-5 molecular sieve, a modified ultrastable Y-type molecular sieve and an inorganic oxide, wherein the modified ZSM-5 molecular sieve consists of a ZSM-5 molecular sieve and 0.1wt%-10wt% of rare earth metal oxide which is supported on the ZSM-5 molecular sieve; a mole ratio of SiO2 to Al2O3 in the ZSM-5 molecular sieve is 30-500; the modified ultrastable Y-type molecular sieve consists of an ultrastable Y-type molecular sieve, 0.1wt%-6wt% of alkaline earth metal oxide and 0.1wt%-10wt% of rare earth metal oxide; a mole ratio of SiO2 to Al2O3 in the ultrastable Y-type molecular sieve is 4-15; the alkaline earth metal oxide and the rare earth metal oxide are supported on the ultrastable Y-type molecular sieve; the inorganic oxide is one or a mixture of more than two of aluminium oxide, zinc oxide and silicon oxide; a weight ratio of the modified ZSM-5 molecular sieve to the modified ultrastable Y-type molecular sieve and the inorganic oxide is (35%-85%):(5%-40%):(10%-55%).

Owner:洛阳市科创石化科技开发有限公司

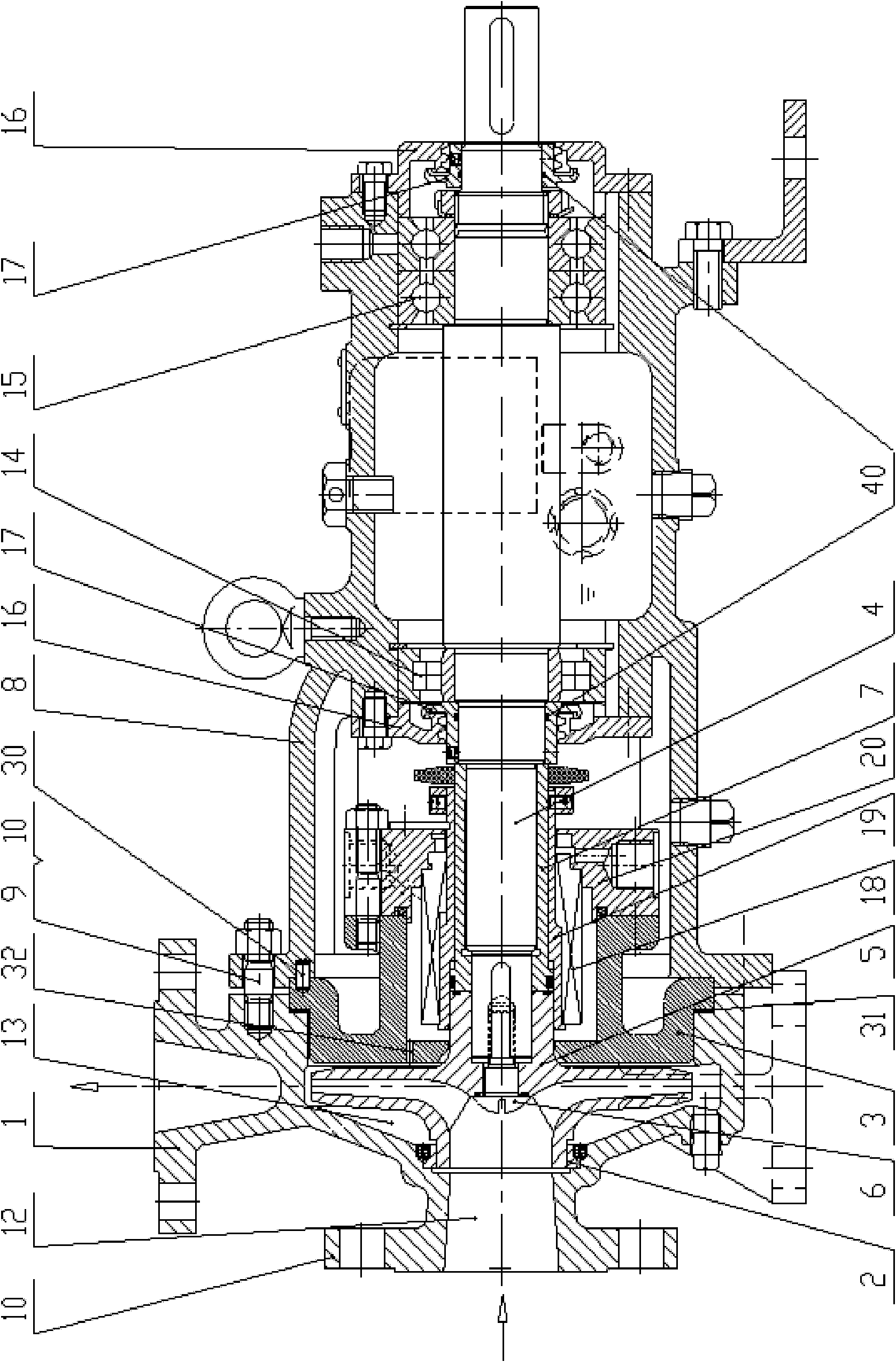

Chemical additive mixing pump for nuclear power station

ActiveCN102146936AImprove efficiencyGood for long-term operationPump componentsPumpsImpellerNuclear power

The invention discloses a chemical additive mixing pump for a nuclear power station, which adopts a straight tapered water-absorbing room to lead liquid to flow in a straight tapered contraction pipe, thereby ensuring that the flow velocity is gradually increased, the distribution is uniform, the hydraulic loss is small, and a uniform velocity field is arranged at an inlet of an impeller; the impeller is matched and locked with a locking structure of a pump shaft through external threads of a special locking bolt and internal threads at the shaft end of the pump shaft; the spherical surface of the locking bolt completely conforms to the hydraulic shape of the impeller, so that the locking bolt is integrated with the streamline shape of the impeller into a whole after being installed, thereby maximally ensuring that the inlet water flow of the impeller is not affected; meanwhile, the diameter of the pump shaft and the specification of a bearing can be increased; the larger bearing can be prolonged in service life and also can bear larger load; a pump body is connected with a pump cover in such a manner that the pump cover is directly pressed between the pump body and a bearing body to shorten the overall axial dimension of the pump; and a bearing oil sealing device achieves the ideal sealing effect by adopting the labyrinth sealing, so that no leakage of lubricating oil exists in the endurance test of 400 hours.

Owner:SHANGHAI APOLLO MACHINERY

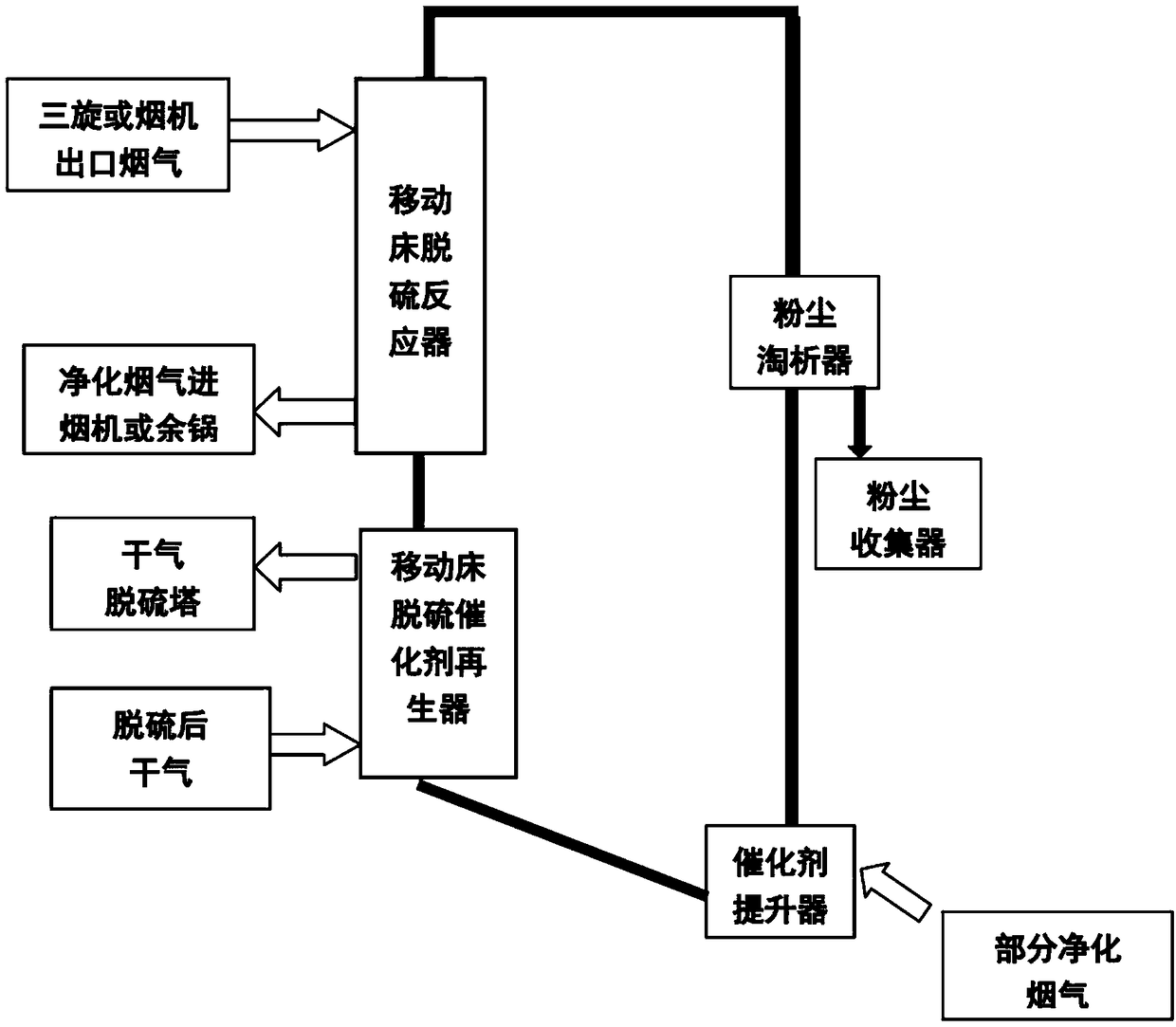

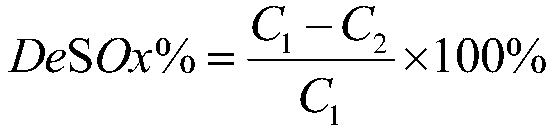

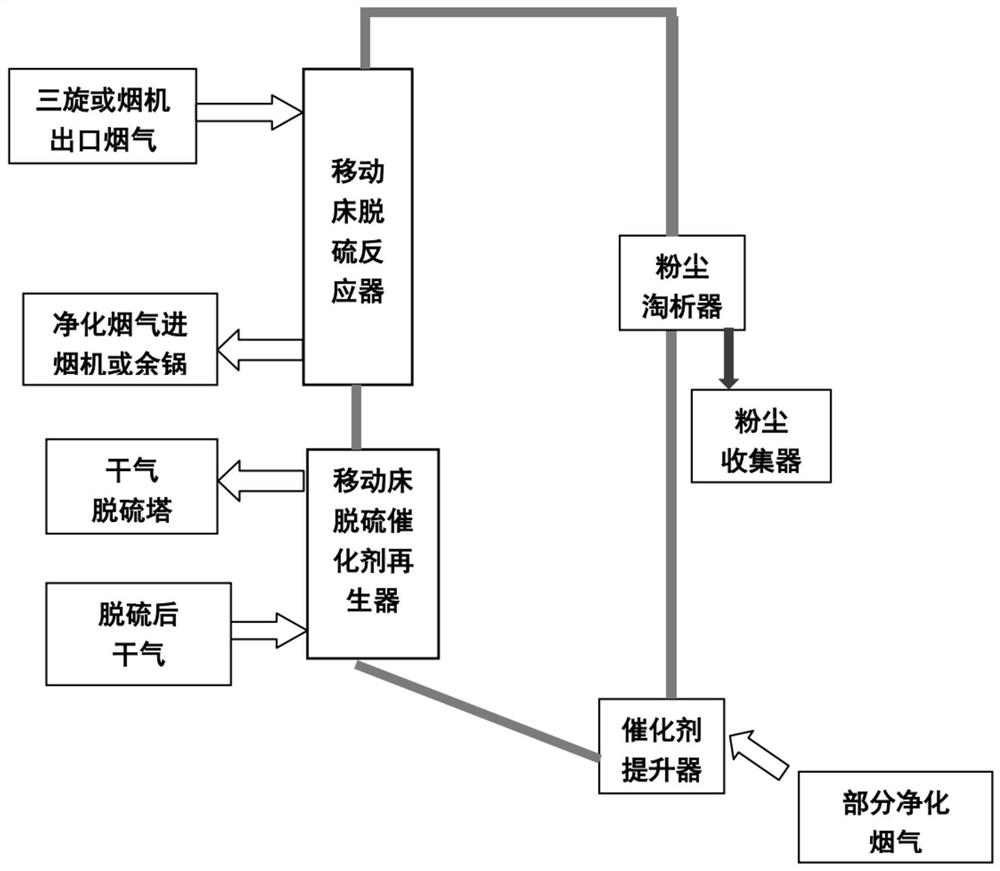

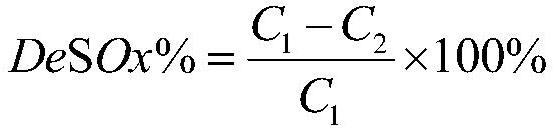

Dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas

ActiveCN109351183AImprove purification efficiencyAvoid emissionsHeterogenous catalyst chemical elementsDispersed particle separationFlue gasElutriation

The invention provides a dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas. The method comprises the steps that catalytic cracking flue gas is introducedin a moving bed desulfuration reactor, the catalytic cracking flue gas and a loaded desulfurization catalyst are subjected to the desulfurization reaction, oxysulfide in the flue gas is subjected to the catalytic reaction to produce metal sulfate, and the metal sulfate is adsorbed on the desulfurization catalyst; the desulfurization catalyst containing the metal sulfate is conveyed to a desulfurization catalyst reproducer, reductive regeneration gas is introduced in the reproducer, and after the metal sulfate on the desulfurization catalyst is reduced to metallic oxide, a part of purified fluegas is utilized for lifting the regenerated desulfurization catalyst into a dust elutriating apparatus through a catalyst lifter, and after dust is recovered through elutriation, desulfurization catalyst is conveyed into moving bed desulfuration reactor for recycling; regenerated acid gas containing hydrogen sulfide is introduced in a dry gas desulfurizer to produce sulphur. According to the method, the desulfuration and dust removal of the catalytic cracking flue gas can be effectively achieved, and the desulfurization rate reaches 99% or above.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

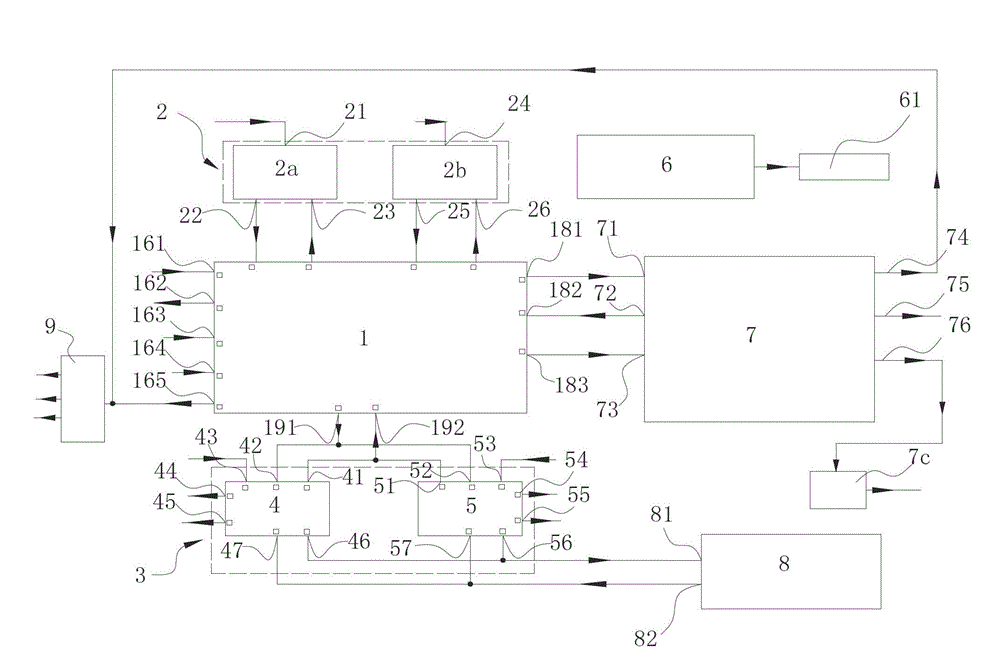

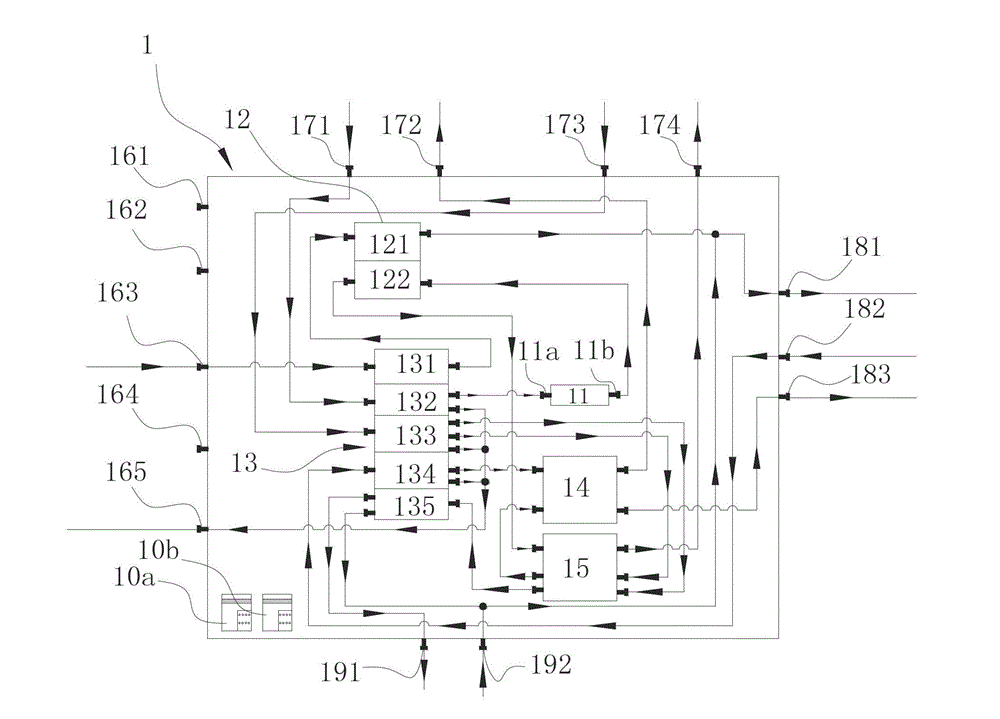

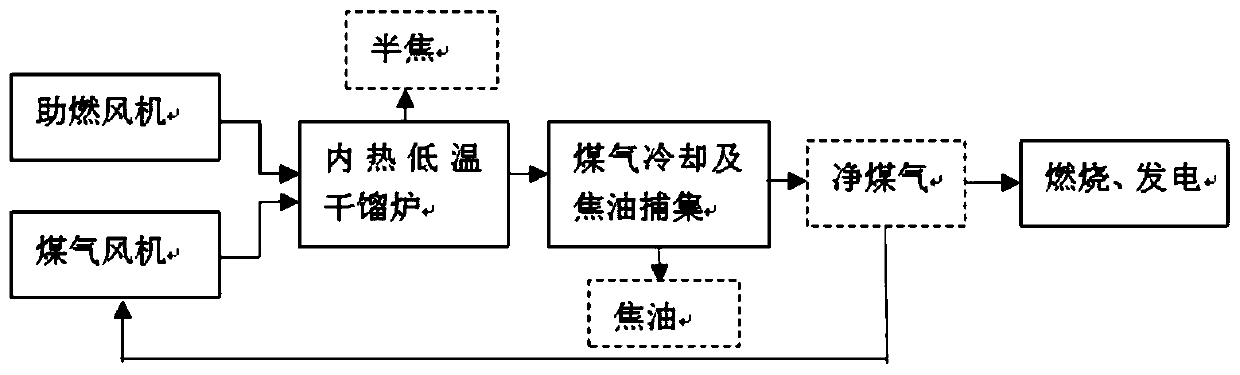

Internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas

ActiveCN111187632AAchieving long-term operationQuality improvementSpecial form destructive distillationThermodynamicsProcess engineering

