Patents

Literature

182results about How to "Achieving Pipeline Operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

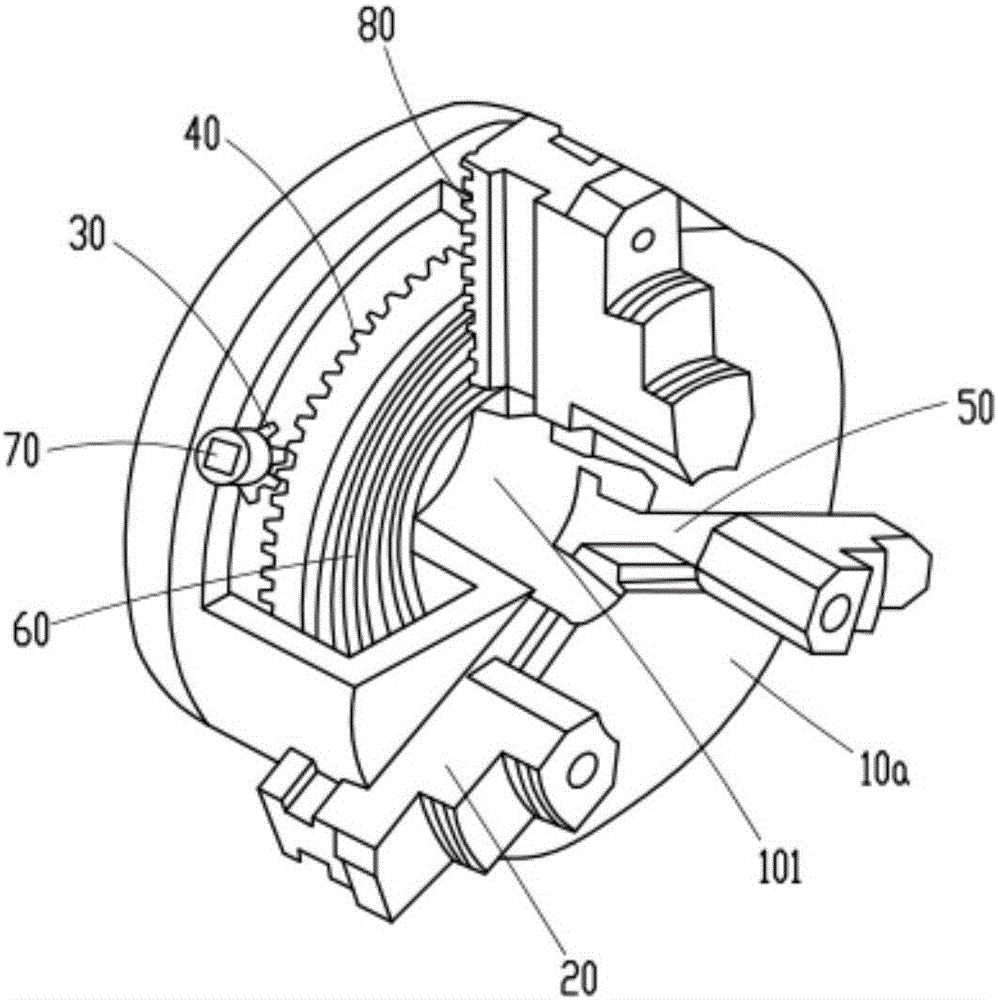

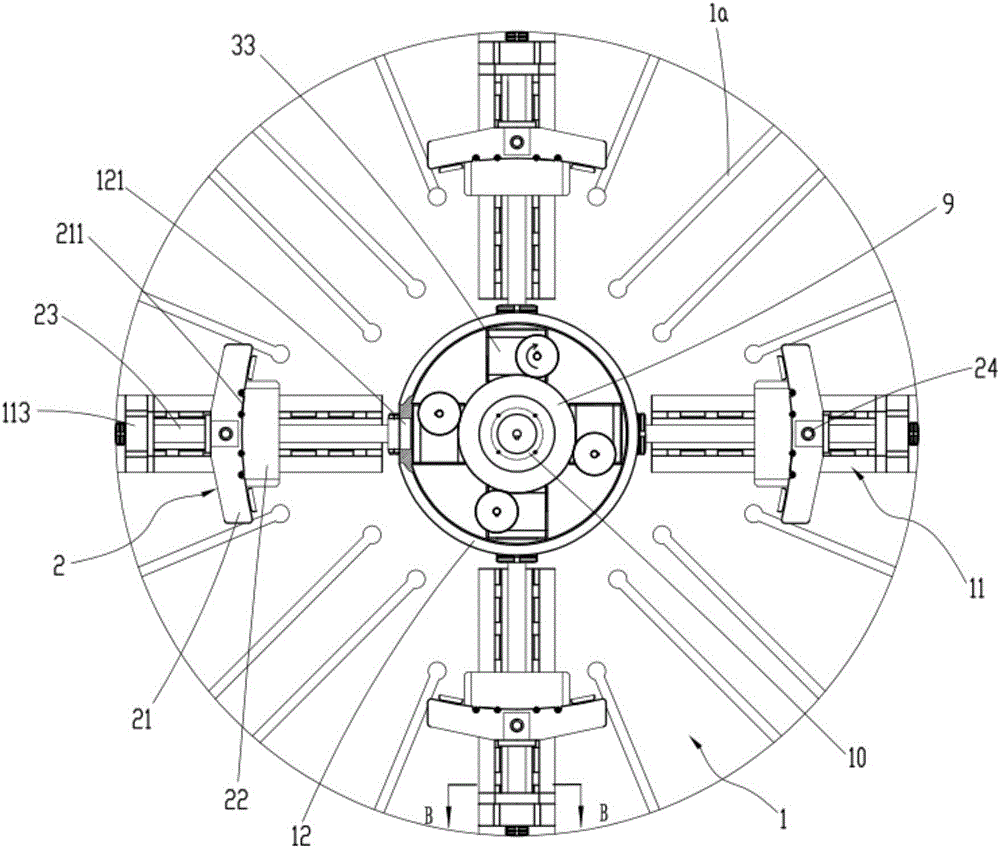

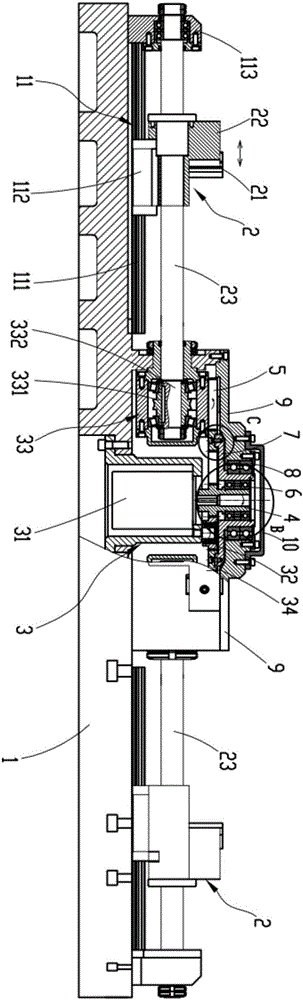

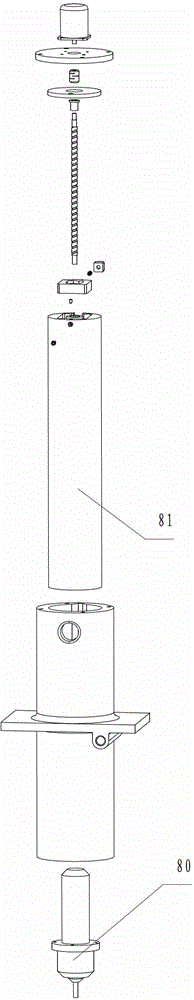

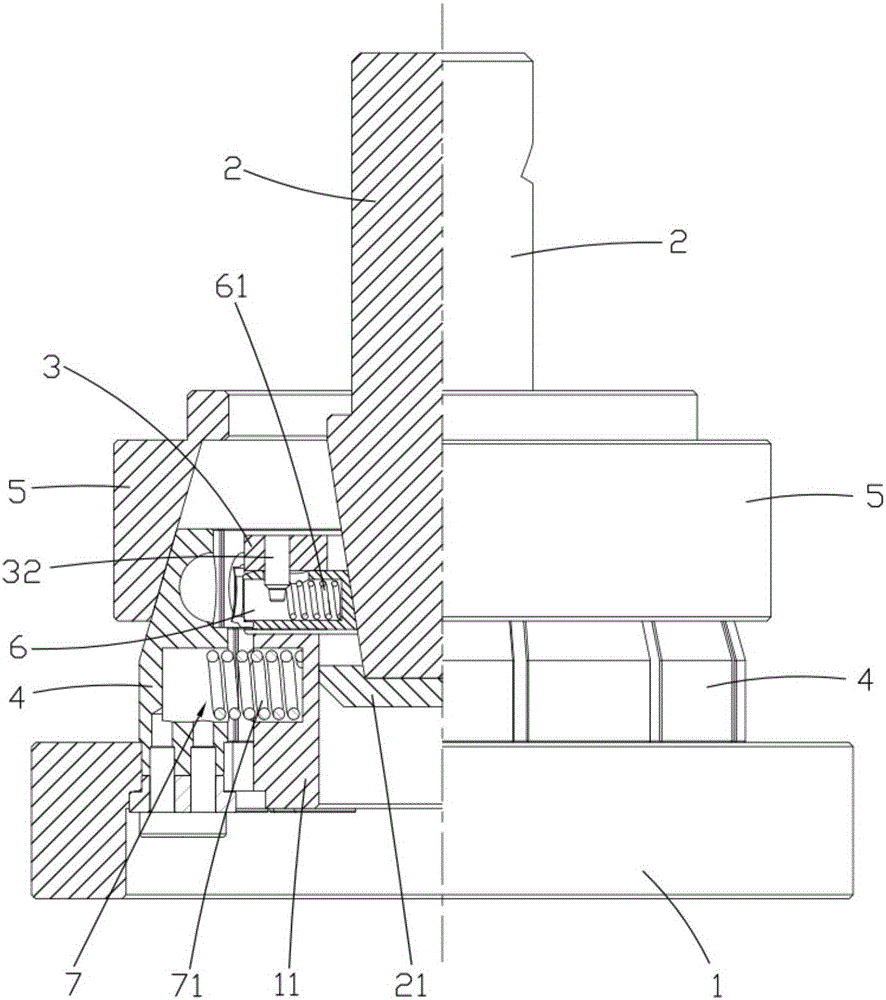

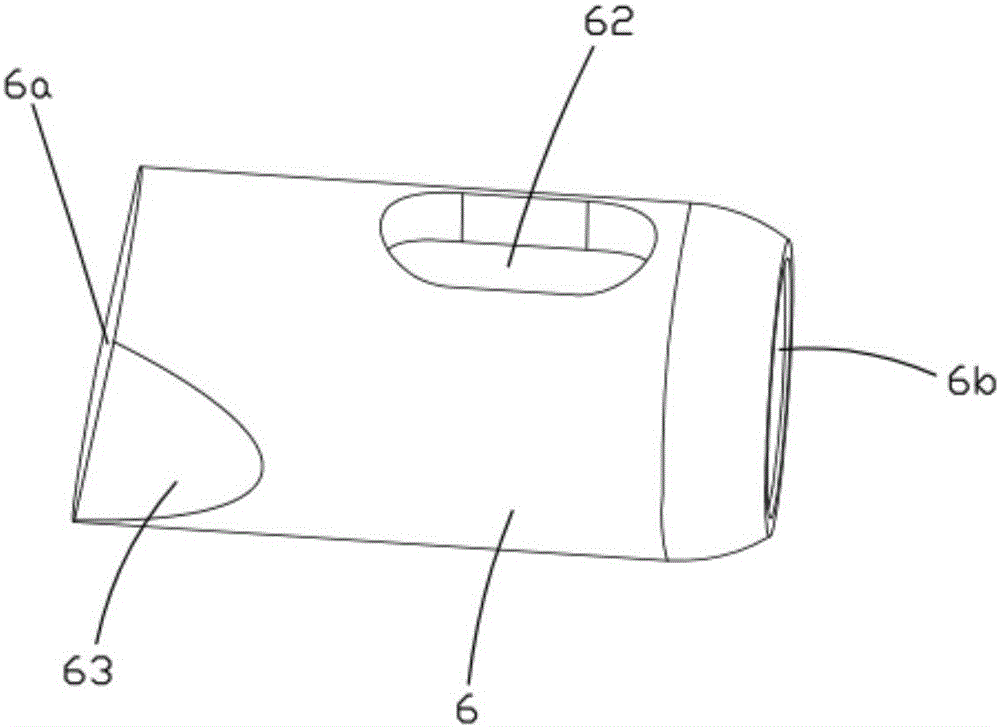

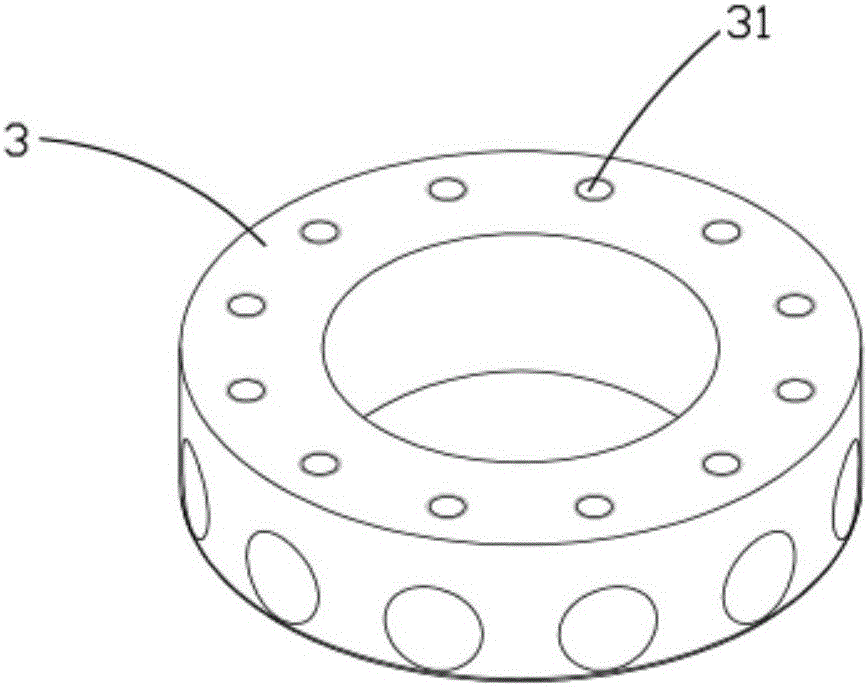

Precise self-centering chuck suitable for super-large workpieces

The invention relates to a precise self-centering chuck suitable for super-large workpieces. The precise self-centering chuck suitable for the super-large workpieces comprises a chuck body and a plurality of jack catch mechanisms arranged on the chuck body in a sliding mode. A jack catch driving mechanism is further arranged on the chuck body and comprises a numerical control moment motor, a plurality of transition gears, a plurality of double-enveloping speed reducers and a first gear. The inner circular surface and the outer circular surface of the first gear are provided with inner teeth and outer teeth correspondingly. The numerical control moment motor is provided with motor teeth. The multiple transition gears are all engaged with the motor teeth and the inner teeth of the first gear. The outer teeth of the first gear are engaged with second gears of the multiple double-enveloping speed reducers. The double-enveloping speed reducers drive the jack catch mechanisms to reciprocate to clamp or release the annular workpieces to be machined. The numerical control moment motor is used for sequentially driving the multiple transition gears and the double-enveloping speed reducers to rotate in a matched mode, so that the multiple jack catch mechanisms move inwards or outwards synchronously. The super-large annular workpieces are subjected to automatic centering clamping or releasing, and the clamping positioning accuracy is high.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

