Segmented upgrading and hot flue gas gradient utilization system for low-rank coal and utilization method thereof

A hot flue gas and low-rank coal technology, applied in the field of low-rank coal staged quality improvement and hot flue gas cascade utilization system, can solve the problems of exacerbated environmental problems, non-compliance with high quality and high use, and meet environmental protection requirements, It is beneficial to the effective use of heat and the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

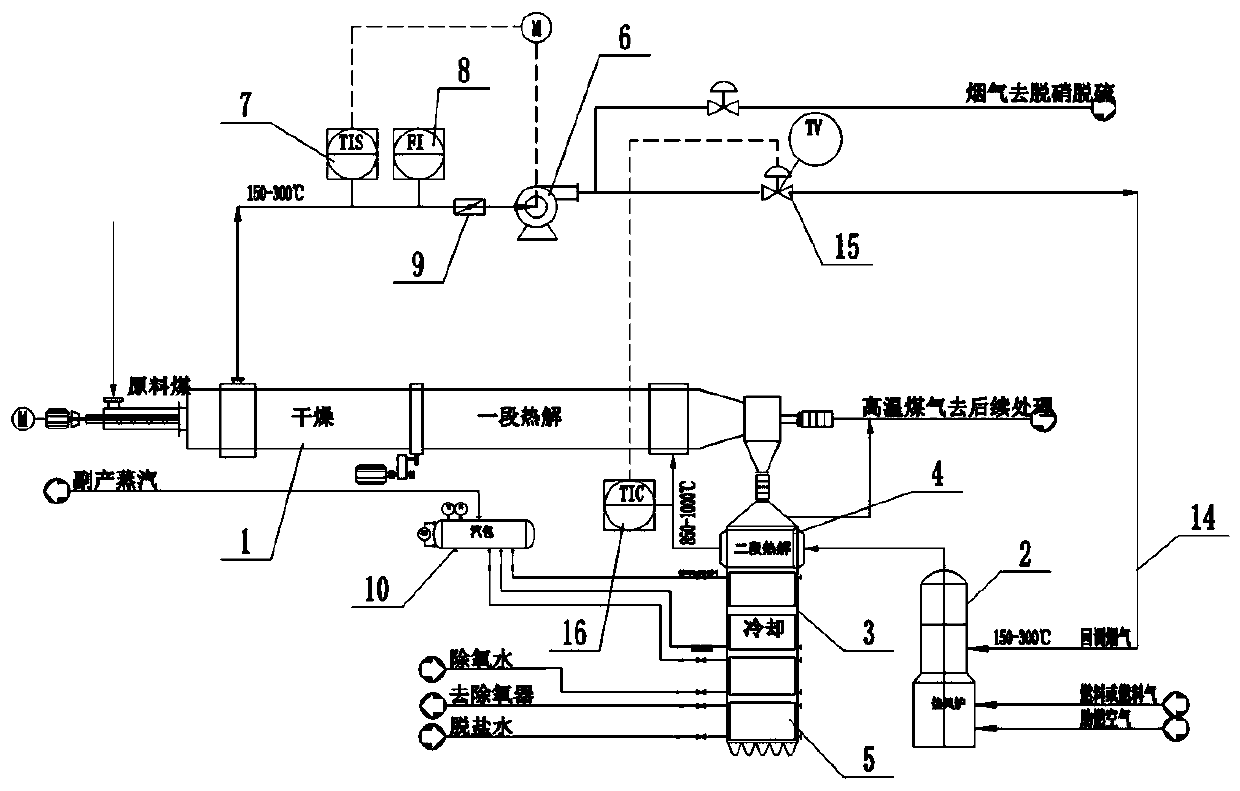

[0018] Such as figure 1 As shown, a low-rank coal sub-level upgrading and hot flue gas cascade utilization system includes a rotary kiln 1 and a hot blast stove 2. The outlet of the rotary kiln 1 is connected to a vertical furnace 3, which is mainly composed of pyrolysis The upgrading section 4 and the cooling section 5 are composed, the pyrolysis upgrading section 4 is arranged on the upper part of the vertical furnace 3, the cooling section 5 is arranged on the lower part of the vertical furnace 3, and the cooling section 5 is mainly composed of a plurality of coolers, the pyrolysis upgrading section The quality section 4 includes a plurality of heat exchange tubes installed in the vertical furnace, the hot blast outlet of the hot blast stove 2 is connected to the heat exchange medium inlet of the pyrolysis upgrading section 4, and the heat exchange medium outlet of the pyrolysis upgrading section 4 is connected to the rotary The inlet of the inlet hood of the kiln 1 is conn...