The invention discloses an internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas. The process comprises the following steps: introducing dehydrogenated coal gas, air and oxygen into an internal heating type low-temperature destructive coal distillation furnace; mixing the air and the oxygen to form oxygen-enriched combustion-supporting gas; and subjecting the dehydrogenized coal gas and the oxygen-enriched combustion-supporting gas to oxygen-enriched combustion in the internal heating type low-temperature destructive coal distillation furnace, wherein the volume fraction of oxygen in the oxygen-enriched combustion-supporting gas is greater than or equal to 30%. A step of acquiring the dehydrogenated coalgas comprises the following sub-steps: carrying out coal gas cooling and tar trapping on coal gas generated by the internal heating type low-temperature destructive coal distillation furnace to obtain purified coal gas; separating and removing hydrogen in the purified gas so as to obtain the dehydrogenated gas. According to the invention, the flame length and the flame temperature of a flame pathcan better meet the requirements of a low-temperature destructive distillation process, the influence of too high combustion speed of oxygen-enriched destructive distillation high-hydrogen-content coal gas is reduced, the long-period operation of an oxygen-enriched destructive distillation process device and the stable quality of dry distillation products are realized, and the high-added-value gradient utilization of the coal gas can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

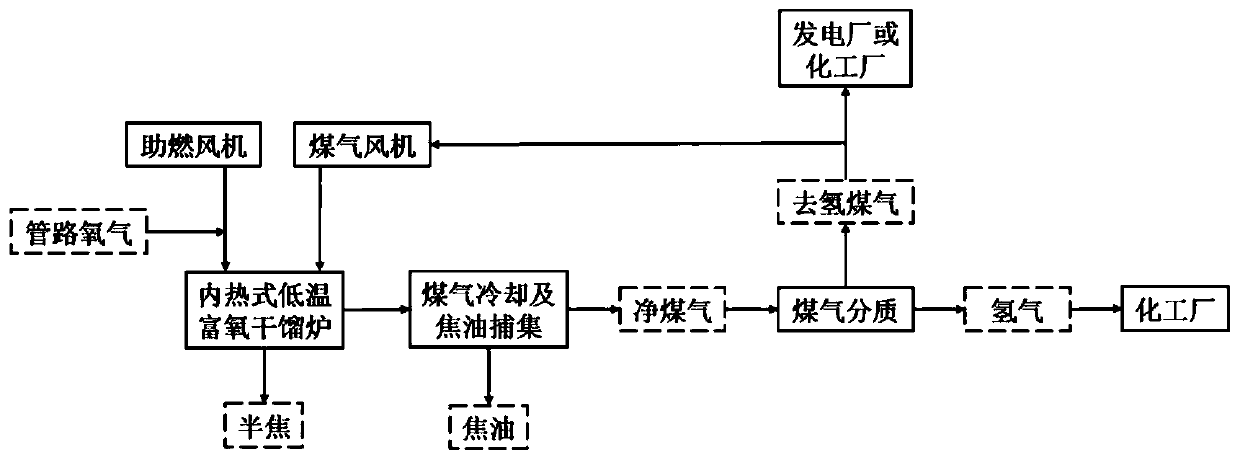

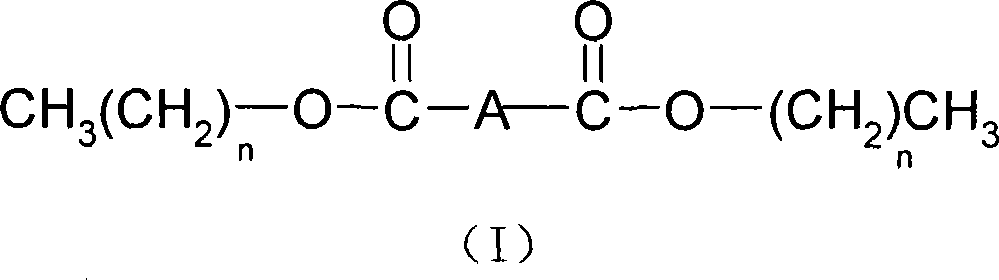

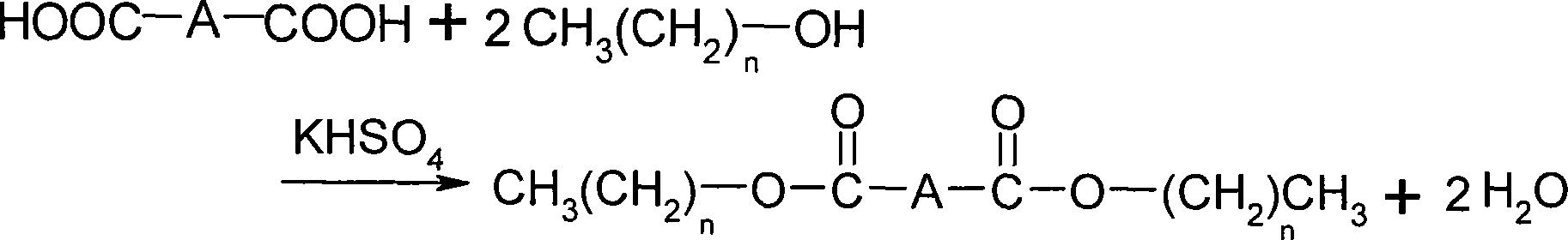

Method for catalyzing and synthesizing bibasic carboxylic ester by potassium hydrogen sulfate

InactiveCN101092357AImprove usage activityEasy to usePhysical/chemical process catalystsOrganic compound preparationSolubilityHydrogen Sulfate

This invention discloses a method for synthesizing dicarboxylate with KHSO4 as the catalyst. The method comprises: adding aromatic or aliphatic dicarboxylic acid and monohydric alcohol into a reaction container, adding KHSO4 as the catalyst for esterification reaction, stirring, heating, and reacting under refluxing to obtain aromatic or aliphatic dicarboxylate. KHSO4 is inorganic solid powder, and has a low solubility in organic solvent, thus can be separated by filtration after reaction. The KHSO4 catalyst thus has such advantages as no contamination to the product, convenient product post treatment, high product purity, low corrosion to apparatus, high catalytic activity after reaction, repeated use by filtration, drying and recovery, easy storage and transportation, and high safety.

Owner:NANJING UNIV OF SCI & TECH

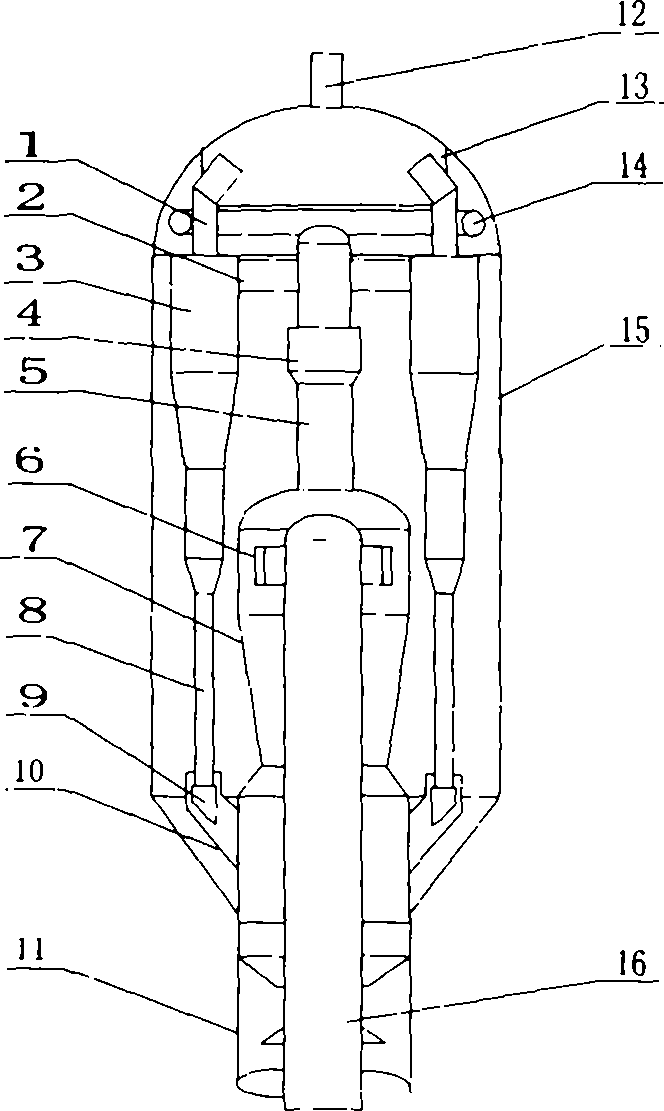

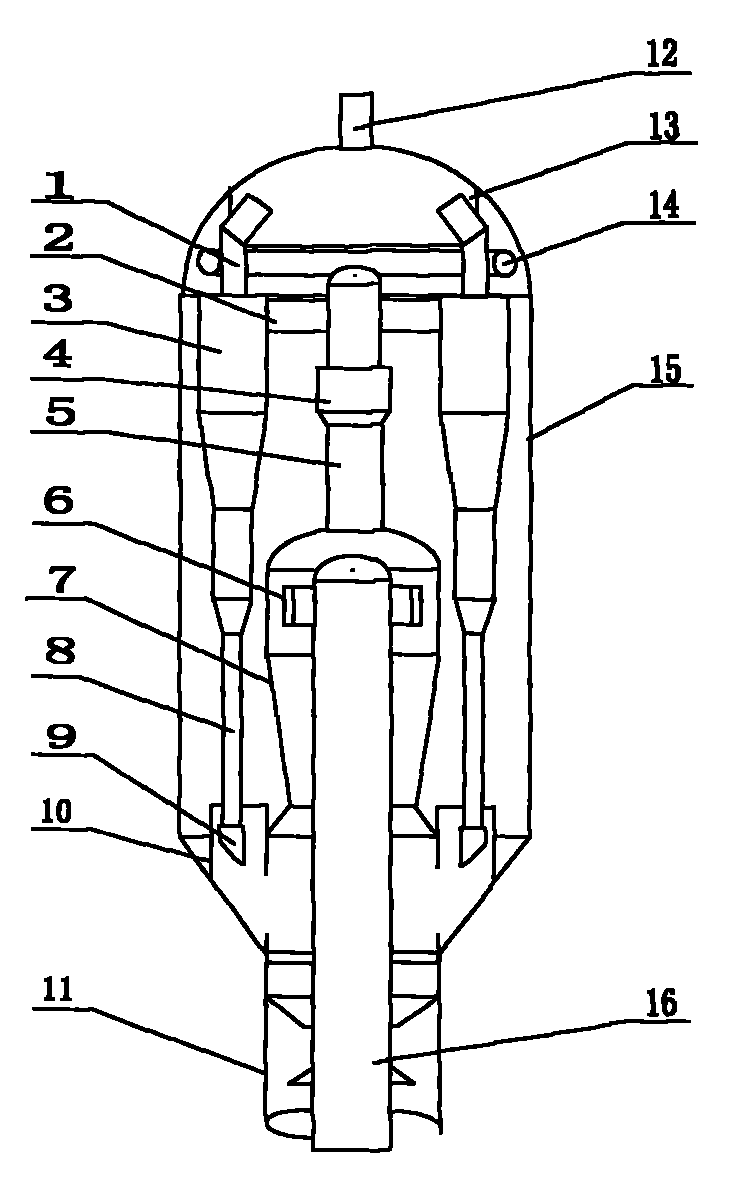

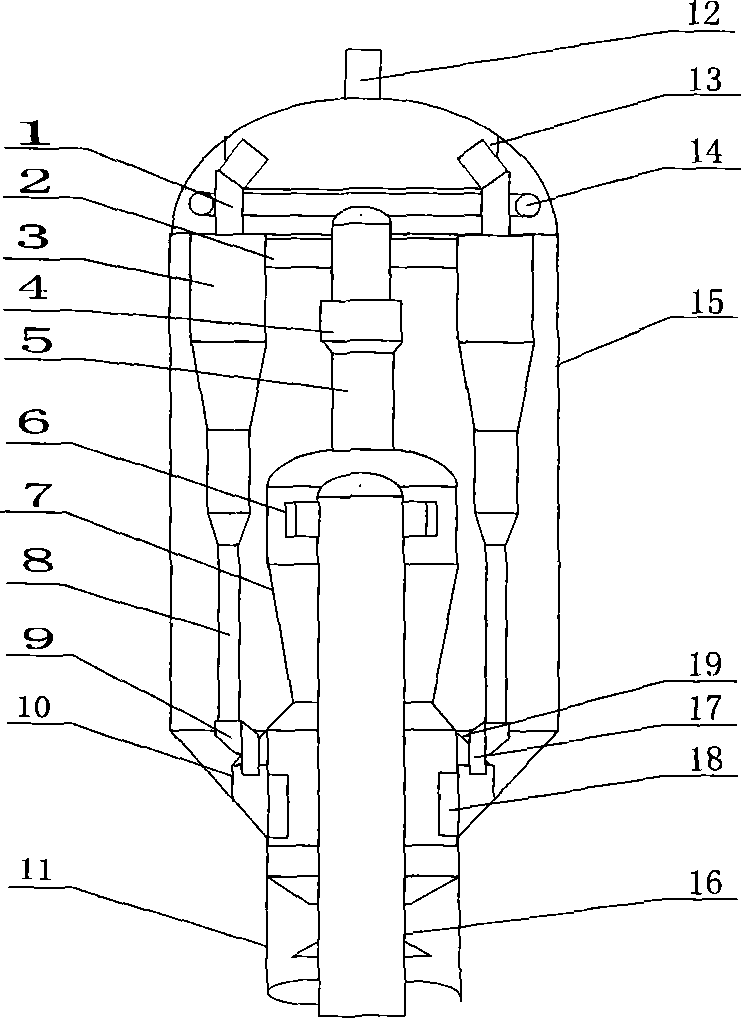

Anti-coking gas-solid separation method and equipment

InactiveCN104277865ASolve cokingReduce excessive thermal cracking reactionsCatalytic crackingChemical/physical processesPetrochemicalDry gas

The invention relates to an anti-coking gas-solid separation method and equipment and belongs to the technical field of petrochemical engineering and fluidization. The method and the equipment are used for solving the problems of reaction that settlers undergo coking and excessive thermal cracking. The method comprises the processes of rapid gas-solid separation, second-stage separation, second-stage dipleg flutter valve discharge and oil vapor lead-out and is characterized by adopting closed rapid cyclone separation, arranging catalyst diversion facilities, enabling the catalyst diversion facilities to be connected with the closed rapid cyclone separation and the second-stage separation, so as to form a closed separation system, and closely guiding a catalyst, oil vapor and anti-coking steam, which are discharged from second-stage dipleg flutter valves, into the closed separation system. According to the method disclosed by the invention, only steam exists in a settler without oil vapor and a catalyst, so that cleanup is realized, the problem of coking of the settler is thoroughly solved, the reaction of excessive thermal cracking of the oil vapor is reduced, the yield of dry gas is lowered, and the yield of products is increased. The invention further provides a closed rapid cyclone separator and catalyst diversion equipment, which are used for implementing the method disclosed by the invention. The method and the equipment are applied to devices for catalytic cracking, catalytic pyrolysis and the like of heavy oil.

