Patents

Literature

84results about How to "Avoid processing difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

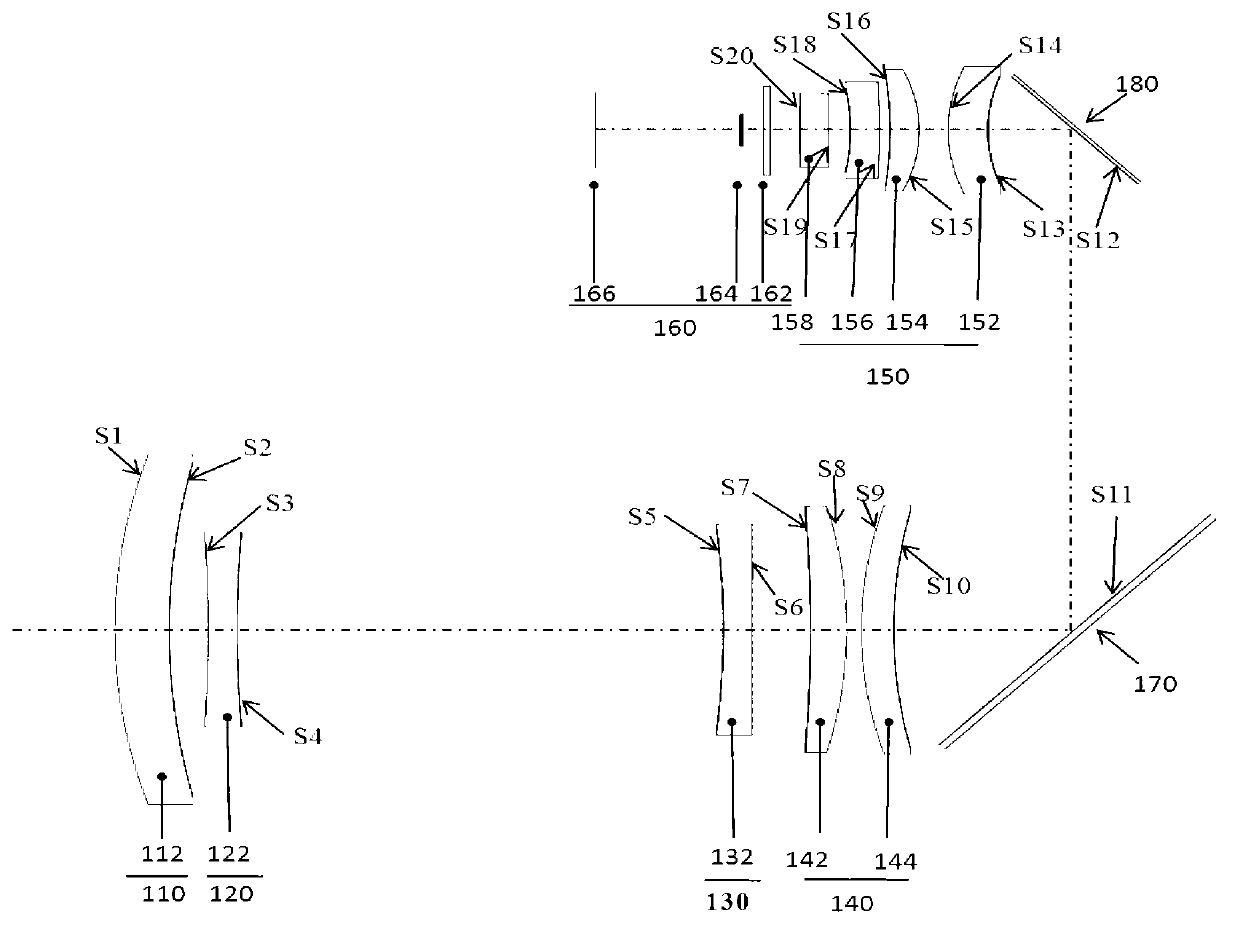

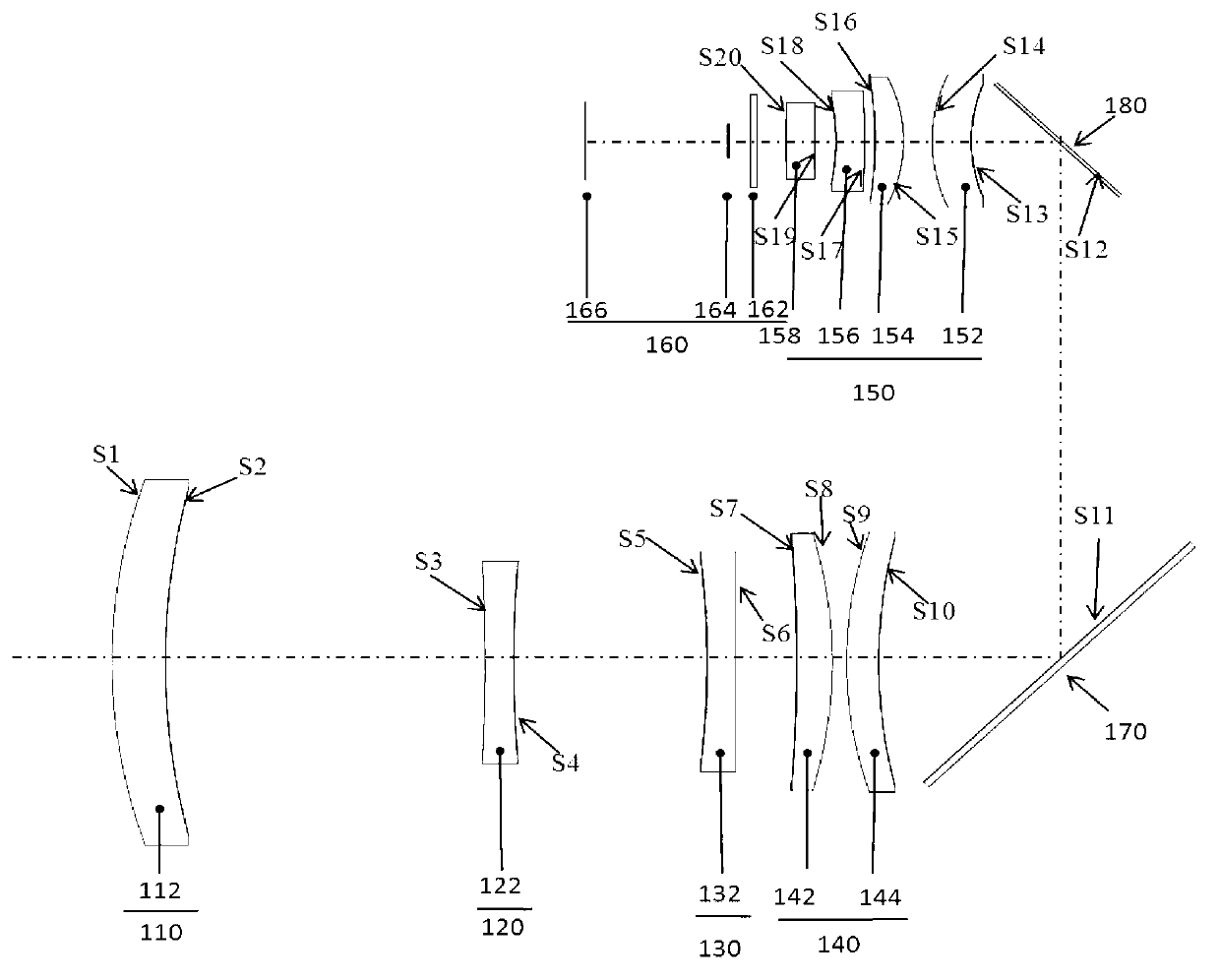

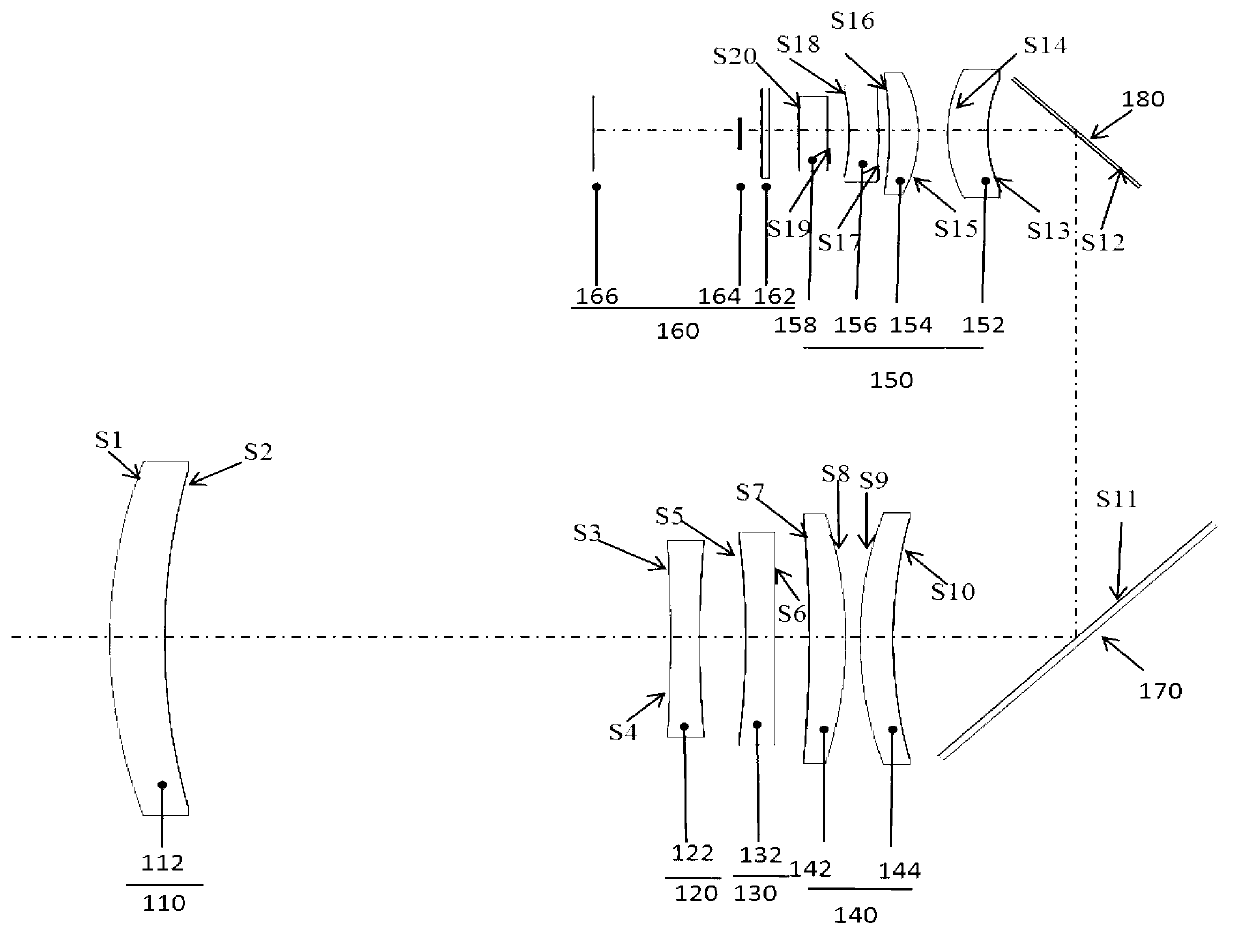

Light small-size medium-wave infrared continuous zooming imaging lens

ActiveCN103345047ASmall form factorAvoid processing difficultyOptical elementsCamera lensImaging lens

A light small-size medium-wave infrared continuous zooming imaging lens comprises a first lens set (110), a second lens set (120), a third lens set (130), a fourth lens set (140), a first reflector (170), a second reflector (180), a fifth lens set (150) and a detector (160) from an object space to an imaging space in sequence, wherein the first lens set (110) has positive focal power and is used as a front fixing set, the second lens set (120) has negative focal power and is used as a zooming set, the third lens set (130) has negative focal power and is used as a compensation set, the fourth lens set (140) has positive focal power and is used as a rear fixing set, the first reflector (170) and the second reflector (180) are used for bending a light path, and the fifth lens set (150) has positive focal power. Spherical mirrors are adopted in all the lens, and the light small-size medium-wave infrared continuous zooming imaging lens is simple in structure, small in size, light in weight, and especially suitable for being used in small-size pod equipment.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

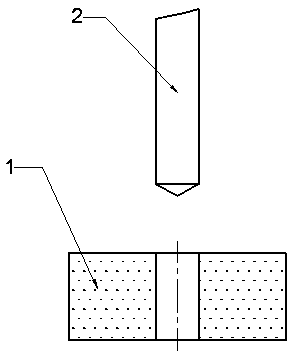

Forming method of hard alloy threaded hole

InactiveCN107695618AAvoid processing difficultyGuaranteed accuracyThread cutting machinesNumerical controlCompression molding

The invention discloses a forming method of a hard alloy threaded hole. The forming method of the hard alloy threaded hole is characterized by comprising the following steps of preparing materials, wherein PEG is used as a forming agent, raw materials are ground with ethyl alcohol, and after spray drying is conducted, a mixture is generated; conducting mold pressing, wherein compression molding isconducted on the mixture; conduct semi-machining, wherein through a numerical control milling machine or a lathe or a machining center, a dedicated cutter of a special material is used, accurate thread dimension calculation is conducted, and then a threaded hole of a fixed parameter is machined on the pressed blank; and conducting sintering, wherein the needed threaded hole is obtained through sintering formation finally. The forming method of the hard alloy threaded hole has the beneficial effects that through accurate pressed blank shrinkage coefficient control, inner threads are machined on the pressed blank, the machining difficulty existing when the alloy threaded hole is machined after sintering is avoided, and a scheme is provided for machining of the hard alloy threaded hole.

Owner:九江金鹭硬质合金有限公司

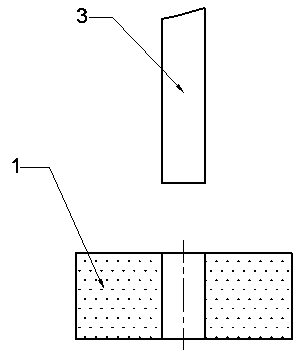

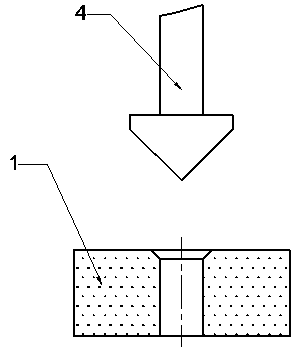

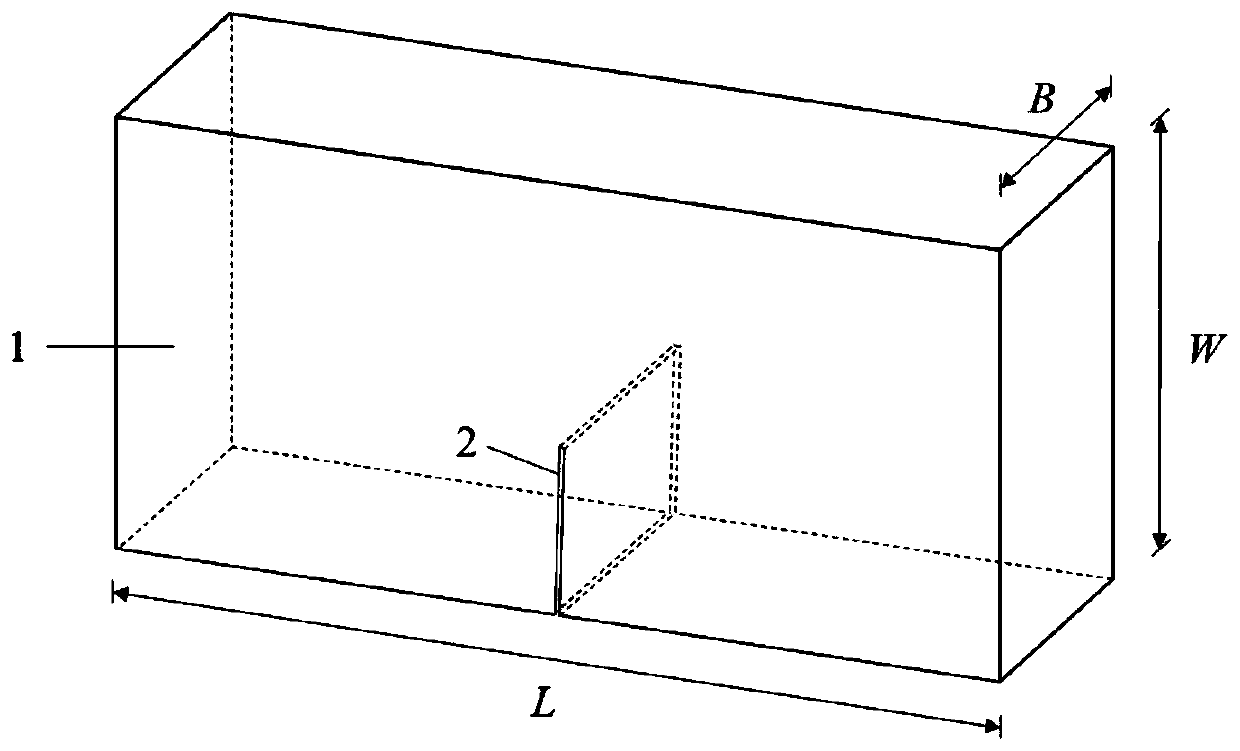

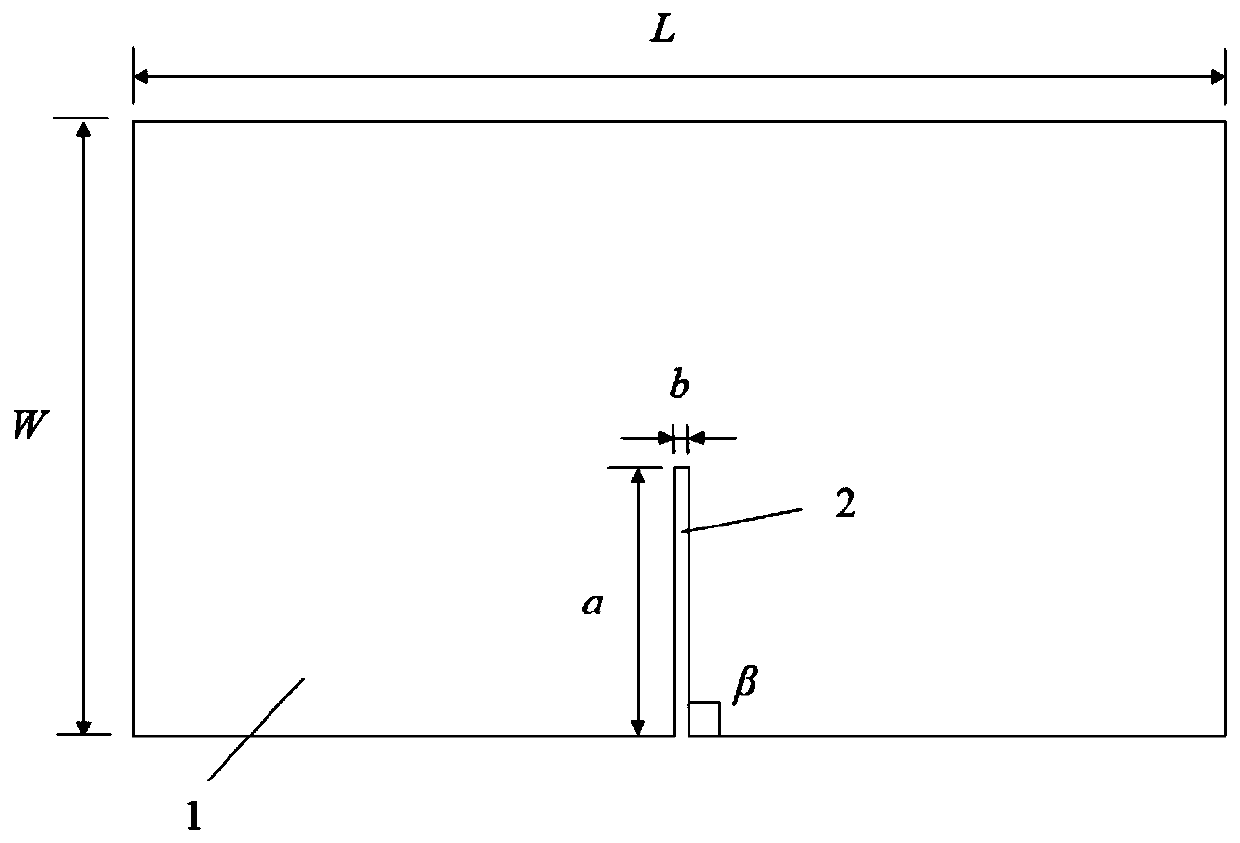

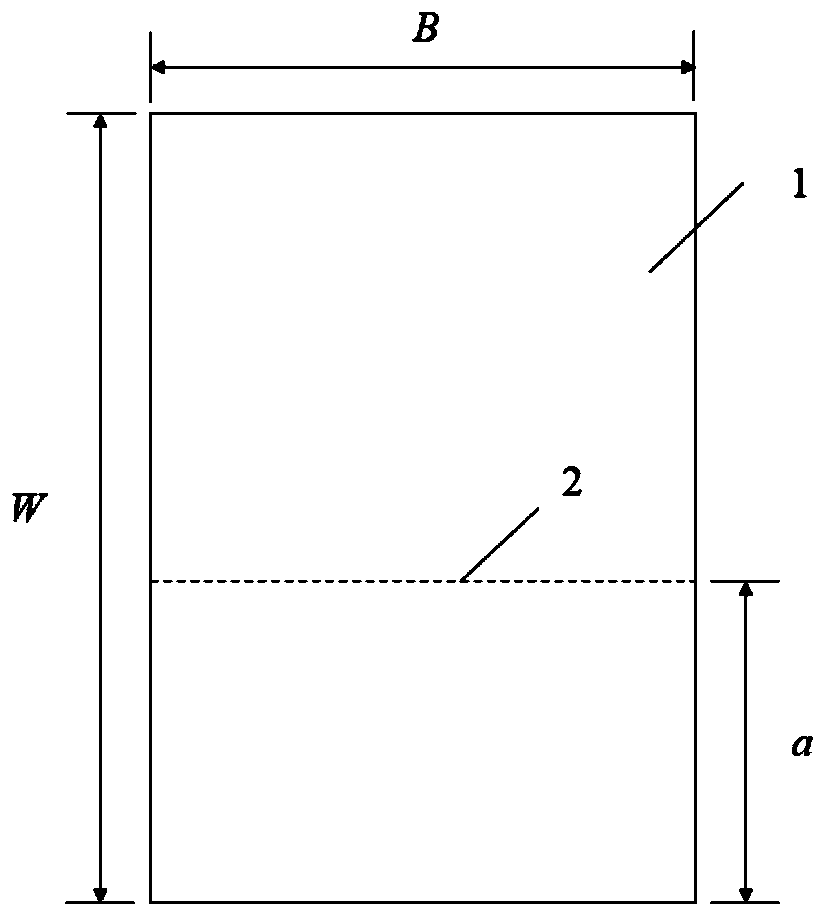

Method for testing rock composite fracture toughness based on asymmetric three-point bending loading of NDB sample

ActiveCN109781548ARich fracture toughness testing technology systemSimple structurePreparing sample for investigationMaterial strength using steady bending forcesNon symmetricEngineering

The invention provides a method for testing rock composite fracture toughness based on asymmetric three-point bending loading of an NDB sample, and the method comprises the steps: enabling a test piece body to be a rectangular deep beam (NDB) with a cutting groove, enabling the shape of the test piece body to be a cuboid, prefabricating a cutting groove with the height of a in the middle cross section of the body, extending towards the thickness direction of the body, and penetrating through the front and rear end faces in the body thickness direction; wherein the length L of the test piece body is twice the width W of the test piece body, and the thickness B is not less than 0.8 W. Based on the NDB sample, the invention provides a method for carrying out rock purity type I, rock purity type II and rock purity type I-II composite fracture toughness testing by using asymmetric three-point bending loading, and application of tension and shear load is realized through asymmetric loading.The NDB sample used in the invention has a simple structure and is easy to process by using rock blocks. A clamp used for loading is a common three-point bending clamp, only asymmetric arrangement ofthe supports is needed, experiment loading is quite convenient, and the pure I type, the pure II type and the I-II-type composite fracture toughness of the whole composite loading interval can be achieved.

