Modularized combined machining center

A combined processing and processing center technology, applied in the field of machinery manufacturing and processing, can solve the problems of restricting production efficiency, greatly affecting product quality and precision, and increasing enterprise costs, so as to facilitate organization and management, prevent falling deviation, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

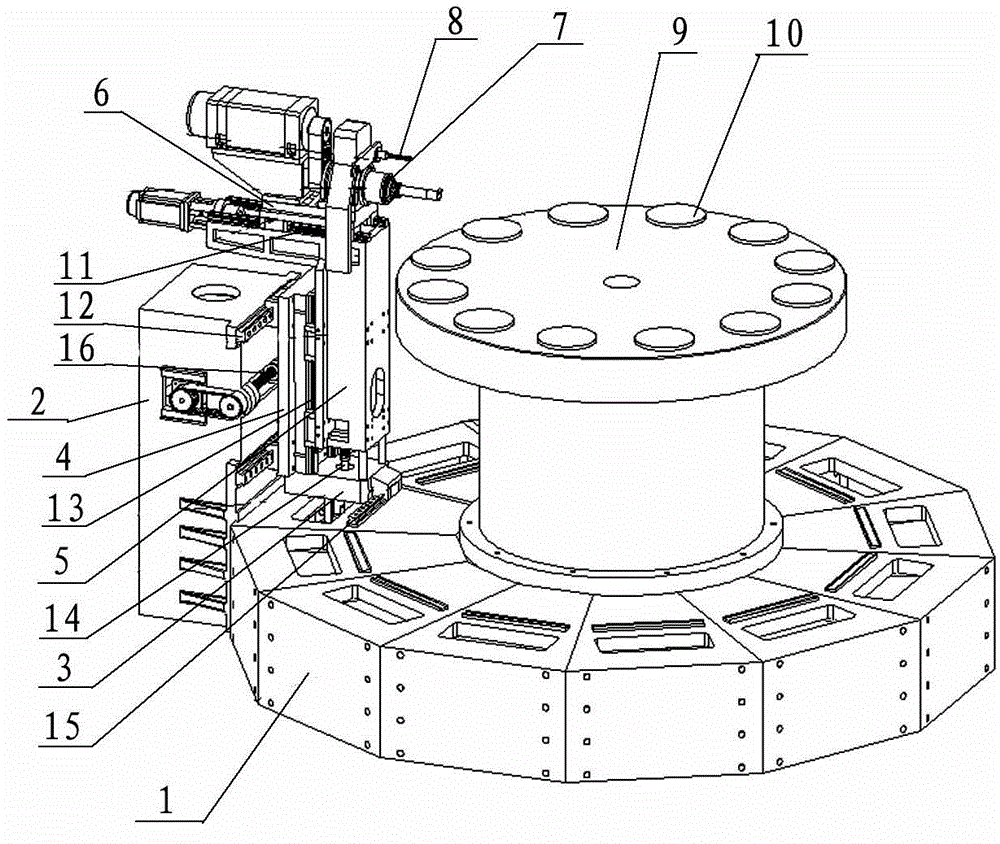

[0015] see figure 1 , a modular combined machining center, comprising a modular disc base and several machining center bodies, the modular disc base is composed of several fan-shaped modules 1, and the center of the modular disc base is provided with an equal-angle turntable 9. The equal-divided angle turntable 9 is evenly equipped with several C-axis tooling angle turntables 10, the C-axis tooling angle turntable 10 is provided with tooling fixtures, and the design number of the fan-shaped modules 1 is consistent with the number of workpiece processing steps , the design diameter of the modular disc base is proportional to the diameter of the workpiece, and the demanding enterprise should design the size of the workpiece and the number of processing steps before placing an order with the supplier to obtain a satisfactory product.

[0016] The plurality of fan-shaped modules 1 correspond to the plurality of machining center bodies respectively, and the machining center body in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com