Owner:刘英聚

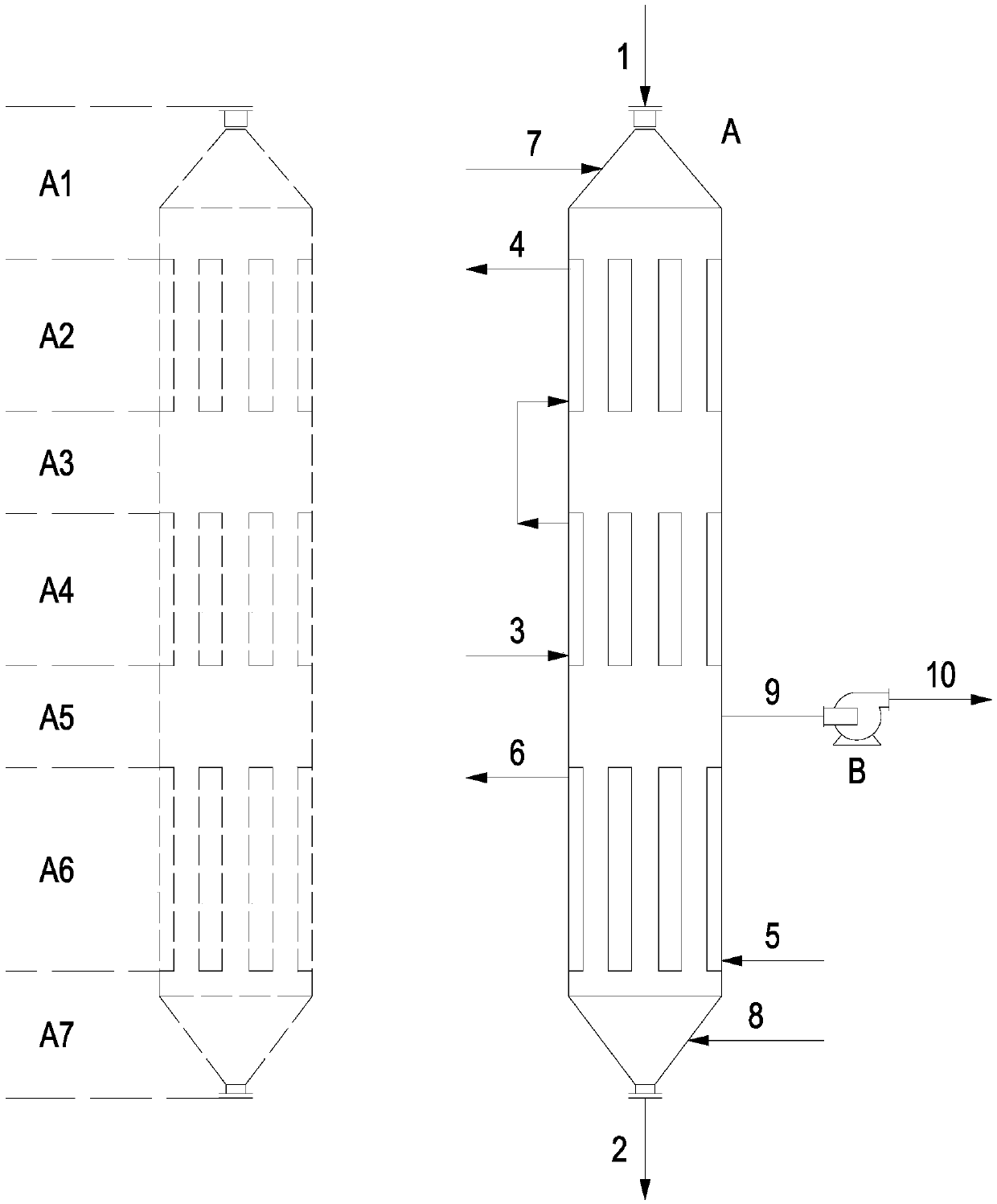

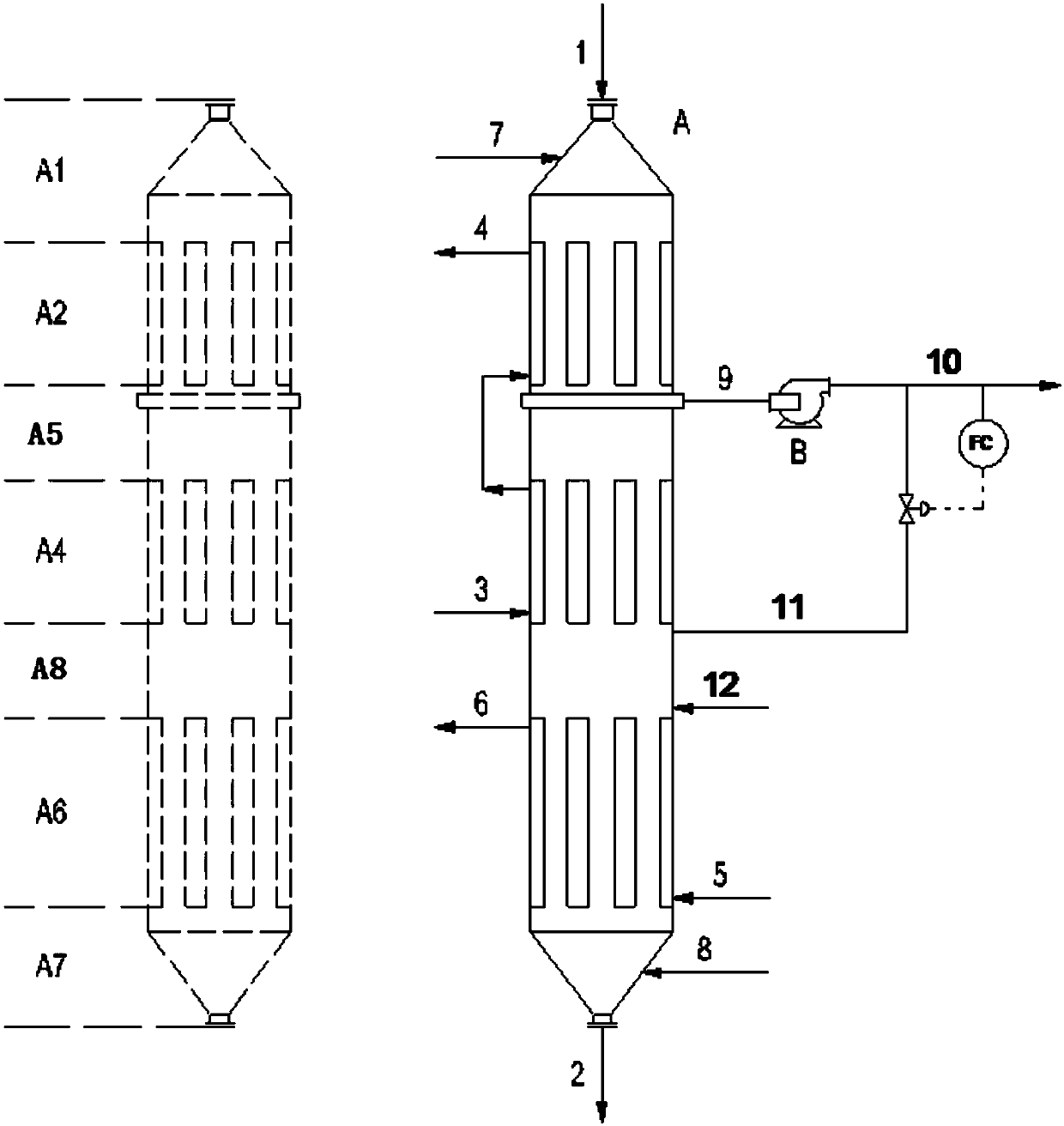

System and method for regenerating active coke

ActiveCN110624525AReduce contentStable flowGas treatmentDispersed particle separationDeposition temperatureEngineering

The invention belongs to the field of chemical engineering, and discloses a system and a method for regenerating active coke. The system for regenerating active coke comprises a regeneration tower anda regeneration fan, and the regeneration tower is sequentially provided with a feeding distribution section, a preheating section, a regeneration tail gas extraction section, a heating section, a redistribution and activation section, a cooling section and an outlet collection section from top to bottom. A process flow of circulating the regeneration tail gas to the bottom of the heating sectionis adopted to generate new oxygen-containing and nitrogen-containing functional groups on the surface of the active coke and improve the desulfurization and denitrification performance of the active coke; the flow and composition stability of regeneration tail gas can be guaranteed, the flow and the SO3 content of the regeneration tail gas can be reduced, the SO2 concentration is improved, the salt deposition temperature of a regeneration tail gas system is reduced, and the salt deposition tendency is reduced, so stable operation of a downstream regeneration tail gas treatment system is facilitated; and the process flow is simple, and is safe and reliable to operate, so the stability and reliability of the active coke regeneration technology are improved.

Owner:SINOPEC ENG +1

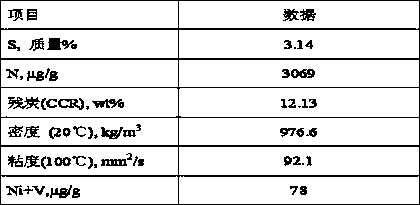

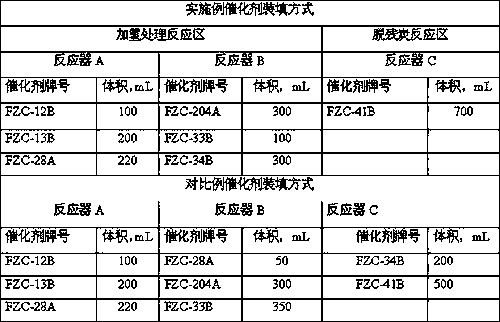

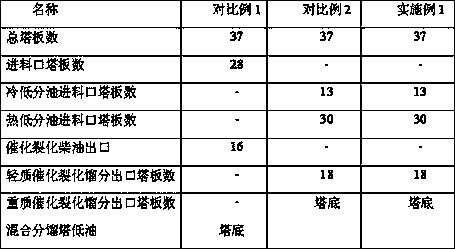

Combined process of hydrotreating and catalytic cracking for inferior oil products

ActiveCN107794088AProcess advantagesImprove responseLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesFractionationMixed materials

The invention discloses a combined process of hydrotreating and catalytic cracking for inferior oil products. The process comprises the following contents: raw oil and a hydrogen gas are mixed, the mixed material enters a hydrotreating reaction zone, and the obtained effluent of a hydrogenation reaction is subjected to gas-liquid separation, so that hot low-separation oil and cold low-separation oil are obtained; the obtained hot low-separation oil and cold low-separation oil are directly enter a fractionation tower through different material inlets for separation, so that a light catalytic cracking raw material and a heavy catalytic cracking raw material are obtained; a part of the obtained heavy catalytic cracking raw material and a hydrogen gas are mixed, the mixed material enters a hydrogenation residual-carbon removing reaction zone, the reaction product enters a separation unit, and the reaction product and the reaction effluent of the hydrotreating reaction zone are subjected toseparation; and the obtained light catalytic cracking raw material and the rest of the heavy catalytic cracking raw material individually enter a catalytic cracking device or enter the catalytic cracking device after mixing for a catalytic cracking reaction, and the reaction product enters a catalytic cracking product separation system. The combined process provided by the invention can produce amaximum amount of high-value-added products, and can greatly reduce the overall energy consumption of a hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of clean diesel oil with low condensation point

ActiveCN103805244ARealize comprehensive utilizationGuaranteed yieldTreatment with hydrotreatment processesNaphthaSulfur

The invention discloses a production method of clean diesel oil with a low condensation point. The method comprises the following steps: mixing diesel oil with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst, and a hydro-upgrading catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the clean diesel oil product with a low condensation point, and a little light naphtha and liquefied gas. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-refining and hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

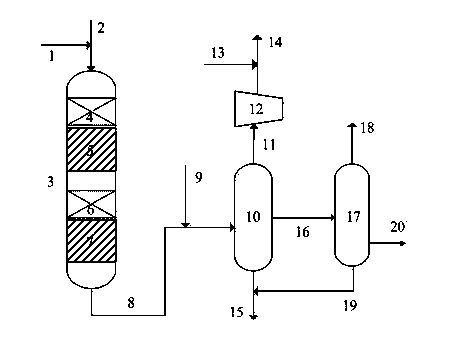

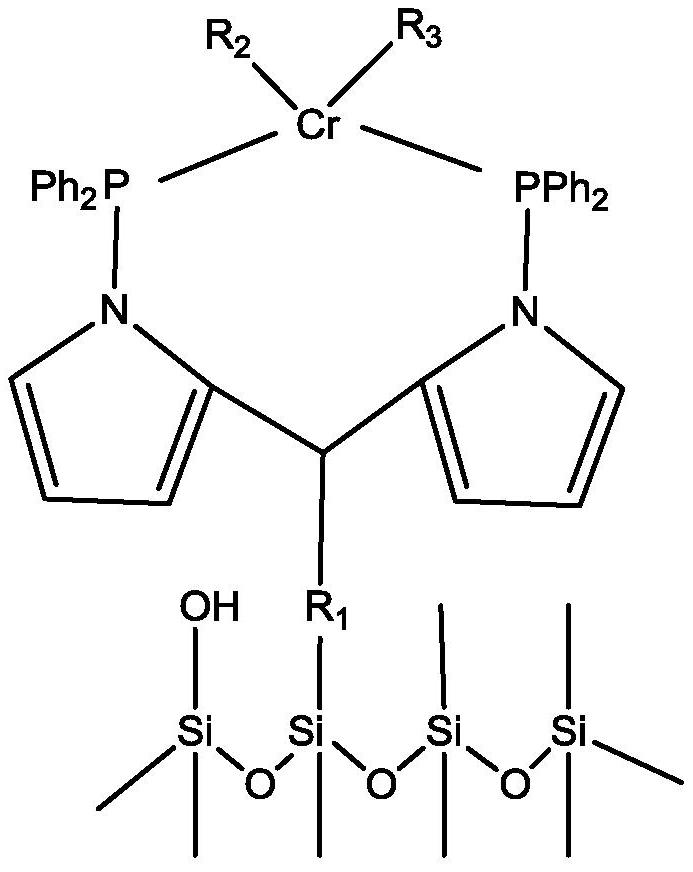

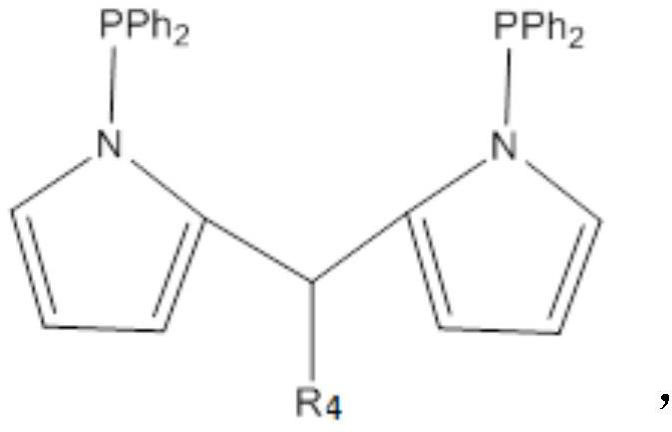

Ethylene oligomerization catalyst and preparation method and application thereof

ActiveCN111841646AReduce use costReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPolymer sciencePtru catalyst

The present invention relates to an ethylene oligomerization catalyst and a preparation method and application thereof, the structure of the catalyst is shown in the specification, or R1 is selected from-CH2-,-(CH2) 2-,-(CH2) 3-,-(CH2) 4-,-C (CH3) 2-,-C (CH3) 2CH2-, a cyclohexyl linking group or a phenyl linking group, and R2 and R3 are respectively selected from chlorine or methyl. The preparation method of the catalyst comprises the following steps: (1) grafting a ligand on silica gel; and (2) loading an active component Cr. The catalyst disclosed by the invention and an aluminum alkyl cocatalyst form an ethylene oligomerization catalyst system; the catalyst can catalyze an ethylene oligomerization reaction with high activity, the catalytic activity of the carrier catalyst can reach 4.99* 10 < 6 > g product / (mol.Cr.h), the selectivity of 1-hexene and 1-octene with high added values is high, and the catalyst is easy to separate from the product.

