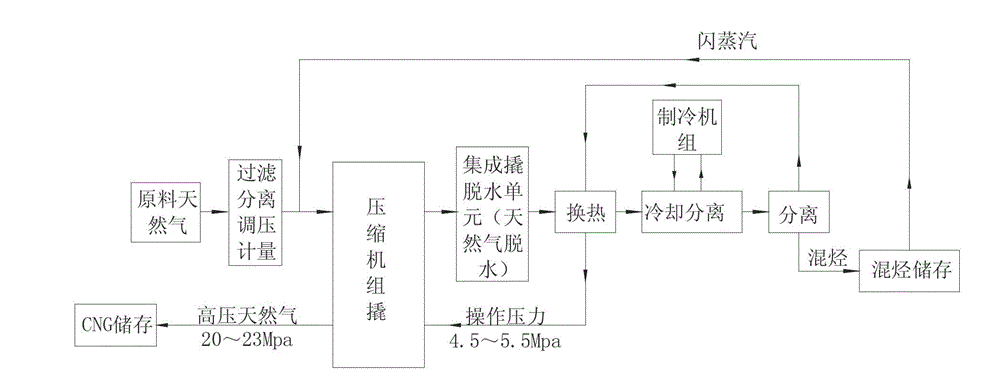

Natural gas recovery process

A technology of natural gas and process, applied in the field of recovering light hydrocarbons and natural gas at the same time, can solve the problems of unstable reserves, inconvenient construction of fixed equipment for mining, energy waste, etc., to ensure normal and durable operation, facilitate long-term operation, The effect of reducing the amount of flash gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

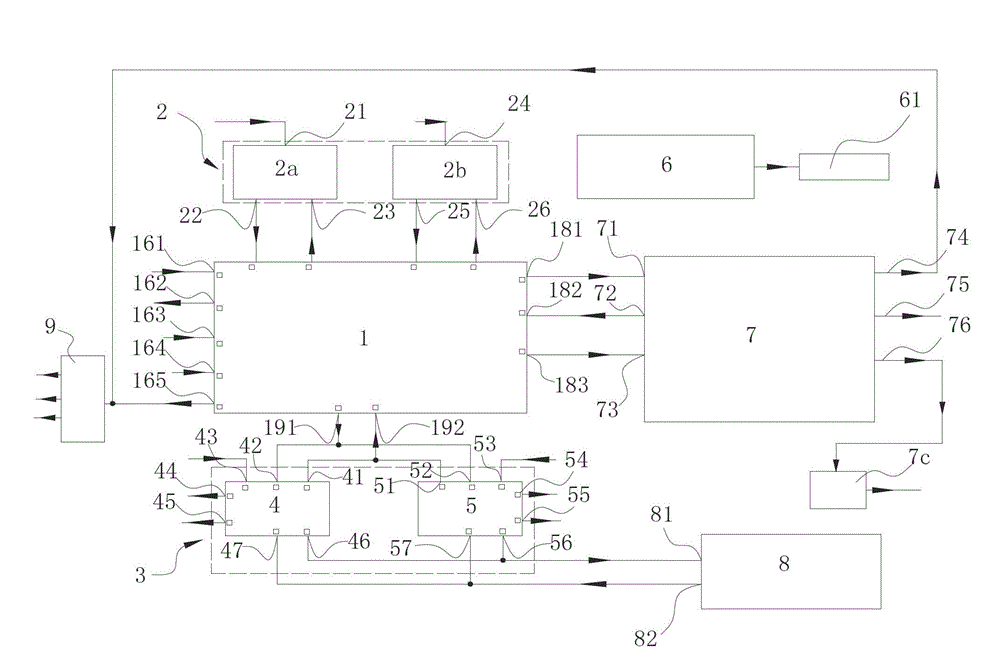

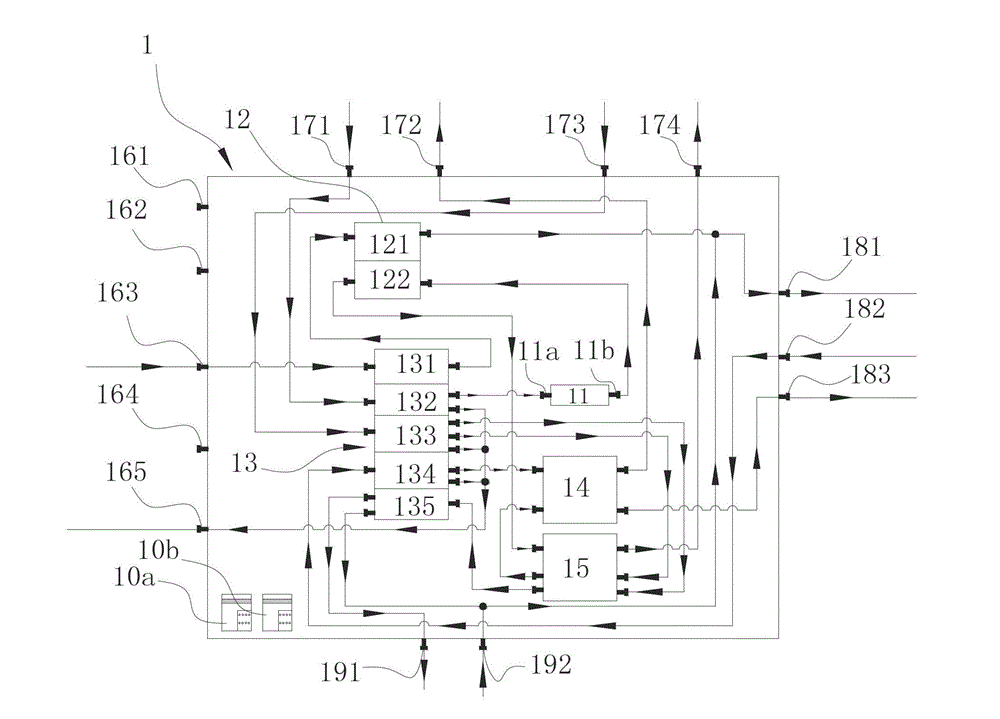

[0087] like figure 2 , 3 , 4, 5, 6 and 8 show that the equipment used in this embodiment to realize the natural gas recovery process includes compressor skid 7, integrated skid 1, refrigeration unit skid 2, mixed hydrocarbon storage loading skid A4, mixed hydrocarbon storage loading skid B5, air column 7c, instrument air skid 6, loading crane tube 8, three-phase separator 9. The integrated skid 1 includes a dehydration unit 11 , a filter unit 12 , a separator unit 13 , an air-air heat exchanger 14 , and a plate heat exchanger 15 . The compressor skid 7 includes a feed gas compressor 7a and a CNG compressor 7b.

[0088] Separator unit 13 includes inlet separator 131, normal temperature separator A132, low temperature separator 133, normal temperature separator B134, normal temperature separator C135; filter unit 12 includes low pressure dust filter 121, high pressure dust filter 122; refrigeration unit The skid 2 includes a high-temperature ice machine 2a and a low-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com