Full-automatic plant factory with photovoltaic power generation system

A photovoltaic power generation system, fully automatic technology, applied in the field of plant factories, can solve problems such as transportation difficulties, achieve obvious social benefits, good long-term operation, and suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

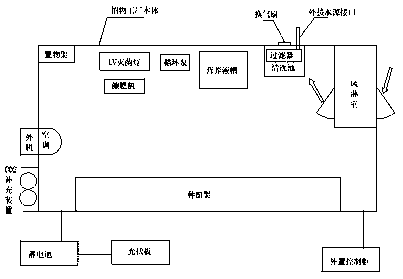

[0016] As shown in the figure, a fully automatic plant factory with its own photovoltaic power generation system described in the present invention includes a plant factory body, photovoltaic panels, batteries, CO 2 Supplementary device, constant temperature device, shelf, UV sterilizing lamp, circulation pump, nutrient solution tank, cleaning pool, air shower room, planting frame, external control cabinet, the left side of the plant factory body is equipped with CO 2 Supplementary device and constant temperature device, the rear side of the plant factory is provided with racks, UV sterilization lamps, circulation pumps, nutrient solution tanks, cleaning pools, and air showers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com