Owner:WANHUA CHEM GRP CO LTD +1

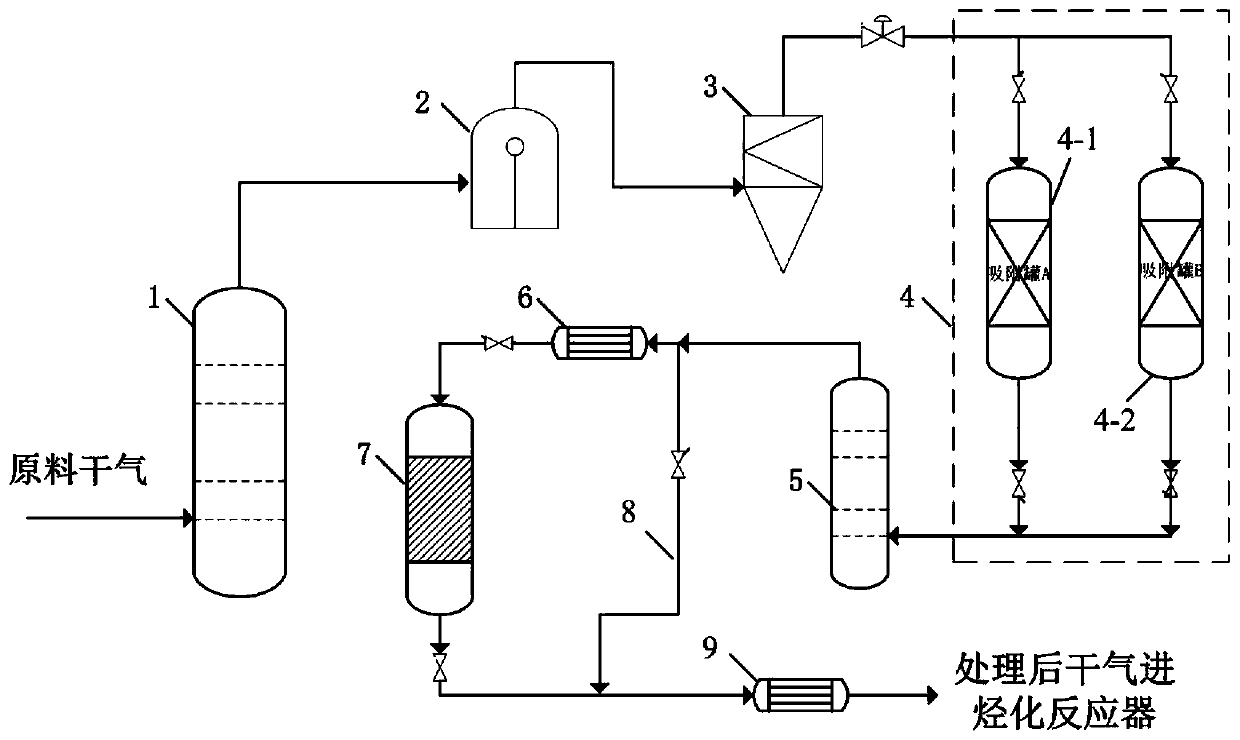

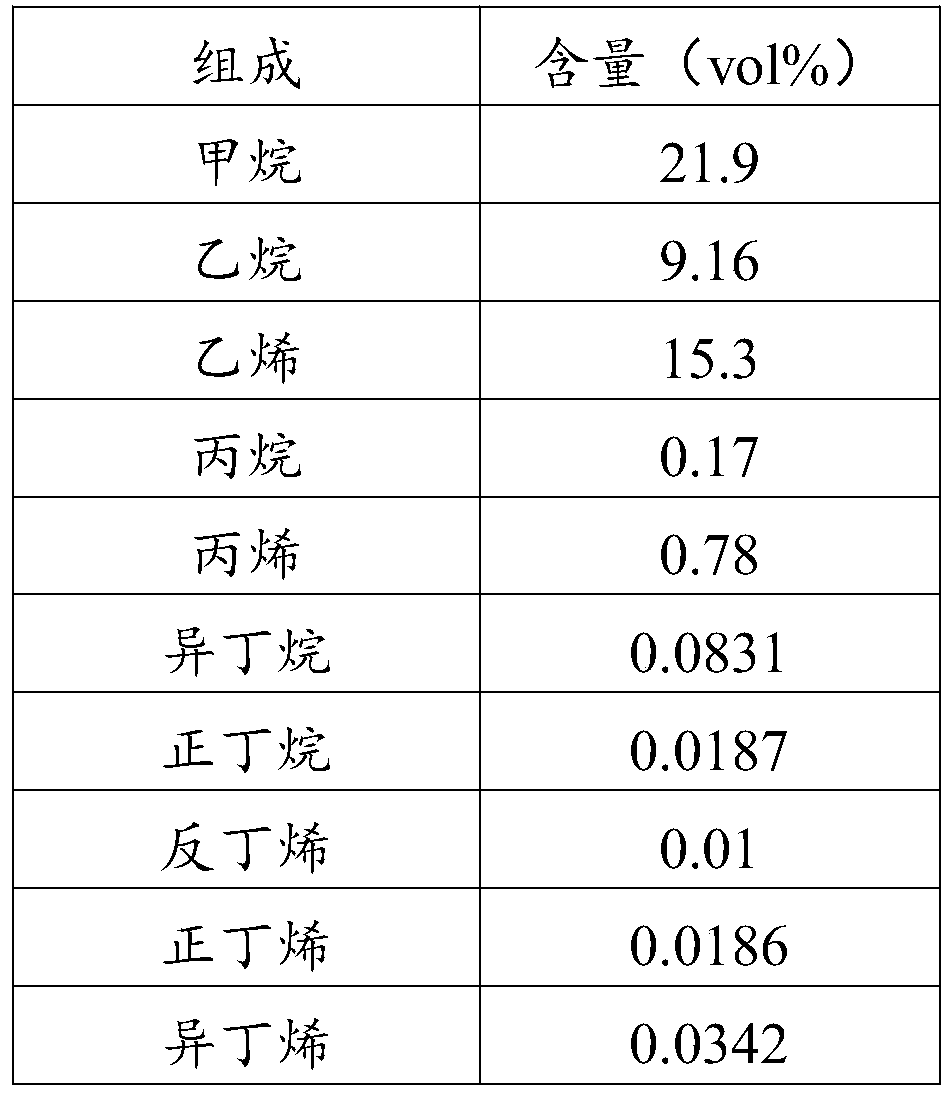

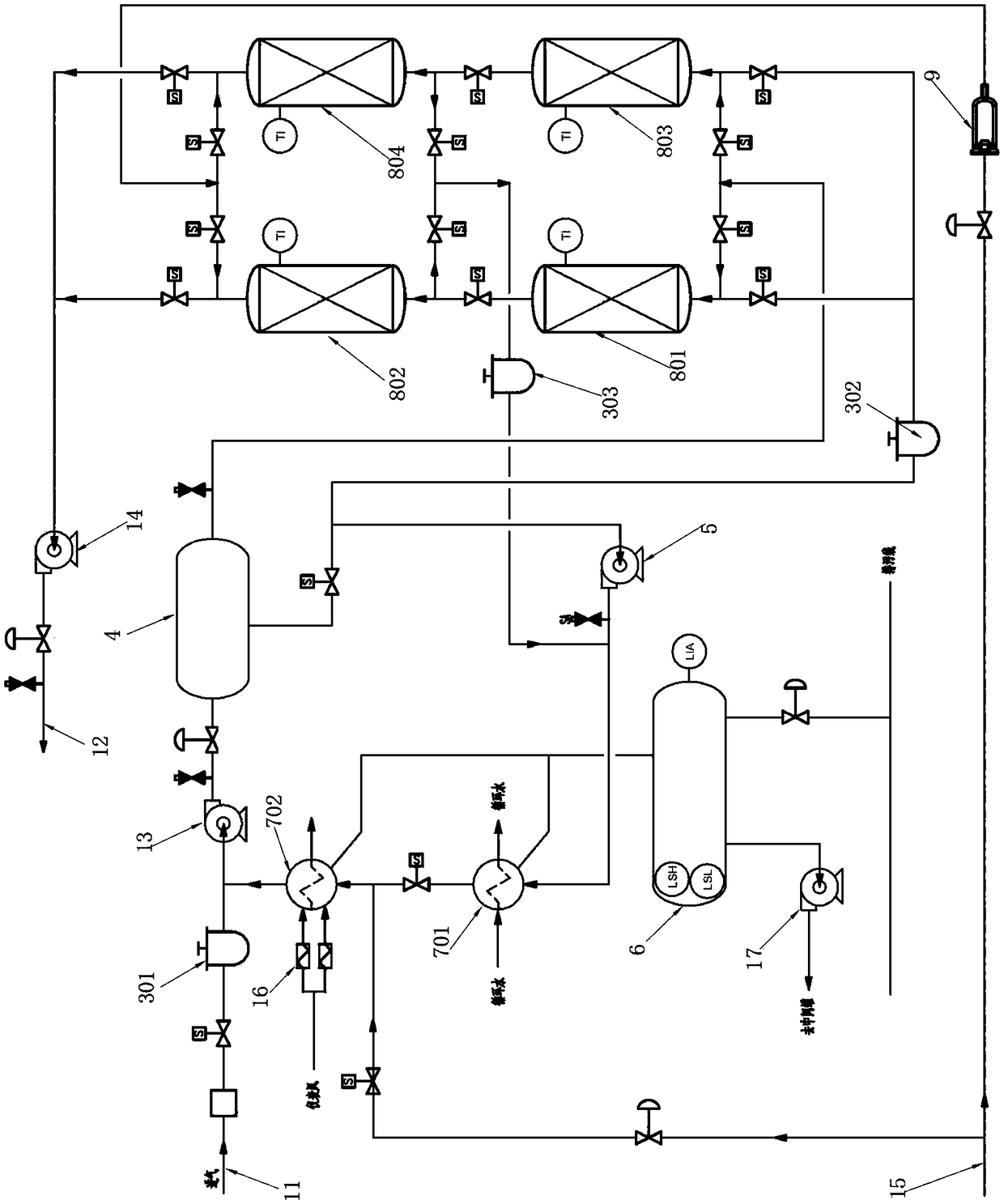

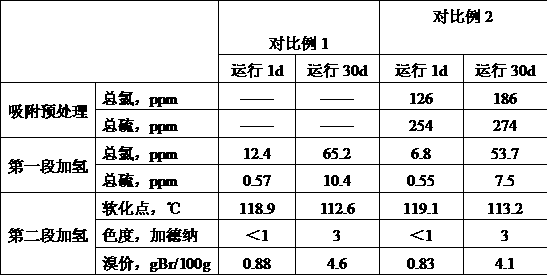

Method and device for purifying dry feed gas for preparing ethyl benzene

ActiveCN111450662AAvoid poisoningExtend the life cycleGas treatmentDispersed particle separationPtru catalystSide reaction

The invention relates to the technical field of ethyl benzene preparation from dry gas, in particular to a method and device for purifying dry feed gas for preparing ethyl benzene. The method comprises the following steps: A) carrying out primary de-amination on dry feed gas in a water washing tower; wherein the temperature of the primary de-amination is 0-50 DEG C, and the pressure is 0.7-1.0 MPa; B) after primary de-amination, carrying out primary gas-liquid separation on the dry gas in a cyclone separator; C) after primary gas-liquid separation, carrying out secondary gas-liquid separationon the dry gas in a coalescer; D) after secondary gas-liquid separation, carrying out de-amination on the dry gas in an adsorption tower again; E) carrying out heavy component removal on the dry gas subjected to de-amination again in a propylene absorption tower; and F) subjecting the dry gas after heavy component removal to heat exchange, and carrying out hydrogenation acetylene removal reactionto obtain purified dry gas. The purification method can effectively purify dry feed gas, the purified dry feed gas enters an alkylation reactor, ammonia poisoning of a catalyst can be avoided, carbondeposition rate and side reaction can be inhibited, and long-term operation of an alkylation reaction device is facilitated.

Owner:SHANDONG CHAMBROAD PETROCHEMICALS CO LTD

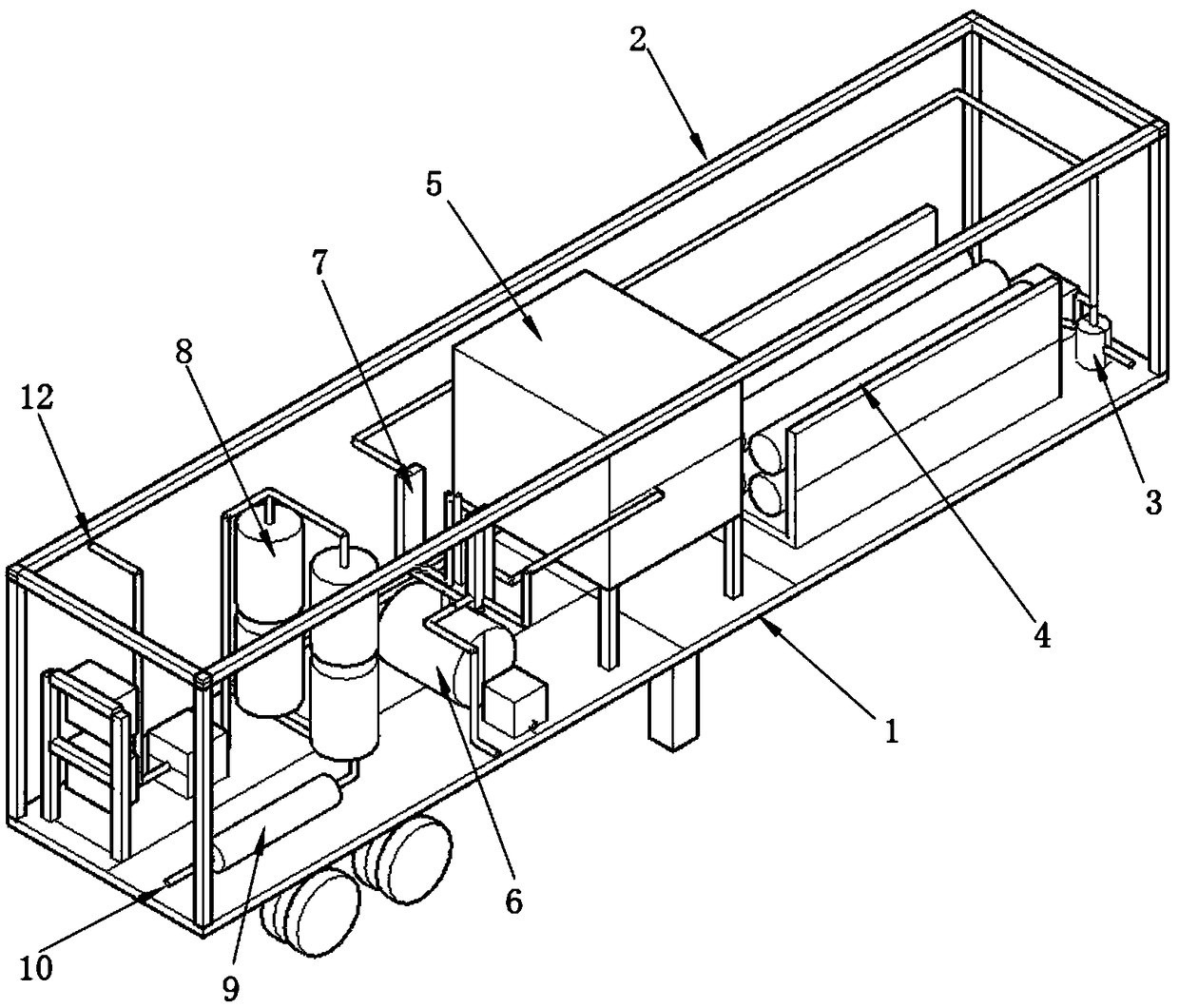

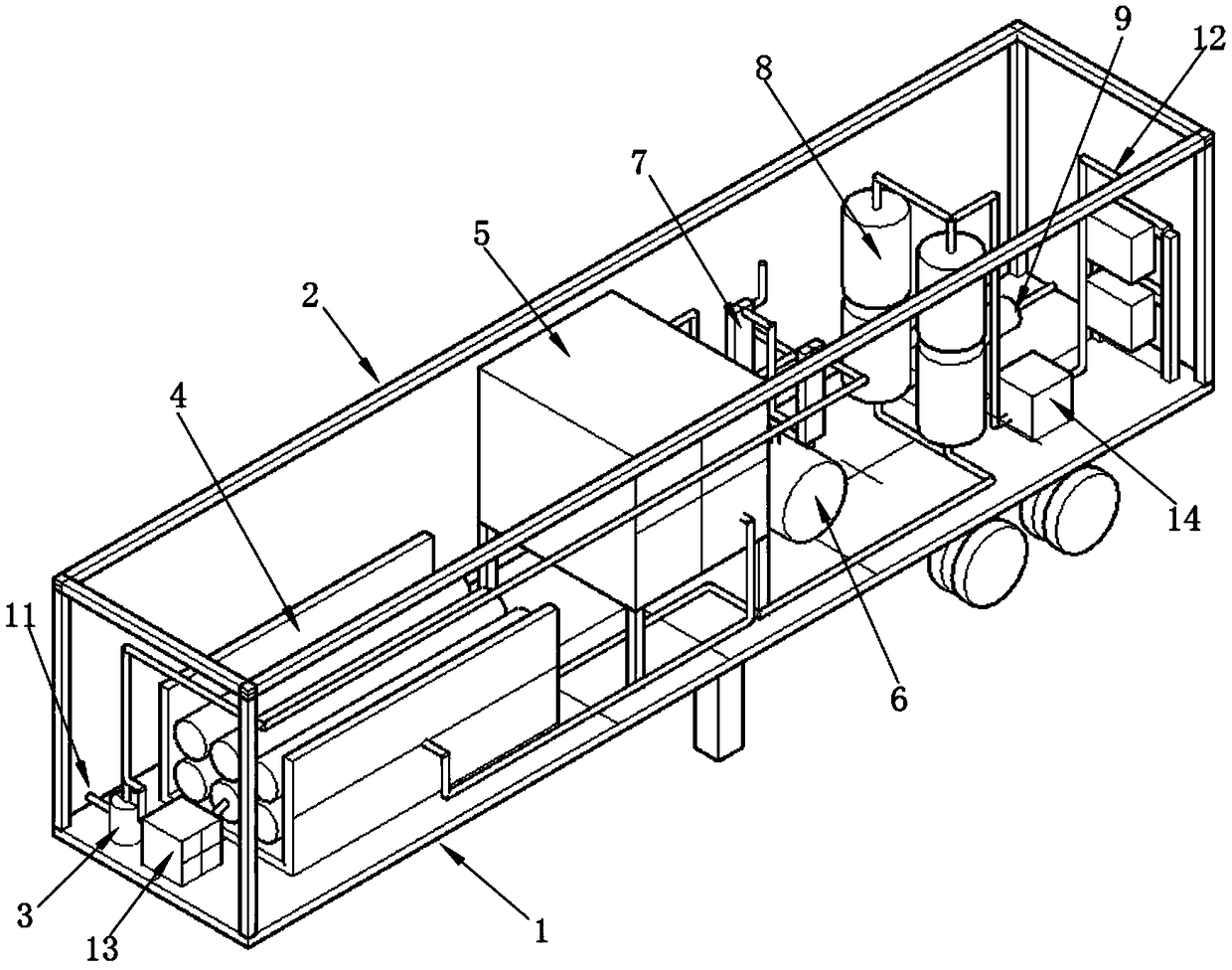

Vehicle-mounted mobile volatile organic compound waste gas treatment device, system and method

PendingCN109224783AReduce pollutionSimple structureGas treatmentDispersed particle separationRecuperatorVacuum pump

The invention relates to a vehicle-mounted mobile volatile organic compound waste gas treatment device, system and method. Residual volatile organic compound waste gas in a container is introduced into a membrane separation component to carry out enrichment concentration treatment; volatile organic compound waste gas at an enrichment side of the membrane separation component is introduced into a heat exchange component by a vacuum pump to carry out primary heat exchange with circulating water by a first heat exchanger, and after primary heat exchange, enters a second heat exchanger to carry out secondary heat exchange with compressed air at a cold end outlet of a vortex tube of a vortex component; after heat exchange, condensate enters a condensate recovery tank of a condensate recovery component to be recovered, and noncondensable gas is returned to the membrane separation component by a first fan; low-concentration volatile organic compound gas at a raffinate side of the membrane separation component is introduced into an adsorption component to be adsorbed by an adsorption tank, and after adsorption, purified gas is discharged into the atmosphere via a second fan at an outlet ofthe adsorption tank. According to the vehicle-mounted mobile volatile organic compound waste gas treatment device, system and method, treatment on the residual volatile organic compound waste gas inopen container equipment can be completed, product waste and atmosphere pollution are reduced, and flexibility is high.