Embodiment 2

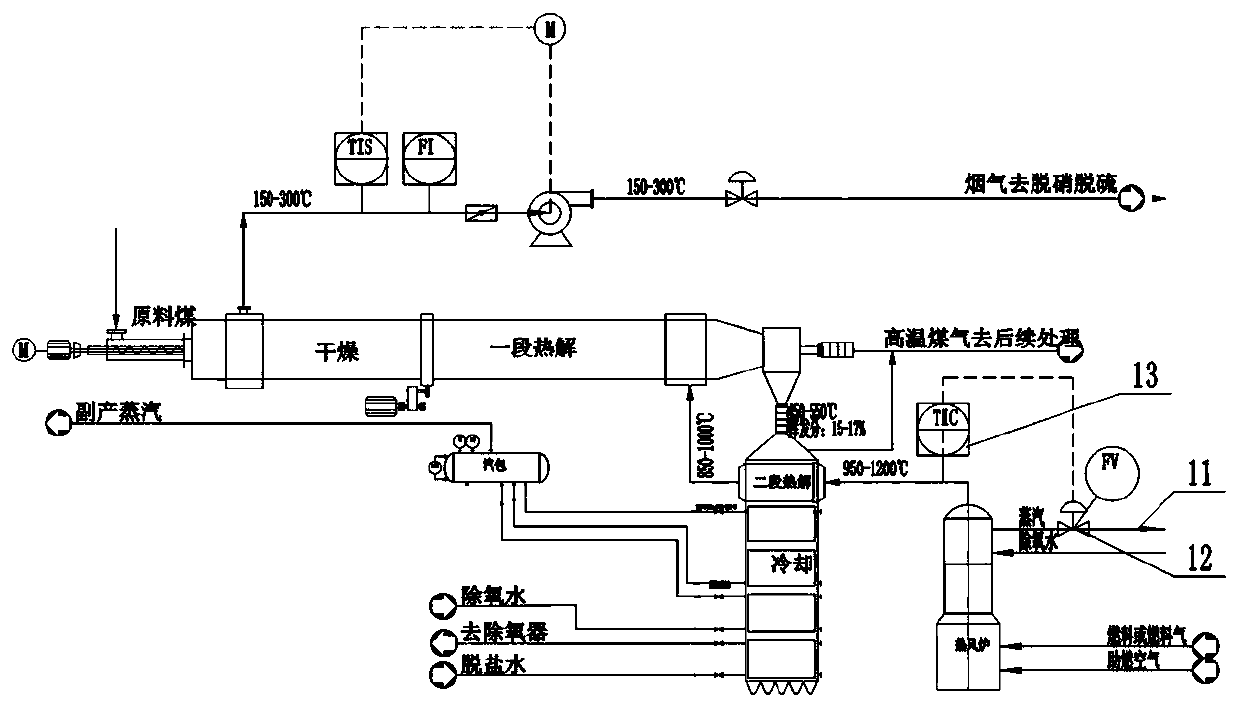

[0022] The hot blast outlet of the hot blast stove 2 is connected with a hot blast regulating pipeline 11, and the hot blast regulating pipeline 11 is provided with a first control valve 12, and the temperature control of the hot flue gas is realized by controlling the steam level and the amount of steam produced by the boiler. A second temperature sensor 13 is installed on the pipeline between the hot air outlet and the heat exchange medium inlet of the pyrolysis upgrading section 4 , and the second temperature sensor 13 is interlocked with the first control valve 12 for control. All the other are the same as the first embodiment.

[0023] In this embodiment, the hot air regulating pipeline 11 is controlled to control the temperature of the hot air entering the pyrolysis upgrading section 4, and the second temperature sensor 13 directly detects the outlet temperature of the hot air stove, and then adjusts the opening degree of the first control valve 12 according to the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com