Owner:SICHUAN UNIV

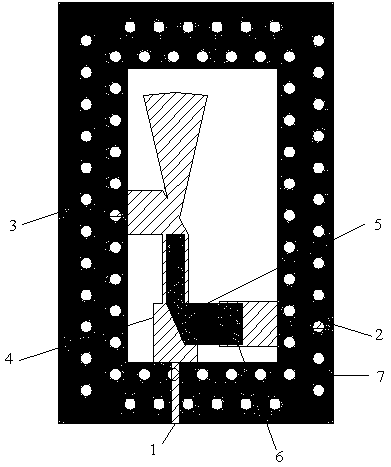

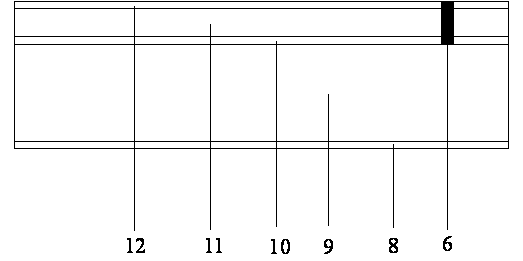

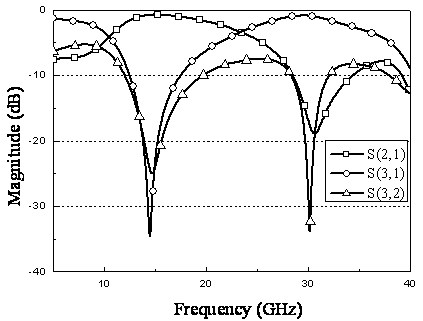

0-dB directional coupler based on multilayer technology

The invention discloses a 0-dB directional coupler based on a multilayer technology, and relates to the technical field of microwaves. The directional coupler is a three-port device with a first port, a second port and a third port. One end of an upper-layer coupling line is connected with the first port to form a first coupling port, the other end of the upper-layer coupling line is connected with the third port to form a straight-through port, a quarter wavelength open circuit branch knot is loaded to the straight-through port, one end of a lower-layer coupling line is connected with the second port through a connecting hole to form a second coupling port, and the other end of the lower-layer coupling line is in an open circuit mode. The 0-dB directional coupler based on the multilayer technology is achieved through a multi-layer three-dimensional structure in a broad-brimmed coupling mode, effectively reduces the size of a circuit, reduces processing difficulties caused by tight coupling, improves circuit stability, simplifies the circuit structure, can be applied to sub-harmonic mixer signal feed-in networks and other functional circuit modules in a radio frequency communication system and achieves high-strength isolation between signals.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

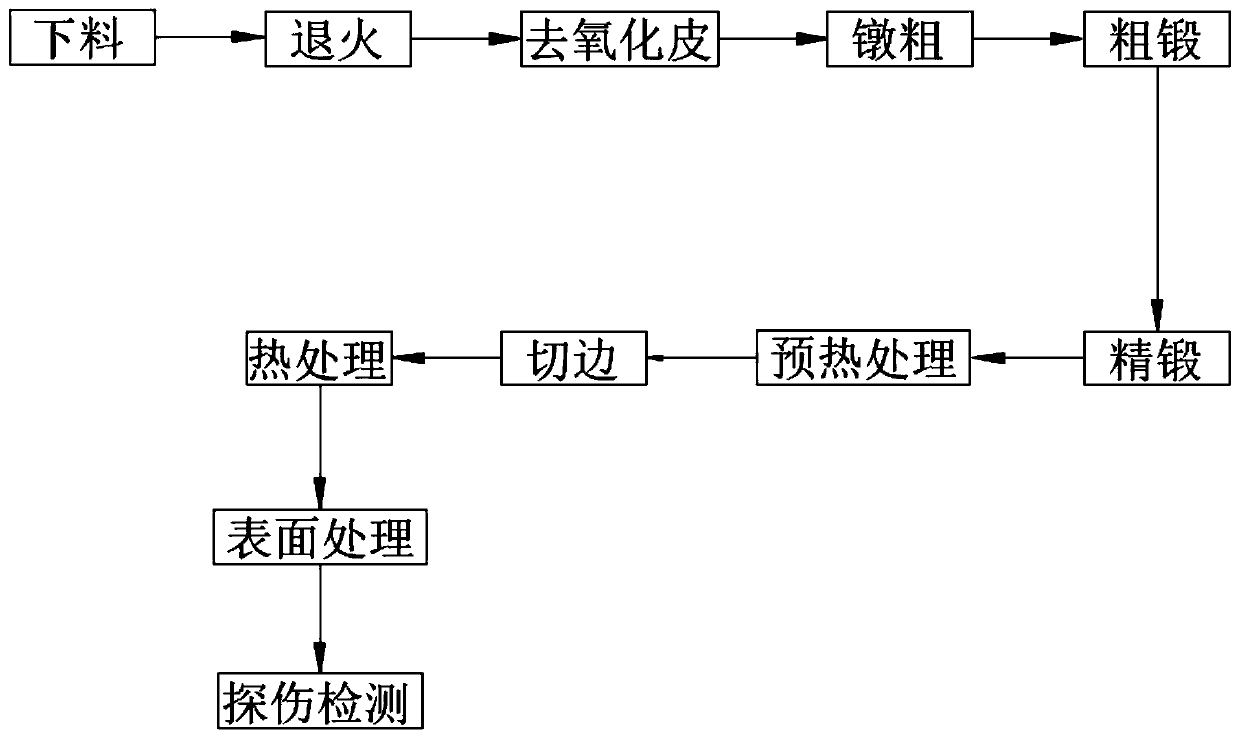

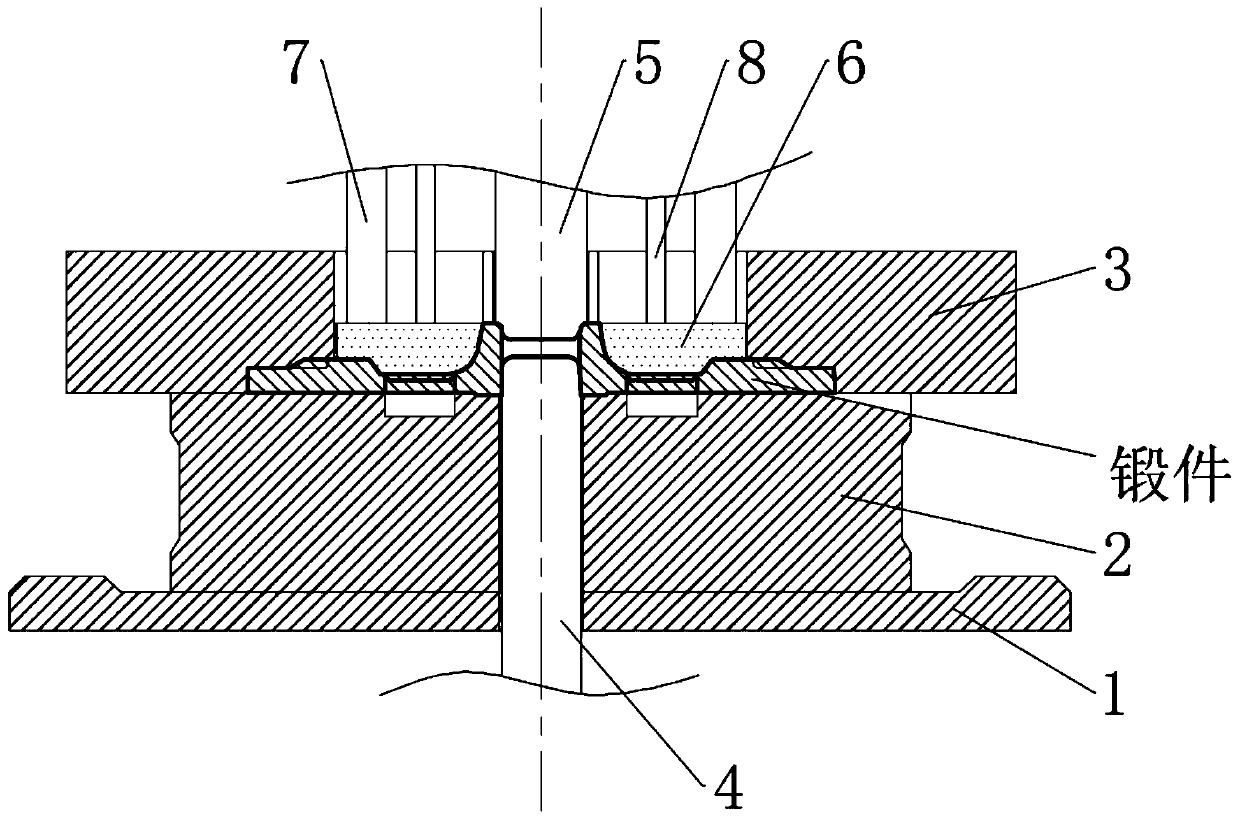

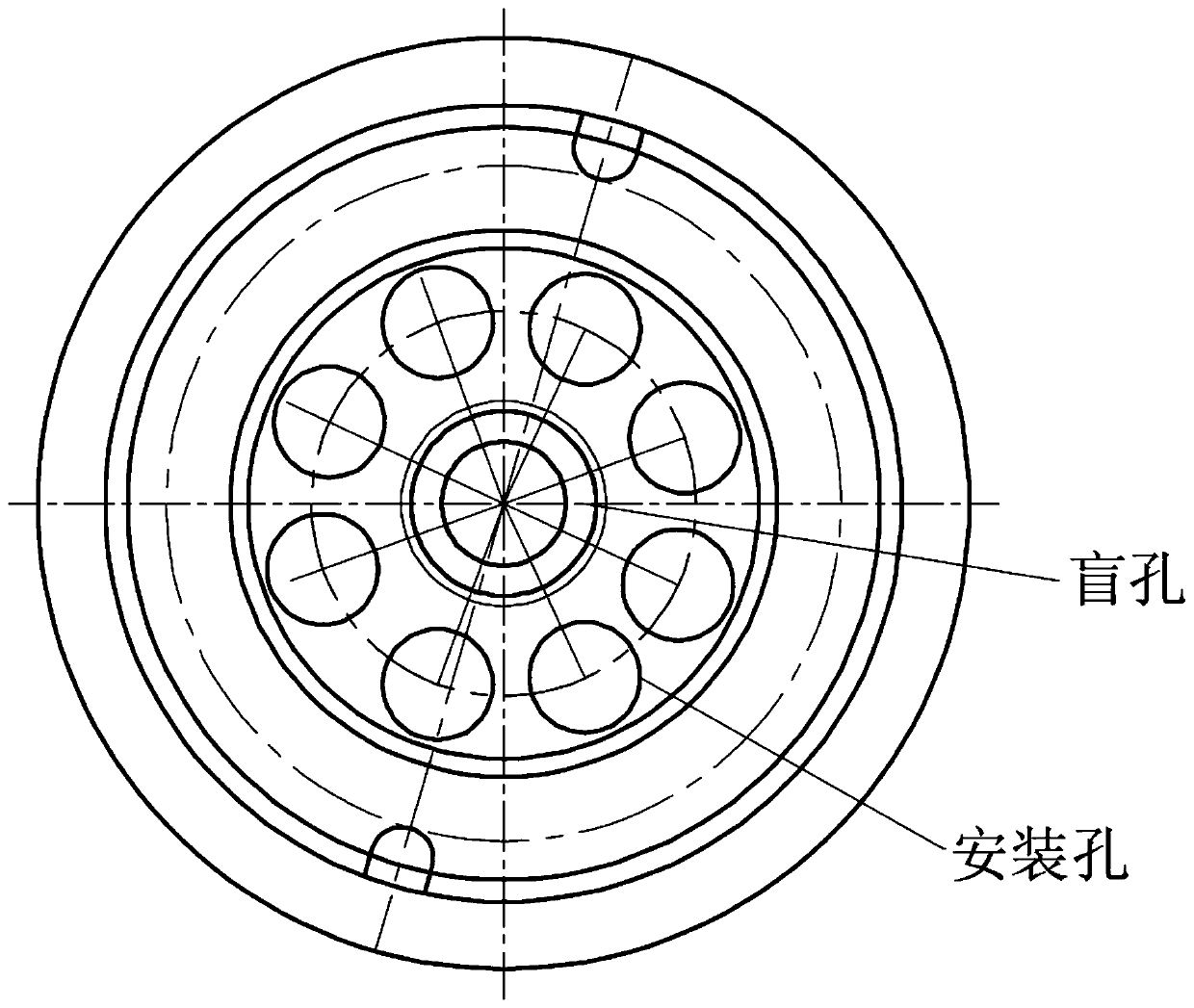

Forging technology for synchronous waste-removing and weight-reduction of forge piece

ActiveCN110722078AAvoid local deformationEasy to useForging/hammering/pressing machinesForging press detailsTemperature controlPunching

The invention discloses a forging technology for synchronous waste-removing and weight-reduction of a forge piece, and belongs to the technical field of forge piece processing. A weight-reduction partand an installation hole part of the forge piece can be achieved in the forging process; by installing a fractional punching mechanism in an existing precision forging die, the forge piece can be directly formed at a time in the forging process based on a thermal stress principle and a plastic deformation rule of the forge piece, and local deformation of the forge piece is prevented. Wastes are removed at a time, the machining difficulty and cumbersome operation brought by a machining process after forging are avoided, and the cost is further reduced; moreover, punching burrs on a non-machining surface can be avoided, and the whole machining workload is reduced; assisted by precise temperature control in the whole process, the shape of the flange hub forge piece can be obtained, dimensional deviations are not likely to be produced, structures in metal can be improved, the mechanical performance and the physical performance of the metal are improved, and therefore, the flange hub forgepiece higher in use performance and longer in life.