Owner:孙文举

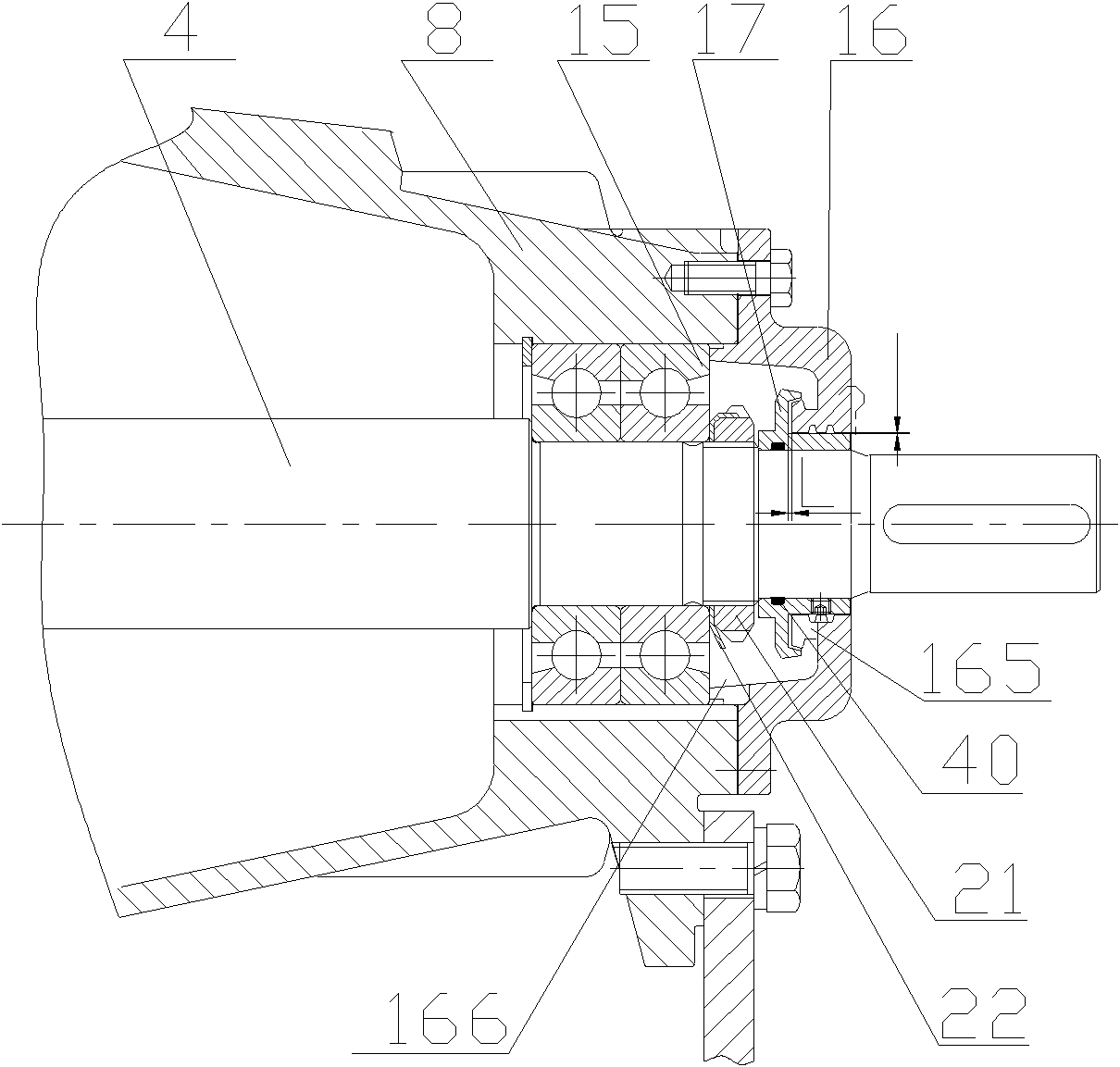

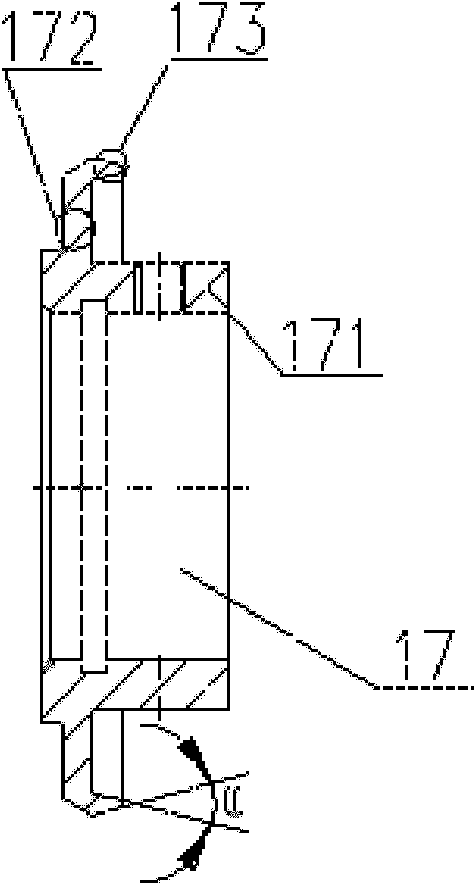

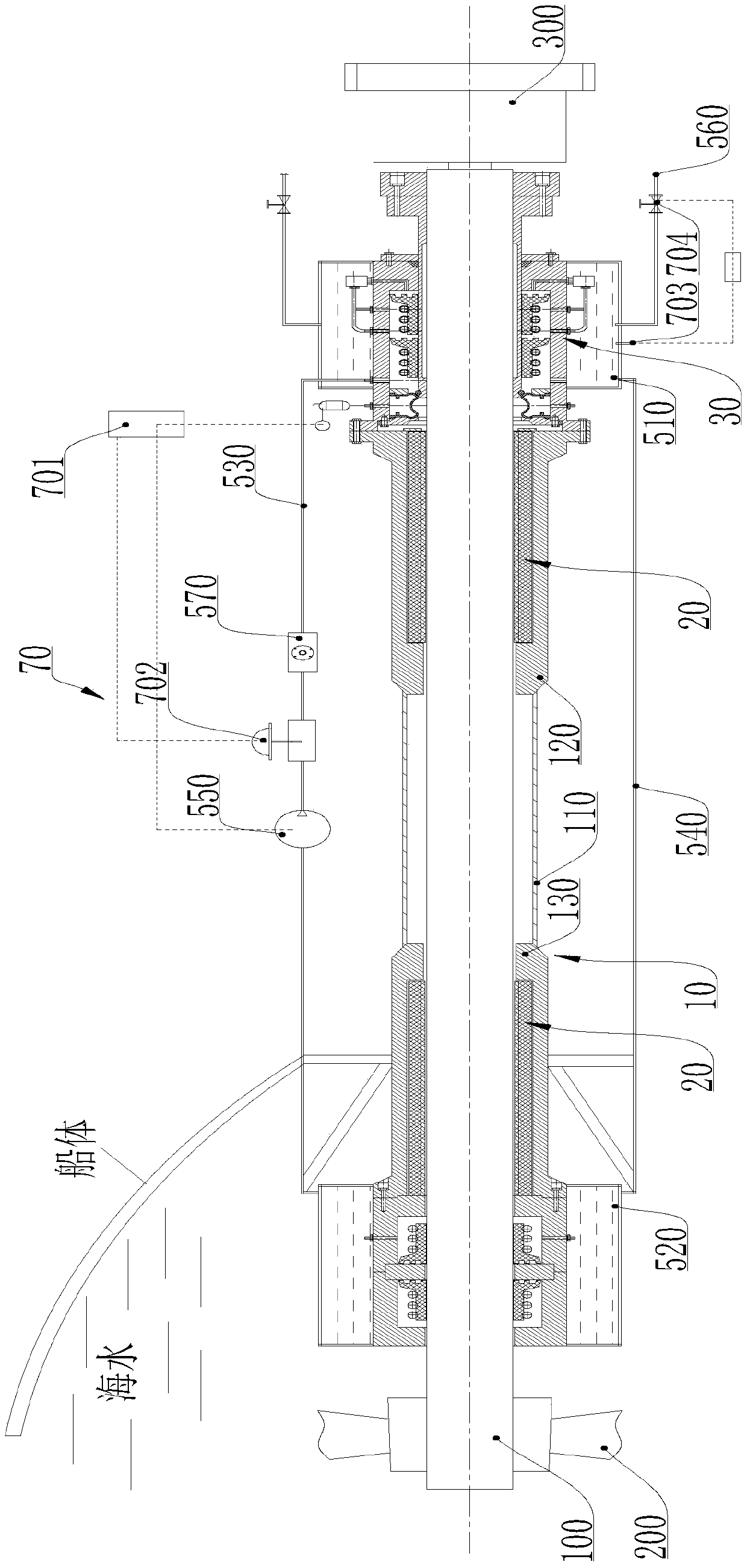

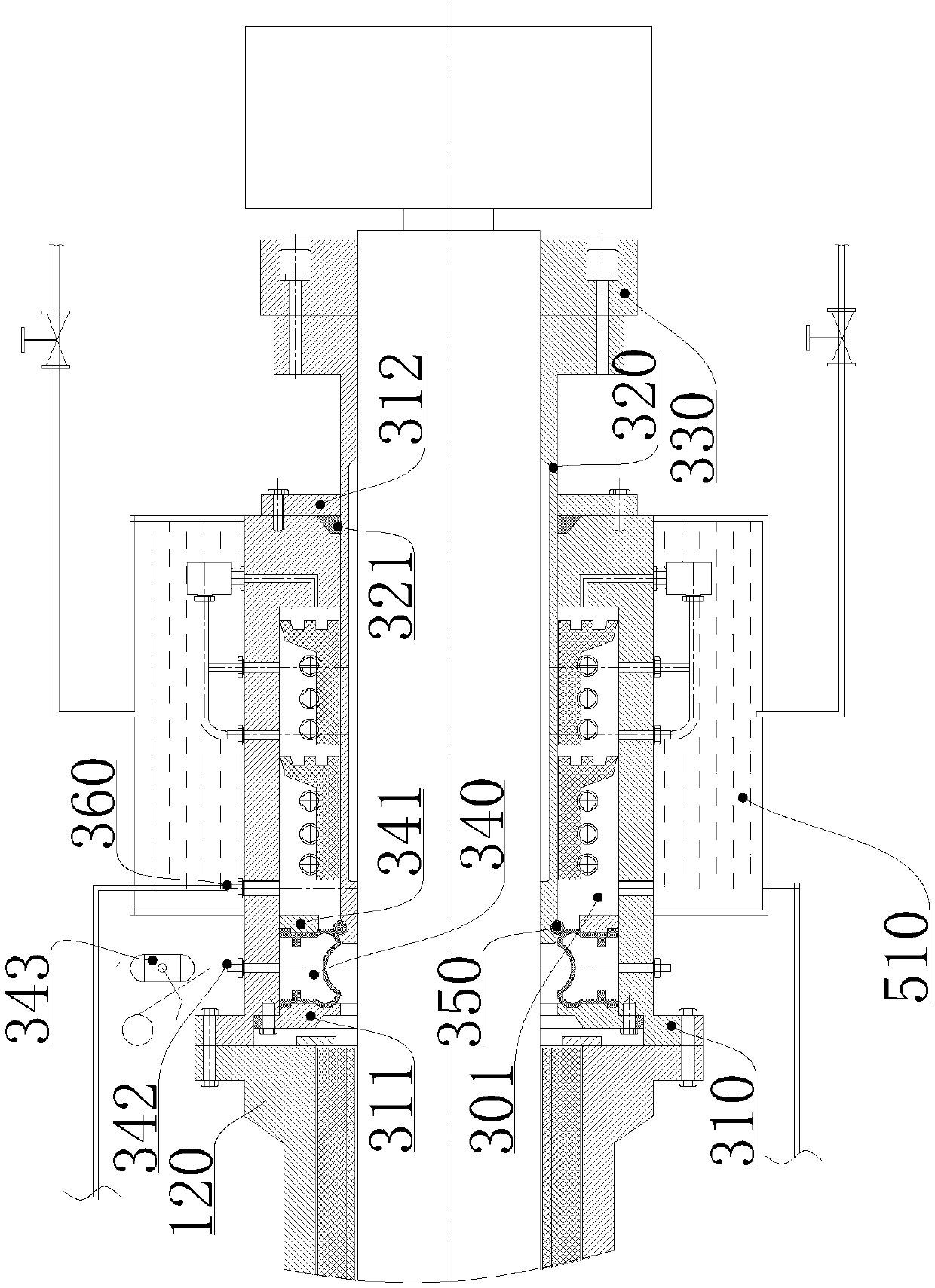

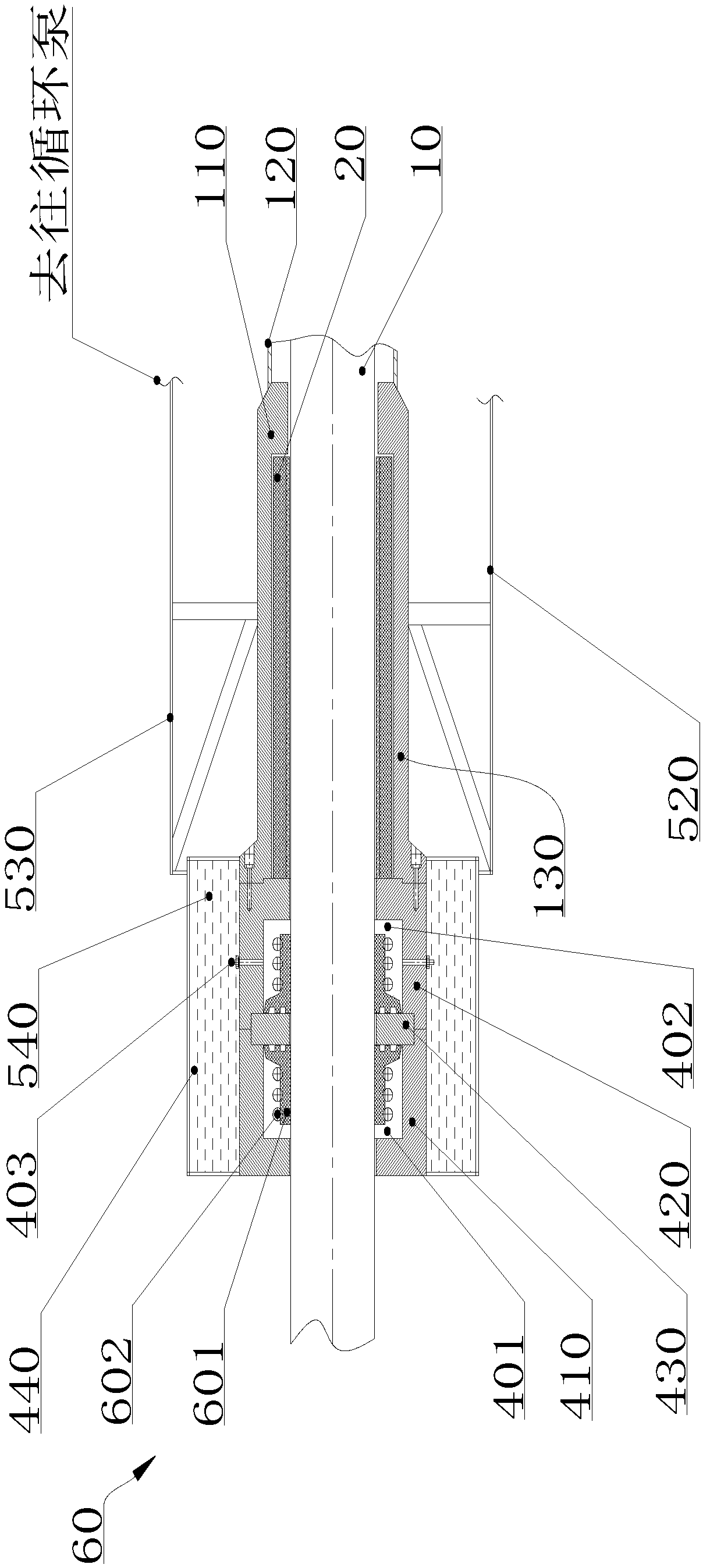

Closed type water-lubricating bearing system

ActiveCN109681533AVersatileMeet growth requirementsEngine sealsPropulsive elementsCouplingControl system

The invention discloses a sealed type water-lubricating bearing system. The sealed type water-lubricating bearing system comprises a shaft sleeve assembly and water sealing bearings which support a tail shaft, wherein the inner peripheries of the water sealing bearings and the outer periphery of the tail shaft are in water lubrication; the front sealing assembly is used for sealing one group of water sealing bearings at one end close to a shaft coupler, and is used for preventing circulating fresh water from leaking towards the shaft coupler; a rear sealing assembly is used for sealing anothergroup of water sealing bearings, close to one end of a propeller, and is used for preventing circulating fresh water from leaking towards the propeller, and preventing seawater from passing through the rear sealing assembly; and the closed type water-lubricating bearing system is further provided with a water supply system for forming flowing fresh water circulation between the shaft sleeve assembly and the water sealing bearings, and cooling the front sealing assembly and the rear sealing assembly. The closed type water-lubricating bearing system provided by the invention is more perfect inintegral function, can provide good sealing requirements and cooling performances during operation, and facilities better maintenance and operation by judging a flowing condition of fresh water through a control system.