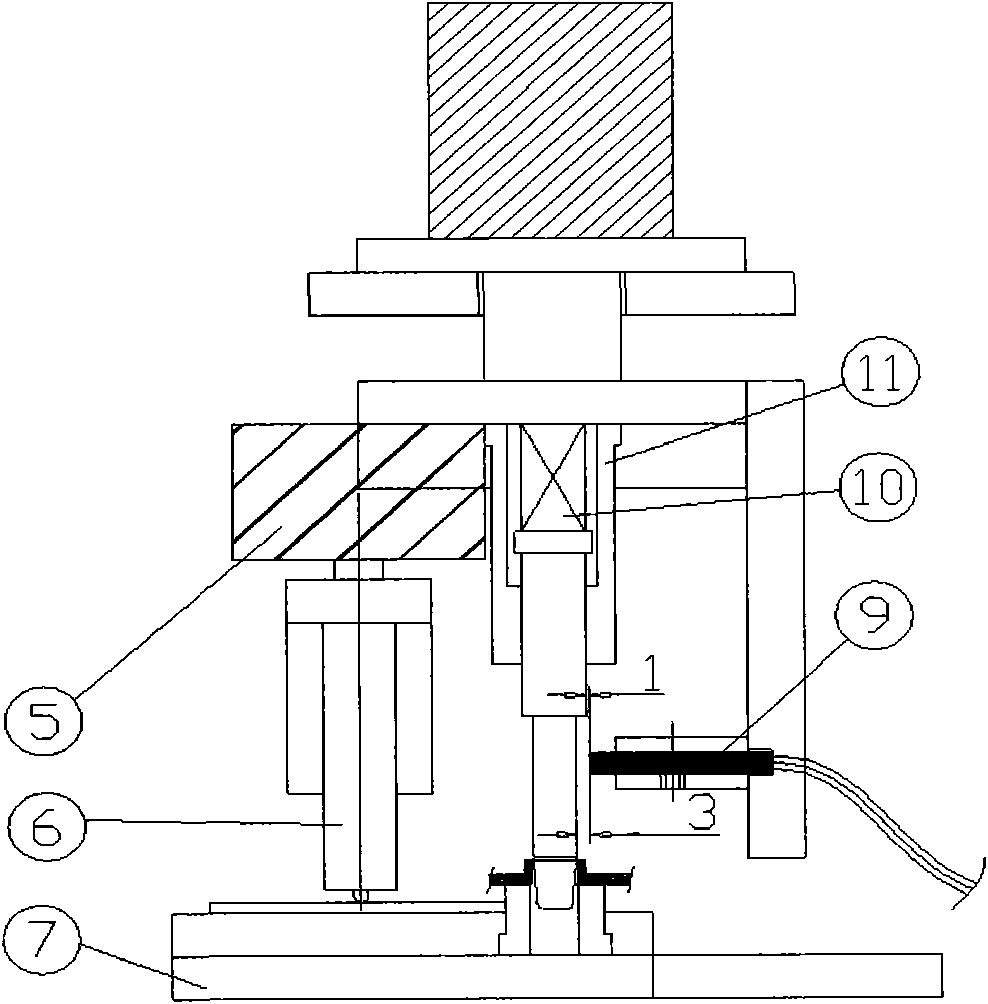

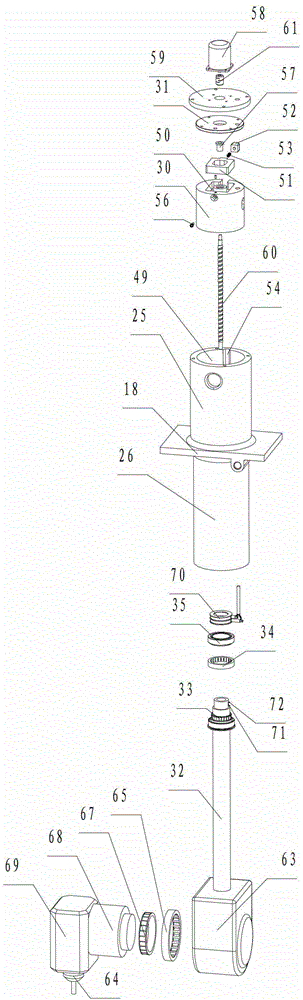

Screw thread automatic detecting equipment and method

InactiveCN101603804AImprove satisfactionFacilitate the realization of assembly line operationMechanical diameter measurementsFixed frameVia device

The invention relates to screw thread automatic detecting equipment and a method thereof; the main frame of the equipment is a fixing frame, a screw thread detecting pin is driven by a working air cylinder fixed at the center of the outer part of the top side to move downwards to carry out detection, a product detecting fixture is arranged on a base of the fixing frame, and the position of a screw thread hole of the product to be detected is arranged right below the screw thread detecting pin; a sensor is arranged at one side of the screw thread detecting pin, the front end part of the sensor is vertical to the screw thread detecting pin and is arranged at a distance from the screw thread detecting pin, the sensor is triggered to carry out detection by the insertion of a screw thread detecting rod at the front end of the screw thread detecting pin or by different working states generated by preventing from moving downwards. The equipment fully utilizes the difference of pore diameter of an extruding and tapping product before tapping and after tapping to carry out judgment and identification, and full-inspection identification and marking are automatically carried out by the equipment, thereby being beneficial to realizing assembly line work, avoiding changing or lagging the production flow, reducing the risk on producing defective products in the process and having remarkable economic benefit.