Owner:浙江众盈汽车零部件有限公司

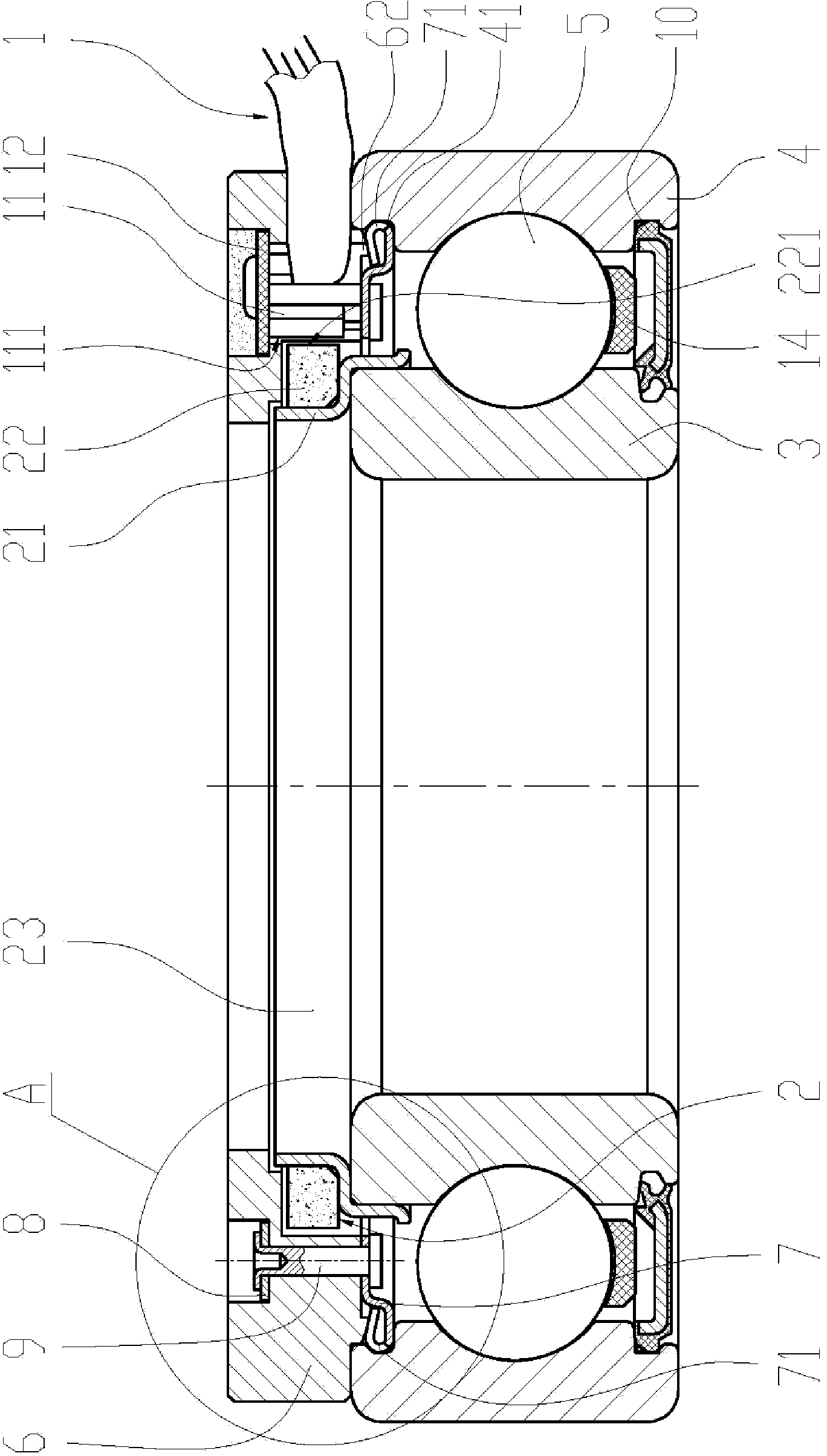

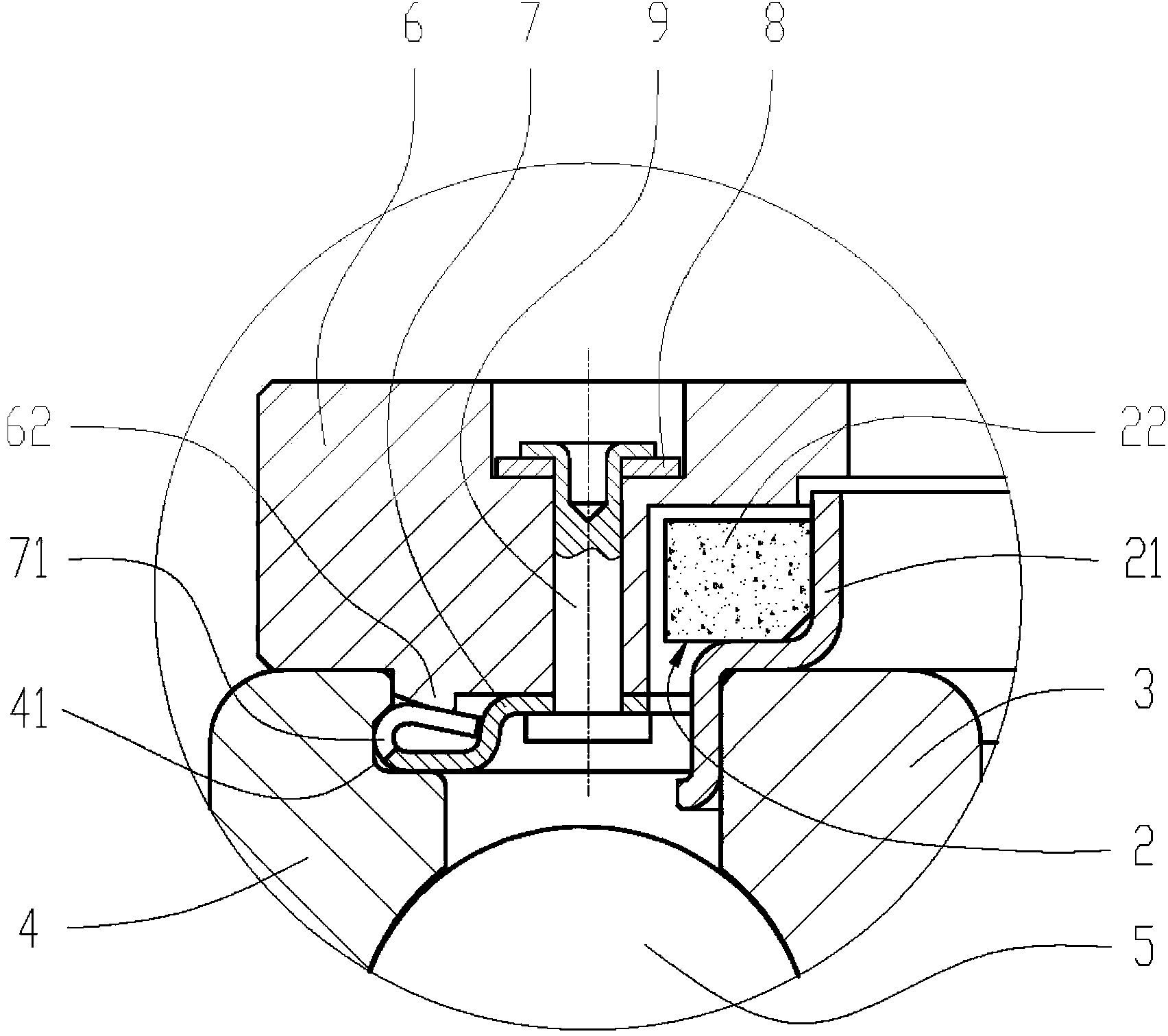

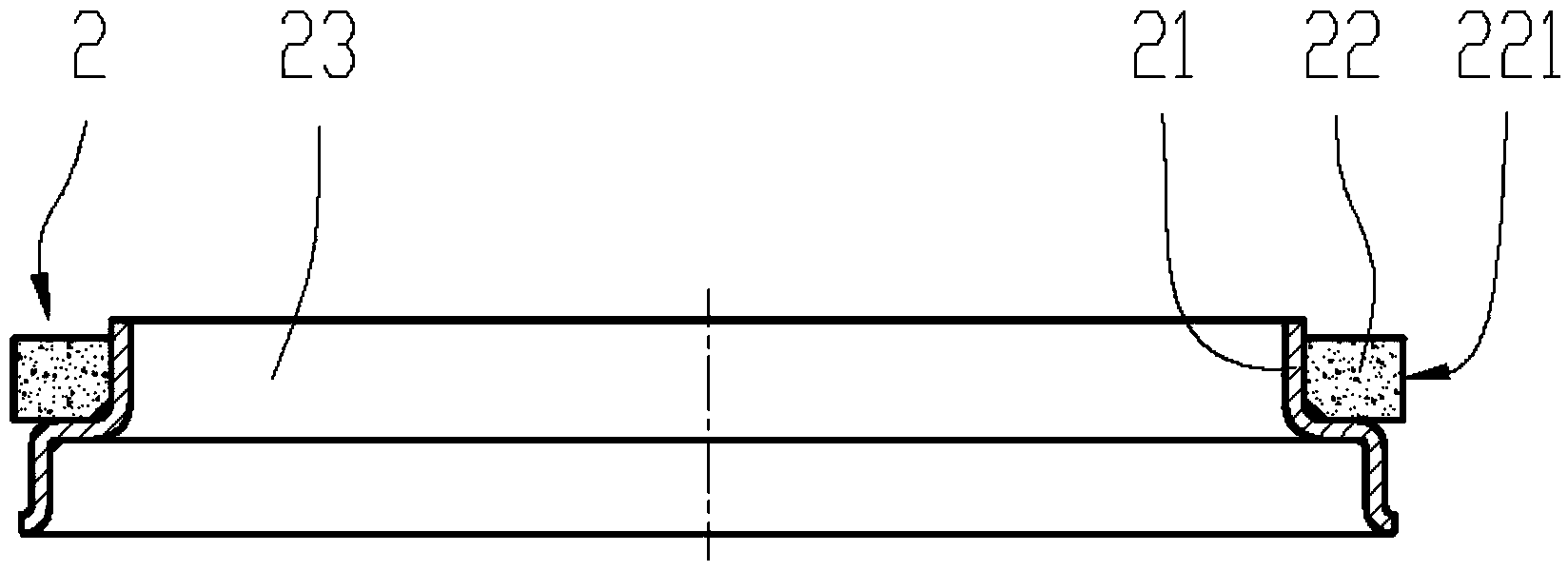

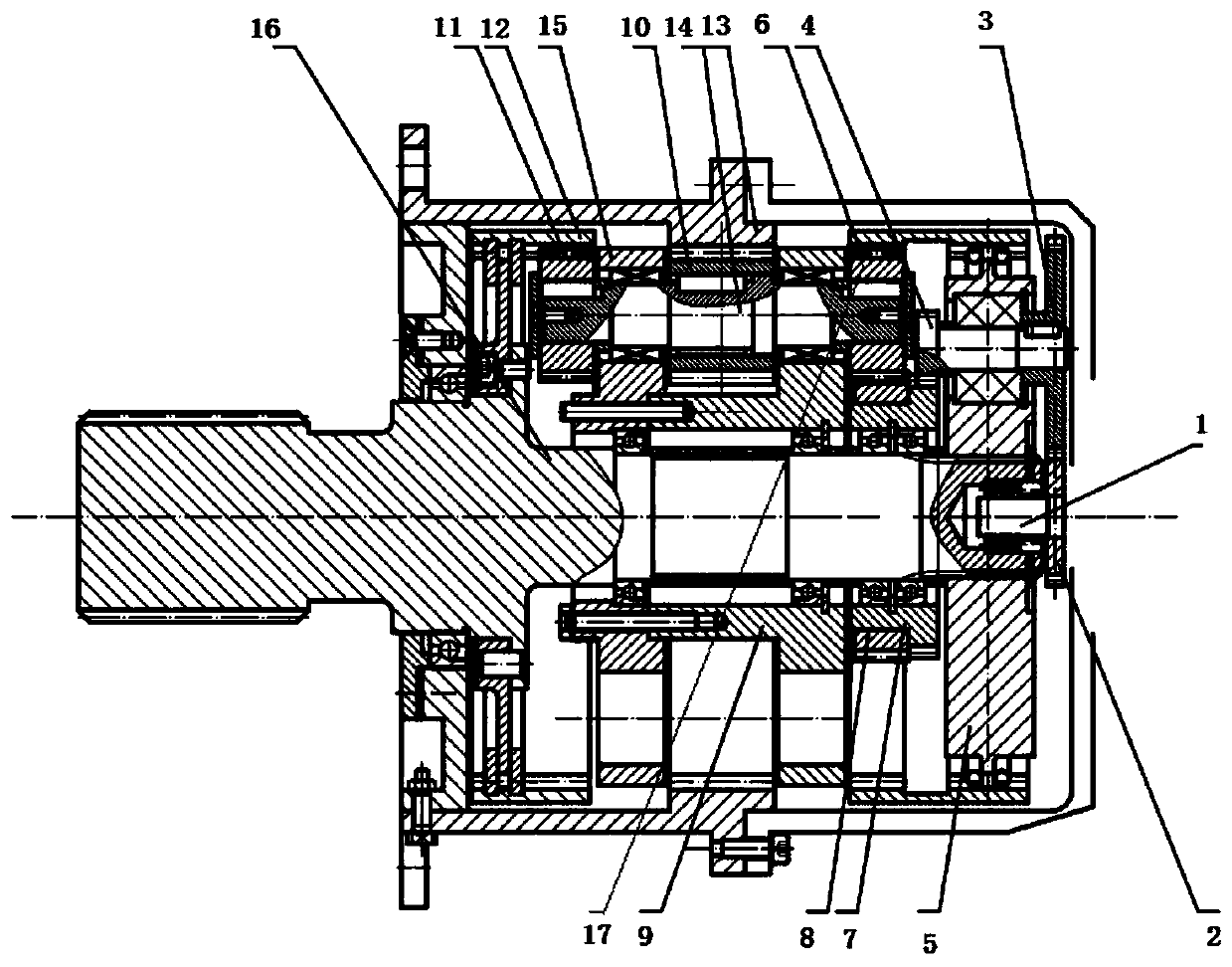

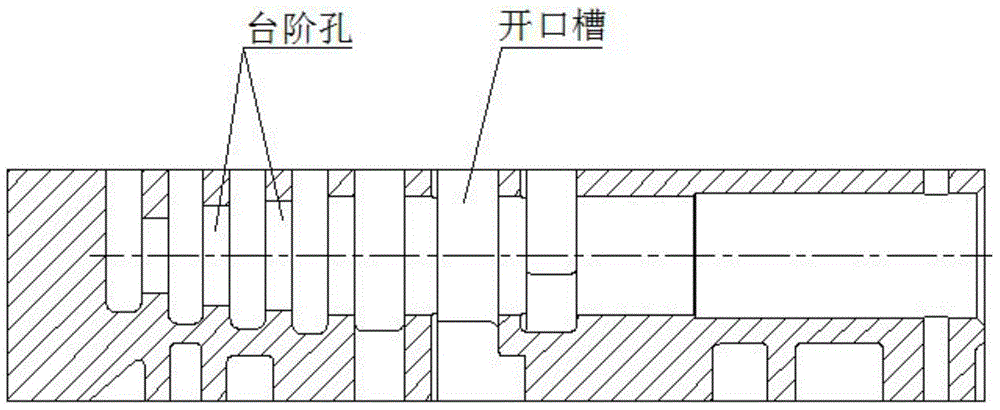

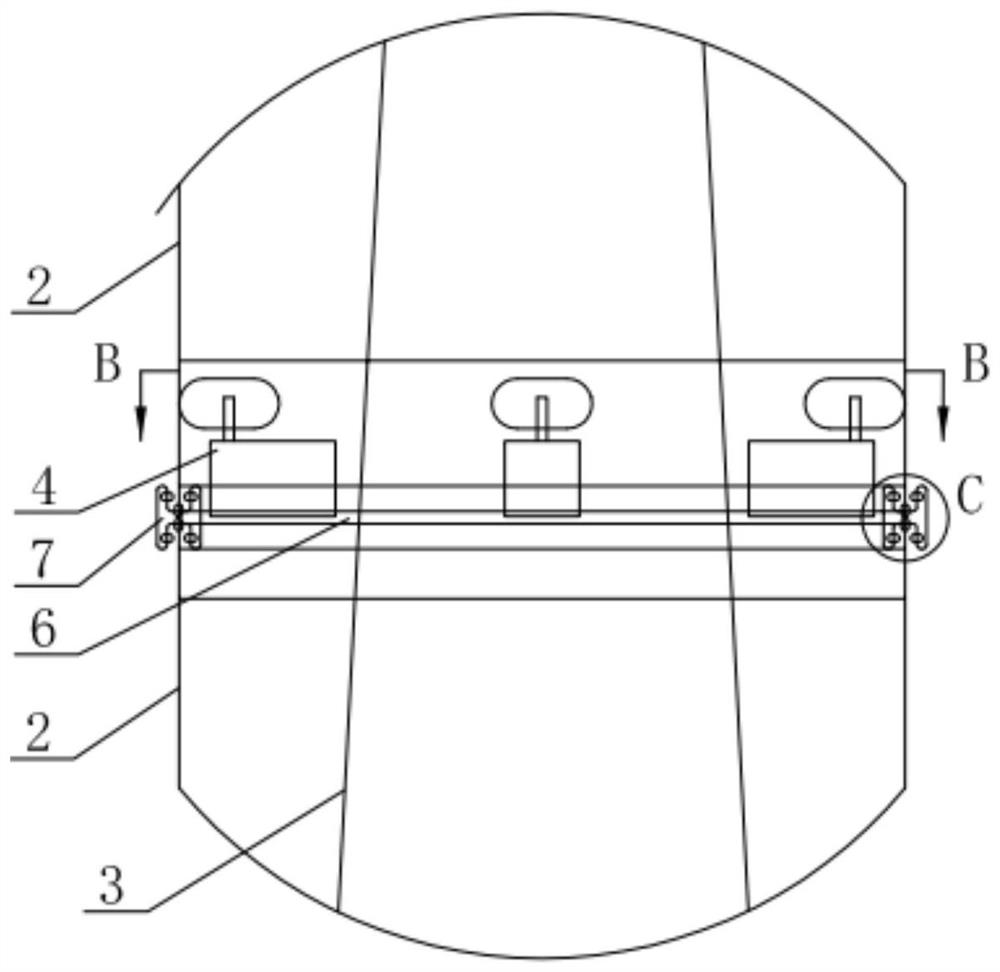

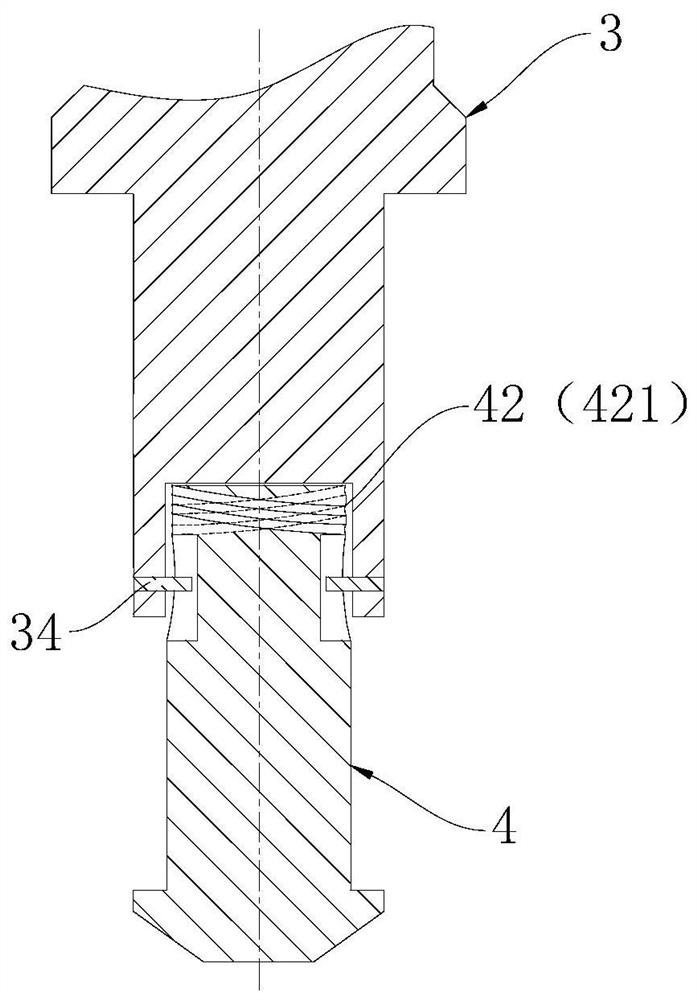

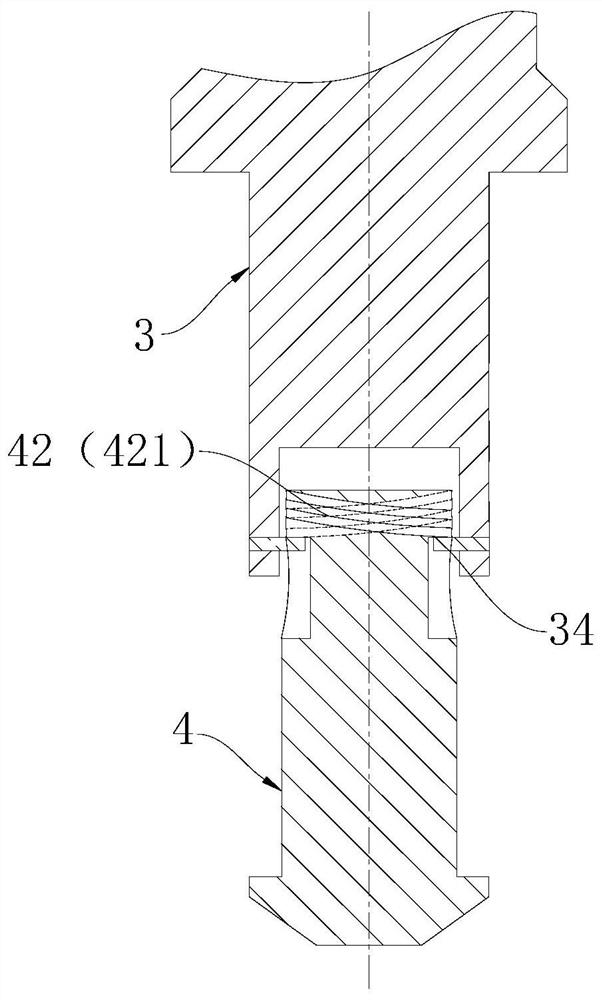

Bearing capable of detecting motion

InactiveCN103883628AImprove connection strengthHigh measurement accuracyBearing assemblyConverting sensor output electrically/magneticallyPhase differenceEngineering

The invention discloses a bearing capable of detecting motion. The bearing comprise a bearing body, a magnetic sensor and a magnetic ring with multiple poles, wherein the bearing body comprises an inner ring, an outer ring and a rolling element; the magnetic ring is fixedly arranged at the upper end surface of the inner ring; the magnetic sensor is fixed on the outer ring through a pressing cover; a step hole of which the upper end is big and the lower end is small penetrates through the end surface of the pressing cover; a through hole is radially formed in the side wall of the pressing cover; the through hole penetrates through a small hole part of the lower end of the step hole and extends to the inner wall of the pressing cover; the magnetic sensor is arranged on the step surface of the step hole in an inverted manner and the sensing surface of the magnetic sensor is arranged opposite to the magnetized surface of the magnetic ring at an interval through the through hole; an insulating material is filled above the magnetic sensor, so that the magnetic sensor is firmly bonded in the step hole; the pressing cover is detachably arranged at the upper end surface of the outer ring. The bearing capable of detecting motion disclosed by the invention is small in assembly error, long in service life and capable of outputting two-channel rectangular wave which has a duty factor of 50% and a phase difference of 90 DEG, so that the detecting accuracy is improved.

Owner:宁波艾森博林轴承有限公司

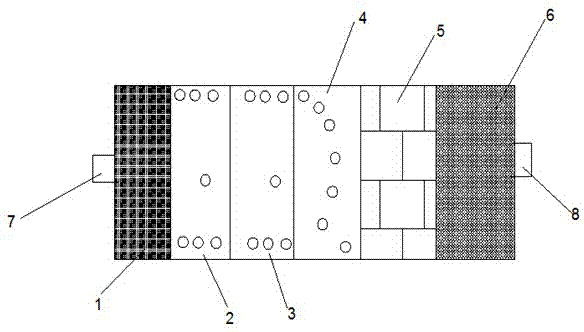

Fat-based waste gas odor absorption agent, fat-based waste gas odor absorption plate, fat-based waste gas odor absorption plate preparation method, dry-method odor removing process, and dry-method odor removing equipment

ActiveCN107020003AEasy to combineEasy to carryCombination devicesGas treatmentFiltrationPhysical chemistry

The present invention discloses a fat-based waste gas odor absorption agent, an odor absorption plate loading the absorption agent, a preparation method for the odor absorption plate, a dry-method odor removing process achieved by using the odor absorption plate, and dry-method odor removing equipment. According to the present invention, according to the fat-based waste gas odor absorption plate, the oxidizing agent and the catalyst are loaded on the substrate plate, such that the module combination, the carrying and the transporting can be conveniently performed, and the recycling can be achieved after the loading failure; according to the dry-method odor removing process, coarse filtration, electrostatic adsorption, UV light deodorization, catalytic oxidation degreasing deodorization and acid-alkali neutralization are sequentially performed, and the treated fat-based waste gas is changed into the odorless and tasteless gas so as to achieve the safe discharge standard, such that the atmosphere pollution problem caused by the fat-based waste gas is solved; and according to the dry-method odor removing equipment, the catalytic oxidation technology is immobilized on the alumina substrate plate, and the obtained substrate plate is installed on the composite waste gas treatment equipment, such that the treatment difficulty is solved by the dry process, the damage of the strong oxidizing substances on personal can be avoided, and the installation and the maintenance are convenient.

Owner:SHANGHAI HONGLAI ENVIRONMENTAL EQUIP CO LTD

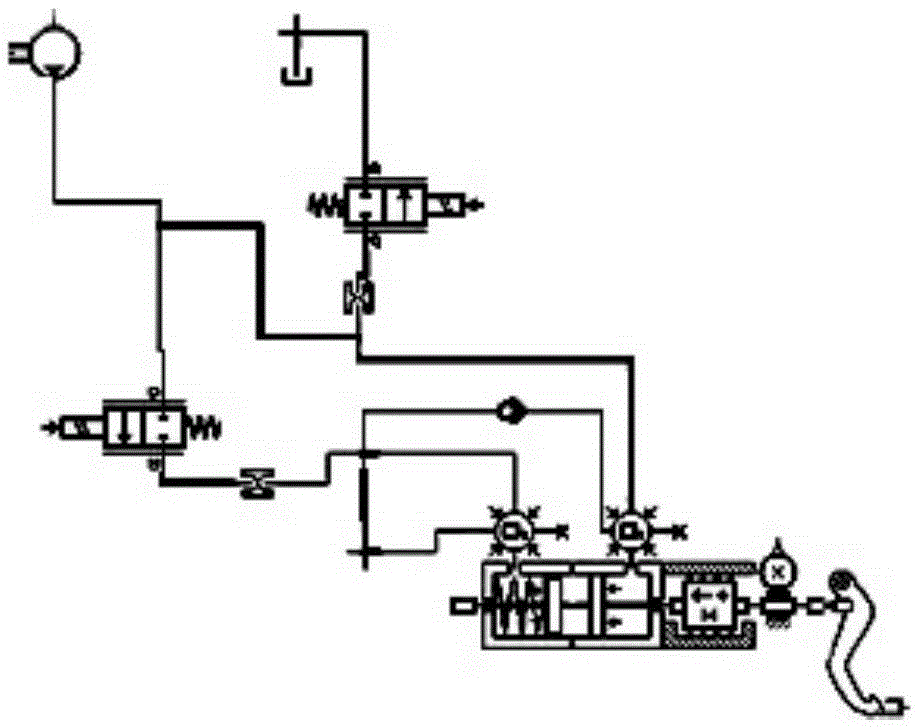

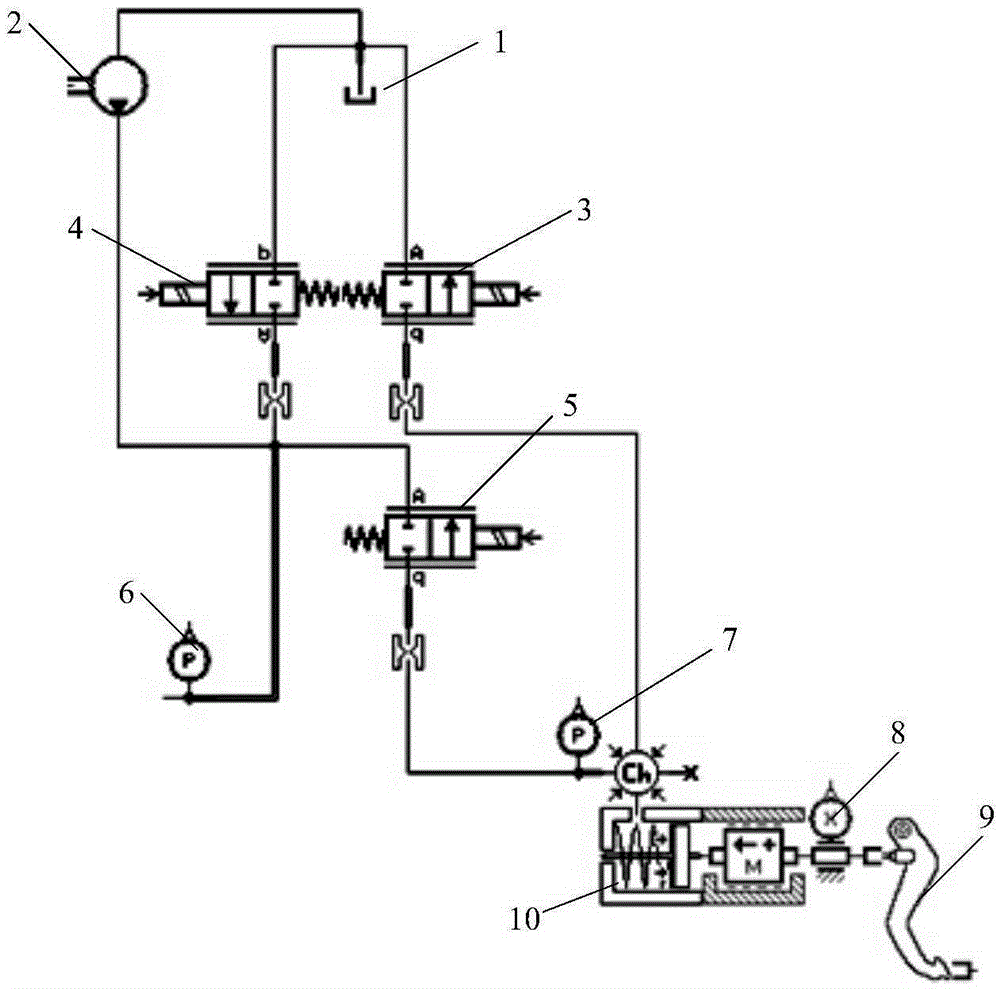

Brake-by-wire and pedal-force feedback system and braking method

ActiveCN105270375AAchieve independent controlAvoid processing difficulties and leakage problemsBraking action transmissionPlunger pumpSystem pressure

The invention discloses a brake-by-wire and pedal-force feedback system and a braking method. In the braking process, a liquid infusion device cuts off a communication passage between a working cavity and an outlet of a plunger pump, so that a pedal-force control system and a system-pressure control system are totally separated each other; therefore, the dependence of pedal feedback force on the system pressure is avoided, namely the main cylinder pressure and the system pressure are separately controlled; the phenomenon that when ABS braking is performed, the fluctuation of the system pressure leads to the fluctuation of the main cylinder pressure, and the pedal feedback force fluctuates is avoided, so that the independent control of pedal feedback force is realized; a main braking cylinder is simplified into a single-end structure, so that the processing difficulty of a complicated main braking cylinder is reduced, and the leaking problem of the complicated main braking cylinder is solved. When brake-by-wire is failed, braking liquid in the working cavity of the main braking cylinder passes through the liquid infusion device and then is applied on a braking wheel cylinder, so that standby brake of a vehicle is realized.