Owner:CHANGCHUN A&Z SCI CO LTD

Method for producing clean low freezing point diesel oil by treating high nitrogen diesel oil

ActiveCN105087064AQuality improvementLowering the freezing pointTreatment with hydrotreatment processesIsomerizationHydrogenation reaction

The invention discloses a method for producing clean low freezing point diesel oil by treating high nitrogen diesel oil. The method comprises: after mixing a diesel oil raw material with hydrogen, sequentially feeding the mixture through at least two serial hydrogenation reaction regions, wherein each of the hydrogenation reaction regions according a material flowing direction sequentially comprises a hydrogenation refining catalyst bed layer and a compound catalyst bed layer mixed and filled with a hydrodewaxing catalyst and a hydrogenation modified isomerization-visbreaking catalyst; and separating and fractionating a reaction effluent obtained in the last hydrogenation reaction region to obtain the low freezing point diesel oil. According to the method disclosed by the invention, temperature rise in a modified depressing process and temperature drop in a hydrodewaxing process are reasonably utilized,so that the yield and cetane number of the diesel oil are improved while the low freezing point diesel oil is produced, and therefore, the hot-spot temperature is reduced and the operating period is prolonged. In addition, the consumption of cold hydrogen or the gas loss of a heating furance is reduced, and the operating cost is further lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing clean diesel oil with low condensation point by treating inferior diesel oil

ActiveCN103805268ARealize comprehensive utilizationGuaranteed yieldTreatment with hydrotreatment processesFractionationLiquid gas

The invention discloses a method for producing clean diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydrodewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst, and a simple hydro-upgrading catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the clean diesel oil product with a low condensation point, and a few light naphtha and liquefied gas products. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-refining and hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

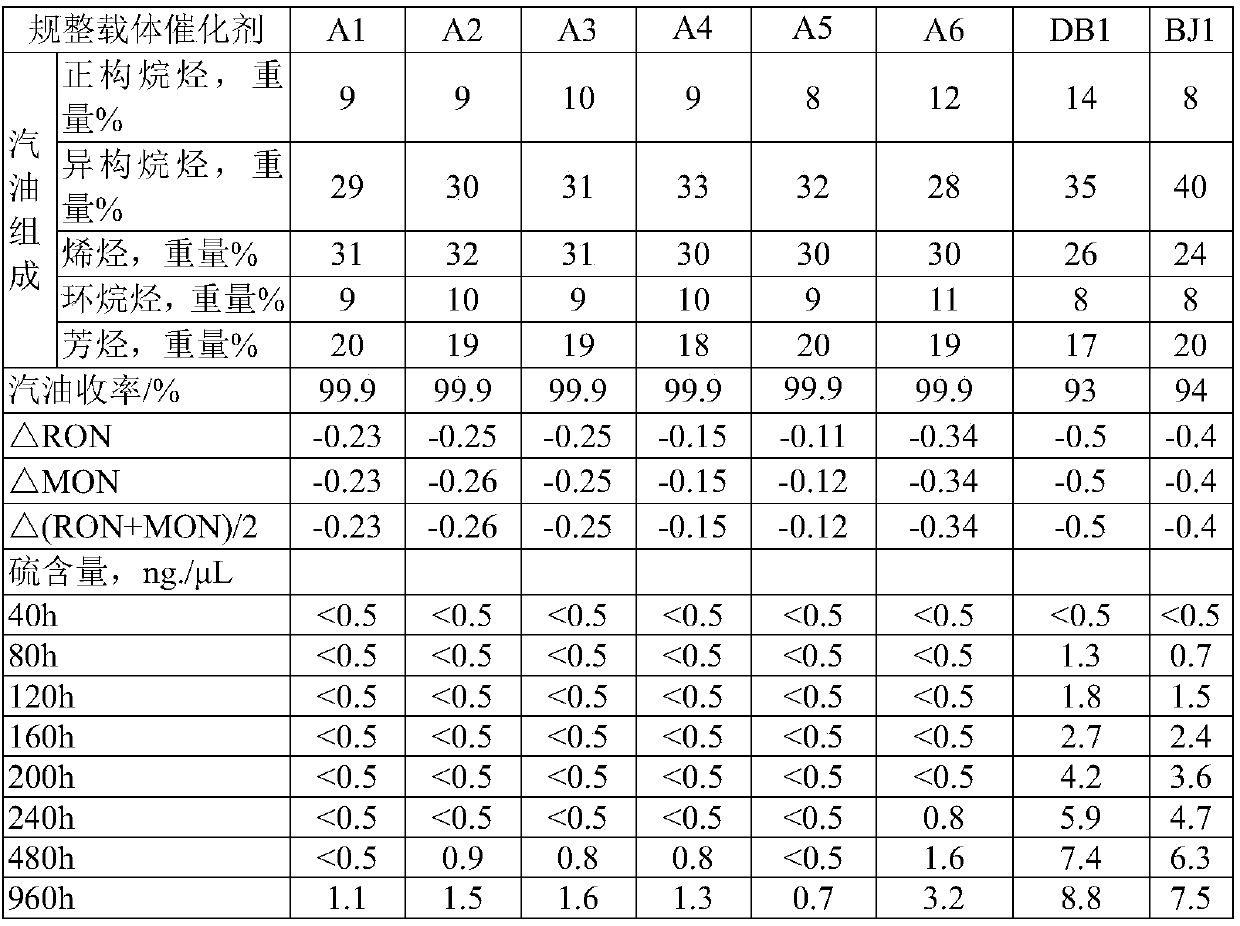

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

PendingCN111085187AHigh activityHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsPtru catalystActive agent

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the surface of the regular carrier, wherein the active coating comprises a matrix containing IIA and IIB group metal oxides and a modified metal film attached to the outer surfaceof the matrix, the modified metal film comprises a modified metal, and the modified metal comprises one or more of Cr, Mo and W. The preparation method comprises the following steps: forming a mixturefrom metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; after the ultrasonic treatment, separating the mixed solution to obtain suspension; contacting the suspension with matrix particles, carrying out freeze drying to obtain matrix particles containing a modified metal film, andcoating the regular carrier with the matrix particles containing the modified metal film to obtain the regular carrier catalyst. The catalyst is used for hydrocarbon hydro-desulfurization, has high desulfurization activity and good stability, and can reduce the octane number loss of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

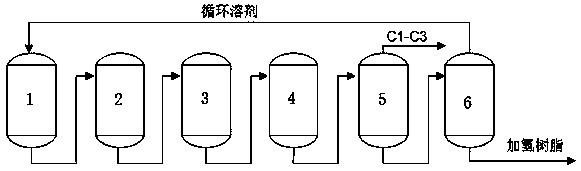

Hydrogenation method of high-chlorine C9 petroleum resin

ActiveCN111548450AAvoid inactivationShorten the life cyclePlastic recyclingHydrogenation reactionPetroleum resin

The invention discloses a hydrogenation method of high-chlorine C9 petroleum resin, which comprises the following steps: (1) feeding a dissolved C9 petroleum resin raw material into a dechlorination tower of a first-stage hydrogenation reactor, and carrying out hydrogenation adsorption dechlorination reaction; (2) feeding the first-stage reaction product into a desulfurization tower of a second-stage hydrogenation reactor, and carrying out a hydrogenation adsorption desulfurization reaction; (3) feeding the second-stage reaction product into a third-stage hydrogenation reactor decolorizing tower, and carrying out olefin and aromatic hydrocarbon hydrogenation saturation reaction; and (4) enabling the third-stage reaction product to sequentially pass through a stripping tower, a normal-pressure distillation tower and a reduced-pressure distillation tower to obtain hydrogenated C9 petroleum resin. The method has the characteristics of simple process, low hydrogenated resin chroma and highresin yield.

Owner:WUHAN KELIN FINE CHEM

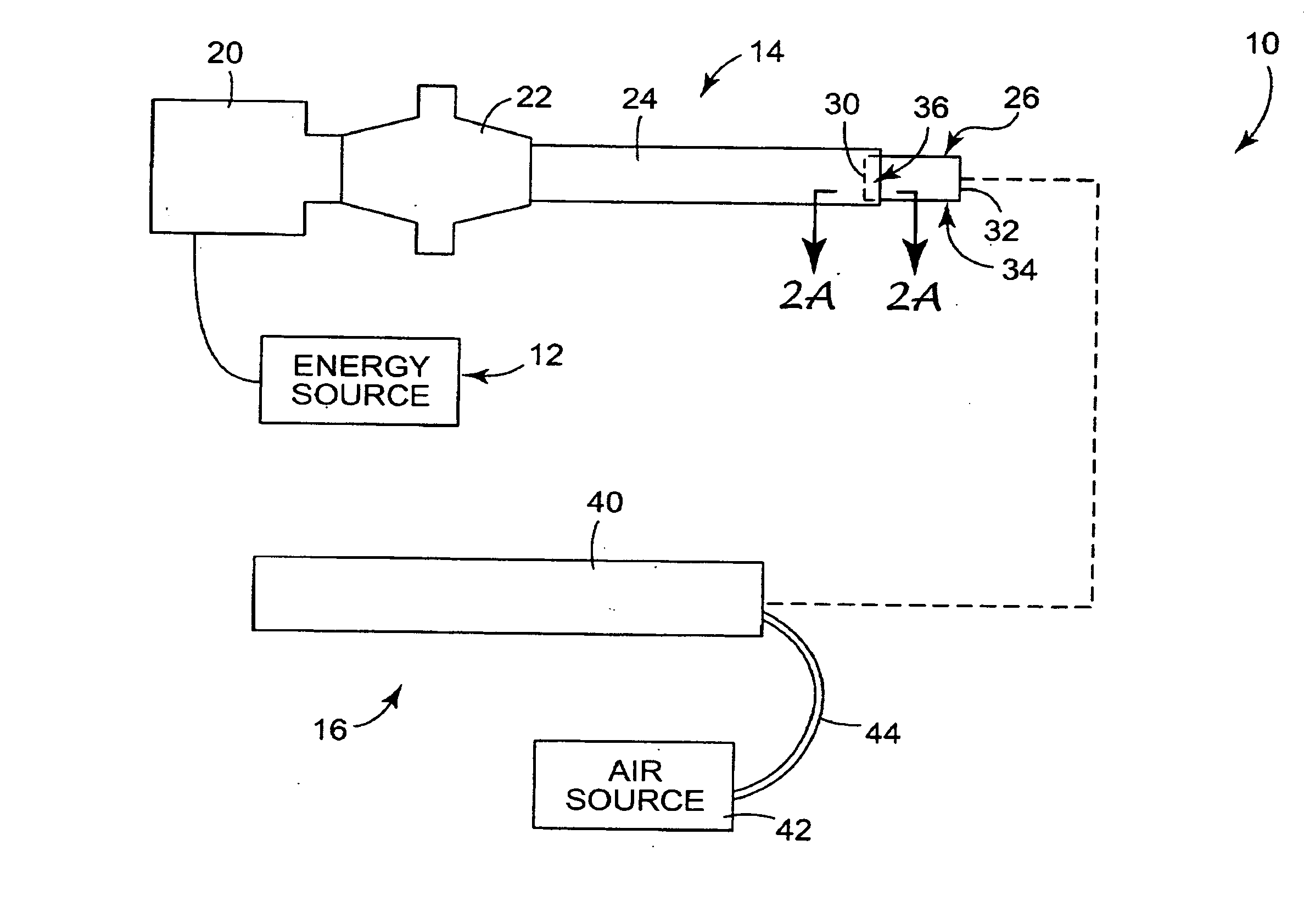

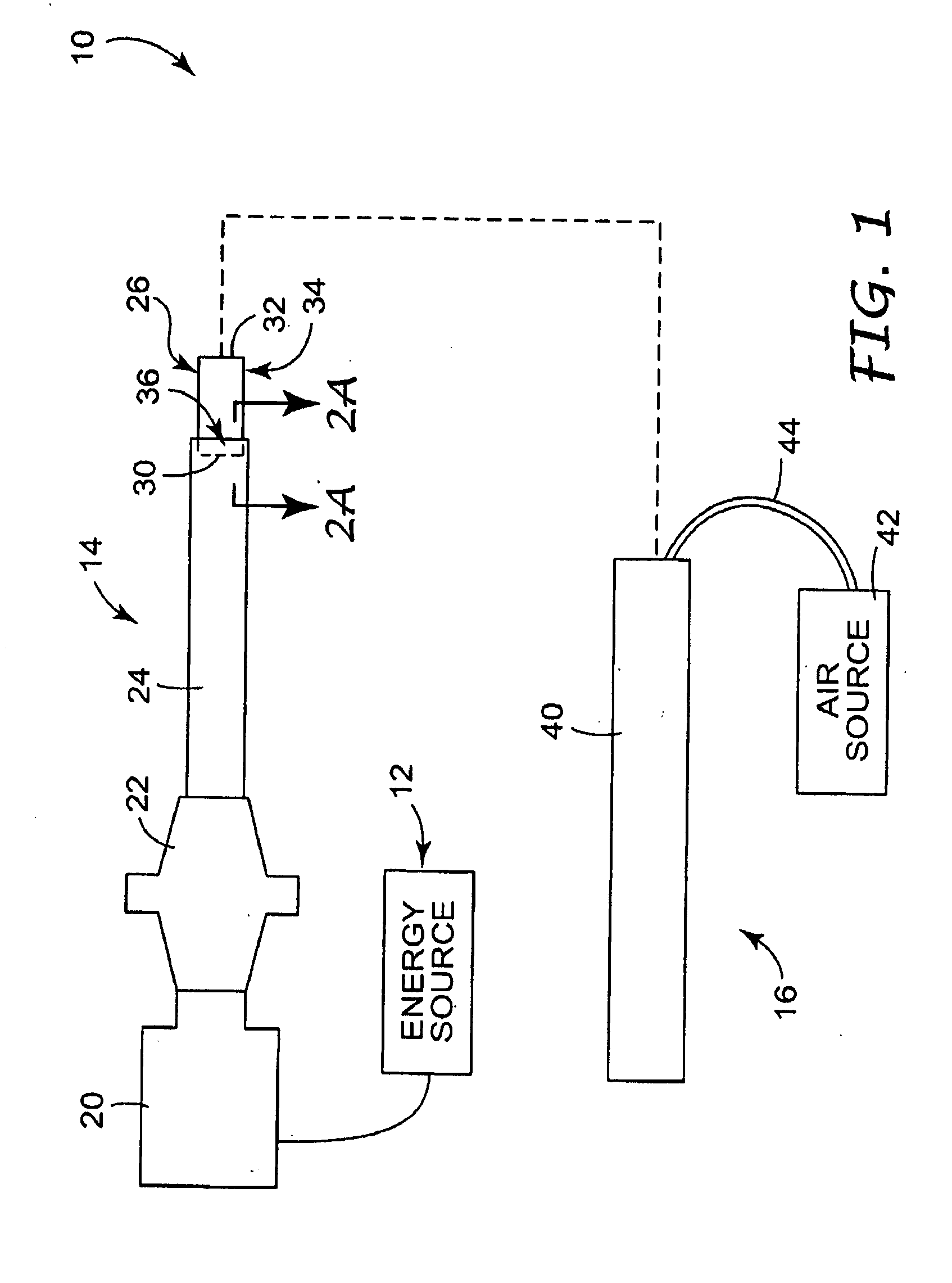

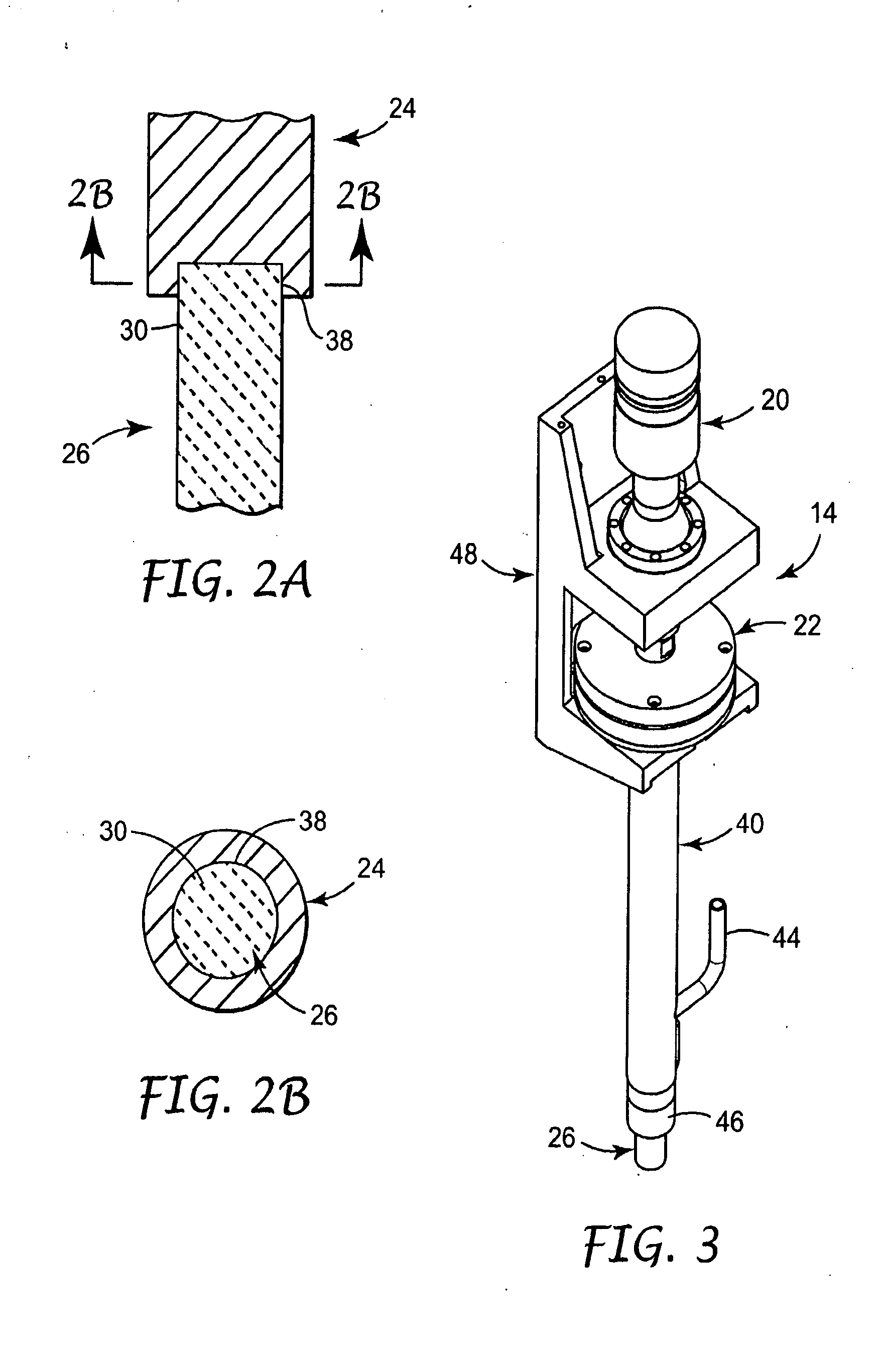

Ultrasonic energy system and method including a ceramic horn

InactiveUS20070290575A1Good for long-term operationNo chemical reactivityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksInterference fitLength wave

An acoustic system for applying vibratory energy including a horn connected to an ultrasonic energy source. The horn defines an overall length and wavelength, and at least a leading section thereof is comprised of a ceramic material. The leading section has a length of at least ⅛ the horn wavelength. In one preferred embodiment, an entirety of the horn is a ceramic material, and is mounted to a separate component, such as a waveguide, via an interference fit. Regardless, by utilizing a ceramic material for at least a significant portion of the horn, the ultrasonic system of the present invention facilitates long-term operation in extreme environments such as high temperature and / or corrosive fluid mediums. The present invention is useful for fabrication of metal matrix composite wires.