Owner:无锡雄伟精工科技有限公司

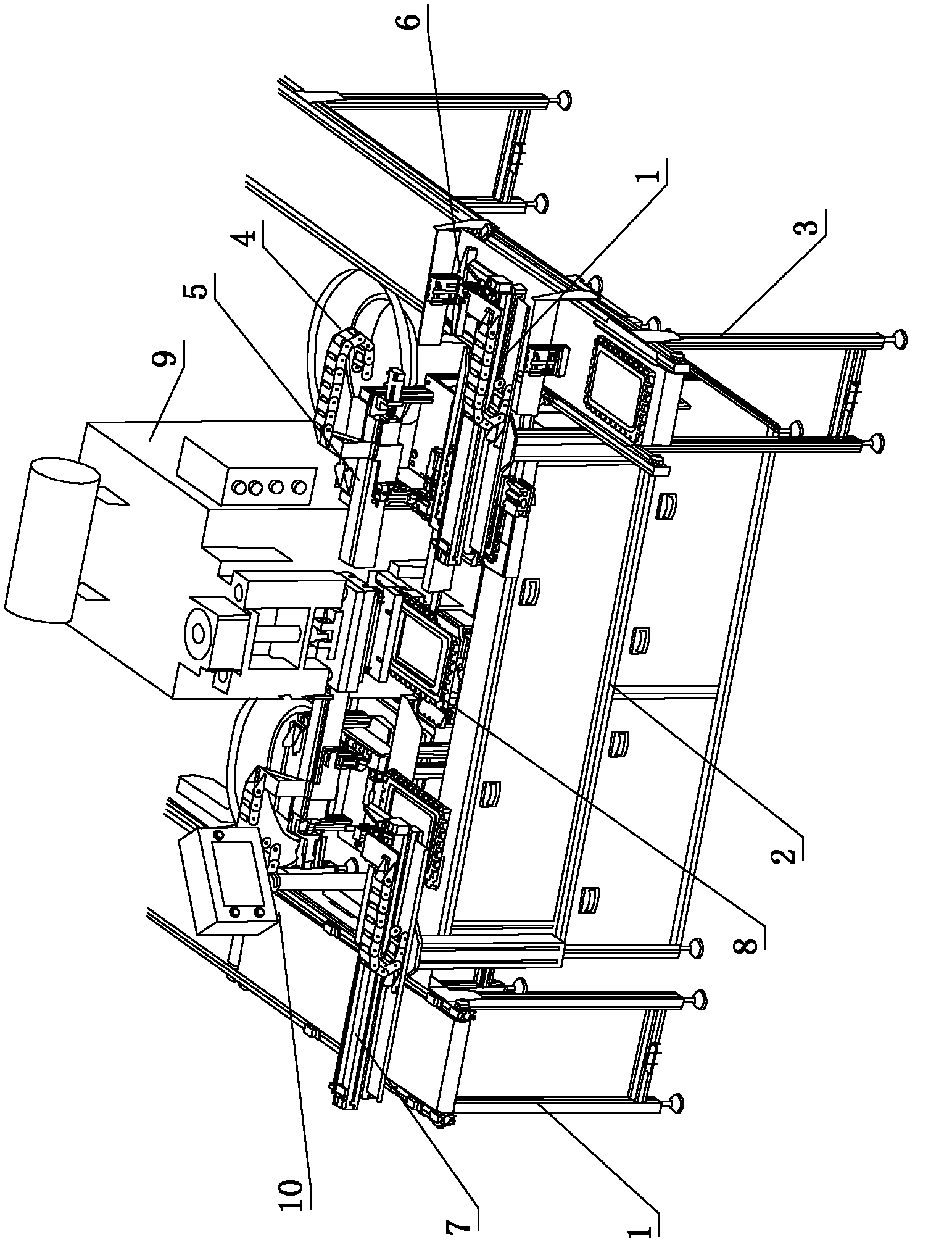

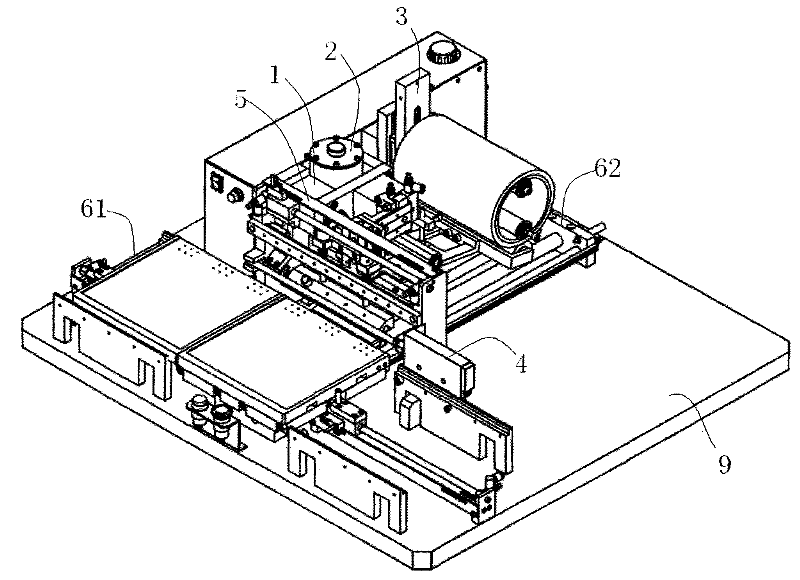

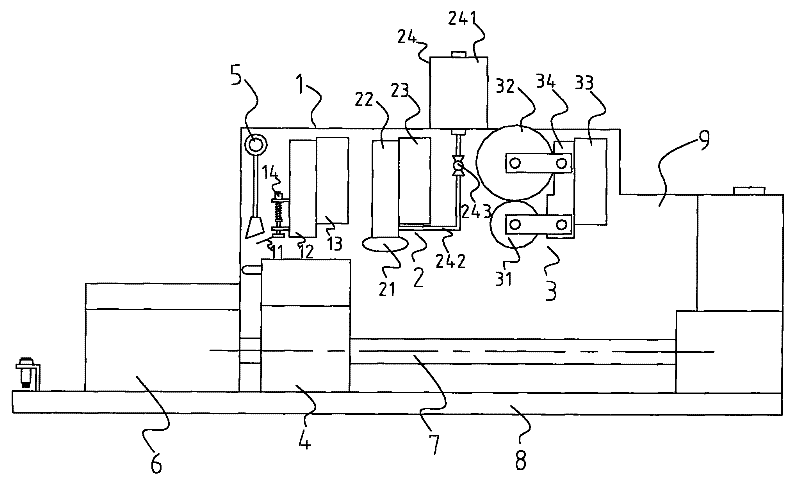

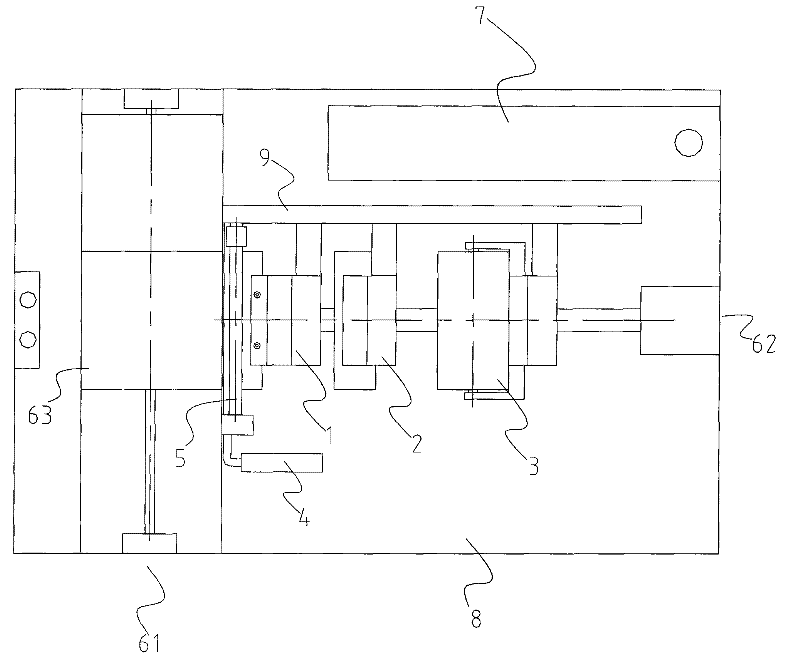

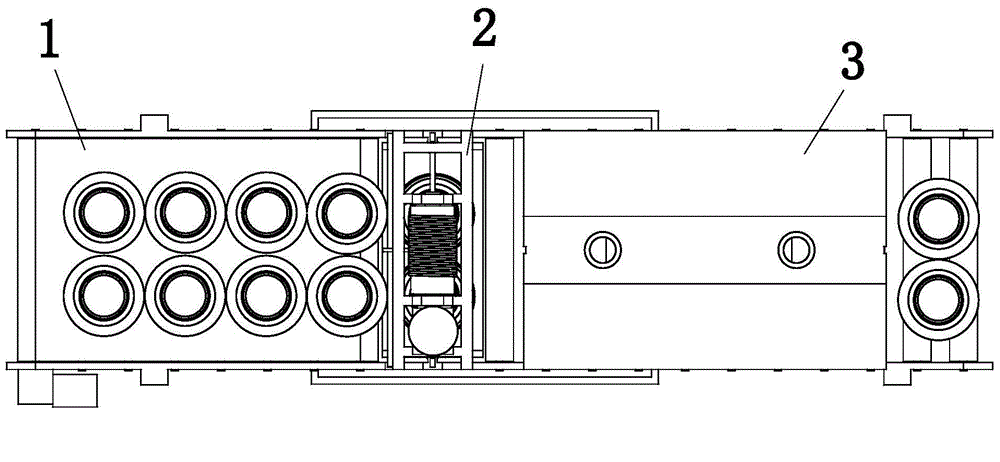

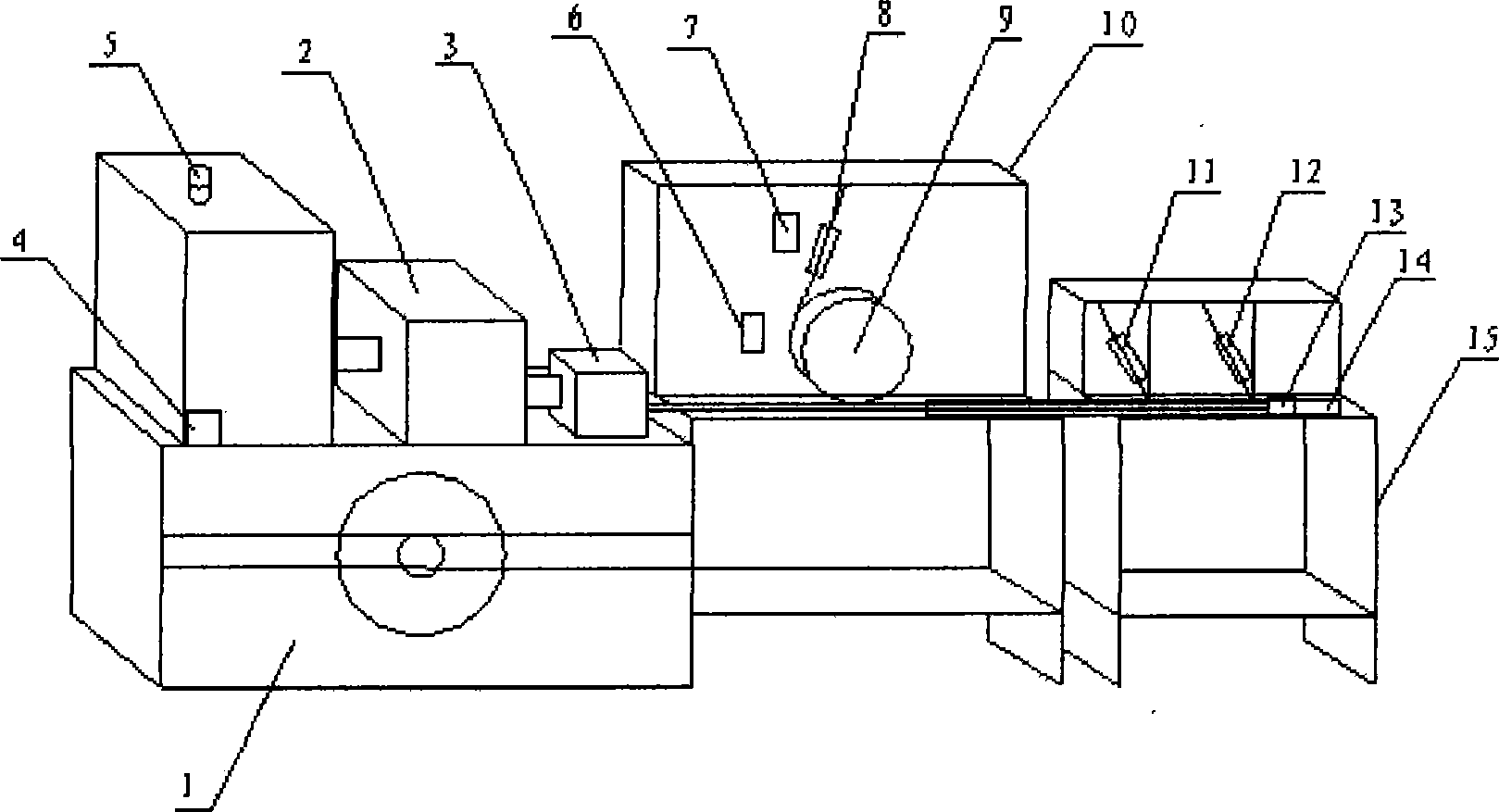

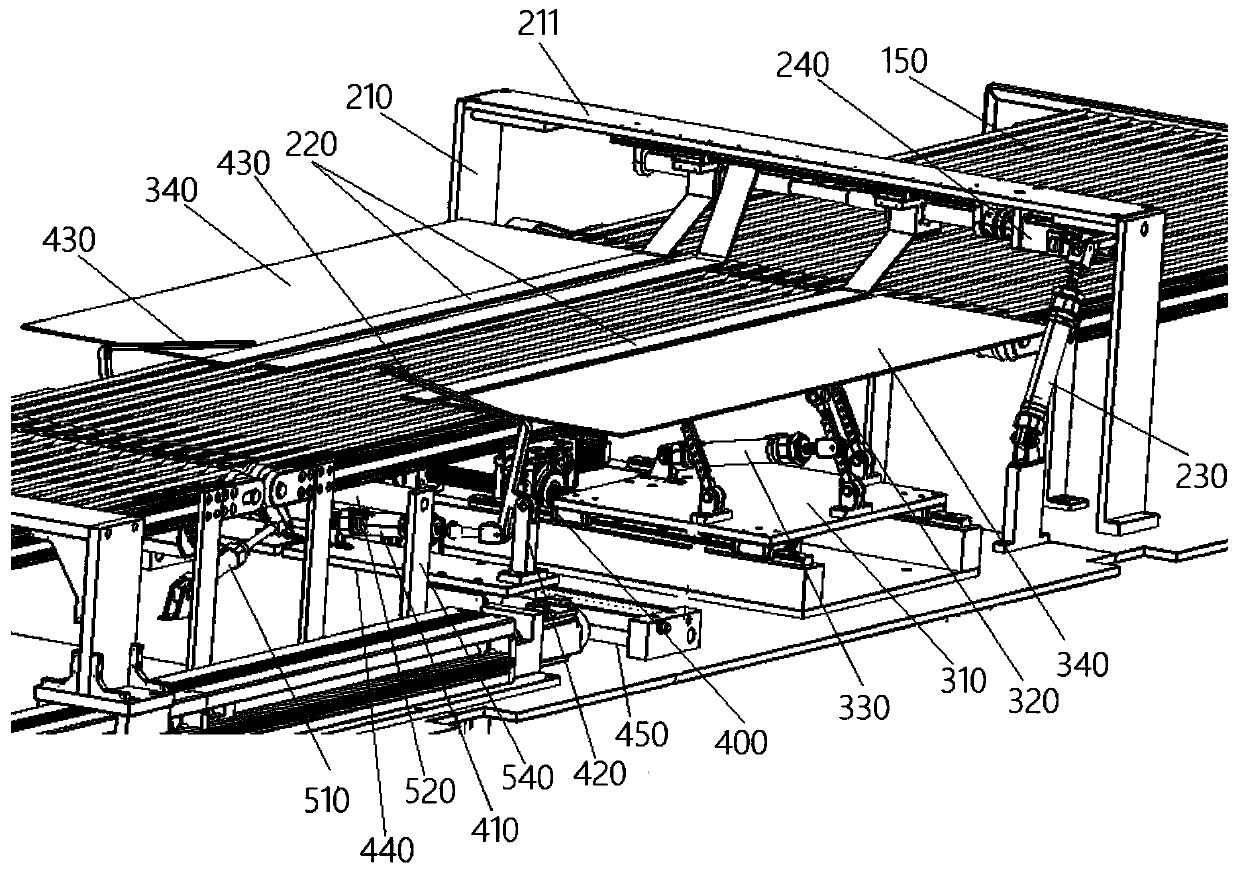

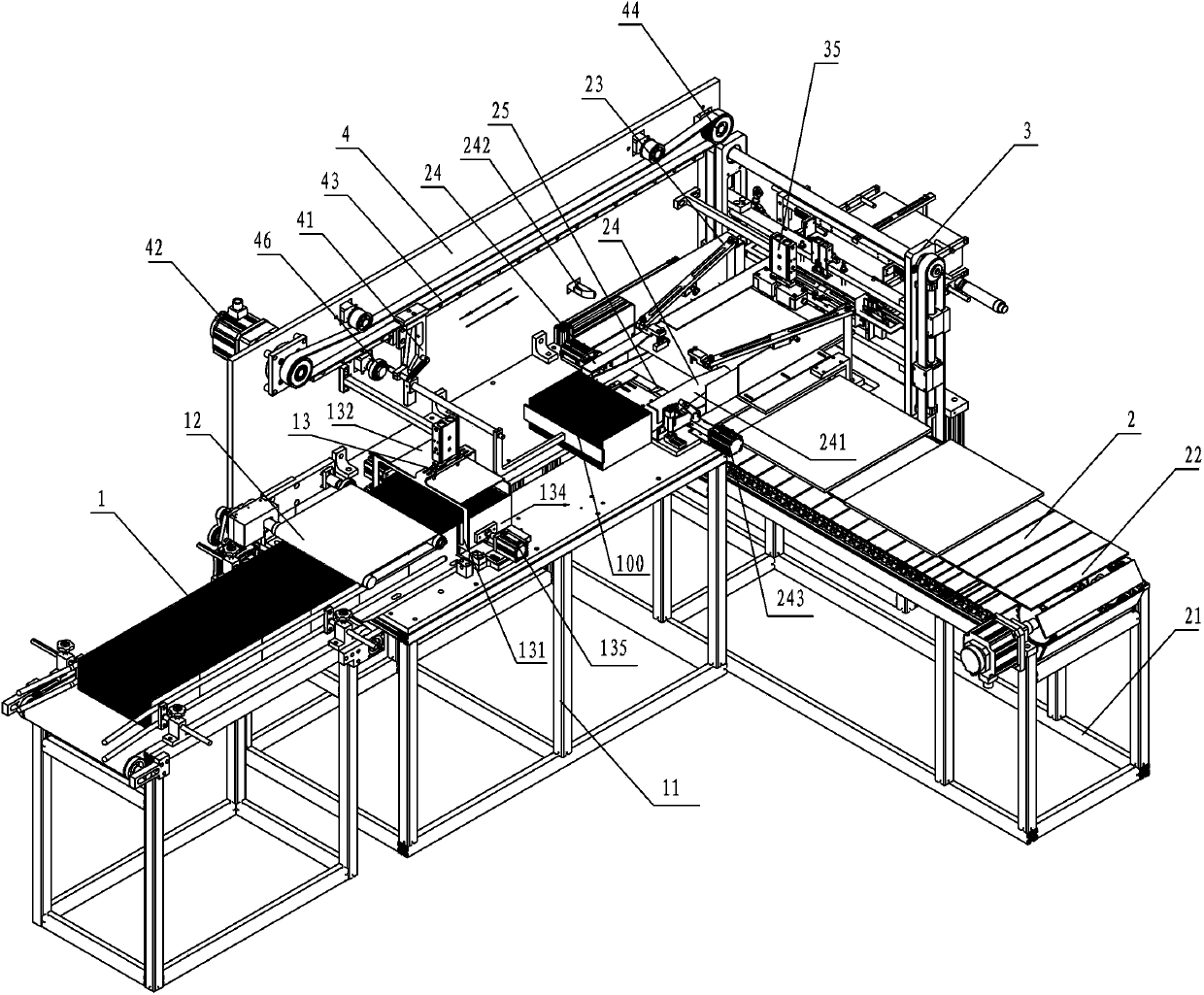

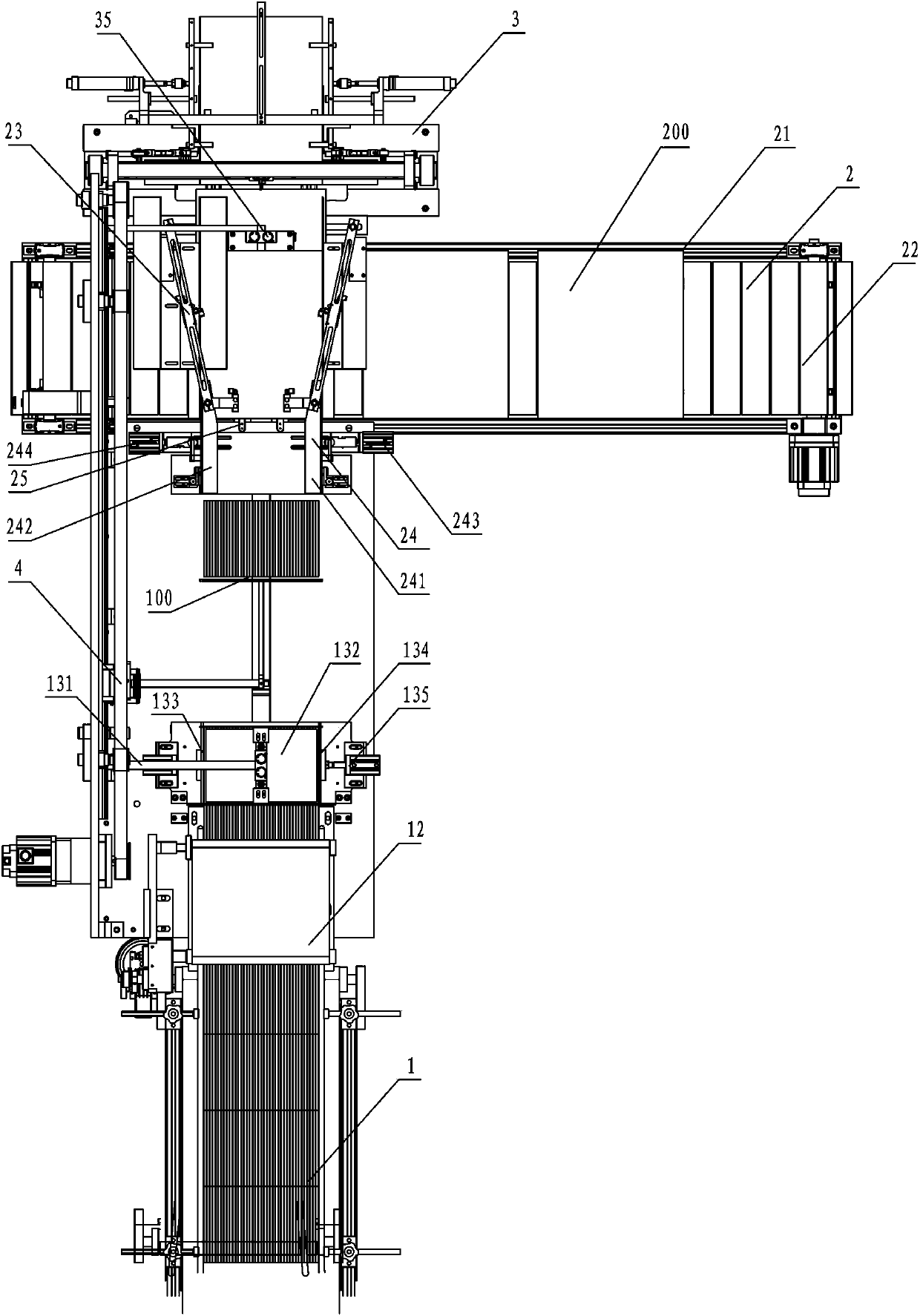

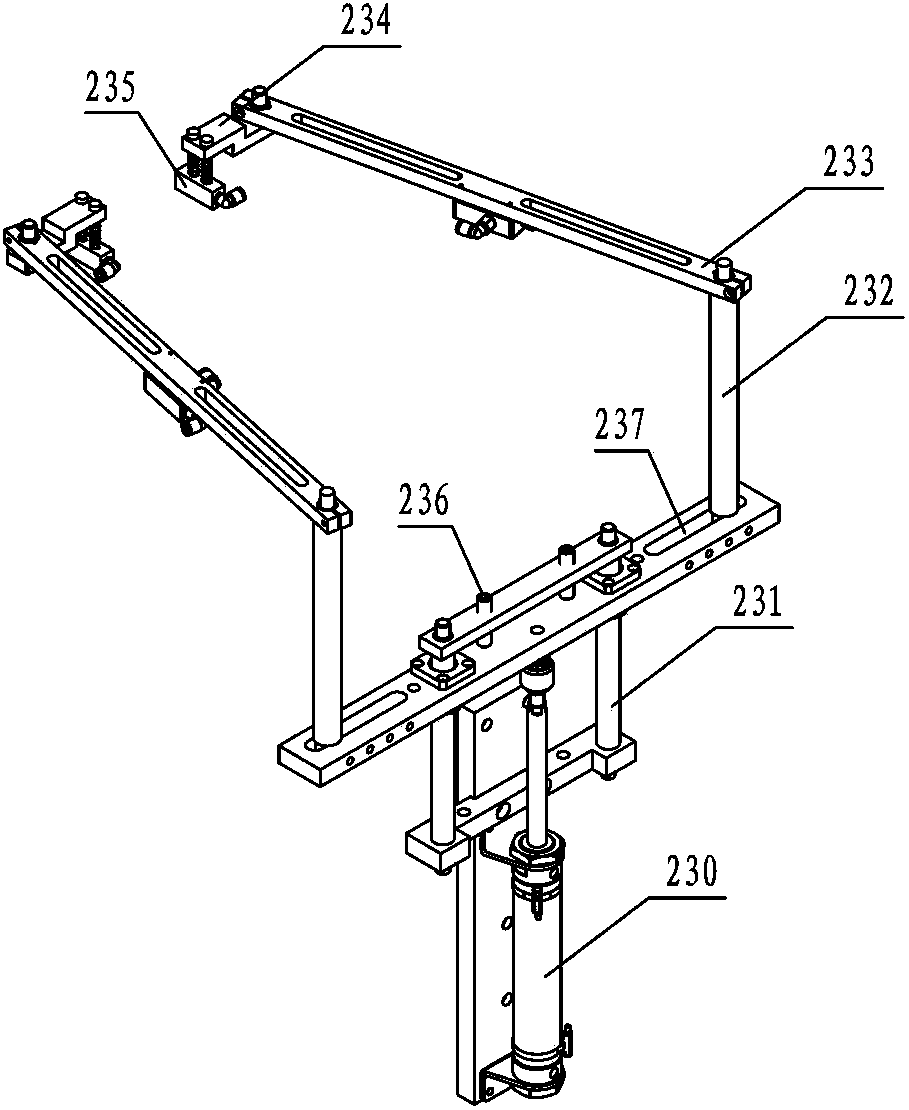

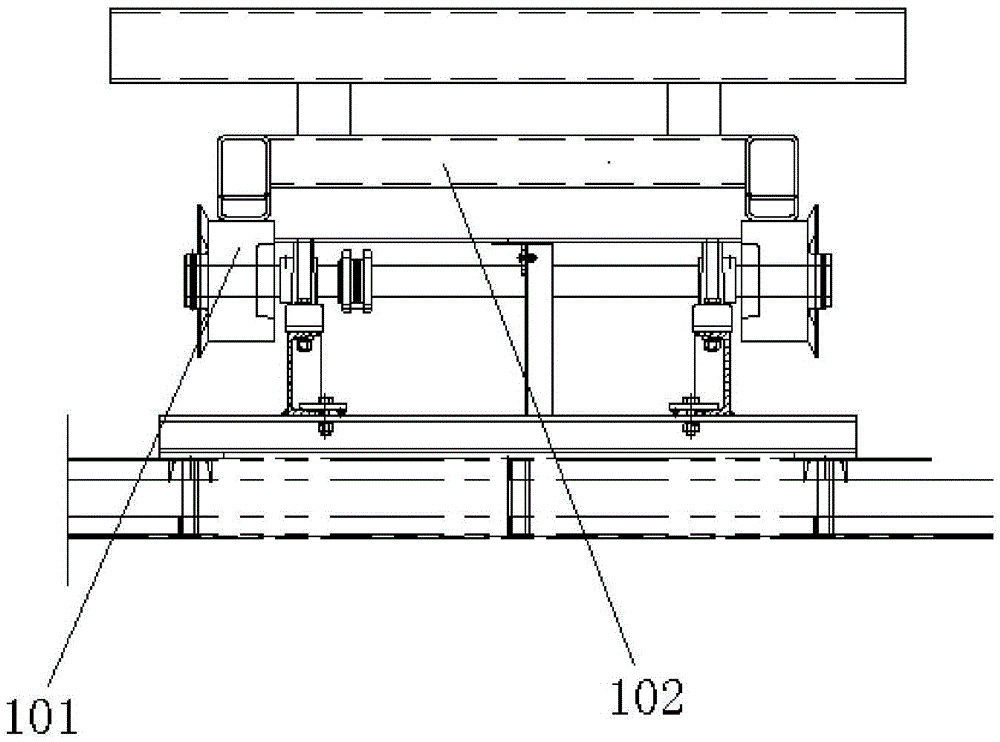

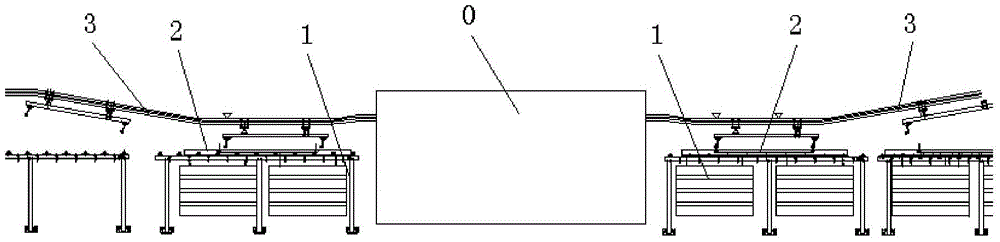

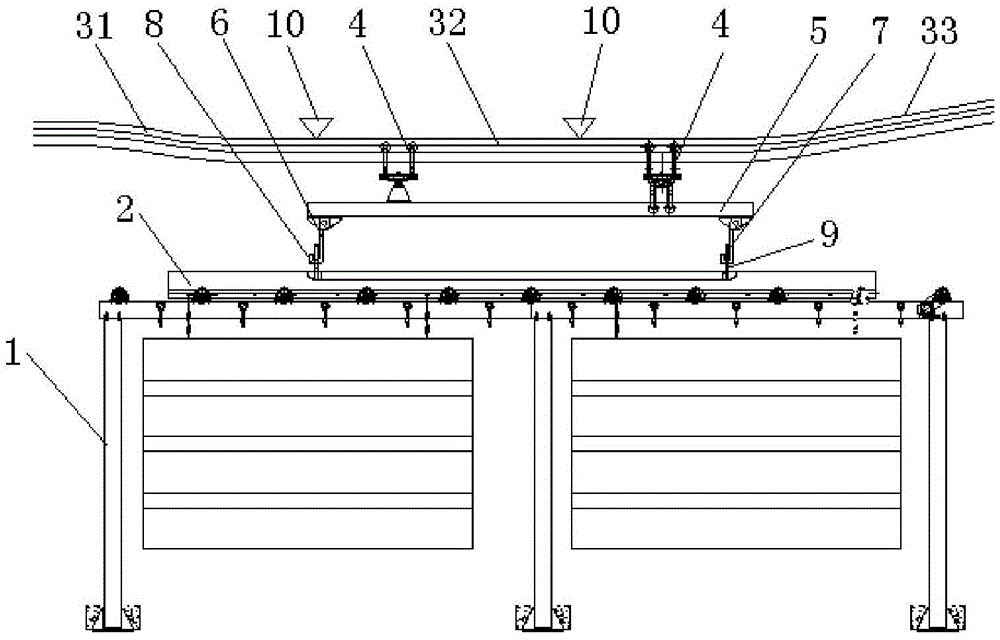

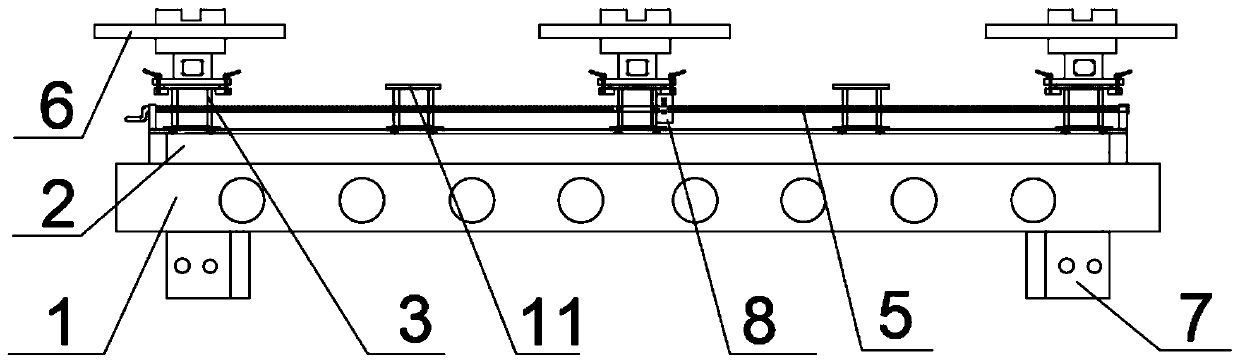

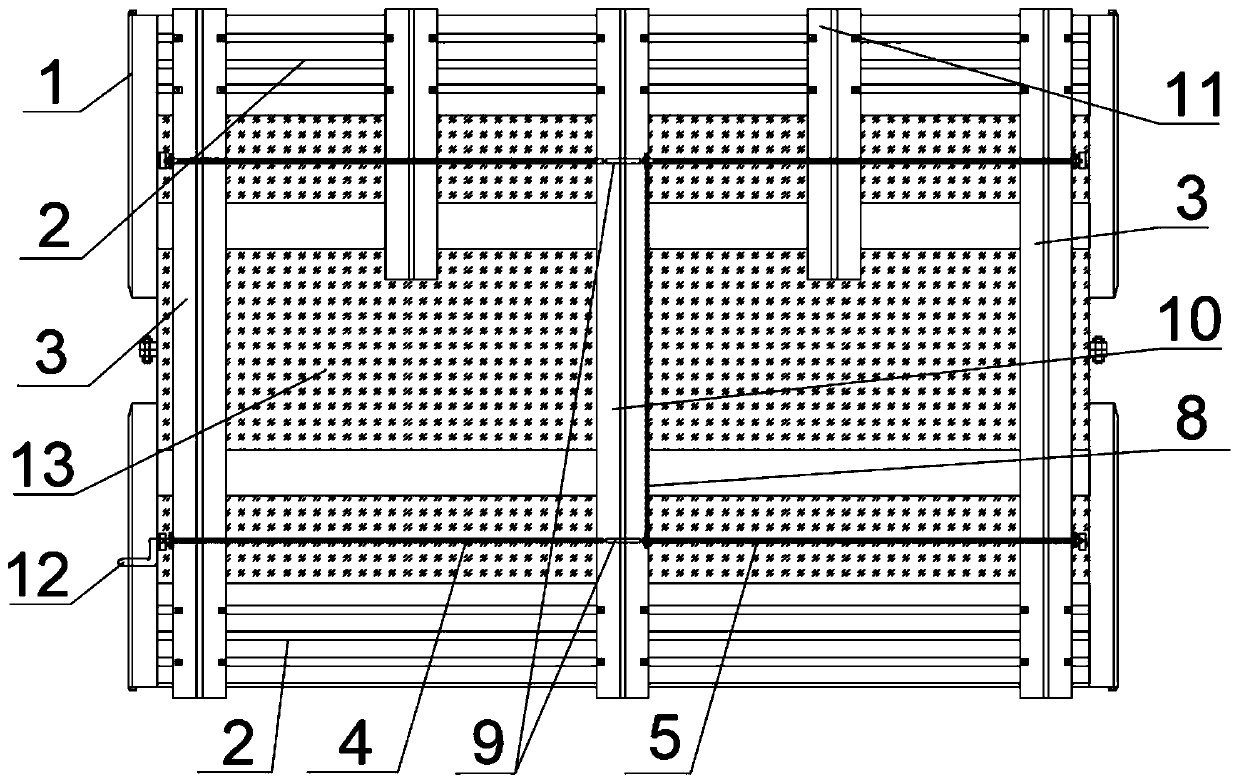

Full-automatic door body butt-welding machine

InactiveCN102398107ARun syncAchieving Pipeline OperationsResistance welding apparatusAssembly lineIndustrial engineering

The invention provides a full-automatic door body butt-welding machine. The machine comprises a left base, a main base and a right base which are used for bearing and provided with supporting feet, a material conveying module arranged on the main base and used for conveying a welding material, a material taking module arranged on the main base and used for conveying the welding material from the material conveying module to the next operation link, a lead-in device arranged on the left base and used for leading a workpiece in, a lead-out device arranged on the right base and used for leading the welded workpiece out, a workpiece conveying and taking module matched with the lead-in module and the lead-out module to convey and take the workpiece, a welding module for welding the workpiece, and a control module for system control of the butt-welding machine. The full-automatic door body butt-welding machine can fully automatically convey the material and the workpiece and take the workpiece, a double working point welding mode is adopted, assembly line work can be realized, a plurality of welding machines can be synchronously operated, welding accuracy and consistency are achieved, labor is saved, and work efficiency is high.