Owner:ZHEJIANG WANXIANG PRECISION IND +1

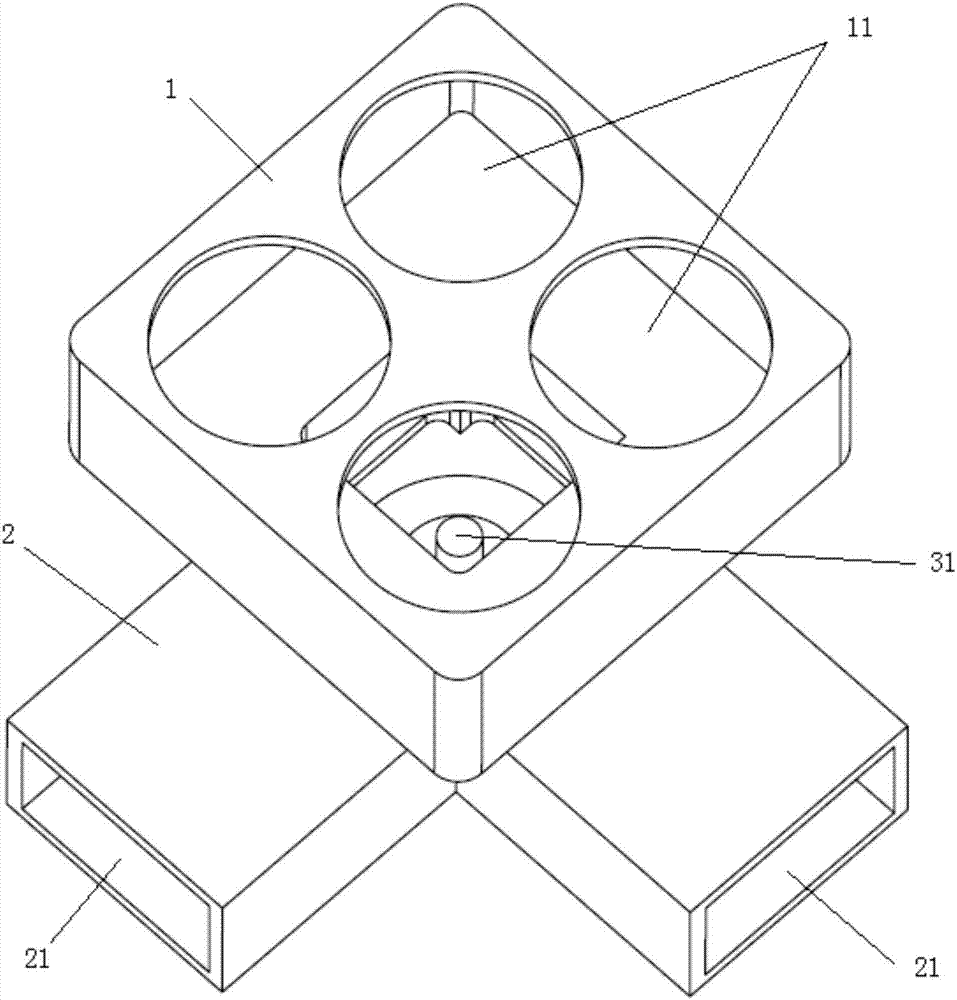

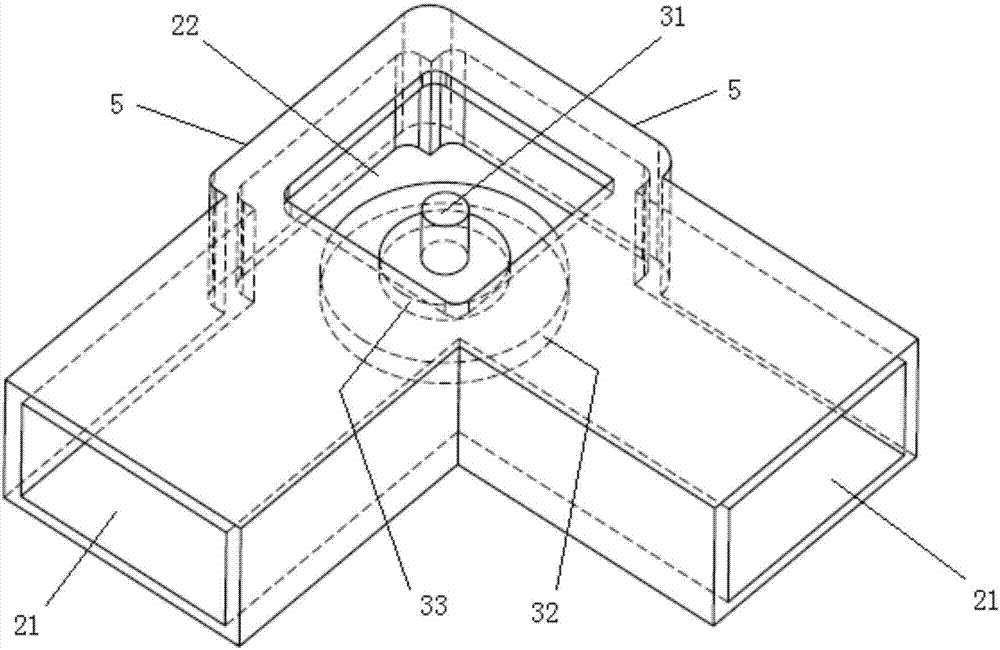

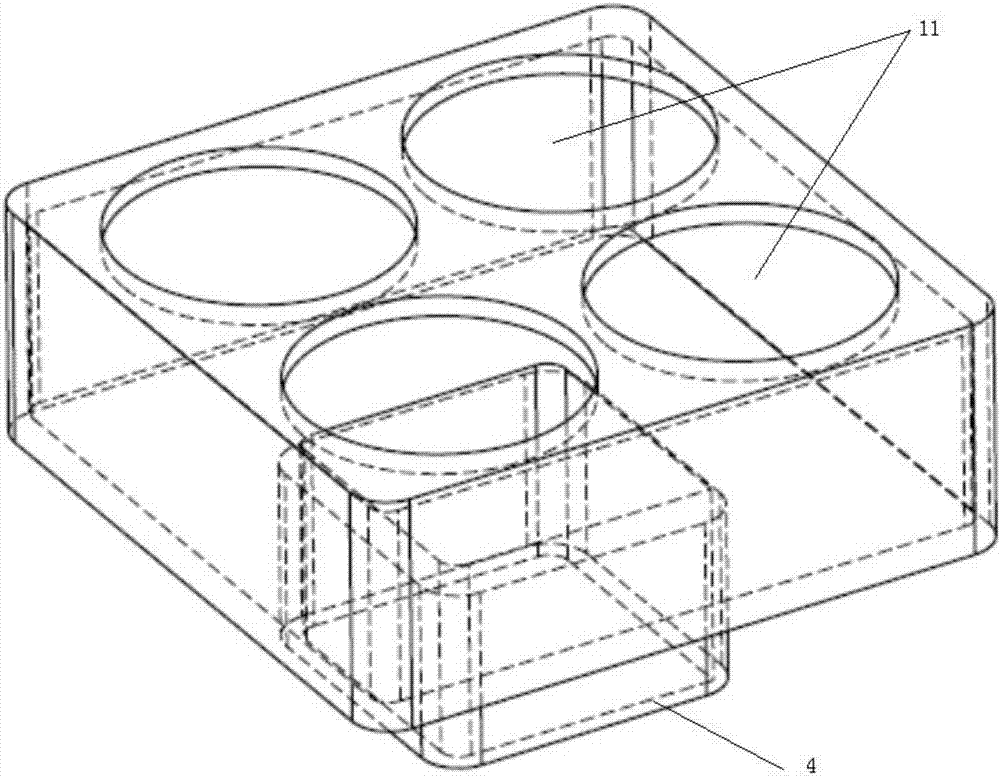

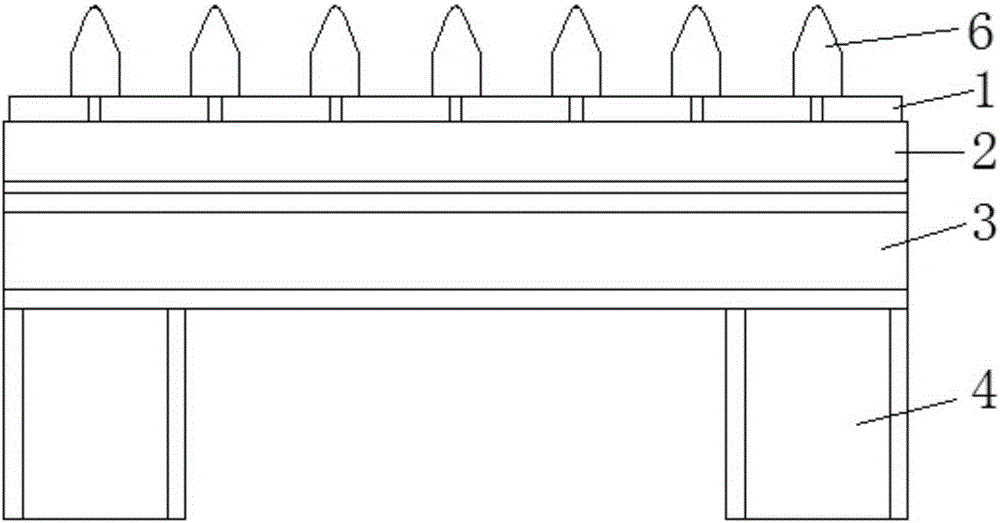

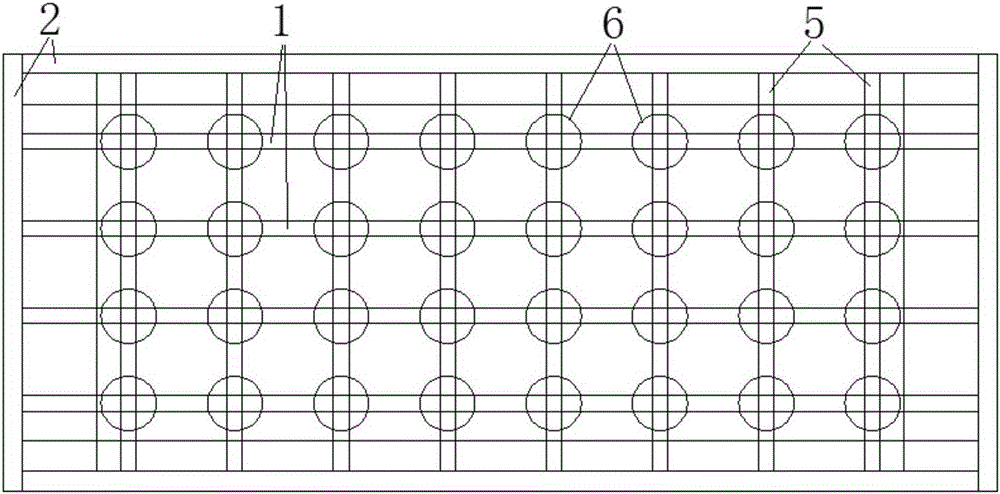

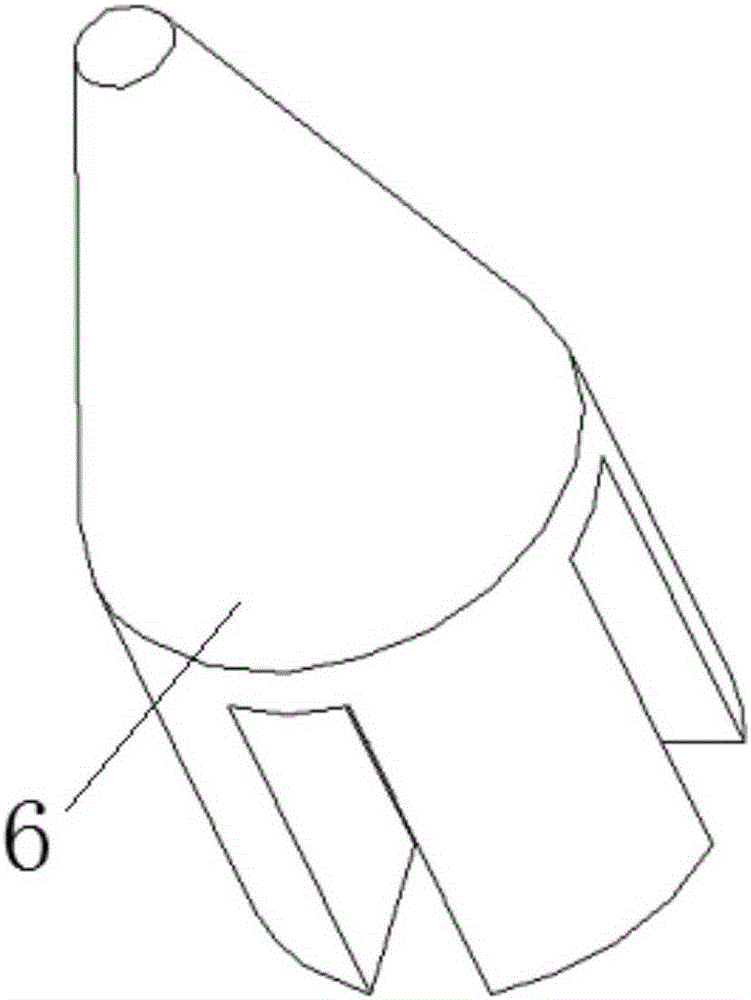

Dual-port feeding type array antenna

ActiveCN107359405AImprove radiation efficiencyThere are various ways to realizeRadiating elements structural formsAntennas earthing switches associationCoaxial cavityMechanical engineering

The invention discloses a dual-port feeding type array antenna, and belongs to the technical field of an antenna. The dual-port feeding type array antenna comprises a radiation cavity and a coaxial cavity which communicate with each other, a plurality of radiation ports are arranged in a top surface of the radiation cavity, the coaxial cavity is provided with two waveguide input ports perpendicular to each other, a vertical and cylindrical probe having coaxial characteristic is arranged on a bottom surface in the center of the coaxial cavity, two matching steps are arranged at the bottom of the probe and comprise a first cylinder and a second cylinder, the first cylinder and the second cylinder are coaxial to the probe, the first cylinder is directly arranged on the bottom surface of the coaxial cavity, and the second cylinder is arranged on a top surface of the first cylinder. By the dual-port feeding type array antenna, the gap opening coupling processing difficulty can be prevented, the problem of air live-line feeding loss also can be prevented, and the dual-port type array antenna is an important improvement compared with the prior art.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

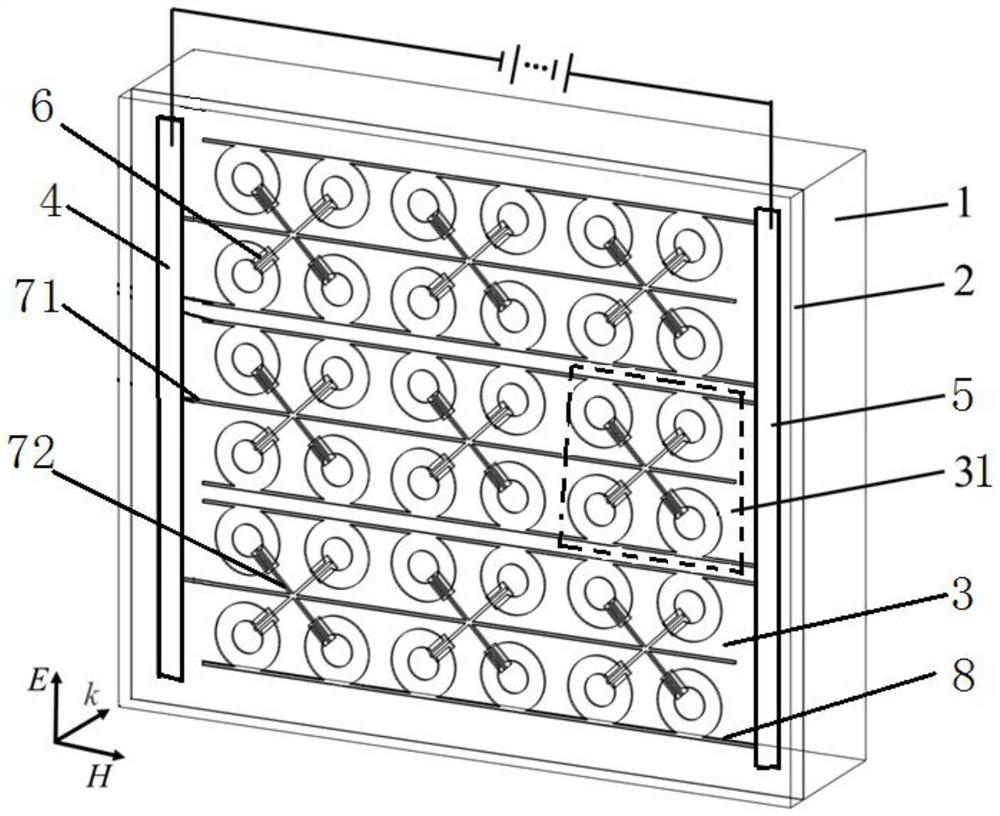

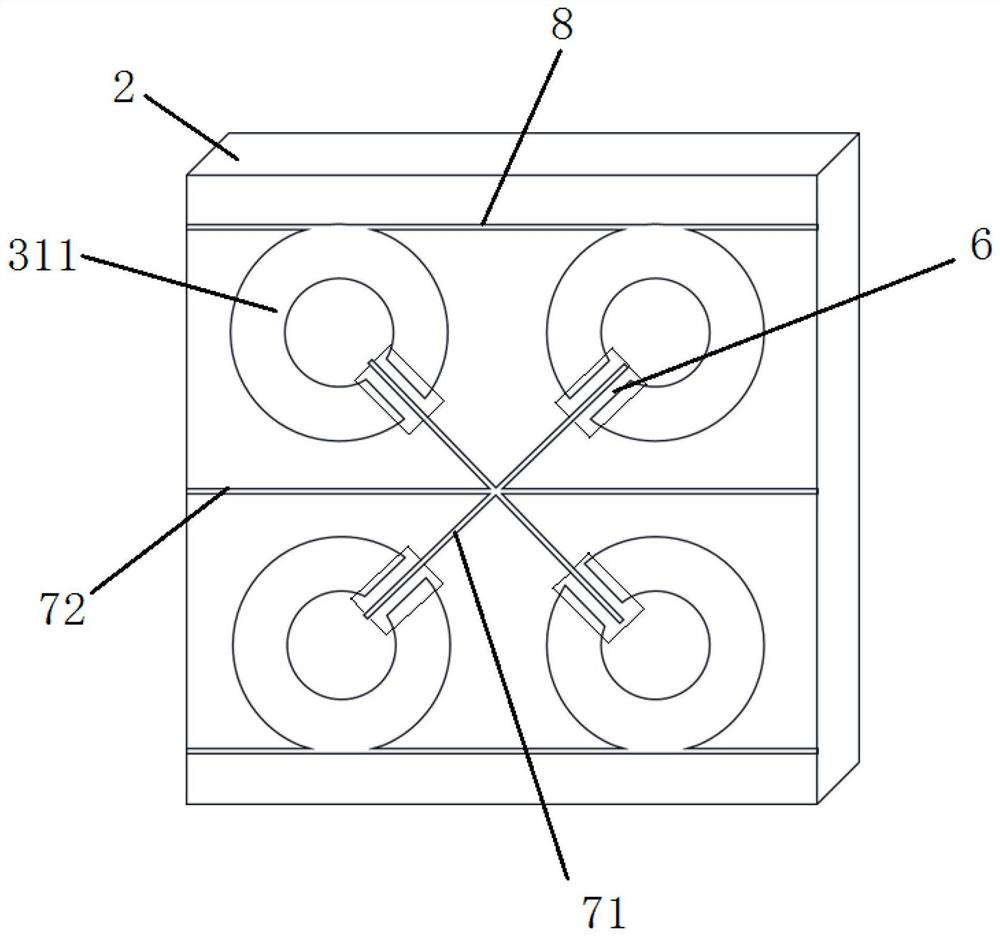

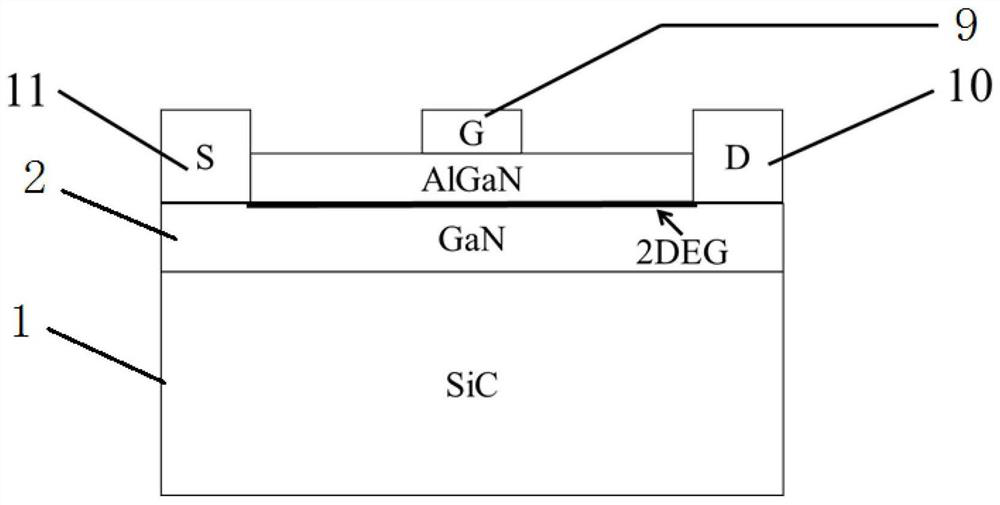

HEMT-based annular opening terahertz amplitude modulator and manufacturing method

ActiveCN111884593AEnhanced resonance strengthFast modulationAmplitude-modulated carrier systemsAmplitude modulation with minimum 3 electrode semiconductor deviceExternal biasEngineering

The invention discloses an HEMT-based annular opening terahertz amplitude modulator and a manufacturing method thereof. The modulator comprises a semiconductor substrate; an epitaxial layer located onthe surface of the semiconductor substrate; and a modulation array, a Schottky electrode and an ohmic electrode which are arranged on the epitaxial layer. The modulation array is formed by periodically arranging M * N modulation array elements, each modulation array element is composed of four structural units with annular openings, a high-electron-mobility transistor is matched at the opening ofeach structural unit, and a grid electrode of each high-electron-mobility transistor is connected with a Schottky electrode through a grid electrode feeder line and then connected with a negative electrode of a power source. The source electrode and the drain electrode of the high-electron-mobility transistor are connected with the two sides of the opening of the structural unit respectively, andthe structural unit is connected with the ohmic electrode through the source-drain feeder and then connected with the positive electrode of the power supply. A high-electron-mobility transistor is controlled by an external bias voltage to perform conversion of a metasurface resonance mode, rapid amplitude modulation of terahertz waves propagated in a free space is achieved, and modulation of multiple frequency points is achieved by mutual conversion of different modes of a structural unit.

Owner:重庆太赫兹科技发展有限公司

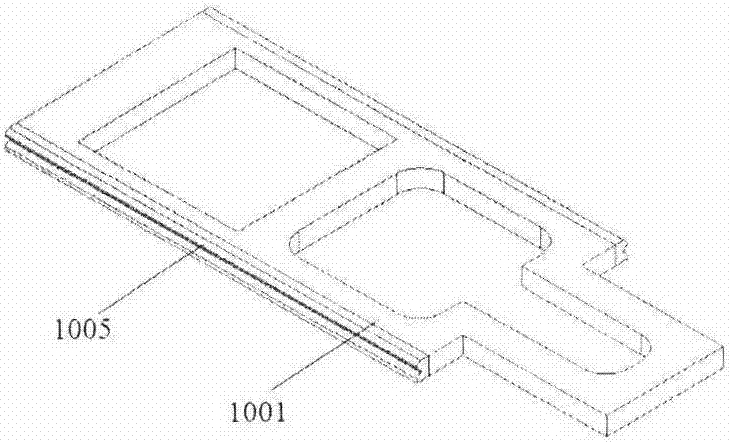

Processing, shaping and modulation method of hollow retroreflector

ActiveCN109856716AEasy to adjust neatnessMaintain visual aestheticsMirrorsTectorial membraneLaser cutting

The invention discloses a processing, shaping and modulation method of a hollow retroreflector. The processing, shaping and modulation method includes the steps that firstly, a square substrate assembled with the hollow retroreflector is glued on a solid pyramid, then the whole square substrate is cut to a circle through an engraving machine or a laser cutting machine, then the inner sides of cutelliptic arc-shaped substrates are plated with metal protective films, then the elliptic arc-shaped substrates are glued on an angular accuracy adjustment platform to adjust the angular accuracy, interference fringes are observed through a laser interferometer, and the vertical angular accuracy of the three substrates in pairs is adjusted through the fringe change. By gluing the square substrate on the solid pyramid, then overall tilt circle cutting engraving is conducted through the cutting machine, a gap between the solid pyramid and the substrate is filled with glue during cutting, and thesingle irregular elliptical arc-shaped substrates can be obtained through tilt processing of the substrate in one step; and meanwhile, the fact that damage of cutting to the reflective surface of a coating film is caused, and consequently the product quality is affected is avoided, and the visual attractiveness and consistency of the hollow retroreflector are maintained while the angular accuracyis ensured.

Owner:UNION OPTIC

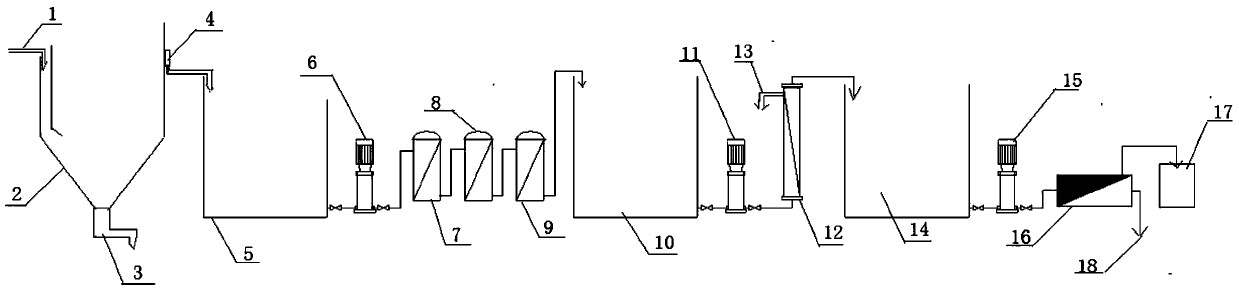

Concentration recovery system and method for active ingredients of machining cleaning solution

InactiveCN104176843AImprove the efficiency of waste liquid treatmentReduce sewage treatment costsMultistage water/sewage treatmentUltrafiltrationWater storage tank

The invention relates to the technical field of wastewater treatment, and in particular relates to a concentration recovery system and method for active ingredients of a machining cleaning solution. Settling, coarse filtration, multi-times fine filtration, ultra-filtration and nano-filtration technologies are combined by adopting a system consisting of a waste liquid inlet, a settling tank, a settlement discharge opening, an infusion pump, a supernate tank, a booster pump a, a coarse filter, a primary fine filter, a secondary fine filter, a filtrate tank, a booster pump b, an ultra-filtration system, an ultra-filtrate discharge opening, an ultra-filtration water storage tank, a booster pump c, a nano-filtration system, a nano-filtration effluent storage tank and a nano-filtration concentrate recovery opening; and the active ingredients of the machining cleaning solution are recycled through the steps of settling, coarse filtration, multi-times fine filtration, ultra-filtration and nano-filtration, so that the recycle cost of the machining cleaning solution is reduced, the recycle rate of the machining cleaning solution is improved, the quality of the recycled machining cleaning solution is improved, and the system and the method have significant economic benefit and environment-friendly value.