Owner:3M INNOVATIVE PROPERTIES CO

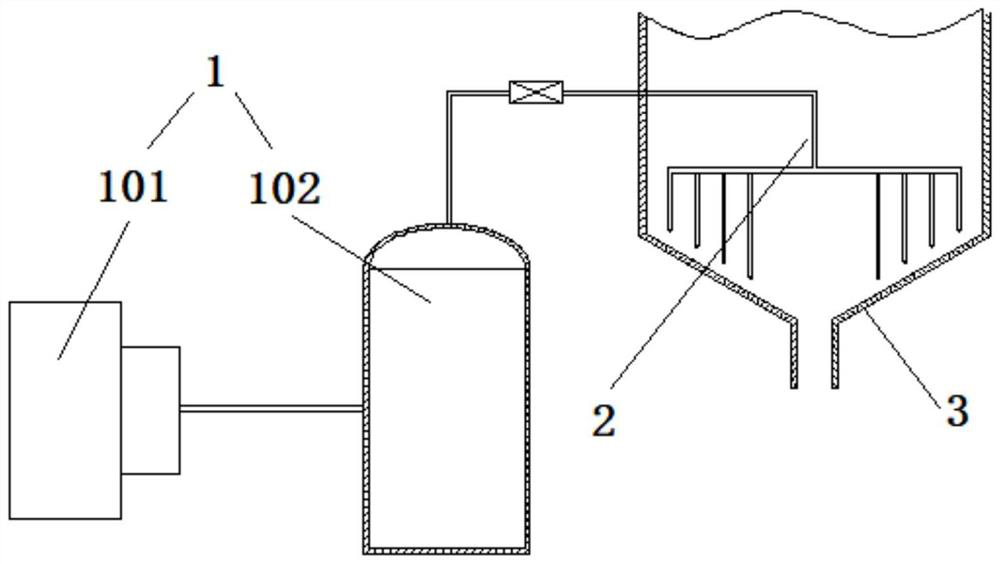

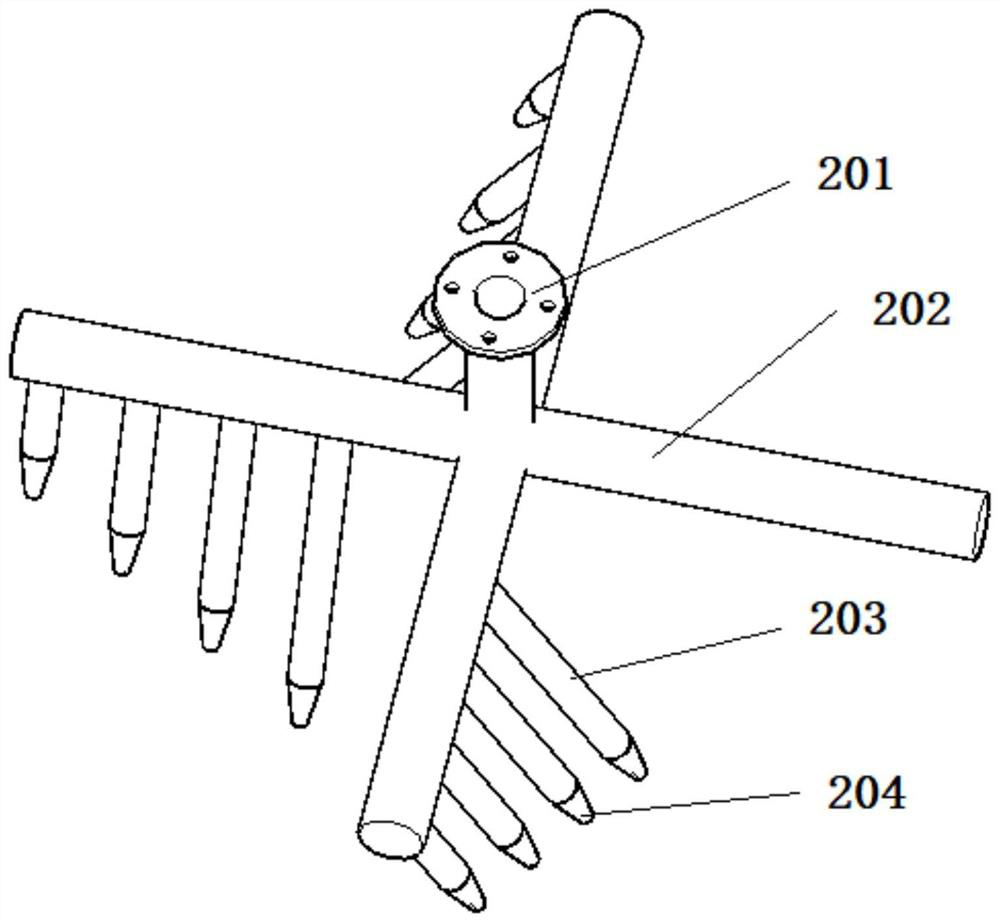

Blockage removing device for wet desulphurization process

ActiveCN112604483AAvoid cloggingGood for long-term operationDispersed particle separationGrain treatmentsAcute angleProcess engineering

The invention discloses a blockage removing device for a wet desulphurization process. The blockage removing device comprises a distributor and a gas source system, wherein the distributor comprises a central pipe and a plurality of branch pipes, the central pipe is used for supplying air to the branch pipes, one end of each branch pipe is communicated with the central pipe, the other ends of the branch pipes are radially arranged in a star shape around the central axis of the central pipe, each branch pipe is provided with a nozzle, the nozzle faces downwards, an included angle between the nozzle and the central axis of the central pipe is an acute angle, and the gas outlet of the gas source system is communicated with the central pipe and used for intermittently providing compressed gas for the distributor. According to the invention, a fluid intermittently impacts sulfur blocks on the wall surface of a container while a desulfurization liquid rotates to form stirring and scouring, so that sulfur can be well prevented from caking on the wall surface of the container, the caked sulfur can be well impacted and crushed, and can be prevented from being agglomerated into large blocks, the good capacity of cleaning the sulfur on the wall surface of the container is achieved, shutdown caused by blockage of the container due to settlement is avoided, and long-period operation of the device is facilitated.