Owner:SUZHOU SKYLINE MACHINERY TECH DONGGUAN BRANCH

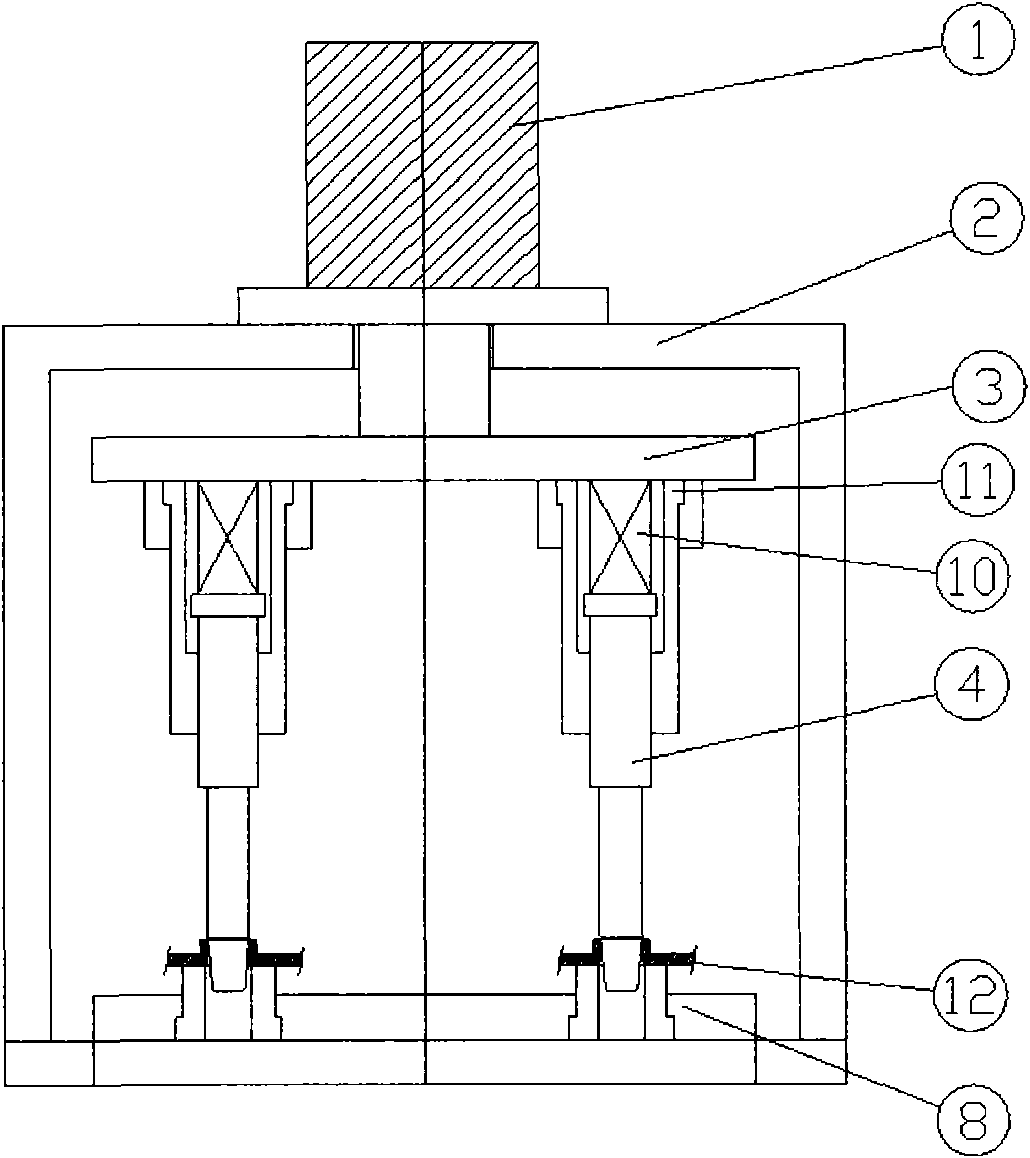

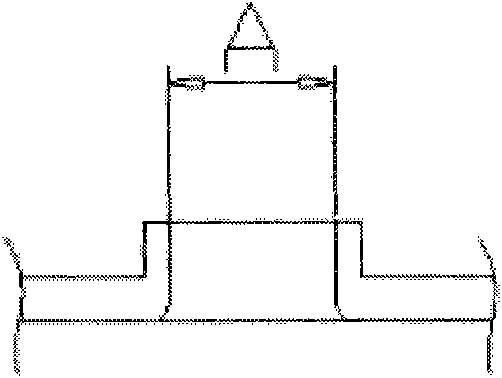

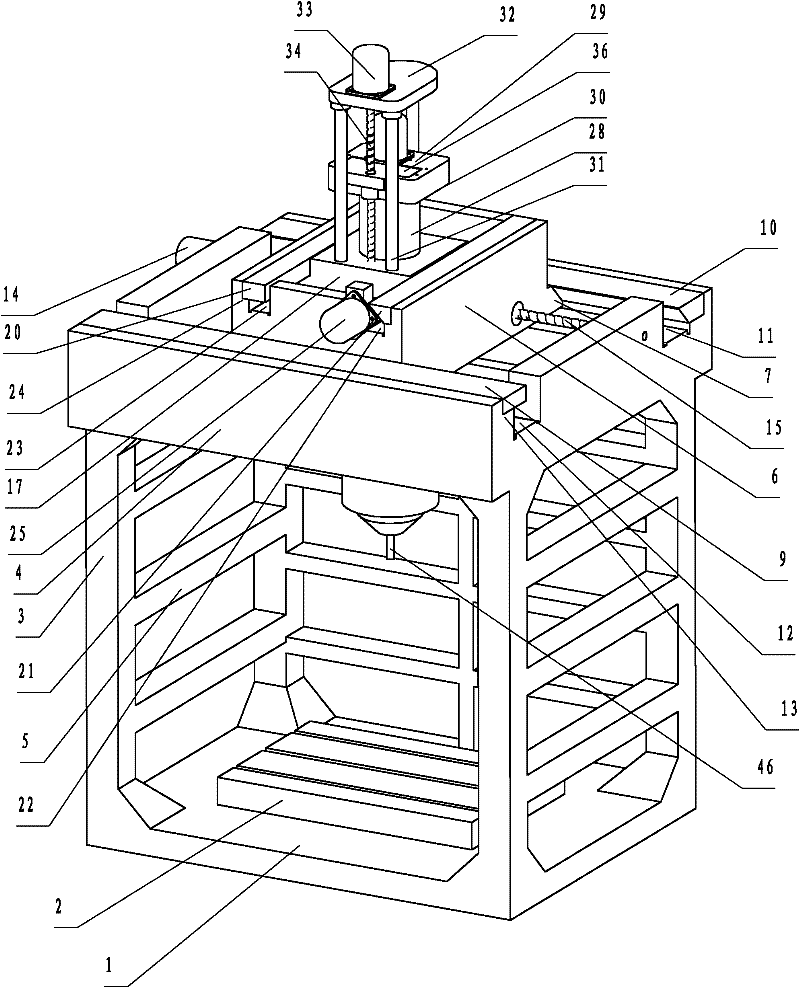

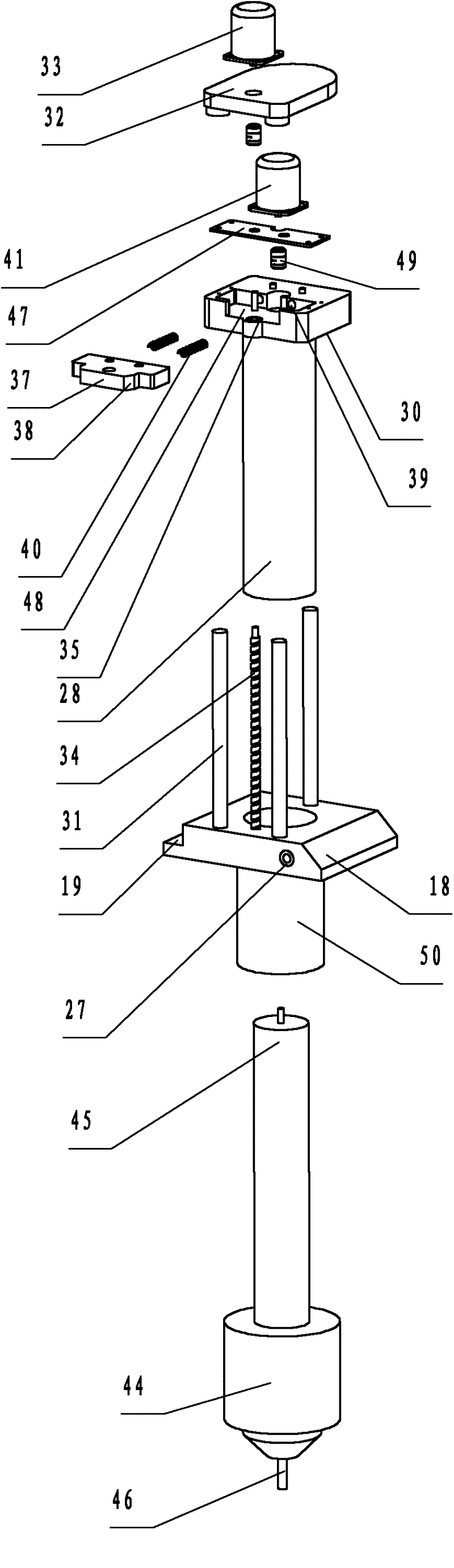

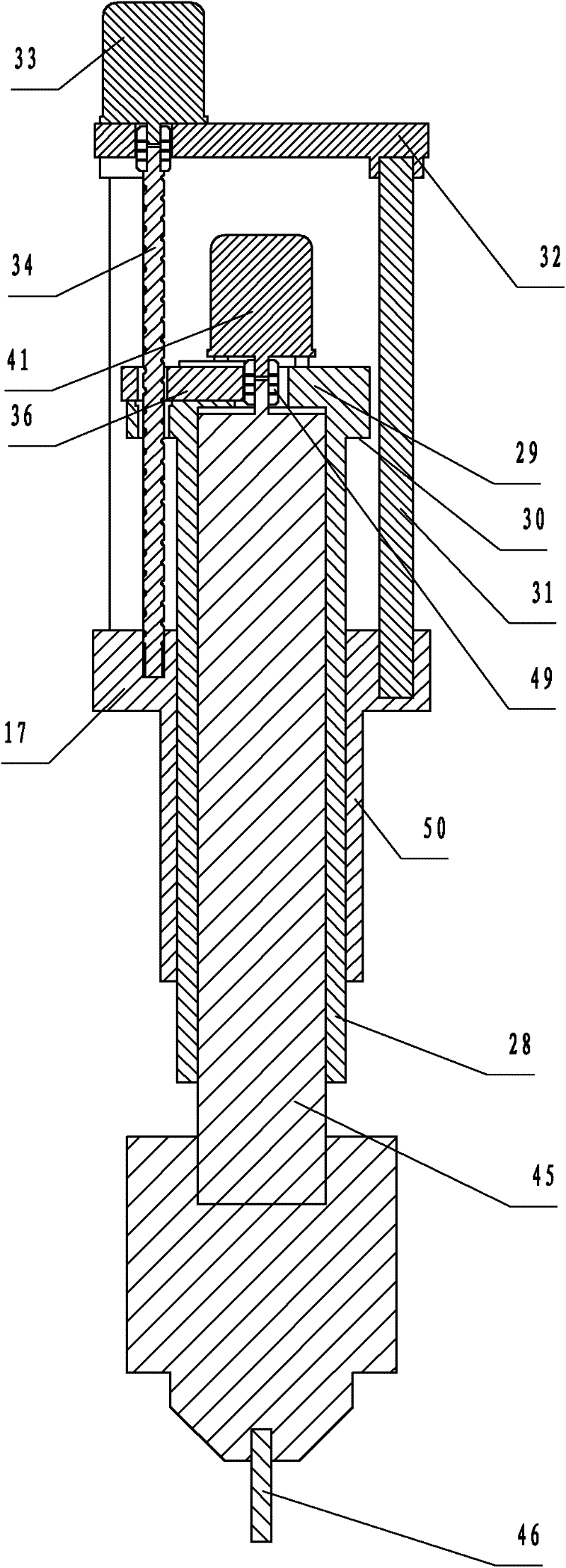

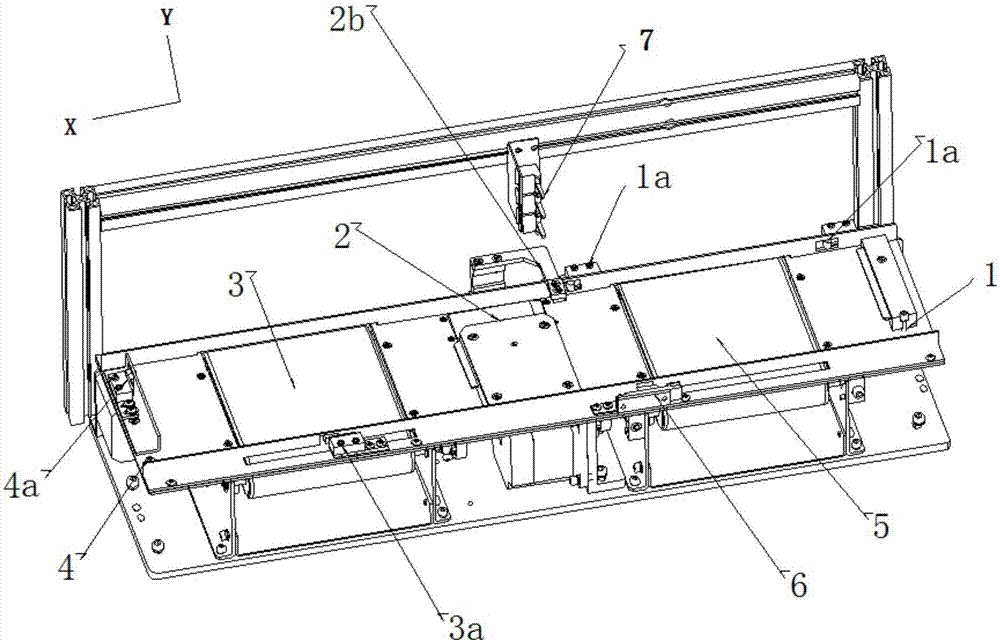

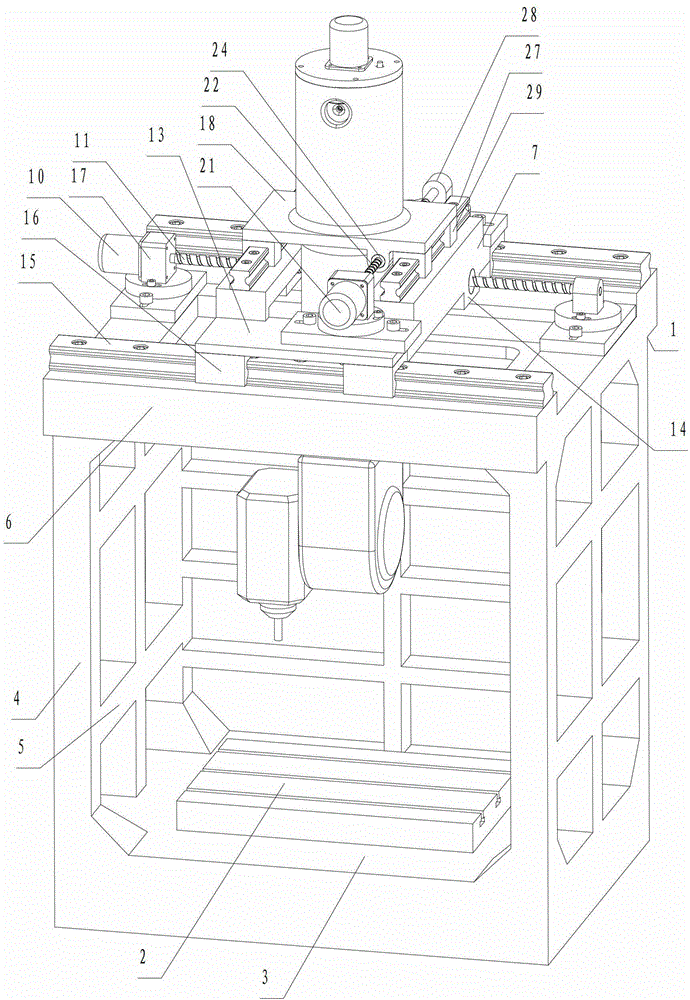

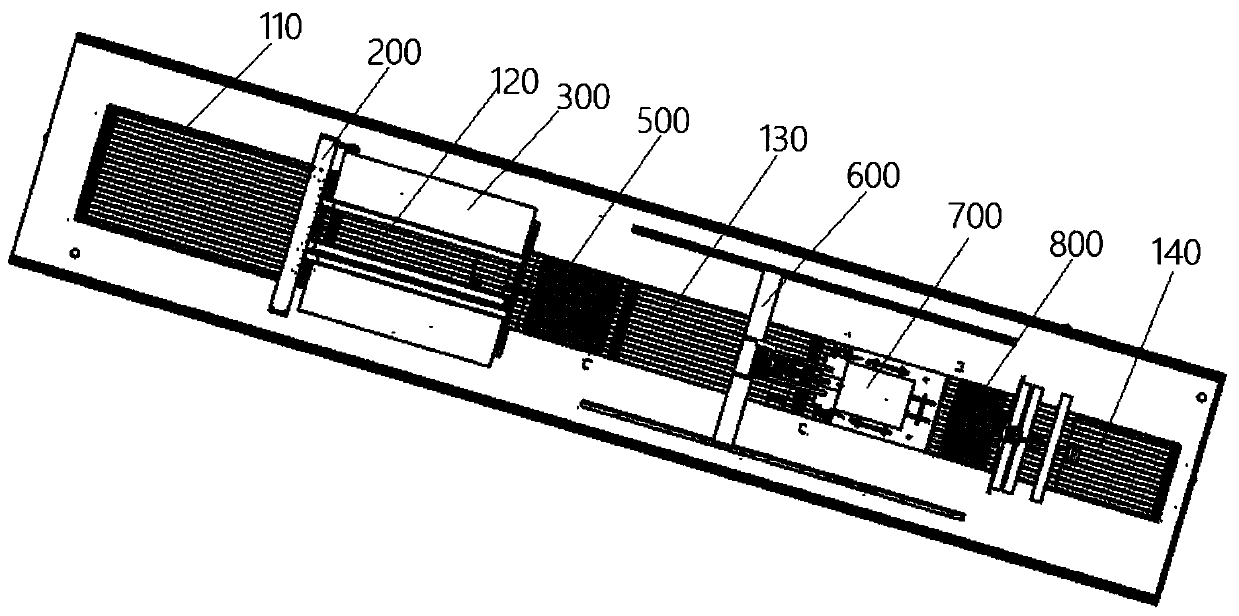

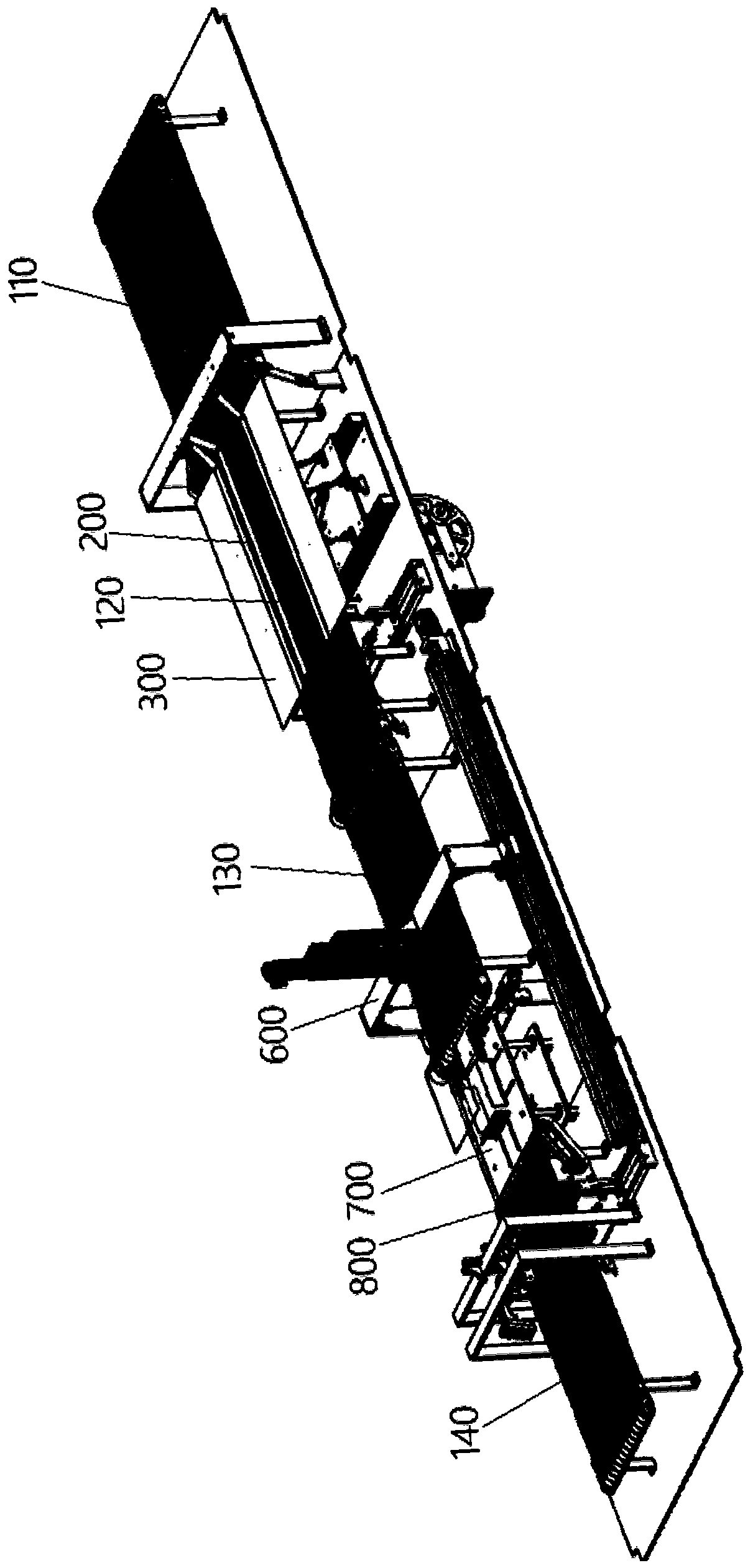

Numerical control equipment, machining process, numerical control production line and automatic article storage system

InactiveCN102528567AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersProduction lineNumerical control

Numerical control equipment comprises a main frame, a workpiece clamping device, an X-directional sliding seat, a first driving device, Y-directional sliding seat, a second driving device and a Z-directional guide device. The main support frame is of a closed-loop structure with a vertical opening; an X-directional front guide rail and an X-directional rear guide rail which are matched with each other are arranged between the main support frame and the X-directional sliding seat; the first driving device drives the X-directional sliding seat to move back and forth and comprises an X-directional lead screw positioned between the X-directional front guide rail and the X-directional rear guide rail; the second driving device drives the Y-directional sliding seat to move back and forth; the Z-directional guide device is mounted on the Y-directional sliding seat and comprises a Z-directional guide rod capable of vertically moving, and a third driving device for driving the Z-directional guide rod to vertically move; and a main machining head is arranged at the lower end of the Z-directional guide rod. The numerical control equipment has the advantages of fine stability, accuracy in positioning and smoothness in movement, and iron scraps falling after machining a workpiece basically cannot enter the guide rail above the machining head without special protection.