Owner:VONTRON MEMBRANE TECH CO LTD

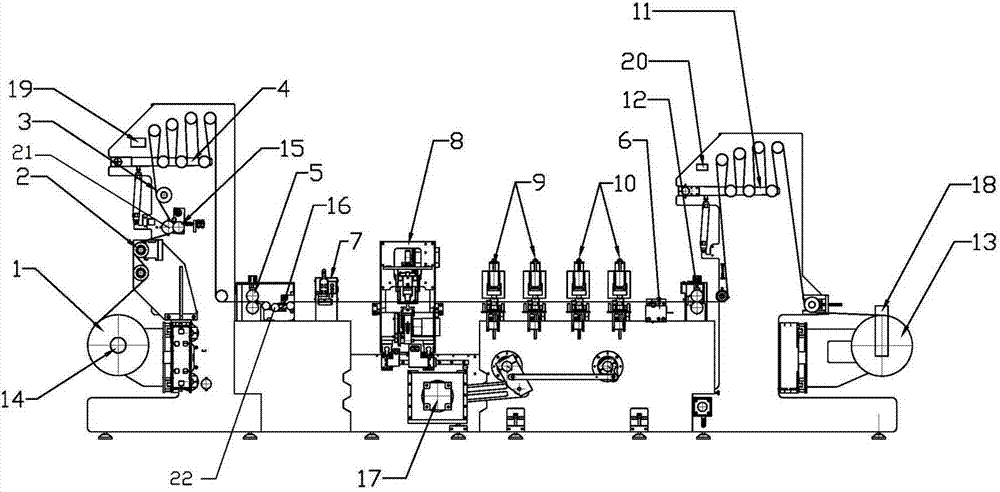

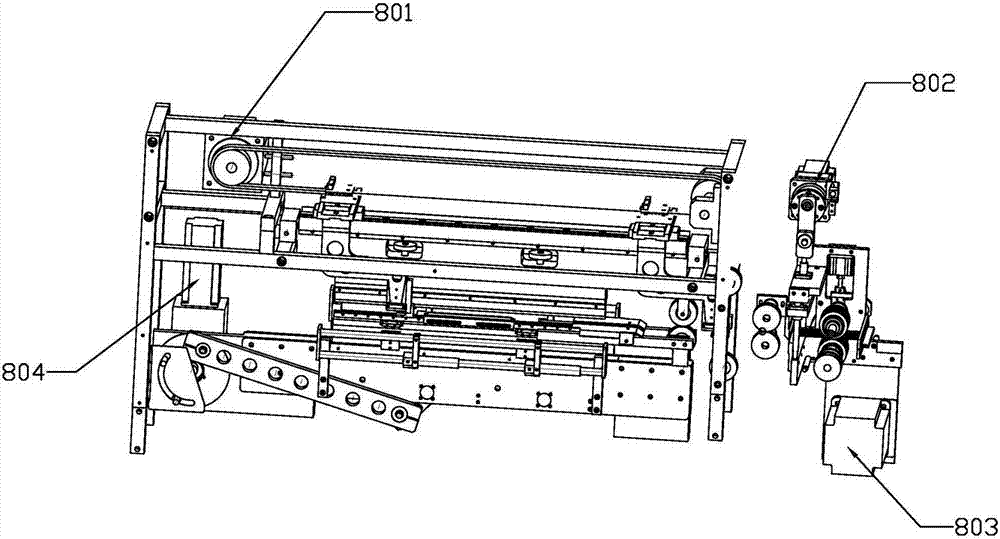

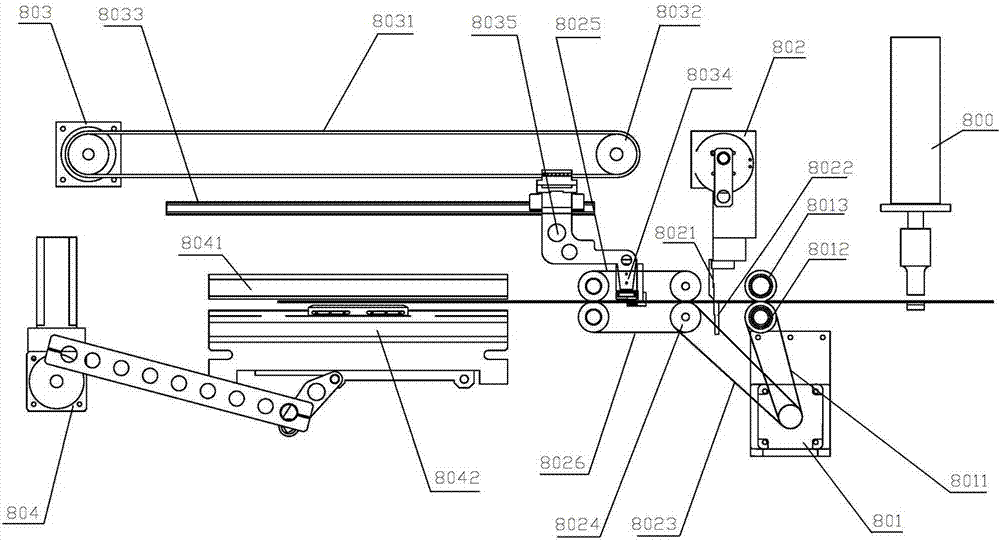

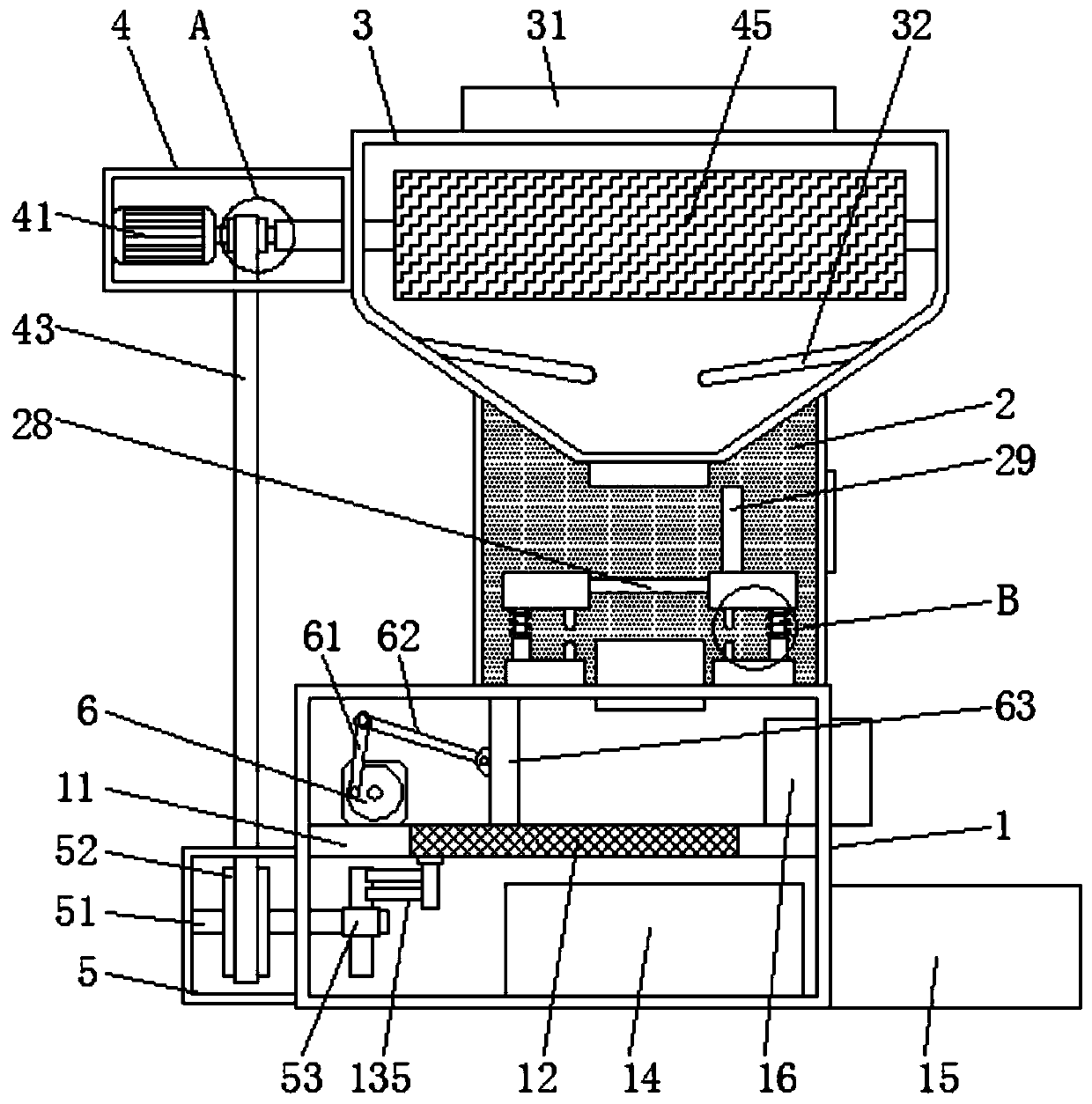

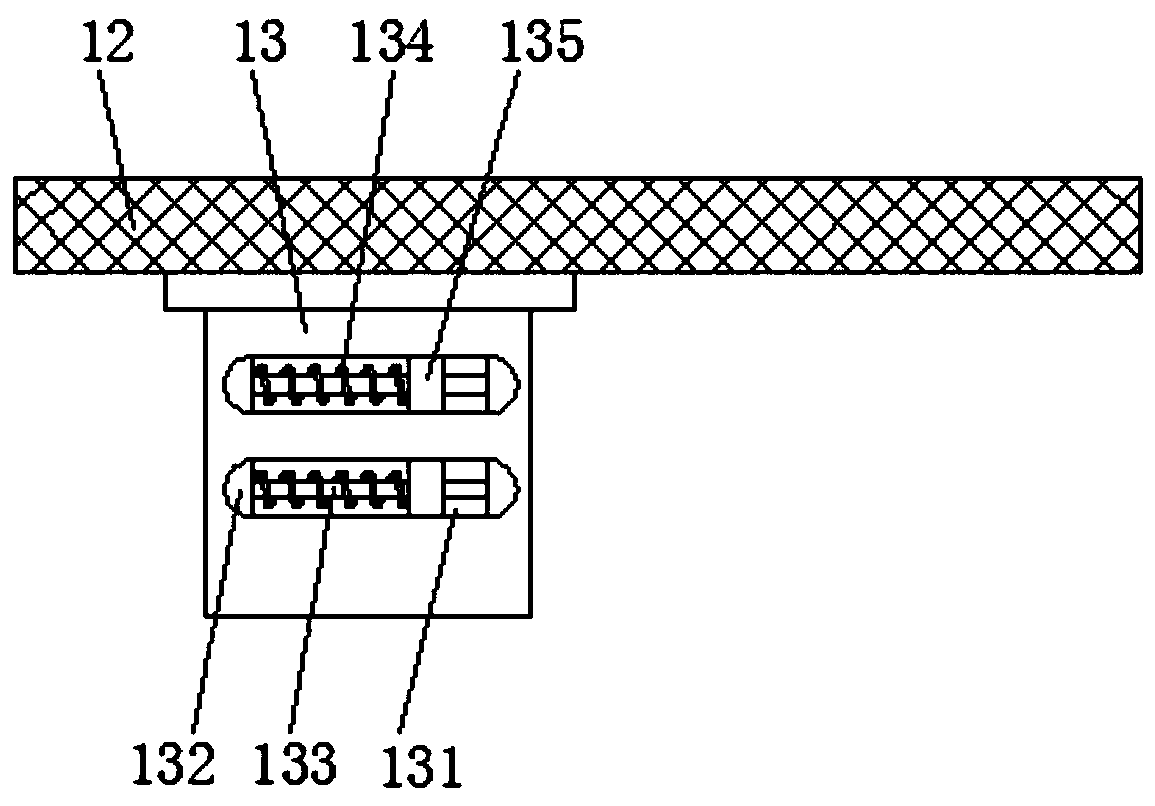

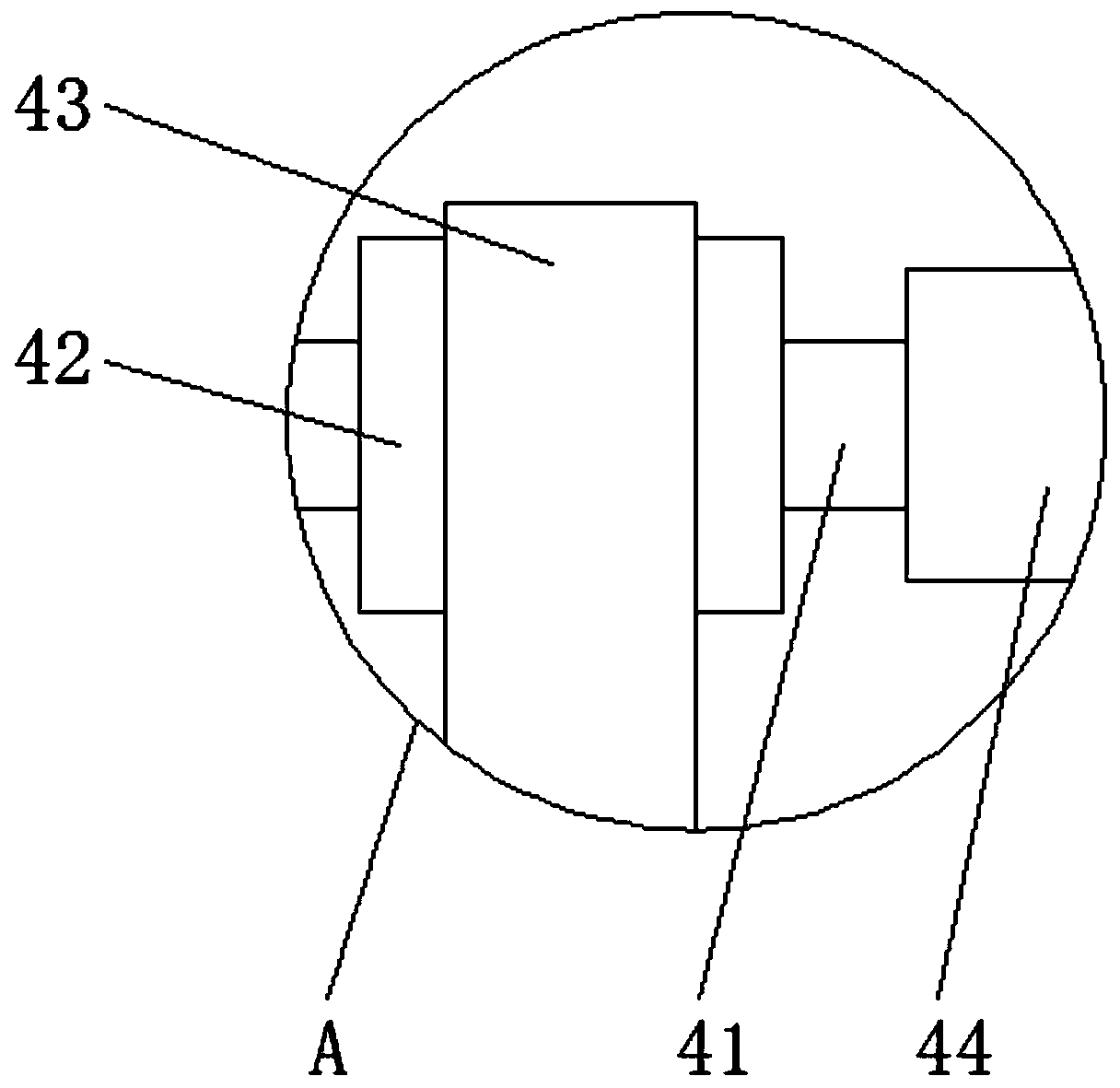

Multifunctional zipper checking machine and method for mounting zipper by applying multifunctional zipper checking machine

PendingCN106965493ATo achieve the purpose of heat sealing and fixingAvoid processing difficultyBag making operationsPaper-makingColor ScaleControl system

The invention discloses a multifunctional zipper checking machine and a method for mounting a zipper by applying the multifunctional zipper checking machine. The multifunctional zipper checking machine comprises an unwinding roller, a pulling roller, a variable frequency motor A, a swing roller (4), a conveying roller A, a dotted-line hole punching device, a transverse zipper mounting device, heat sealing devices, cooling devices, a color scale detecting device, a conveying roller B, a swing roller (11), a winding roller, and a variable frequency motor B, wherein a potentiometer A is arranged above the swing roller (4), and a potentiometer B is arranged above the swing roller (11); the longitudinal swing amplitude data of the swing rollers is respectively transmitted to the variable frequency motor A and the variable frequency motor B to respectively control unwinding speed and winding speed; and the dotted-line hole punching device, the transverse zipper mounting device, the heat sealing devices, the cooling devices and the color scale detecting device are arranged between the conveying roller A and the conveying roller B. According to the multifunctional zipper checking machine, through a PLC control system, zipper strips are transversely fixed on the set positions of a single-layer or multi-layer film at intervals in a heat sealing manner, and a hot knife heat sealing manner or an ultrasonic device and the like can be adopted to achieve the purpose of performing fixing through heat sealing.

Owner:DALIAN ALTMA IND CO LTD

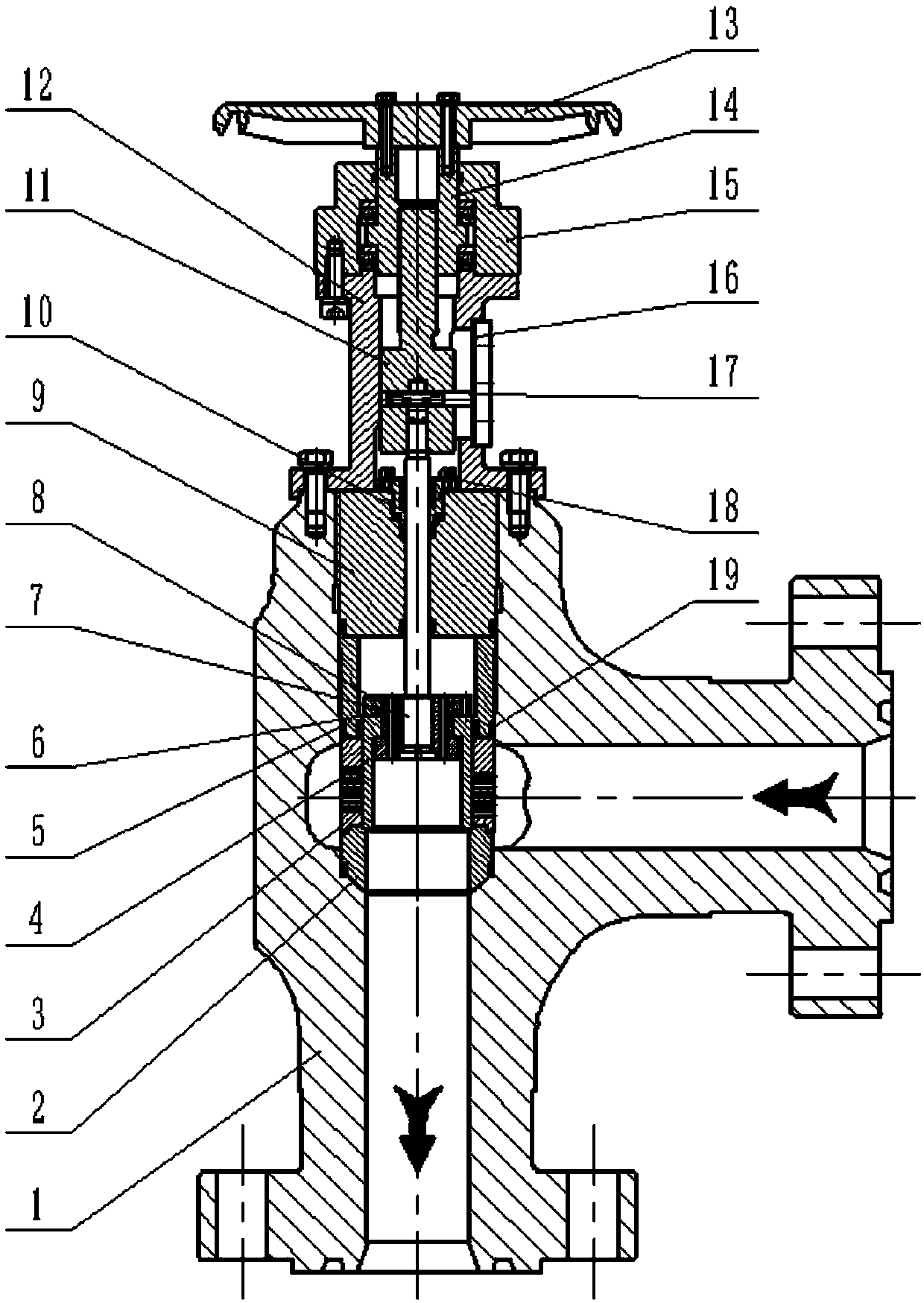

High pressure angle throttle valve

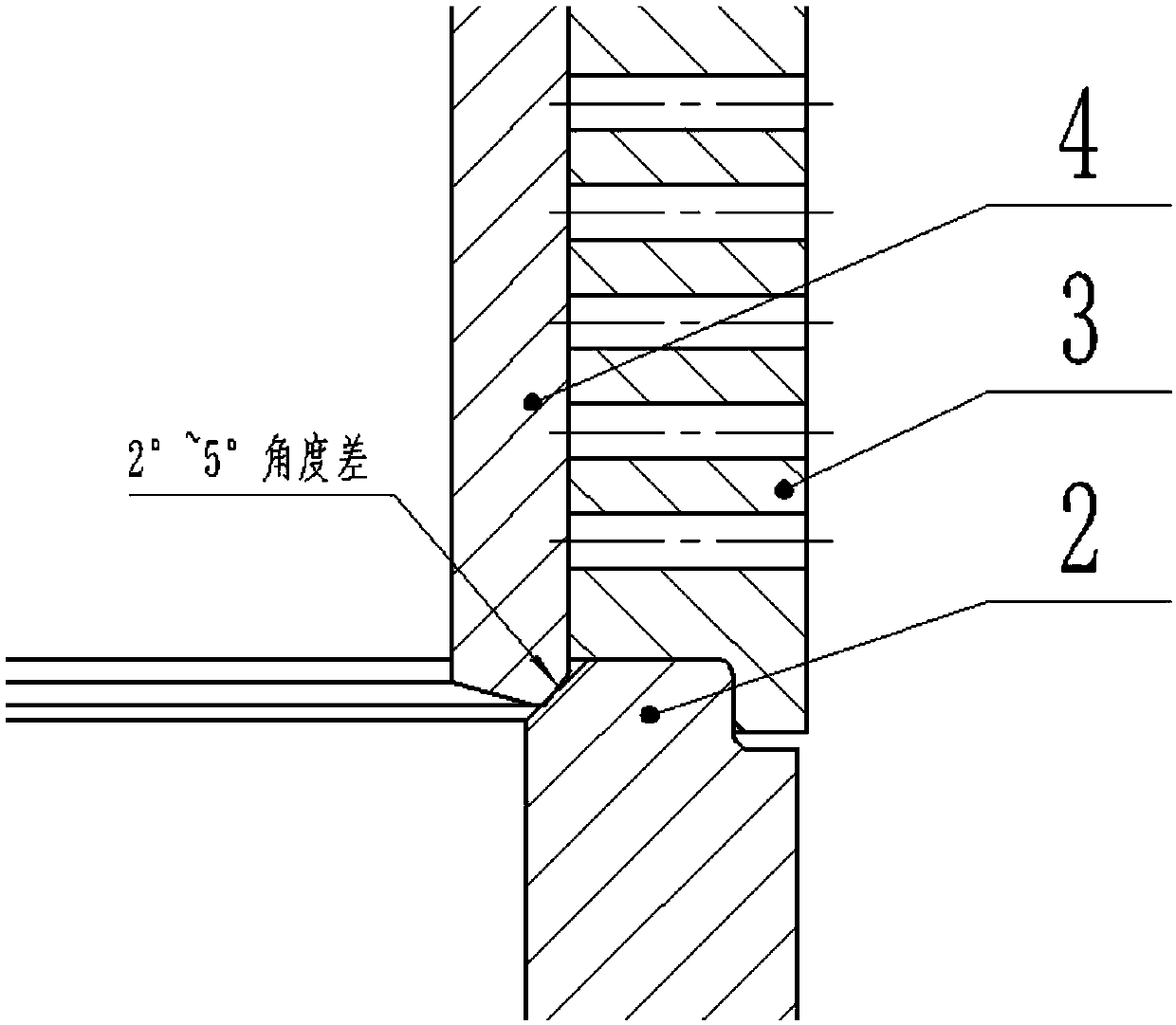

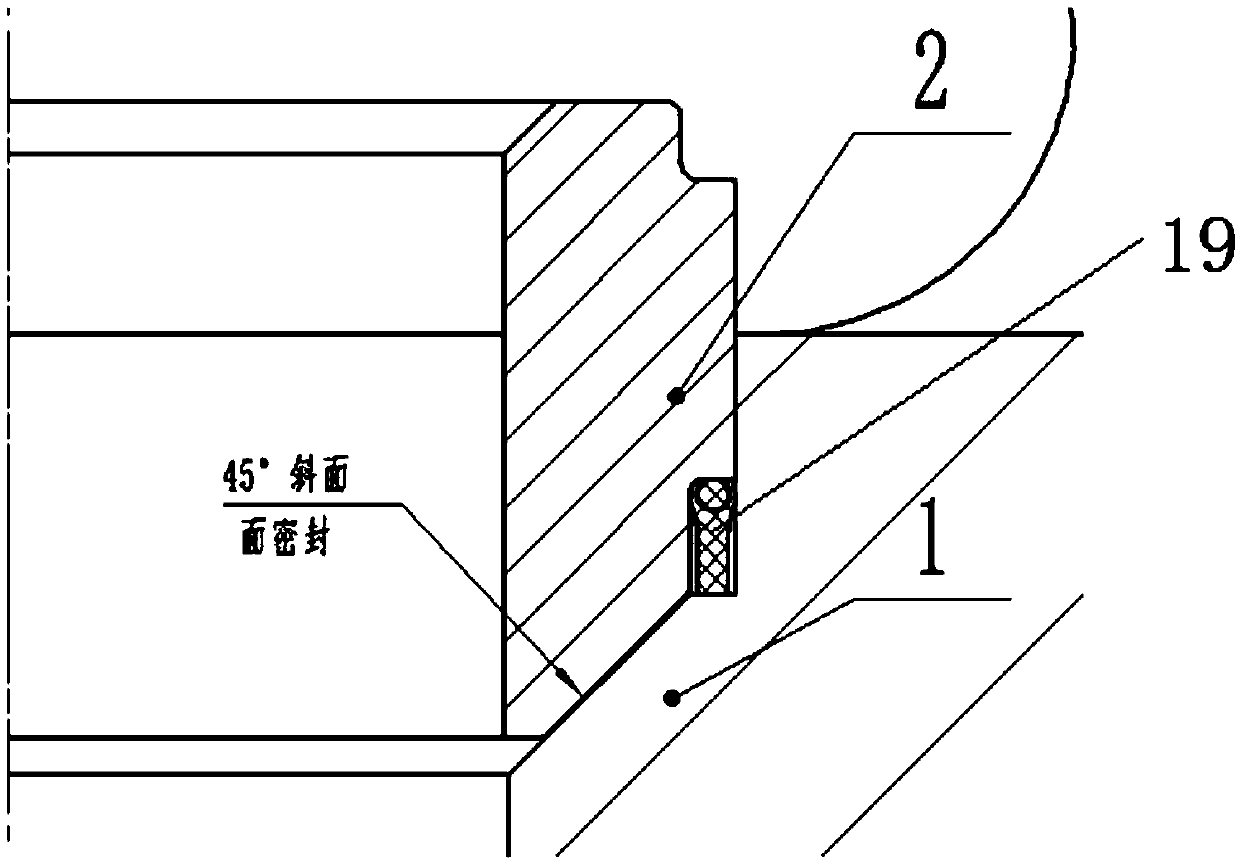

PendingCN109654242AAvoid vibrationReduce intensitySpindle sealingsPressure relieving devices on sealing facesCouplingEngineering

The invention relates to a high pressure angle throttle valve which comprises a valve rod, a valve element assembly, a valve base, a sleeve and an angle valve body. The valve element assembly, the valve base and the sleeve are arranged in the valve body, the valve base is coaxially arranged below the sleeve, at least two longitudinal rows of throttle holes are annularly formed in the sleeve, at least part of throttle holes in part of longitudinal rows are staggered in the longitudinal direction, the lower end of the valve rod stretches into the valve body to be connected with the valve elementassembly, the number of the throttle holes to be opened is selected through up-down movement of the valve element assembly in the sleeve, sealing faces between a sealing shaft sleeve and the valve base have an angle difference of 2-5 degrees to form line seal, a coupling sleeve is in threaded connection with the valve rod, a plug pin prevents rotation, a pin hole of the valve rod is designed intoa U-shaped groove, therefore, the problem that pin hole machining precision and installation difficulty are too high is solved, and the valve rod can be moved up and down in the coupling sleeve to adjust the position. The high pressure angle throttle valve is reasonable in design, simple in structure, good in throttle effect, stable in performance, long in service life, safe, reliable, capable ofachieving high-precision adjustment and capable of cutting off media to close a fluid passage.