Owner:四川恒乐达能源工程有限公司

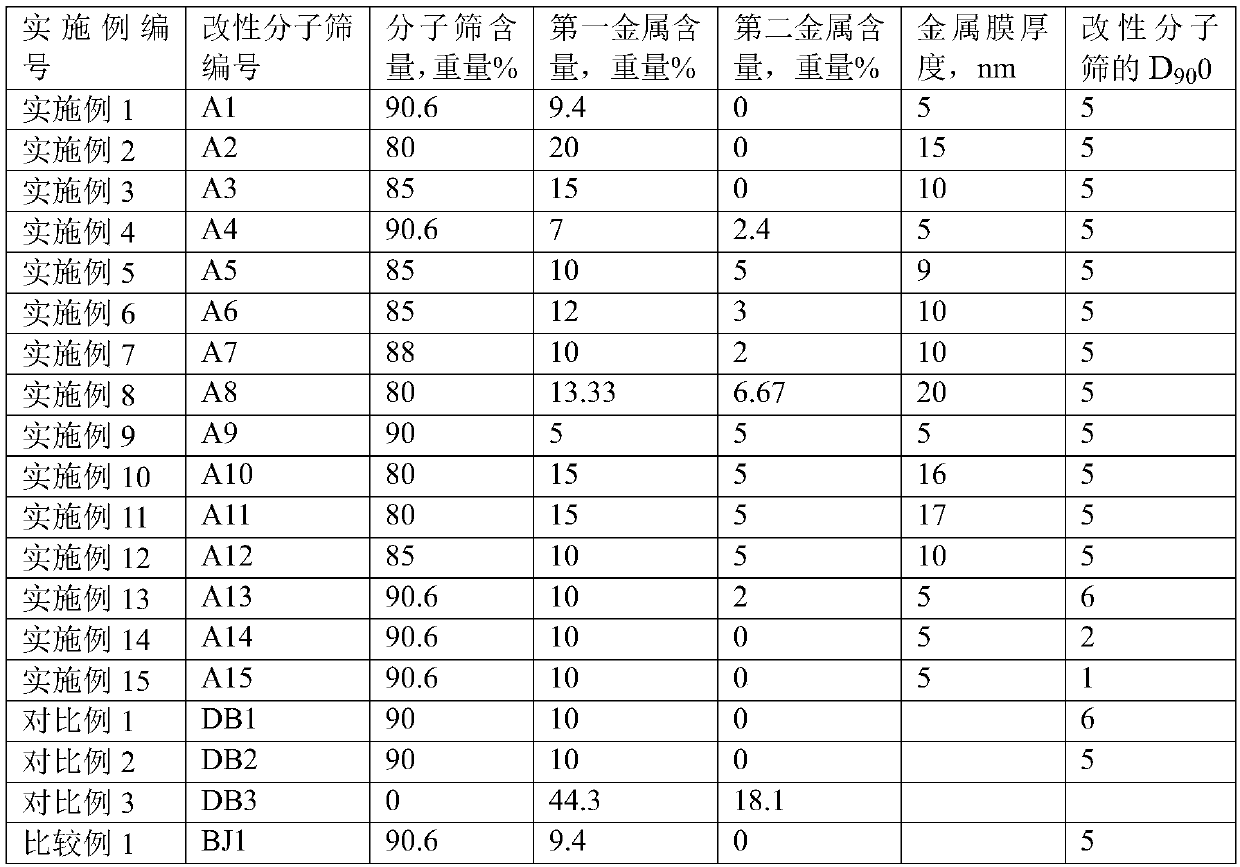

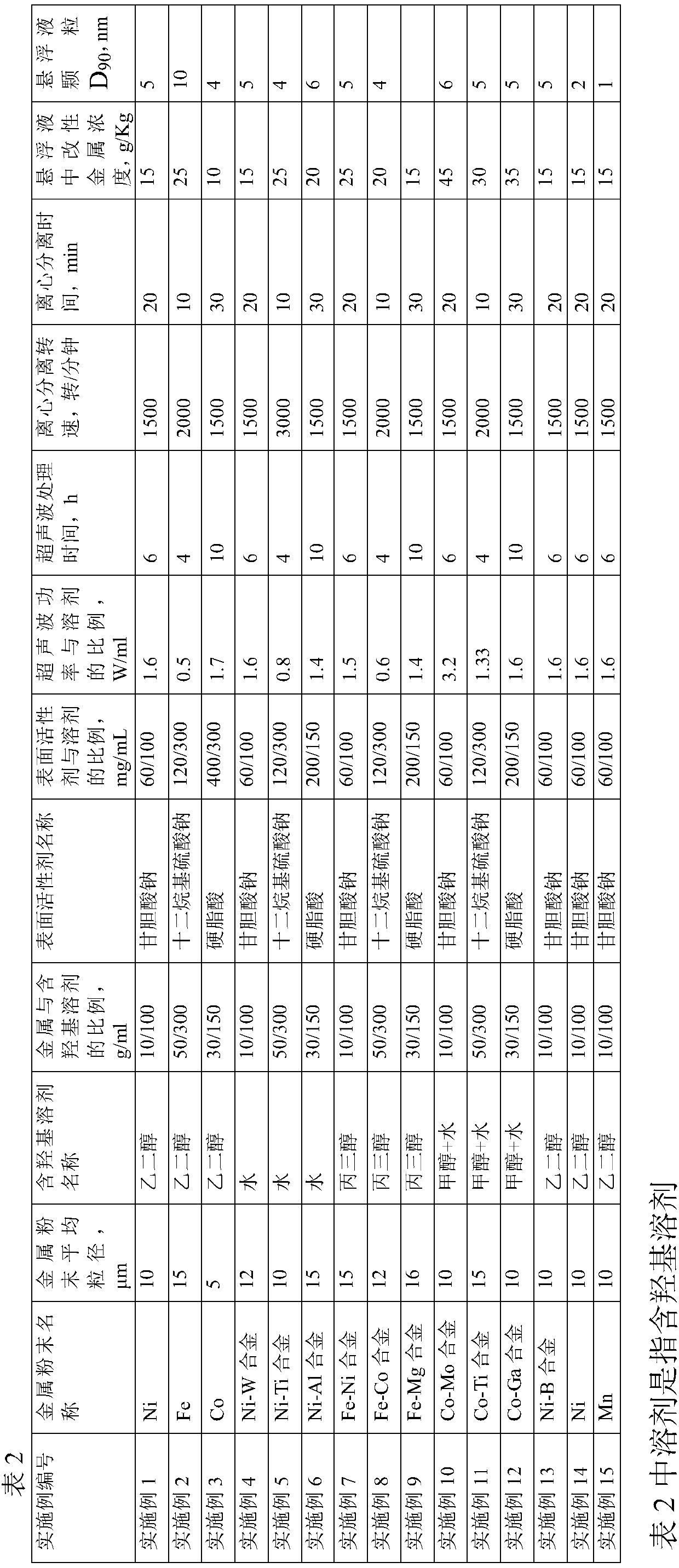

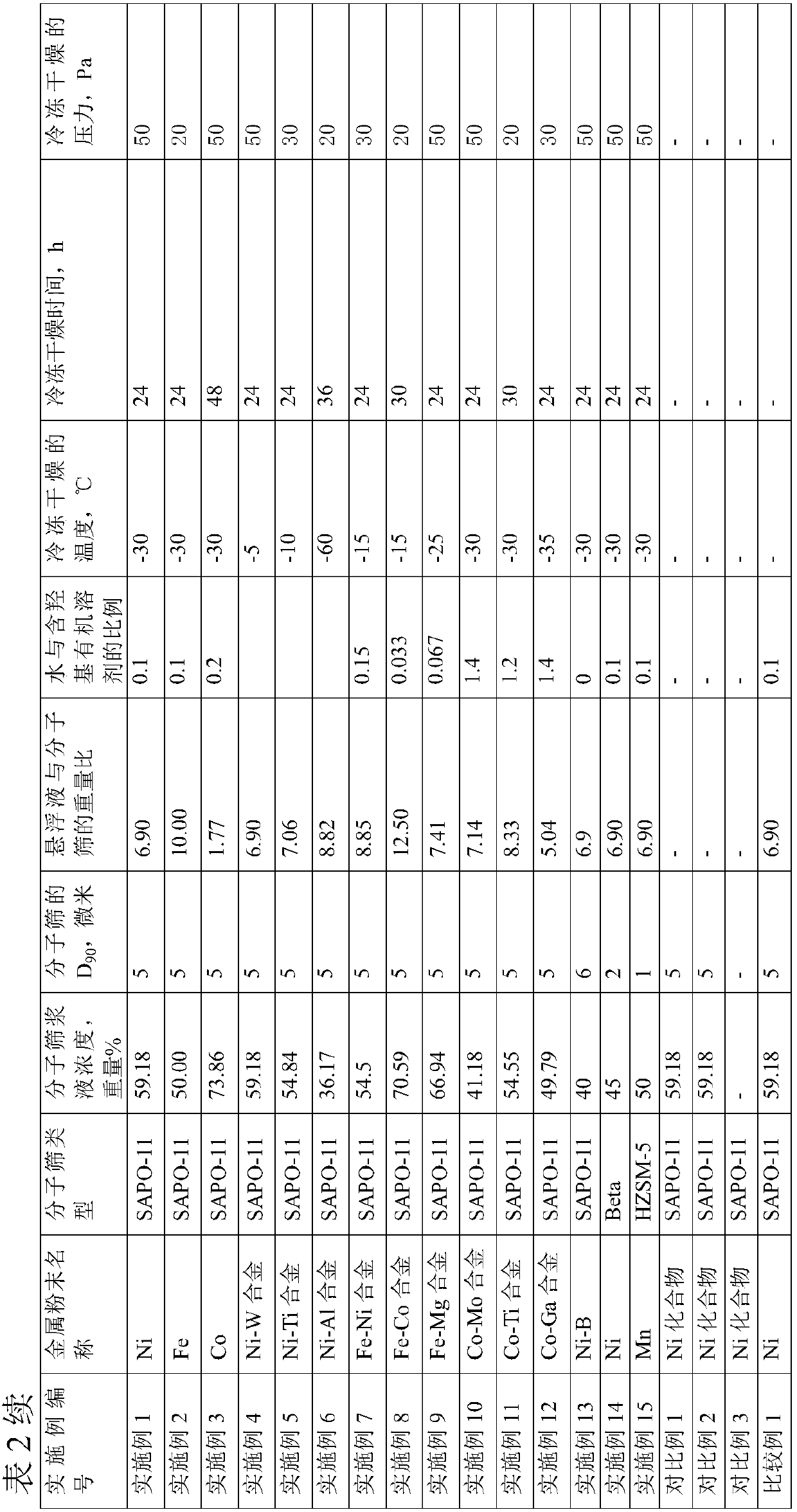

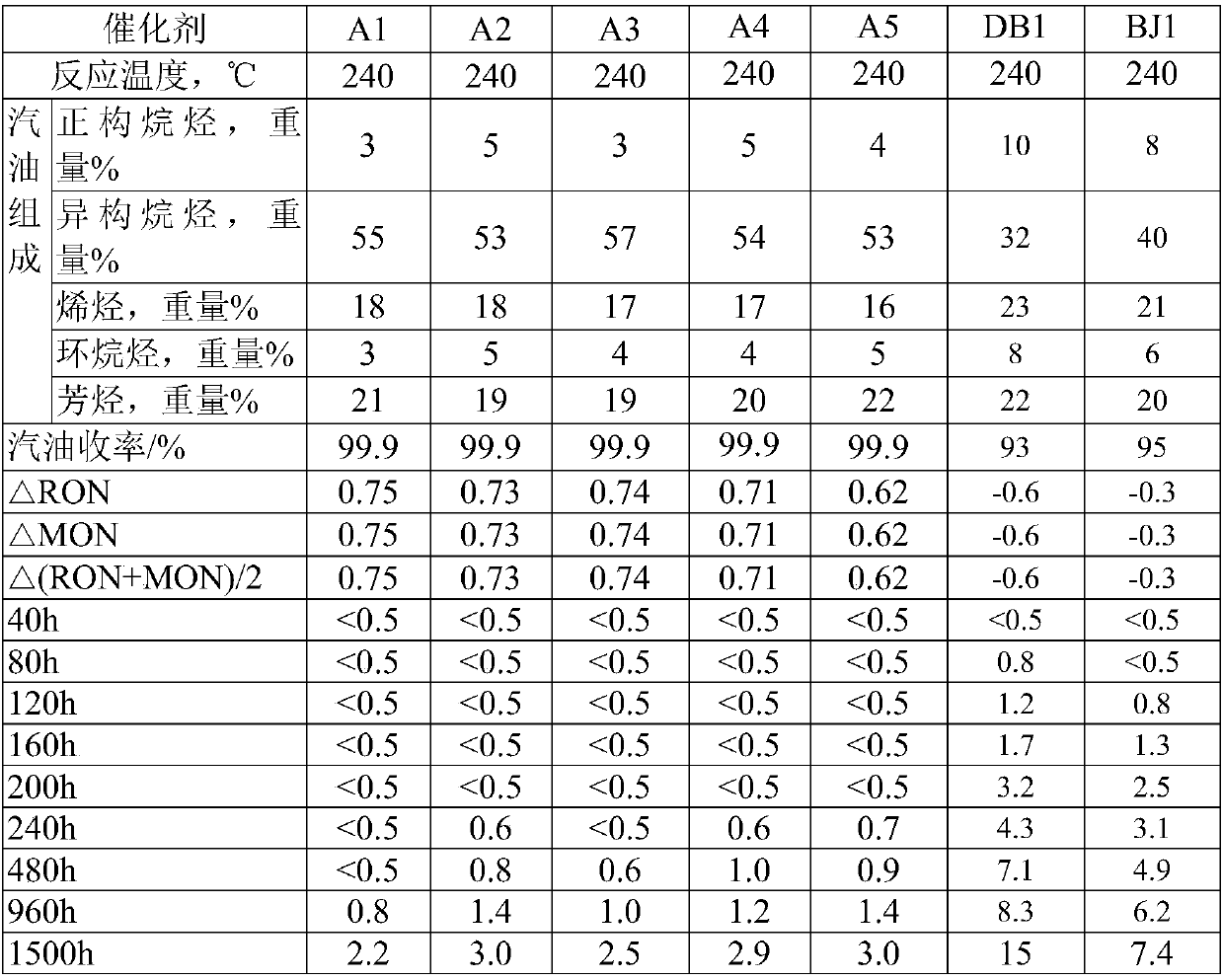

Modified molecular sieve for hydro-desulfurization as well as preparation and application thereof

PendingCN111085262AHigh desulfurization activityHigh desulfurization rateMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveActive agent

The invention discloses a modified molecular sieve for hydro-desulfurization as well as preparation and application thereof. The modified molecular sieve comprises a molecular sieve and a modifying metal film positioned on the outer surface of molecular sieve particles, wherein the modifying metal film contains one or more first modifying metals selected from Fe, Co, Ni and Mn and optional B. Thepreparation method of the modified molecular sieve comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonic treatment to obtain suspension, mixing the suspension with a molecular sieve, and carrying out freeze-drying to obtain the modified molecular sieve. The modified molecular weight is used for hydro-desulfurization of sulfur-containing hydrocarbons, has high activity and stability, can obviously reduce the olefin content, increase the iso-hydrocarbon content and increase the octane number of gasoline when used for gasoline desulfurization, and has a high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Segmented upgrading and hot flue gas gradient utilization system for low-rank coal and utilization method thereof

PendingCN111117671AYield maximizationQuality improvementCoke quenchingIncreasing energy efficiencyThermodynamicsHot air oven

The invention relates to a segmented upgrading and hot flue gas gradient utilization system for low-rank coal and a utilization method thereof, and belongs to the technical field of low-order pulverized coal pyrolysis. The outlet of a discharging cover of a rotary kiln is connected with a coal falling channel; an upgrading pyrolysis section is arranged at the upper part of the coal falling channel; a multi-stage cooler is arranged at the lower part of the coal falling channel; the upgrading pyrolysis section comprises a plurality of heat exchange tubes mounted in the coal falling channel; thehot air outlet of the hot air furnace is connected with the heat exchange medium inlet of the upgrading pyrolysis section; the heat exchange medium outlet of the upgrading pyrolysis section is connected with the inlet of the gas inlet cover of the rotary kiln; the outlet of the gas outlet cover of the rotary kiln is connected with a desulfurization and denitrification system through a fan; a firsttemperature sensor, a flow meter and a butterfly valve are further mounted on a pipeline between the outlet of the air outlet cover of the rotary kiln and the fan; and the first temperature sensor and the fan are in linkage control, the upgraded coal subjected to secondary pyrolysis in the upgrading pyrolysis section enters the cooling section to exchange heat with desalted water, and therefore,the structural design is reasonable, flue gas heat can be fully utilized, and energy consumption is reduced.

Owner:白太宽

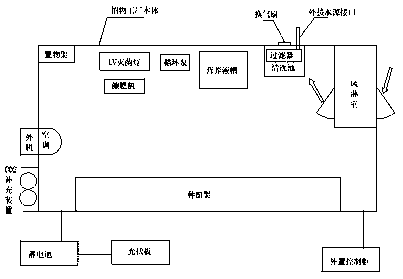

Full-automatic plant factory with photovoltaic power generation system

InactiveCN109076828AGood for long-term operationAchieve self-sufficiencyClimate change adaptationRenewable energy machinesSocial benefitsPlant factory

The invention discloses a full-automatic plant factory with a photovoltaic power generation system. The full-automatic plant factory comprises a plant factory body, a photovoltaic panel, a storage battery, a CO2 supplementing device, a constant temperature device, a containing frame, a UV sterilizing lamp, a circulating pump, a nutrient solution groove, a cleaning pond, an air shower, an plantingframe and an external control cabinet, wherein the CO2 supplementing device and the constant temperature device are sequentially arranged on the left side of the plant factory body from front to back,the containing frame, the UV sterilizing lamp, the circulating pump, the nutrient solution groove, the cleaning pond and the air shower are sequentially arranged on the back side of the plant factoryfrom left to right, the planting frame is installed on the inner surface of the front side of the plant factory body, the photovoltaic panel is connected with the left end of the front side of the plant factory body through the storage battery, and the external control cabinet is connected with the right side of the front end of the plant factory body. According to the full-automatic plant factory with the photovoltaic power generation system, defects of the prior art are overcome, the photovoltaic panel and the storage battery are arranged and used for supplying power to the plant factory, the problem that supplying of plant factory power on a sea island is less is solved, self-sufficiency of plant factory power is achieved, and social benefits are obvious.

Owner:安徽东华农业科技开发股份有限公司

Regular carrier catalyst with desulfurization effect as well as preparation and application thereof

PendingCN111085258AHigh activityHigh desulfurization activityMolecular sieve catalystsHydrocarbon oils refiningPtru catalystFreeze-drying

The invention discloses a regular carrier catalyst with a desulfurization effect as well as preparation and application thereof. The regular carrier catalyst comprises a regular carrier and an activecoating attached to the outer surface of the regular carrier, the active coating comprises a IIA and IIB group metal oxide-containing matrix, a molecular sieve and a modified metal film, and the modified metal film comprises nickel and one or more rare earth metals selected from lanthanum, cerium, praseodymium and neodymium. The preparation method comprises the following steps: forming a mixture from metal powder, a hydroxyl-containing solvent and a surfactant, then treating the mixture under ultrasonic waves to obtain a mixed solution after the ultrasonic treatment; separating the mixed solution after the ultrasonic treatment to obtain suspension; contacting the suspension with matrix particles and / or molecular sieve particles or particles containing a matrix and a molecular sieve, carrying out freeze-drying, and then coating on a regular carrier. The catalyst can be used for hydro-desulfurization of hydrocarbon fuel, has the characteristics of high activity and good stability, is used for gasoline desulfurization, and can increase the octane number of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A dry desulfurization and dust removal process for catalytic cracking regenerated flue gas

ActiveCN109351183BImprove purification efficiencyAvoid emissionsHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystFlue gas

The invention provides a dry desulfurization dust removing technology method for catalytic cracking regenerated flue gas. The method comprises the steps that catalytic cracking flue gas is introducedin a moving bed desulfuration reactor, the catalytic cracking flue gas and a loaded desulfurization catalyst are subjected to the desulfurization reaction, oxysulfide in the flue gas is subjected to the catalytic reaction to produce metal sulfate, and the metal sulfate is adsorbed on the desulfurization catalyst; the desulfurization catalyst containing the metal sulfate is conveyed to a desulfurization catalyst reproducer, reductive regeneration gas is introduced in the reproducer, and after the metal sulfate on the desulfurization catalyst is reduced to metallic oxide, a part of purified fluegas is utilized for lifting the regenerated desulfurization catalyst into a dust elutriating apparatus through a catalyst lifter, and after dust is recovered through elutriation, desulfurization catalyst is conveyed into moving bed desulfuration reactor for recycling; regenerated acid gas containing hydrogen sulfide is introduced in a dry gas desulfurizer to produce sulphur. According to the method, the desulfuration and dust removal of the catalytic cracking flue gas can be effectively achieved, and the desulfurization rate reaches 99% or above.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Coarse stalk fuel gas purification process and purification device thereof

InactiveCN108219861ASimple processIncrease profitGas purification by non-gaseous materials condensationGas dust removalTarEnvironmental engineering

The invention discloses a coarse stalk fuel gas purification process, which comprises the following steps of (1) pretreating the coarse stalk fuel gas; (2) introducing the gas treated in the step (1)into a lower section of a transverse pipe sub condenser to be washed for dust removal; removing carbon particle dust, wood tar and water in the coarse stalk fuel gas; (3) introducing the gas treated in the step (2) into an upper section of the transverse pipe sub condenser to be condensed; removing wood vinegar and rest water; (4) performing further condensation removal on the gas treated in the step (3) through a filter to obtain purified stalk fuel gas. The invention also provides a purification device of the process. The gas effective purification of coarse stalk fuel can be realized; byproducts such as the carbon powder the wood tar and the wood vinegar can be obtained; the requirements of energy saving, environment protection and safety can be sufficiently met.

Owner:WUHAN JINZHONG PETROCHEM ENG

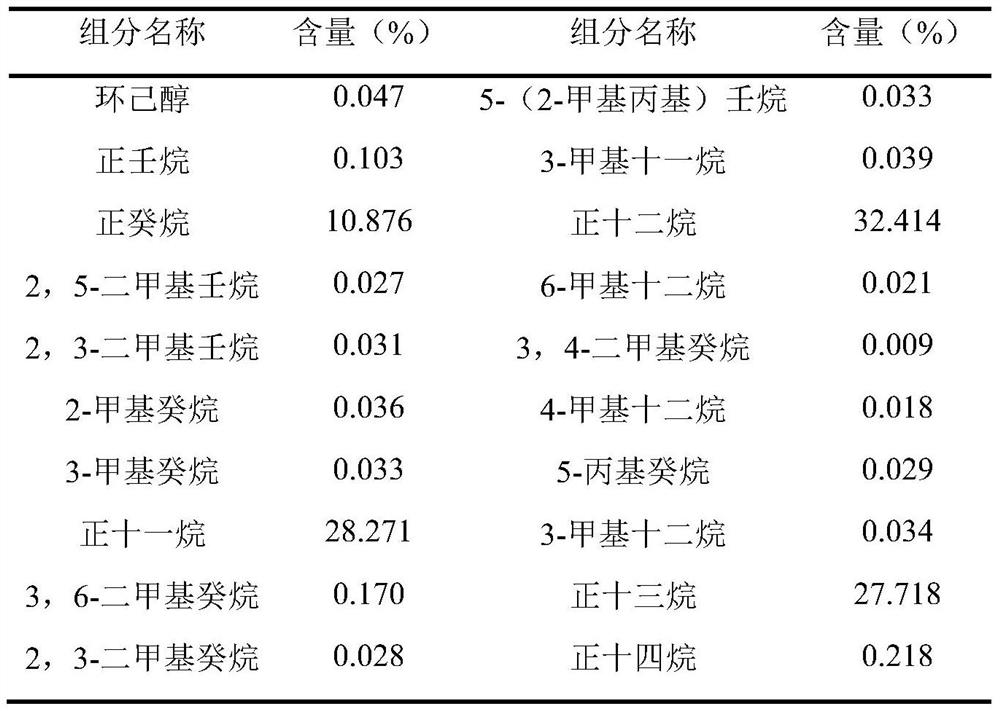

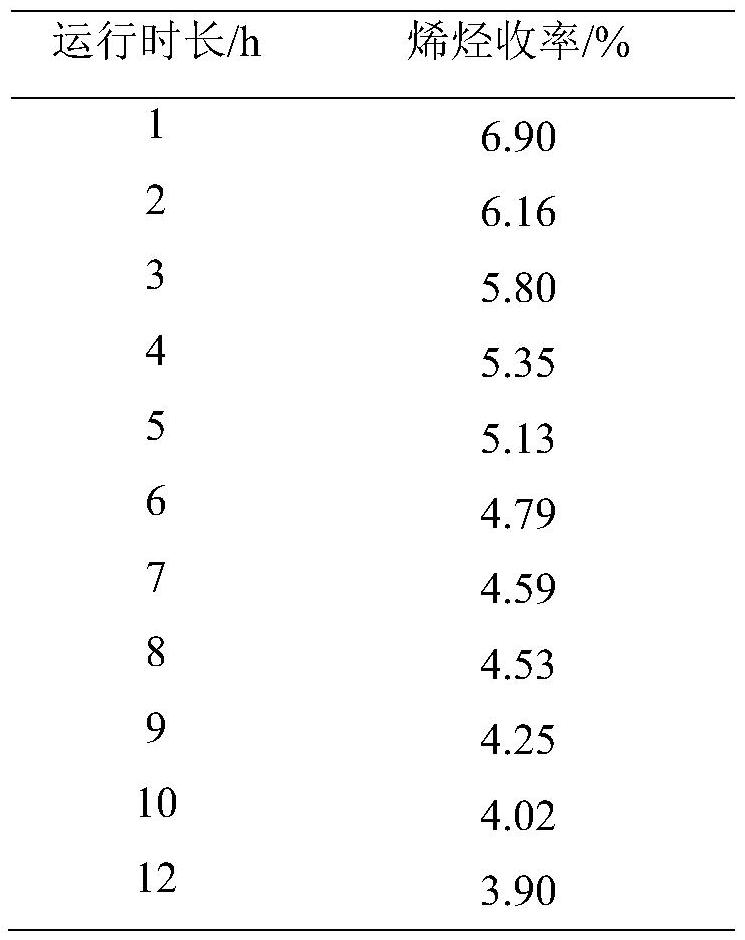

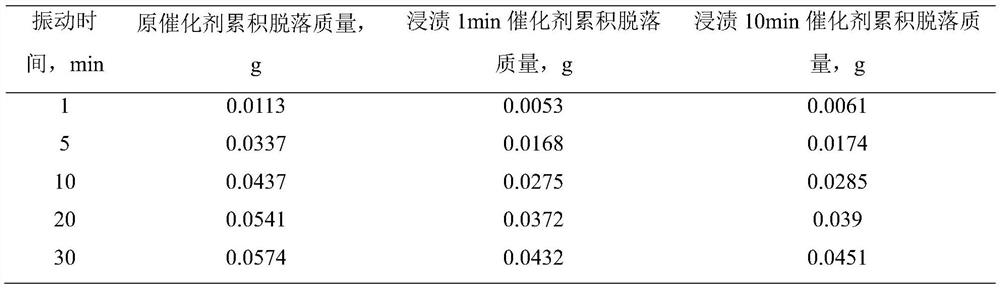

Improved preparation method of dehydrogenation catalyst containing platinum, tin and aluminum

PendingCN114345330AReduced catalyst attrition and breakageReduce sheddingHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneAqueous solution

The invention provides an improved preparation method of a dehydrogenation catalyst containing platinum, tin and aluminum, which is characterized by comprising the following steps of: uniformly stirring and mixing a pseudo-boehmite aqueous solution and a nitric acid aqueous solution according to a certain proportion, standing and layering the solution, and dipping, drying in the shade, drying and roasting a long-chain alkane catalyst by taking the supernate of the solution to obtain an anti-wear catalyst; according to the treatment method, the loss of noble metal elements on the outer layer of the catalyst is reduced, the original dehydrogenation performance of the catalyst is maintained and improved, and the olefin yield is ensured.

Owner:江苏金桐表面活性剂有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com