Improved preparation method of dehydrogenation catalyst containing platinum, tin and aluminum

A dehydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the loss of active components and the reduction of conversion rate of dehydrogenation reaction , Catalyst support layer falling off and other problems, to reduce catalyst wear and damage, reduce the effect of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

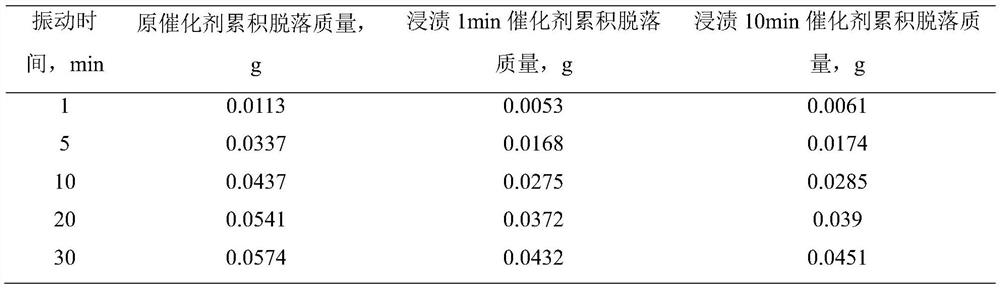

[0026] (1) Weigh 10g of pseudo-boehmite powder, add deionized water to prepare pseudo-boehmite: an aqueous solution with a water mass ratio of 6:100, stir at room temperature for 30min, and drop it into the stirring solution at a uniform speed 12 g of nitric acid aqueous solution with a mass fraction of 35% was added dropwise in the state, and after the nitric acid aqueous solution was added dropwise, the stirring was continued for 2 h to form the required solution. Dilution, the solution system is unstable, and it is difficult to maintain the colloidal state. It is found that after standing for 30 minutes, the solution settles into upper and lower layers, and the solution supernatant is used in step (2) to impregnate the catalyst.

[0027] (2) Take two fresh catalysts of 30g each, put them into the supernatant prepared in step (1) and soak them for 1min and 10min respectively, take them out and drain them, and then put them in a dry, dust-free and organic-volatile-free environ...

Embodiment 2

[0036] (1) Weigh 5g of pseudo-boehmite powder, add deionized water to prepare pseudo-boehmite: an aqueous solution with a water mass ratio of 4:100, stir at room temperature for 30min, and drop it into the stirring solution at a uniform speed State dripping mass fraction is 35% nitric acid aqueous solution 9g, after the nitric acid aqueous solution dropwise is finished, continue to stir 2h, be made into required solution, find that after standing for 30min, the solution settles into upper and lower two layers, takes the solution supernatant for Step (2) impregnating the catalyst.

[0037] (2) Get 30g of fresh catalyst, put it into the supernatant prepared in step (1) and soak for 1min, pull it out and drain it, then put it in a dry, dust-free environment without organic volatile gas and dry it in the shade for 24h at normal temperature, and then Drying at 120°C for 3 hours, and calcining at 500°C for 4 hours to obtain the anti-wear catalyst under the treatment conditions.

[...

Embodiment 3

[0046] (1) Take 5g of pseudo-boehmite powder, add deionized water to be mixed with pseudo-boehmite: an aqueous solution with a water mass ratio of 3:100, stir at room temperature for 30min, and drop it into the stirring solution at a uniform speed Add the aqueous solution of nitric acid with a mass fraction of 35% in the state dropwise. After the addition of the aqueous solution of nitric acid, continue to stir for 2 hours to make the required solution. After standing for 30 minutes, the solution settles into upper and lower layers. Take the solution supernatant for the step (2) Impregnated catalyst.

[0047] (2) Get 30g of fresh catalyst, put it into the supernatant prepared in step (1) and soak for 1min, pull it out and drain it, then put it in a dry, dust-free environment without organic volatile gas and dry it in the shade for 24h at normal temperature, and then Drying at 120°C for 3 hours, and calcining at 500°C for 4 hours to obtain the anti-wear catalyst under the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com