Owner:CHENGDU CHENGFENG VALVE +2

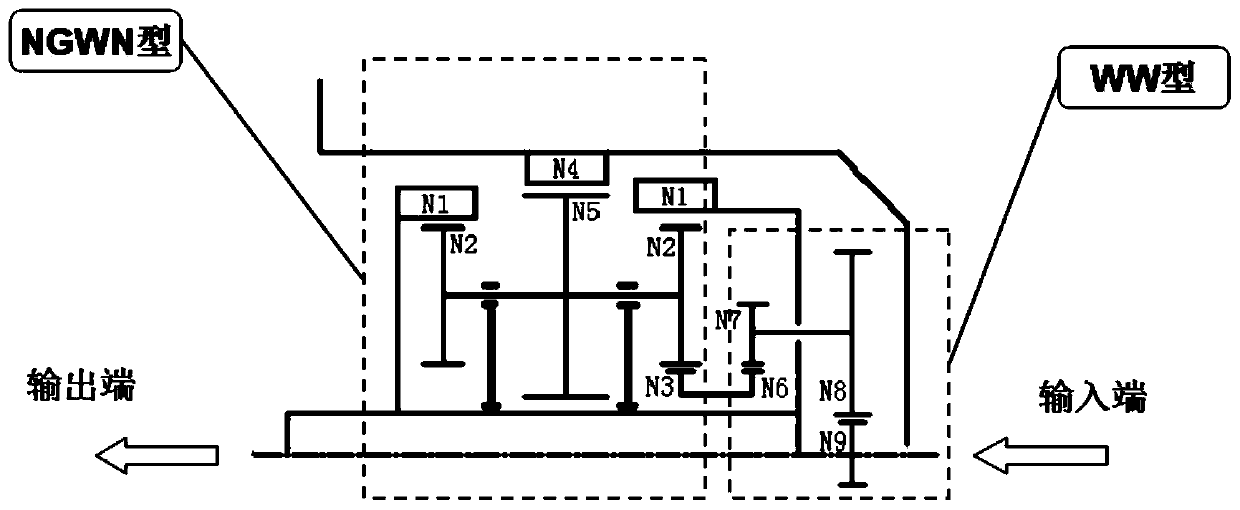

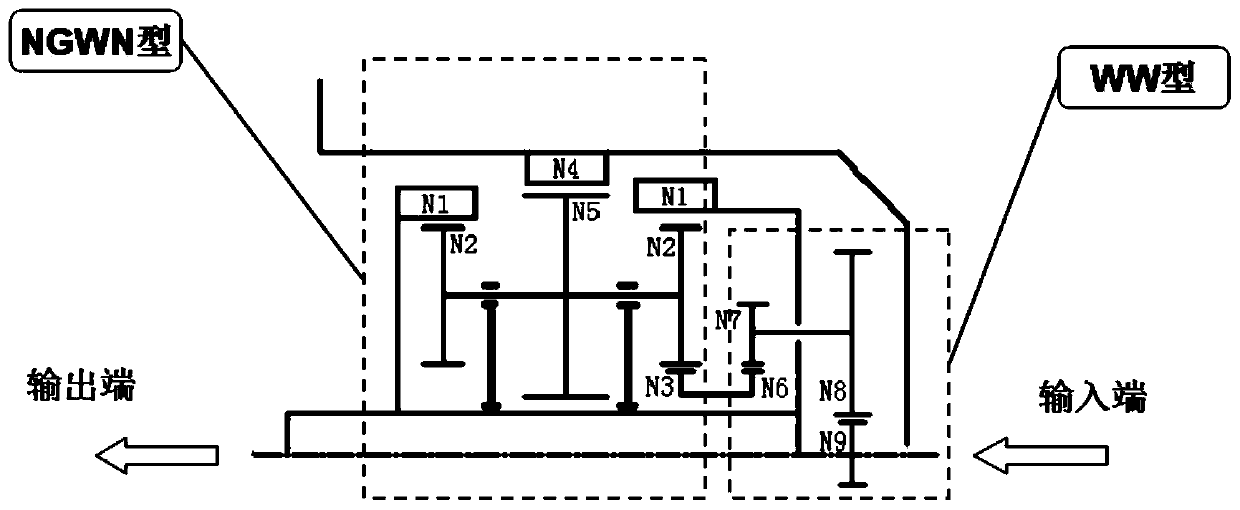

WW-NGWN differential multi-connected planetary reducer

The invention provides a WW-NGWN differential multi-connected planetary reducer comprises a machine base, an input shaft, an output shaft, a central wheel, inner gear rings, a planetary wheel and a planet carrier; the center wheel is divided into a first-stage center wheel and a second-stage center wheel, and the inner gear rings comprise a first inner gear ring and a second inner gear ring; the planet carrier is divided into a first-stage planet carrier and a second-stage planet carrier, and the planet wheels are divided into a first-stage planet wheel and a second-stage planet wheel; the first-stage planet wheel, the first-stage center wheel and the second-stage center wheel simultaneously mesh to form a first differential output of a first-stage deceleration system; the first-stage planetary wheel, the first-stage central wheel and the first inner ring gear simultaneously mesh to form a second differential output of the first-stage deceleration system; the second-stage planet wheelmeshes with the second-stage center wheel, the first inner gear ring and the second inner gear ring simultaneously to form a second-stage reduction system; and the second inner ring gear is fixedly connected with the output shaft. The WW-NGWN differential multi-connected planetary reducer has the advantages of large reduction ratio, large bearing capacity and higher reliability under the conditionof small volume on the premise of having the advantages of NGW and NGWN type planetary reducers.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Crushing and recycling equipment for solid garbage

ActiveCN109847835AAvoid the problem of difficult burning affecting the subsequent burning rateRealize quantitative deliveryMagnetic separationGrain treatmentsEngineeringConstruction waste

The invention relates to the technical field of garbage treatment equipment, and discloses crushing and recycling equipment for solid garbage. The crushing and recycling equipment comprises a dust separation box. A supporting plate is fixedly mounted in the middle of an inner cavity of the dust separation box. A filter screen is fixedly mounted in the middle of the supporting plate. A vibration plate is fixedly mounted at the bottom of the bottom face of the filter screen. Mounting grooves are formed in the left side face of the vibration plate. Fixed blocks are fixedly mounted at the left endand the right end in each mounting groove. According to the crushing and recycling equipment for the solid garbage, due to the fact that concrete is in powder shapes after being crushed, the filter screen is arranged for screening, building garbage is screened out from the solid garbage; meanwhile, a rotating block is arranged to intermittently stirring the vibration plate to vibrate, so that thefilter screen vibrates, therefore, the problem that hole parts of the filter screen are blocked due to powder is avoided, the whole screening efficiency is increased, and the problem that subsequentwaste residue treatment difficulty is increased due to the fact that the building waste cannot be combusted is avoided.

Owner:山东国晟环境科技有限公司

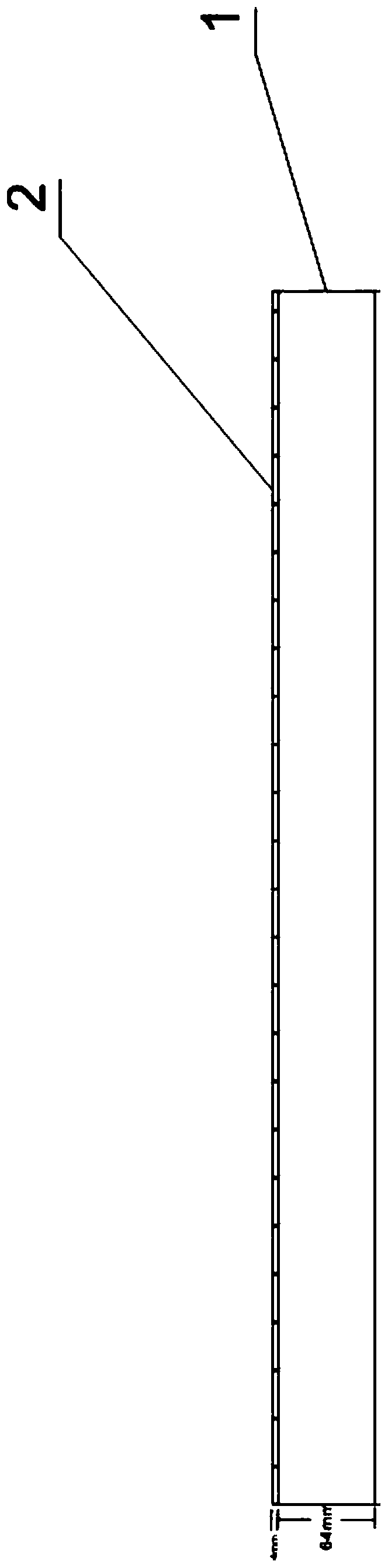

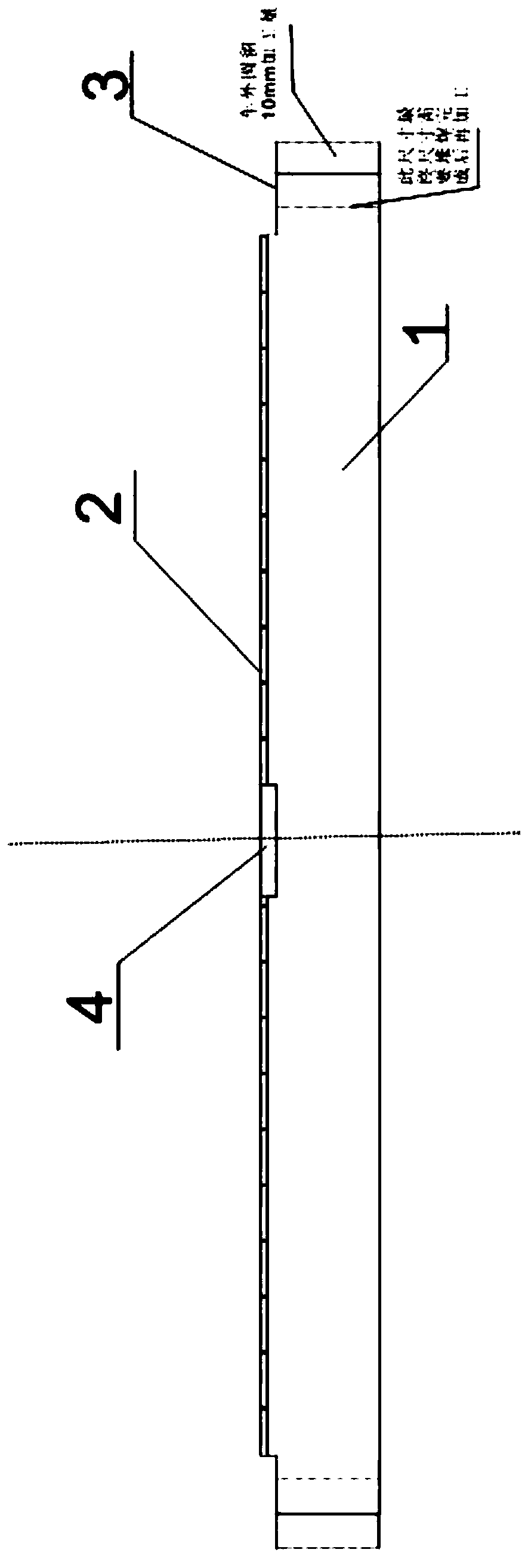

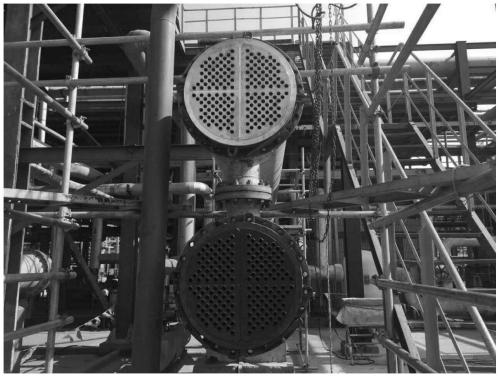

Welding technology of high-purity ferrite stainless steel heat exchanger

ActiveCN111390339AAvoid processing difficultyLow costTesting metalsWelding/soldering/cutting articlesForgeWelding process

The invention provides a welding technology of a high-purity ferrite stainless steel heat exchanger. The technology comprises two steps including overlaying welding of a tube plate and welding of thetube plate and a heat exchange tube, wherein the tube plate comprises a tube plate basic layer and a tube plate multiple layer; the tube plate basic layer is 64 mm thick and made of 16MnIII; the tubeplate multiple layer is S11972 with the thickness of 4 mm; a processing amount of 10 mm is preserved at an outer circular diameter is roughly lathed on a whole forge piece; a seal face is lathed on the tube plate multiple layer to a to-be-overlaid surface, and a baffle groove is dug to the to-be-overlaid surface; then, overlaying welding of nickel base alloy ENiCrMo-3 is conducted on the to-be-overlaid surface, and the heat exchange tube is made of an S11972 material; and during welding of the tube plate and the heat exchange tube, a welding joint is connected through strength welding and pasting expansion, welding is conducted on two layers, self-fluxing is conducted for the first time, and welding wires are added on the second layer. The welding technology provided by the invention has the beneficial effects that the feasible welding technology of the high-purity ferrite stainless steel heat exchanger is formulated, and layering welding of the tube plate, and welding of the tube plate and the heat exchange tube are successfully carried out, so that defects such as hot cracks, inter-granular corrosion and multilayer damage during welding are solved, and product quality is good after welding.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

High-precision deep hole combination drill and machining method thereof

ActiveCN104439397AHigh dimensional accuracySolve the usage quantityTurning machine accessoriesTransportation and packagingWaste productUltimate tensile strength

The invention discloses a high-precision deep hole combination drill which comprises a cutter handle, a blind rivet and a straight fluted drill. The front end of the blind rivet is inserted into a connecting hole in the right end of the cutter handle, and the straight fluted drill is inserted into a mounting hole formed in the left end of the cutter handle and is fixed by a compression screw and a compression groove. The invention further discloses a machining method of the high-precision deep hole combination drill. The machining method specifically comprises the steps of cutter handle machining, straight fluted drill finish machining, cutter handle finish machining, boundary dimension finish machining and dynamic balancing. The combination drill machined through the machining method has the advantages of being high in fatigue durability, high in strength, high in precision, resistant to abrasion, high in chip removal and cooling capacity, high in machining precision and the like, and the number of defective products or waste products can be greatly reduced.

Owner:贵州凯星液力传动机械有限公司

Casing gap blocking device and blocking method

The invention discloses a casing gap blocking device. The casing gap blocking device comprises a pipeline, a reinforcing plate, a backing ring and a casing, wherein the casing is sheathed at the exterior of a pipeline; the backing ring is sheathed at the outer wall of the pipeline; the side surface of the reinforcing plate is fixedly connected with the outer wall of the pipeline; the length direction of the reinforcing plate extends along the axial direction of the pipeline; an epoxy mortar filling layer is filled between the backing ring and the external of the reinforcing plate; both sides of the epoxy mortar filling layer are in sealed connection with the inner wall of the casing and the outer wall of the pipeline; epoxy grout sealing layers are sealed at the two ends of the epoxy mortar filling layer; a leakage-blocking rigid waterproof layer is sealed at the outer side of each epoxy grout sealing layer; the epoxy grout sealing layer and the leakage-blocking rigid waterproof layers are in sealed connection with the outer wall of the pipeline and the inner wall of the casing. The sealing property of the casing gap in the casing gap blocking device is improved. The invention also discloses a casing gap blocking method.

Owner:北京燕化天钲建筑工程有限责任公司

Sulfur-containing gas well oil pipe blocking remover and preparation method thereof

ActiveCN111909676AAvoid severe corrosion problemsAvoid productiveProductsReagentsOil and greaseProcess engineering

The present invention discloses an sulfur-containing gas well oil pipe blocking remover, which is prepared by mixing and reacting the following components: 5-24% of citric acid, 50-55% of ethylene glycol, 25-34% of triethanolamine and 0.3-0.6% of sulfamic acid; technical indices are described as follows: the foaming rate is 6.0-8.5%, the content of water insoluble substances is 2.0-2.5%, the flashpoint (opening) is 112-115 DEG C, the normal-pressure static corrosion rate is 0.45-0.58 g / m2*h, the grease dissolution rate is 92-98%, and water separation rate is zero. The invention also disclosesa preparation method of thesulfur-containing gas well oil pipe blocking remover. The sulfur-containing gas well oil pipe blocking remover disclosed by the invention has a relatively strong surface activity cleaning function, can remove oil and scale in blockages at the same time, gives play to the dual blocking removal effect of an oil pipe, can also avoid the burning explosion risk caused by theuse of flammable and combustible materials in the prior art, and can also avoid the problems of treatment difficulty of flowback wastewater and serious corrosion to equipment and the like; in addition, the preparation method is mature, simple in process operation and easy to control and realize industrial production.

Owner:SICHUAN SHENGNUO OIL & GAS ENG TECH SERVICE CO LTD +2

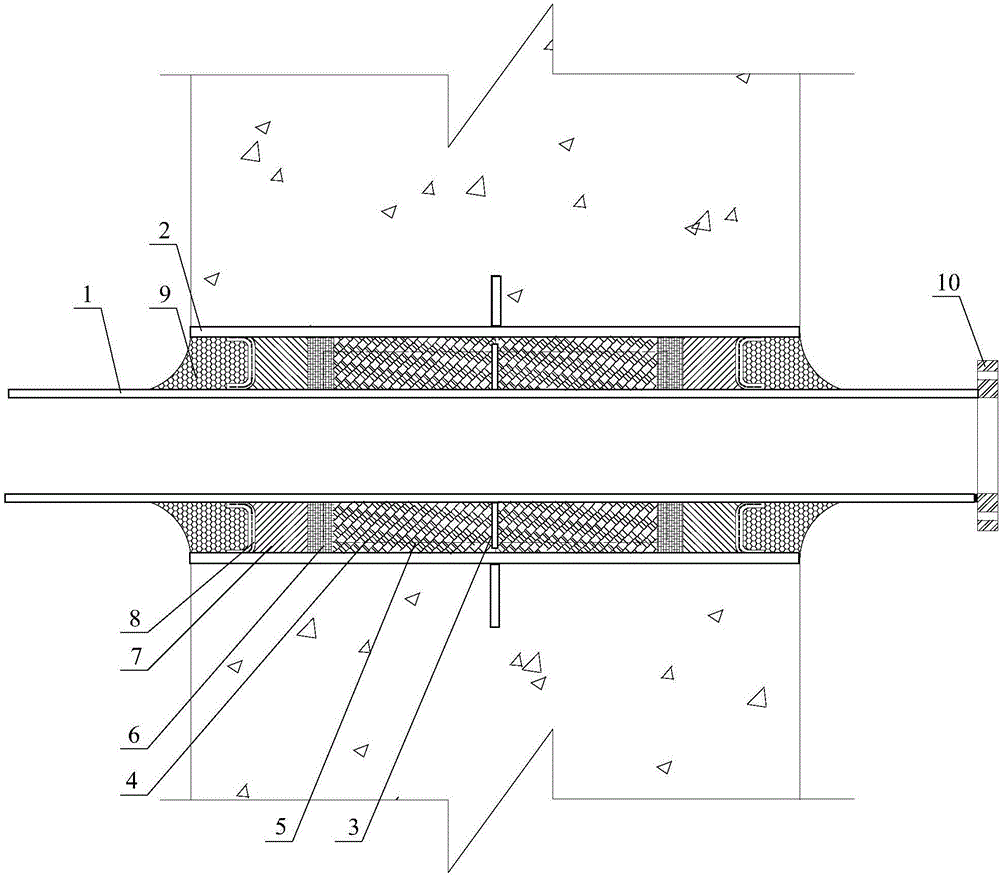

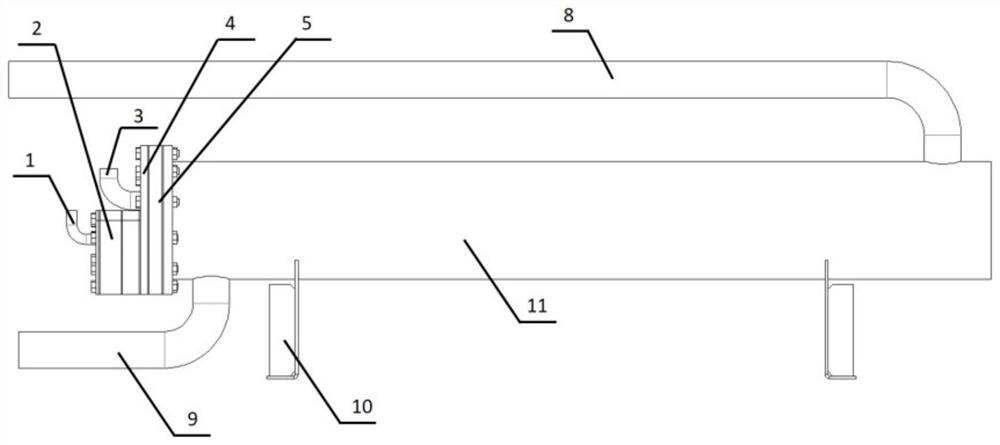

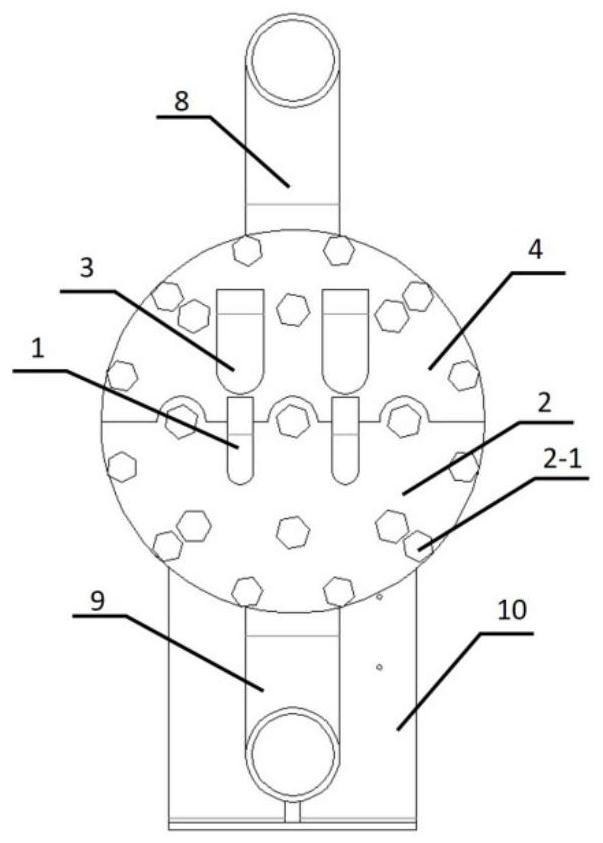

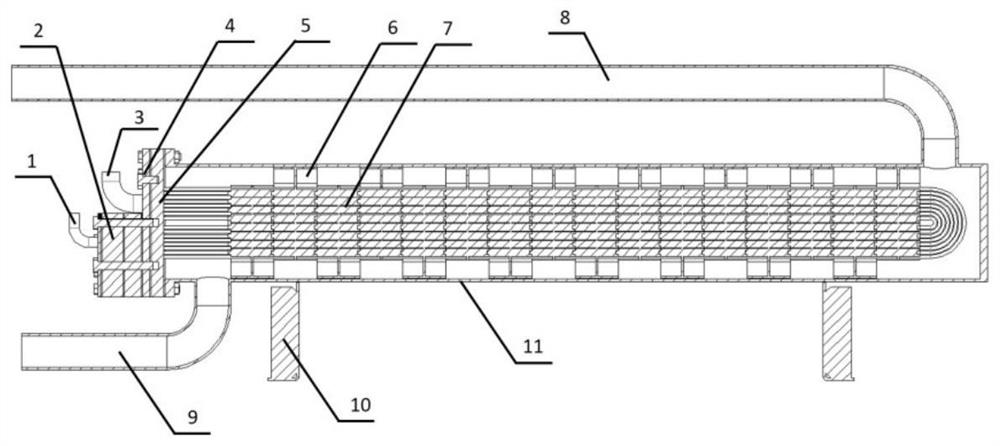

Shell-and-tube dry type evaporator

ActiveCN112923609ASimple structureReduce dosageEvaporators/condensersHeat exchanger casingsWire cuttingEngineering

The invention discloses a shell-and-tube dry type evaporator. The shell-and-tube dry type evaporator comprises a distributor, arch-shaped baffle plates, heat exchange tubes and a barrel; one end of the barrel is closed, the other end of the barrel is open, the heat exchange tubes and the arch-shaped baffle plates are arranged in the barrel, the heat exchange tubes penetrate through the arch-shaped baffle plates, and a multi-stage distributor is arranged at the open end of the barrel; holes are formed in the top and the bottom of the barrel separately, a water side inlet pipe is mounted in the hole in the bottom, and a water side outlet pipe is mounted in the hole in the top; and a distribution channel is machined in the lower portion of an end cover and communicates with inlets of the heat exchange tubes, a convergence cavity is machined in the upper portion of the end cover and communicates with an outlet of a heat exchanger, and an outlet is formed in the convergence cavity. According to the shell-and-tube dry type evaporator, the distributor is simple in structure, can be machined through laser cutting, linear cutting and other machining methods, and is low in manufacturing cost and convenient to popularize and use on a large scale; and through the design and use of an inlet distributor and the arch-shaped baffle plates, the amount of heat exchange tubes is reduced by 30% or above.

Owner:江苏世林博尔制冷设备有限公司

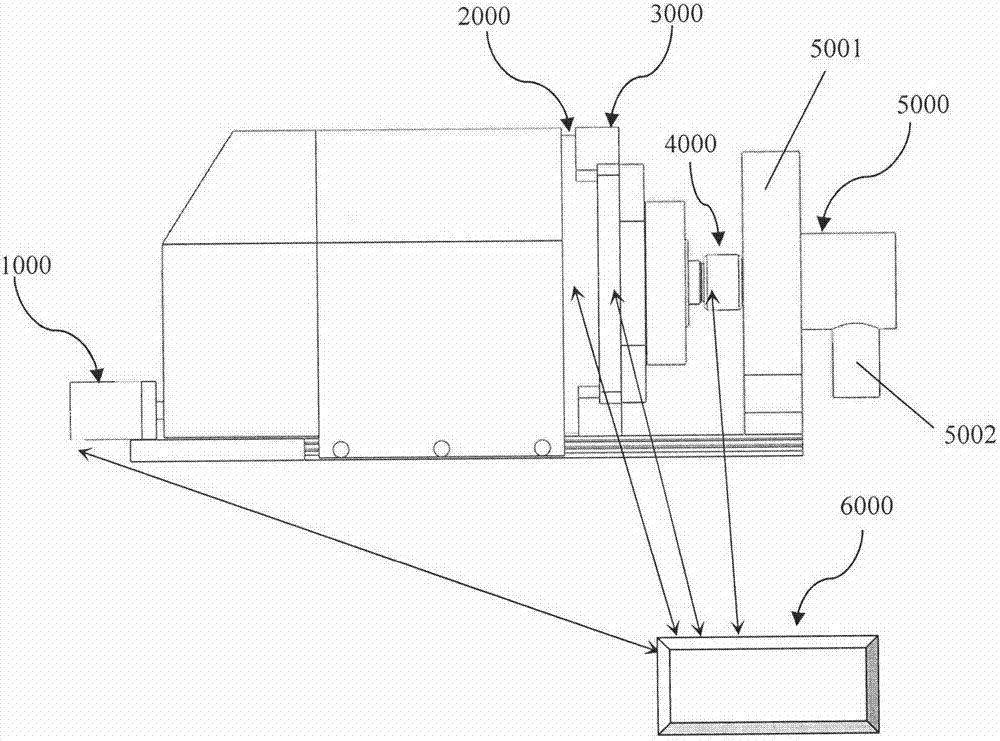

Modularized combined machining center

ActiveCN104889826AReduce manufacturing difficultyImprove work efficiencyMetal working apparatusModularityManufacturing engineering

The invention discloses a modularized combined machining center. The modularized combined machining center has the advantages that modularized design is used, corresponding module units can be set according to user product size and machining procedures, each module unit can be completed separately according to workpiece size, limitation of machine tool machining and transportation is avoided, and multi-face, multi-station, efficient and high-precision machining of complex parts can be performed simultaneously through one-step clamping; original machining procedures are sequentially turned into item and face flow line machining through one-step clamping as compared with the prior art, product quality requirements are satisfied, machining time is shortened, product yield is guaranteed, worker number is reduced, operator labor intensity is reduced, equipment floor space is reduced, and management of large-scale production is facilitated.

Owner:南召县和平制动器有限公司

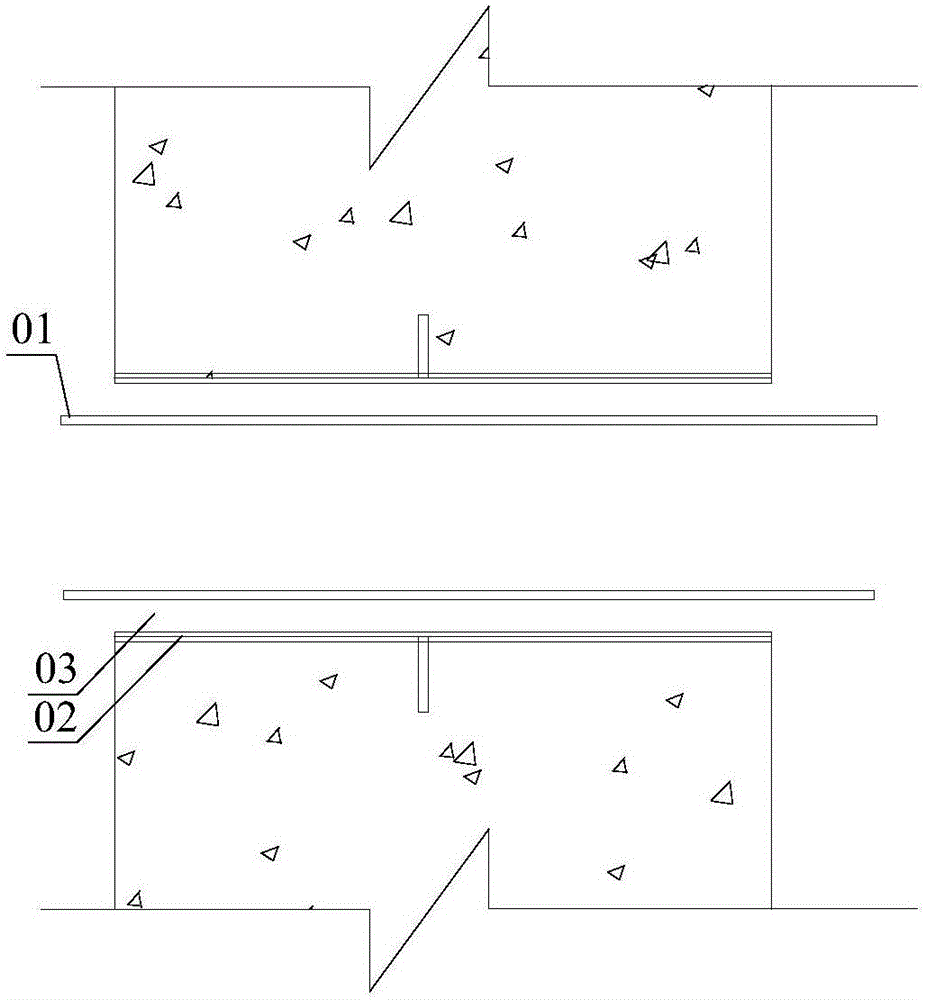

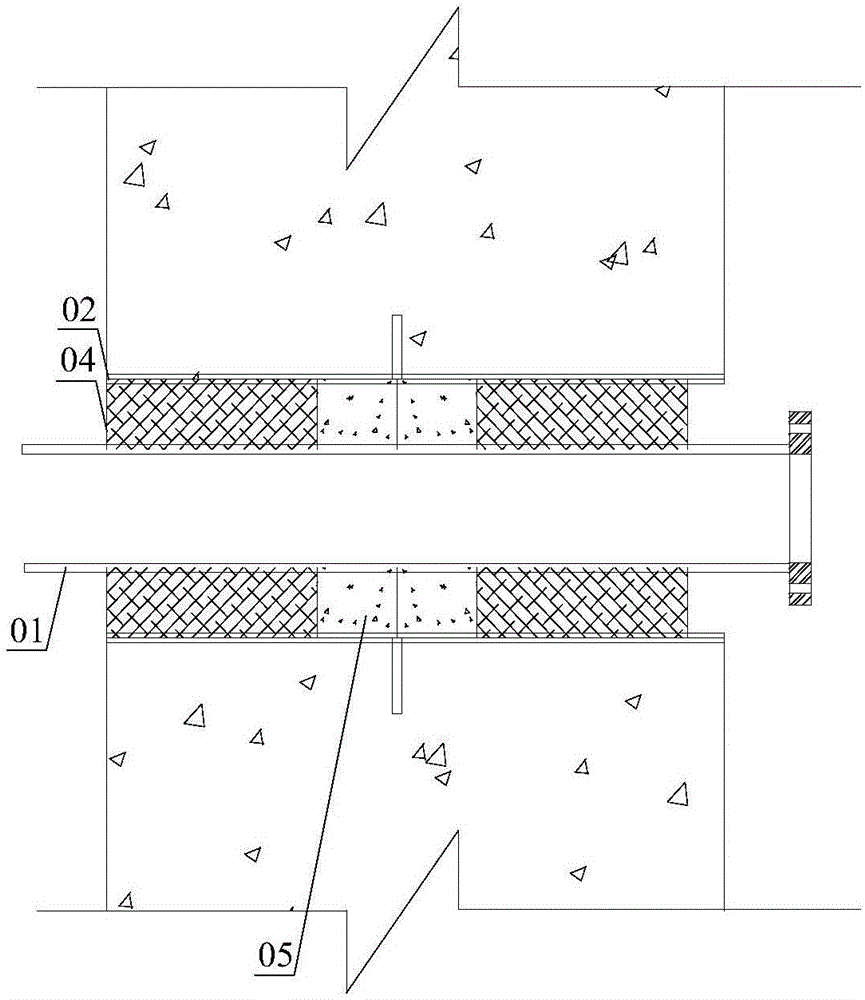

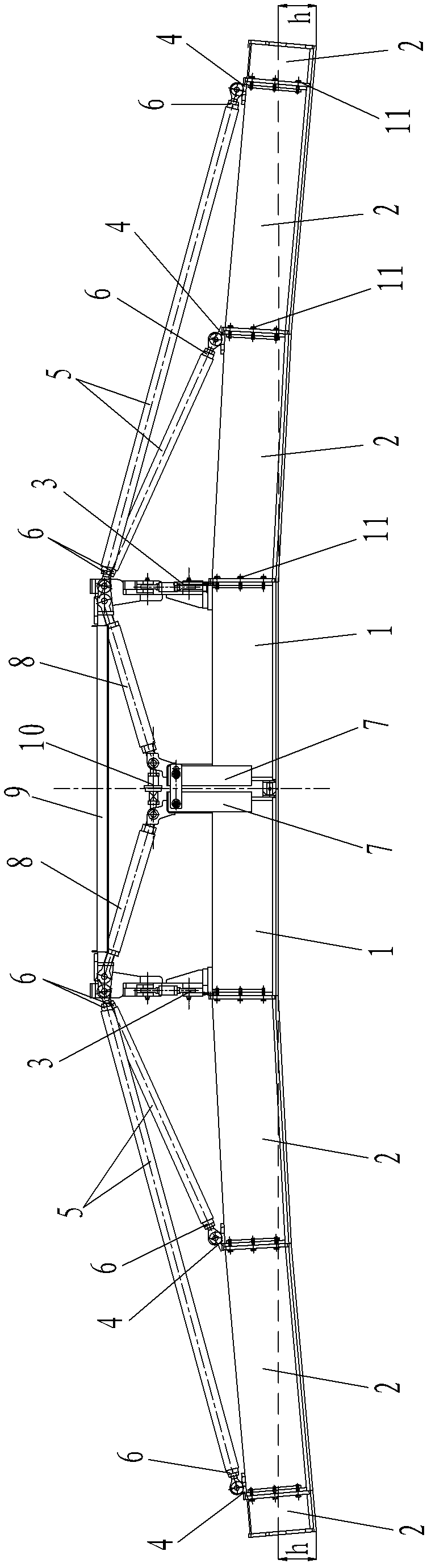

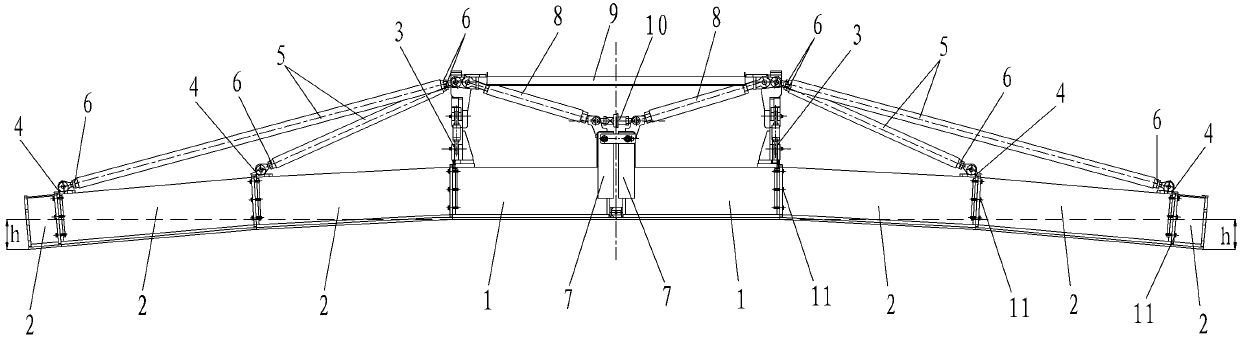

Ironing board of asphalt paver with downward deformation by being pre-pressed by strut and pull rods

InactiveCN102635055ANormal flat shapeImprove paving evennessRoads maintainenceThermal deformationEngineering

The invention discloses an ironing board of an asphalt paver with downward deformation by being pre-pressed by strut and pull rods. The ironing board comprises a base segment ironing board and a mechanically assembled and widened ironing board constituted by a plurality of lengthened segment ironing boards, wherein the base segment ironing board is formed by connecting two single-segment base segment ironing boards; a base segment ironing board support is arranged on each single-segment base segment ironing board, a lengthened segment ironing board support is arranged on each lengthened segment ironing board, and a plurality of strut and pull rods are arranged between the two base segment ironing board supports and a plurality of lengthened segment ironing board supports; and the left side and right side of the mechanically assembled and widened ironing board are symmetrically gradually downwards inclined and deformed along the normal line direction of the bottom surface of the mechanically assembled and widened ironing board under the action of the plurality of strut and pull rods, the downward inclination deformation amount h is 0-60mm, and the greater the width of the mechanically assembled and widened ironing board, the bigger the value of h. The ironing board disclosed by the invention has the advantages of reasonable design, convenience in processing and manufacturing, convenience and quickness in operation, low implementation cost, wide range of application, and capability of effectively solving the thermal deformation problem of the ironing board of the paver during the working process.

Owner:CHANGAN UNIV

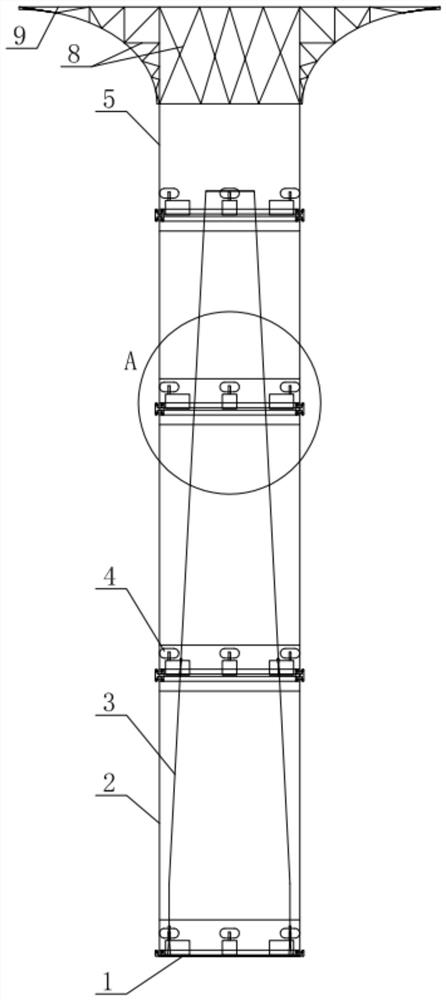

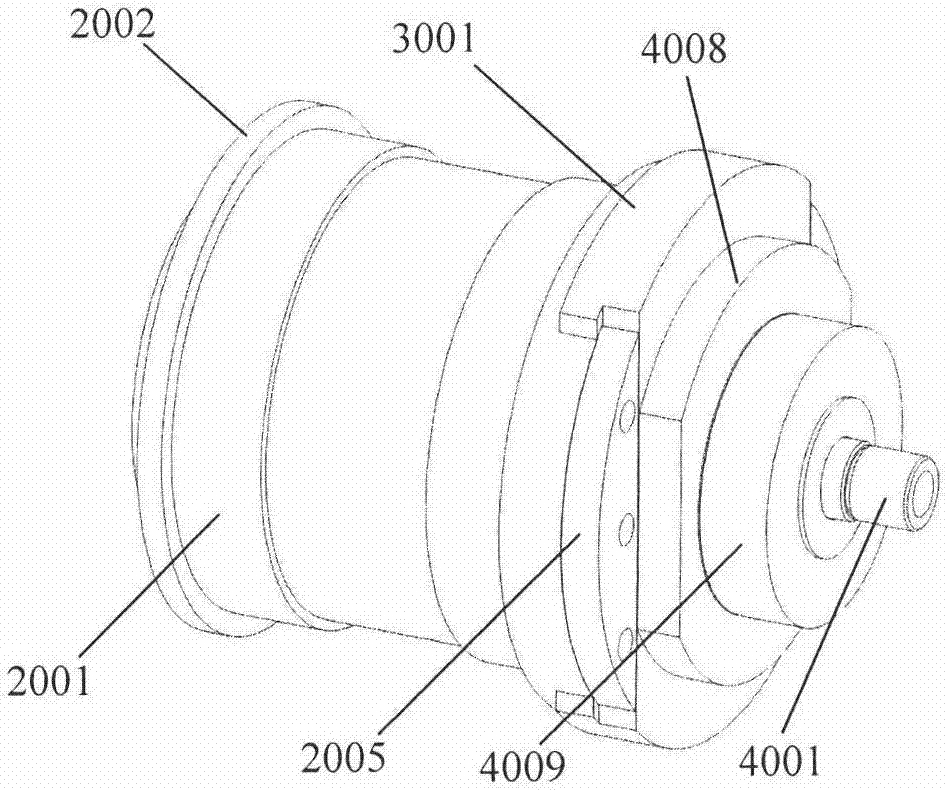

Wind power boosting rotor structure

ActiveCN113815827ACompact structureGood adaptabilityPropulsion based emission reductionWind acting propulsive elementsPhysicsEngineering

The invention relates to a wind power boosting rotor structure which comprises a base, an inner cylinder is fixedly mounted on the base, a plurality of basic rotating cylinders are axially mounted on the base on the outer side of the inner cylinder in a stacked manner, and the basic rotating cylinders are concentrically arranged outside the inner cylinder in a sleeving manner; partition plates are installed on the outer portion, located between the adjacent basic rotating cylinders, of the inner cylinder in the circumferential direction, and each single basic rotating cylinder independently rotates relative to the partition plate making contact with the basic rotating cylinder. The top of the uppermost basic rotating cylinder is provided with the same partition plate, and a top rotating cylinder is rotationally mounted above the partition plate; the inner cylinder is accommodated in the basic rotating cylinders and the top rotating cylinder; an end plate is arranged at the top end of the top rotating cylinder, and the bottom surface of the end plate is in arc transition connection with the top rotating cylinder body; The rotor is constructed in a modular mode, a large-diameter end plate can be configured, the overall height can be flexibly adjusted, the adaptability is good when wind speeds at different heights change, the lift and resistance generated by the rotor are effectively increased, the rotation torque of the rotor is reduced, and the aerodynamic efficiency of rotor rotation is greatly improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

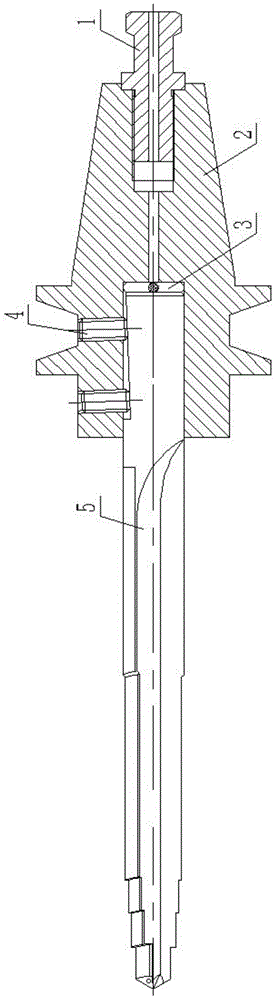

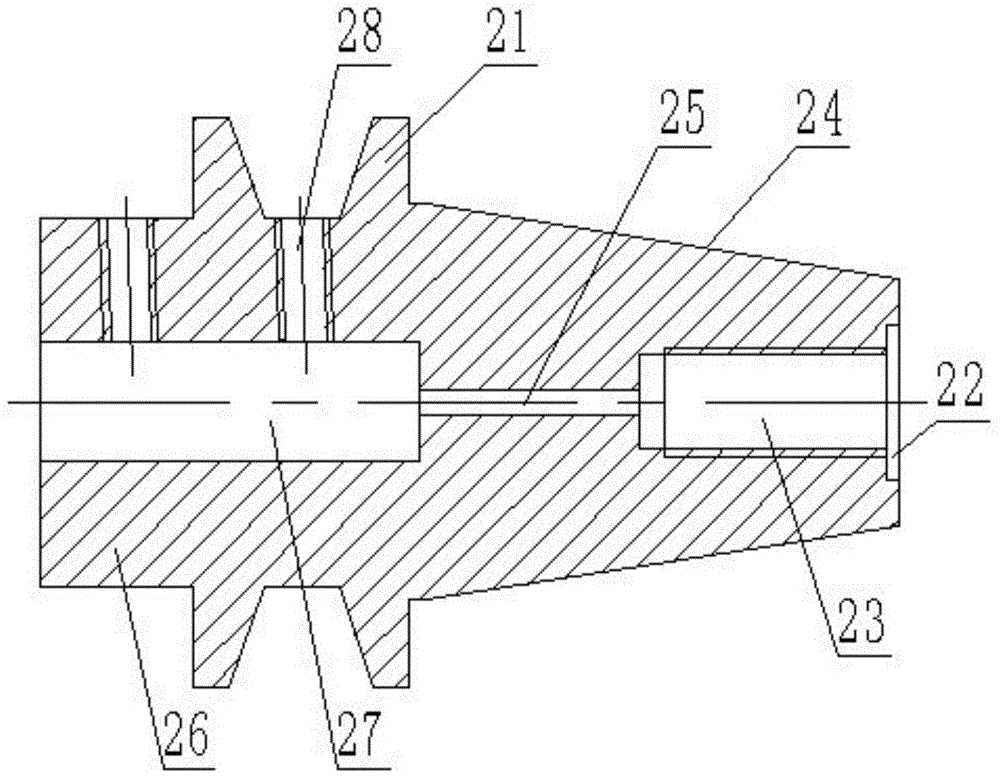

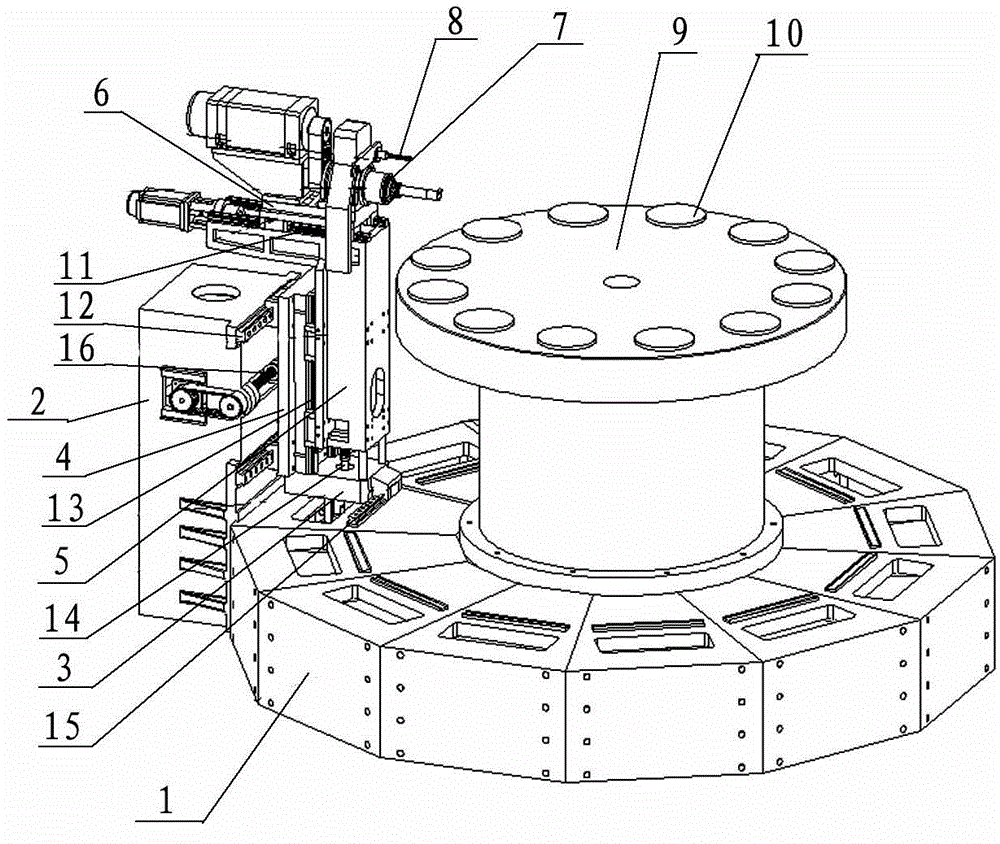

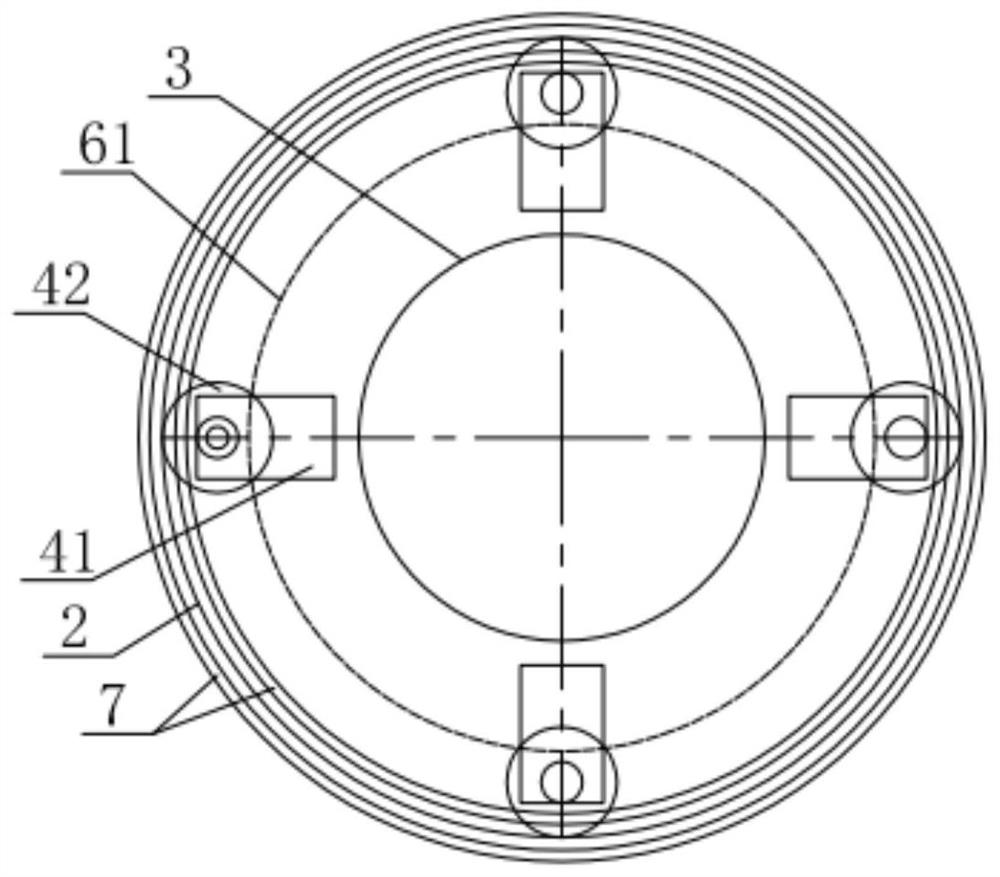

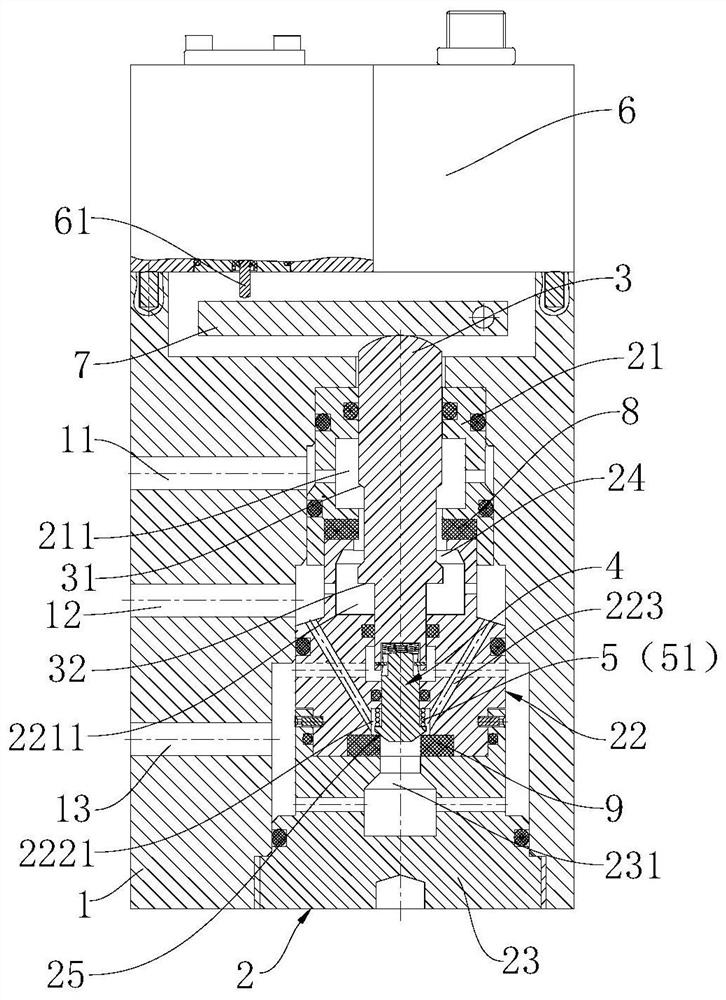

Terminal hole making actuator used for aircraft fuselage component lamination assembling

ActiveCN107322035ASimple structureReduce the weight of the whole machineAircraft componentsBoring/drilling machinesAirplaneHole making

The invention discloses a terminal hole making actuator used for aircraft fuselage component lamination assembling. The terminal hole making actuator comprises a feeding mechanism, a revolution mechanism, a deviation adjusting mechanism, a rotation mechanism, a pressing chip removal mechanism and a system controller. The feeding mechanism, the revolution mechanism, the deviation adjusting mechanism, the rotation mechanism and the pressing chip removal mechanism are controlled by the system controller to carry out corresponding hole making operations. Eccentric adjustment of a tool within a large range is realized through plane thread transmission, various operations such as drilling, helical hole milling and boring can be implemented, hole making efficiency and quality of a fuselage lamination can be remarkably improved, and the terminal hole making actuator is especially suitable for being equipped with a fuselage automatic hole making system.

Owner:NANJING INST OF TECH

Water-based proportional decompression overflow valve

PendingCN113685388AStable output pressureAvoid the disadvantage of easy cloggingServomotor componentsCardiologyValve opening

The invention discloses a water-based proportional decompression overflow valve. The water-based proportional decompression overflow valve comprises a valve body, a valve sleeve, a decompression valve element, an overflow valve element, an elastic piece and an electric-mechanical conversion element, wherein the valve body is provided with a liquid supply channel, a decompression channel and an unloading channel, the valve sleeve is installed in the valve body and provided with a liquid supply cavity, a decompression cavity and an unloading cavity, the decompression valve element is slidably connected to the valve body, the unloading cavity is divided into a first cavity and a second cavity, the first cavity communicates with the decompression cavity, the second cavity communicates with the unloading channel, the overflow valve element is located in the first cavity and connected to the decompression valve element, the decompression valve element can drive the overflow valve element to move so that an overflow valve opening can be conveniently opened, the elastic piece presses the overflow valve element in the direction of closing the overflow valve opening, and the electric-mechanical conversion element is in driving connection with the decompression valve element. The water-based proportional decompression overflow valve has the advantages of being low in machining and assembling difficulty and stable in output pressure of an decompression valve opening.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

Numerical control gas cutting base supporting center

InactiveCN105345219AGuaranteed sizeGuaranteed geometric toleranceGas flame welding apparatusNumerical controlChinese characters

The invention discloses a numerical control gas cutting base supporting center. The numerical control gas cutting base supporting center comprises longitudinal steel plates and transverse steel plates which are assembled together in a sleeved manner to be shaped like a Chinese character "Jing"; a center is arranged at a cross-shaped interface of each longitudinal steel plate and each transverse steel plate in a blocking manner; and a ring of angle steel is arranged on the peripheries of all the longitudinal steel plates and transverse steel plates. The numerical control gas cutting base supporting center has the beneficial effects that the supporting center enables a base to be used for long time and ensures the size and form and location tolerance of cut steel plates; the cutting surface quality also meet related standard requirements by adopting the supporting center; iron castings are used as the supporting centers, thereby avoiding the machining difficulty, saving the machining cost and completely meeting the operating requirements; the supporting center solves the problem that after the base is used for long time or large-thickness sheet materials are cut, a supporting plate is seriously damaged, is out of a supporting effect and seriously deforms; and the supporting center obviously prolongs the service life of the base.

Owner:MCC SFRE HEAVY IND EQUIP

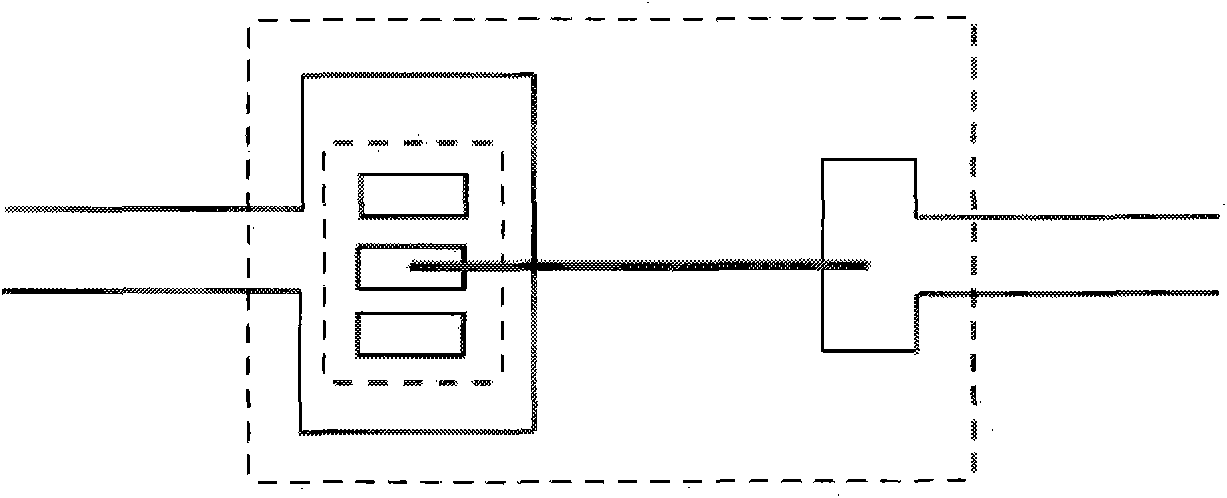

Structural design for improving power tolerance of micro low-capacitance protective device

InactiveCN102110619AAvoid processing difficultyResolving process incompatibilitiesSemiconductor/solid-state device manufacturingTransient voltage suppressorCapacitance

With the continual increase of the transfer speed of communication equipment, a data line protective device has lower and lower capacitance, but the power tolerance is still higher, so that the traditional machined structure can not meet the design requirements. Although the integration of a transient voltage suppressor (TVS) chip and a low-capacitance device chip on the same chip can reduce the occupied space of the chip, the power tolerance can incur loss accordingly. The invention relates to a structural design for improving the power tolerance of a micro low-capacitance protective device. A group of TVS chips and the low-capacitance device are independently designed, and are encapsulated in a structure disclosed in the drawing, thereby greatly lowering the chip machining difficulty and properly increasing the TVS area. The TVS chips and the low-capacitance device can be assembled in the same micro encapsulation body, thus the conflict between low capacitance and high power is solved.

Owner:淮永进 +1

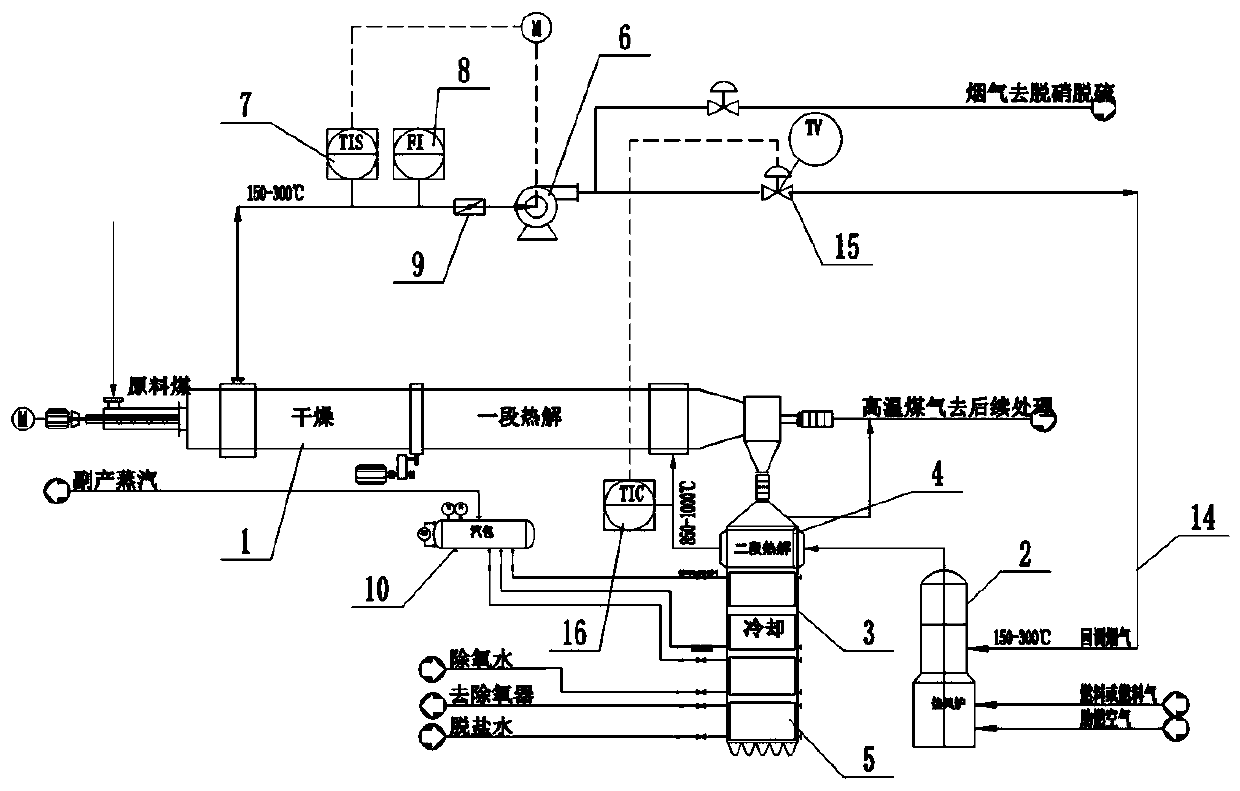

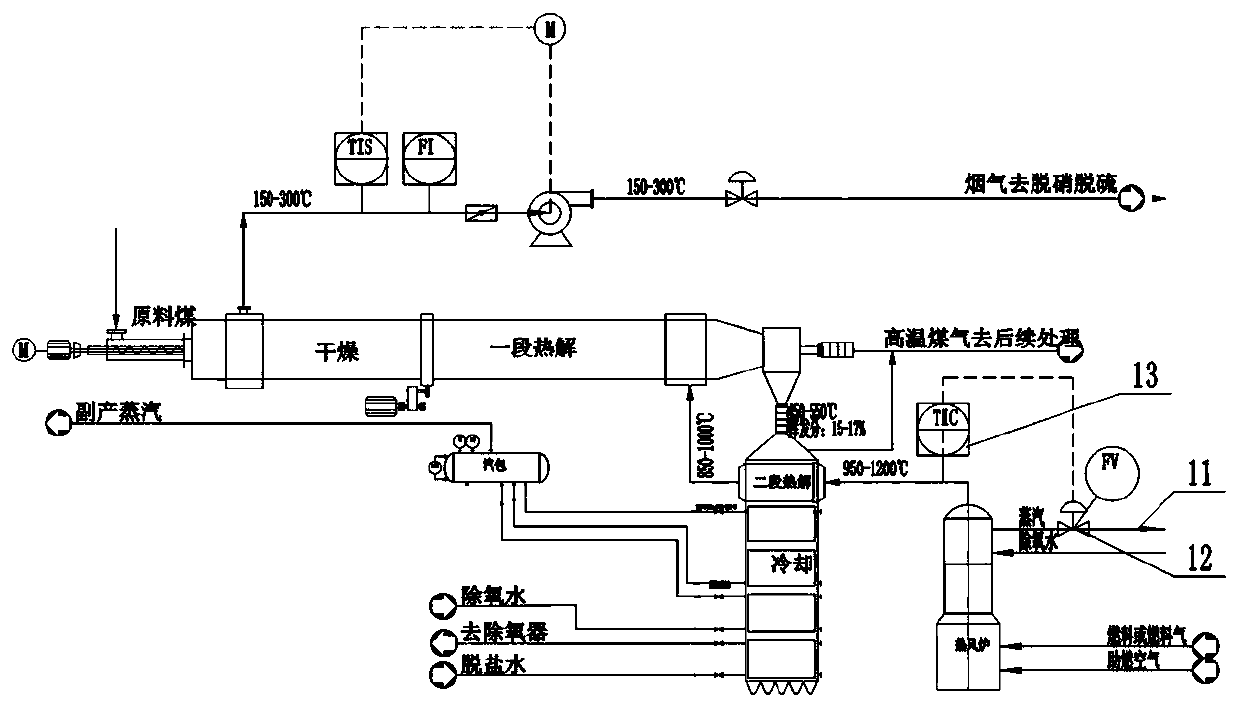

Segmented upgrading and hot flue gas gradient utilization system for low-rank coal and utilization method thereof

PendingCN111117671AYield maximizationQuality improvementCoke quenchingIncreasing energy efficiencyThermodynamicsHot air oven

The invention relates to a segmented upgrading and hot flue gas gradient utilization system for low-rank coal and a utilization method thereof, and belongs to the technical field of low-order pulverized coal pyrolysis. The outlet of a discharging cover of a rotary kiln is connected with a coal falling channel; an upgrading pyrolysis section is arranged at the upper part of the coal falling channel; a multi-stage cooler is arranged at the lower part of the coal falling channel; the upgrading pyrolysis section comprises a plurality of heat exchange tubes mounted in the coal falling channel; thehot air outlet of the hot air furnace is connected with the heat exchange medium inlet of the upgrading pyrolysis section; the heat exchange medium outlet of the upgrading pyrolysis section is connected with the inlet of the gas inlet cover of the rotary kiln; the outlet of the gas outlet cover of the rotary kiln is connected with a desulfurization and denitrification system through a fan; a firsttemperature sensor, a flow meter and a butterfly valve are further mounted on a pipeline between the outlet of the air outlet cover of the rotary kiln and the fan; and the first temperature sensor and the fan are in linkage control, the upgraded coal subjected to secondary pyrolysis in the upgrading pyrolysis section enters the cooling section to exchange heat with desalted water, and therefore,the structural design is reasonable, flue gas heat can be fully utilized, and energy consumption is reduced.

Owner:白太宽

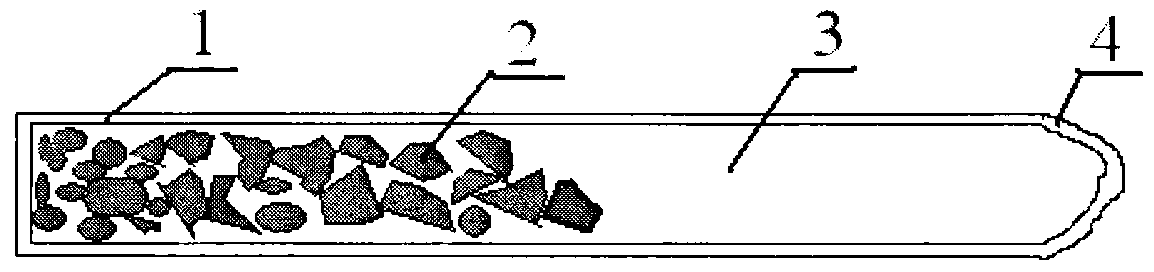

Manufacturing method of low-melting-point glass optical fiber perform coating sleeve pipe

InactiveCN102976606AAvoid mixingAvoid Bubble StreaksGlass making apparatusManufacturing technologyQuartz

The invention relates to a manufacturing method of a low-melting-point glass optical fiber perform coating sleeve pipe. The method belongs to the technical field of glass optical fiber manufacturing. The method is characterized in that the preparation of the coating sleeve pipe comprises the steps that: (1) low-melting-point glass is molten, cooled, and crushed; and the glass is preserved for later use; (2) the low-melting-point glass is weighed and placed in a quartz tube; (3) the loaded quartz tube is vacuumed and sealed; (4) the sealed quartz tube is heated in a rocking furnace, such that the glass in the tube is molten into liquid; (5) an electric furnace rocking switch is tuned on, such that the glass liquid is well mixed; (6) the electric furnace is opened, the quartz tube is rapidly fetched and horizontally placed in a rotation device; the quartz tube is fixed, and high-speed rotation is carried out; (7) the quartz tube is fetched, and is rapidly annealed in an annealing furnace; and (8) the quartz tube is cracked, such that the coating sleeve pipe obtained. The method has the advantages that the manufactured coating sleeve pipe has smooth and non-polluted inner surface, controllable inner and outer diameters, and no bubble and line inside.

Owner:苏州佳因特光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com