Owner:杨东佐

Method for automatically cleaning glass surface

ActiveCN102172592AImprove cleaning efficiencyEliminate cleaning quality impactsFlexible article cleaningForeign matterLiquid-crystal display

The invention discloses a method for automatically cleaning a glass surface, particularly glass and a liquid crystal display. The method comprises the following step of: in the process that a feeding part of a feeding mechanism is driven by an electric control system to convey glass along the feeding direction, sequentially finishing a scraping action for scraping foreign matters on the glass surface, a wiping action for wiping the glass surface and a bonding action for bonding stains left on the glass surface under the action of relative movement between each of a scraping mechanism, a wiping mechanism and a bonding mechanism and glass, wherein the electric control system is used for starting an electrostatic eliminating device to eliminate static electricity generated in the scraping process at least in the process of the scraping action. The method for automatically cleaning the glass surface can be used for automatically cleaning glass, particularly the liquid crystal display. By adopting the method, the cleaning efficiency is increased, the influence of human factors on the cleaning quality is eliminated, and the assembly line work is realized.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD +1

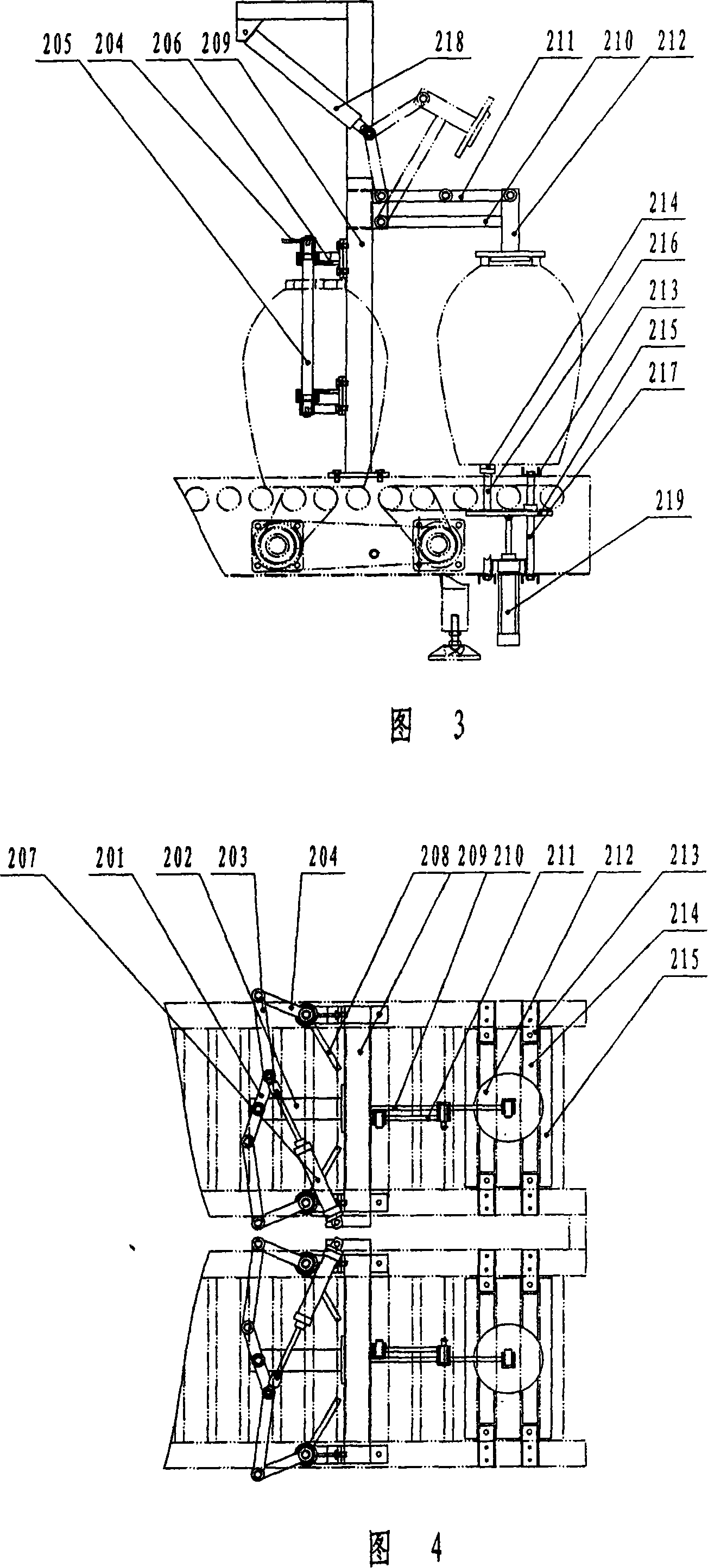

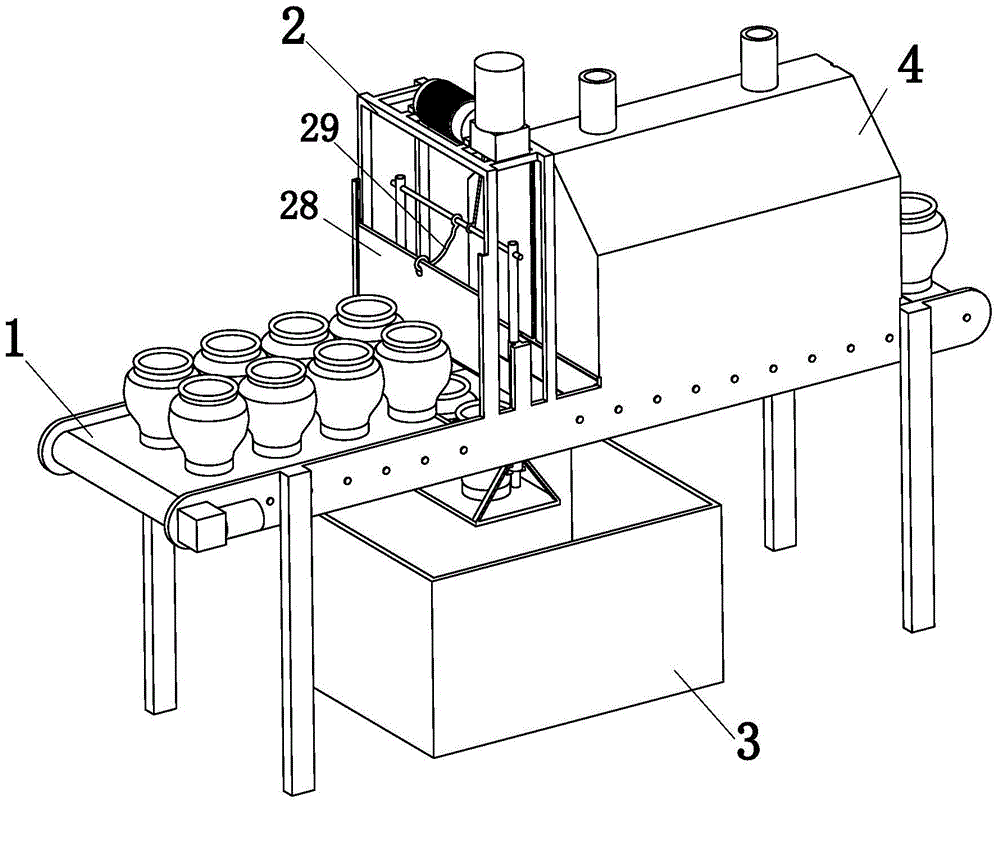

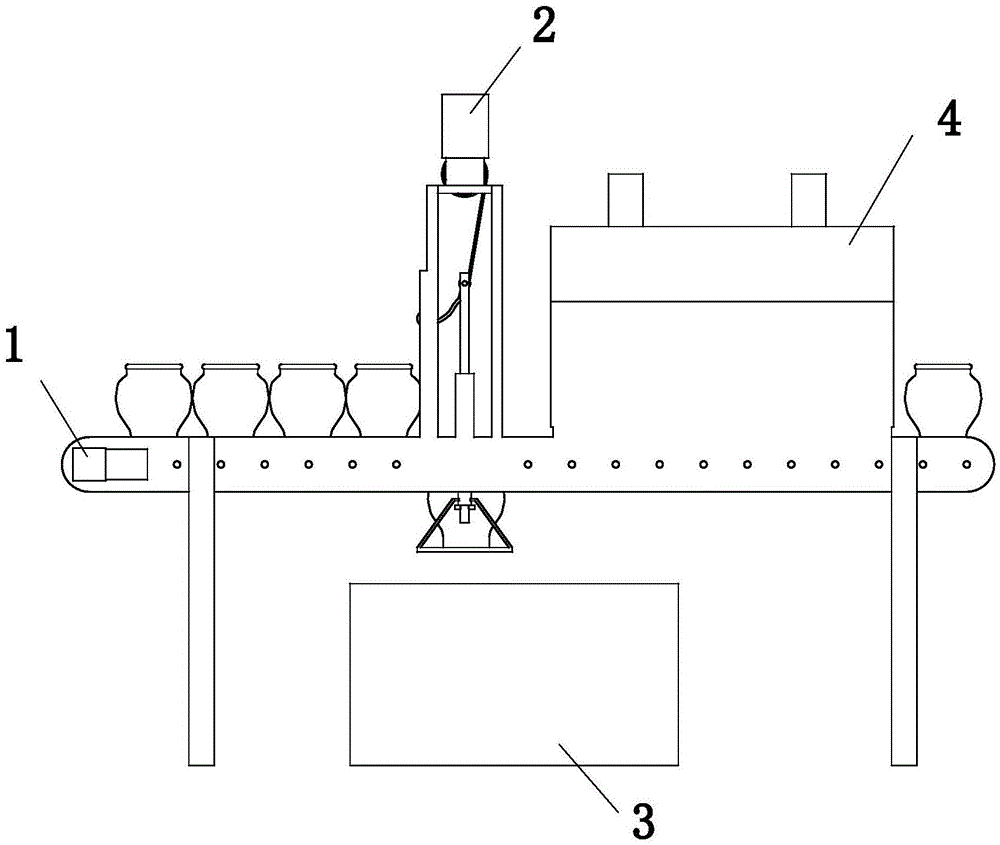

Wine crock cleaning and filling machine set

ActiveCN101125635AAchieving Pipeline OperationsContinuous productionBottle-handling machinesAutomatic controlLimewater

The invention provides an oinochoe washing filling machine unit, which is used for the mechanization package of the jarred wine, comprising a jar transmission mechanism, a positioning mechanism, a washing mechanism, a limewater brushing mechanism and a filling mechanism; wherein, the transmission mechanism is provided with a first transmission machine, a second transmission machine and a third transmission machine; wherein, the first transmission machine is provided with the positioning mechanism; a first manipulator is arranged between the first transmission machine and the second transmission machine, while a second manipulator is positioned between the second transmission machine and the third transmission machine; moreover, the second transmission machine is provided with the washing mechanism and the limewater brushing mechanism, and the third transmission machine is provided with the filling mechanism; whereas, a motor, an air cylinder, an electromagnetic valve, a vacuum valve and a steam heater and a photoelectric detector which are related in the mechanisms are all connected with an electronic automatic control system. The invention automatically complete a mechanism manner of the processes of washing jars in different shapes, brushing limewater and filling wine, further realizes an operation line and a continuous production, thereby improving the production efficiency and saving a large amount of labor as well as releasing the labor intensity.

Owner:象山恒大机械制造有限公司 +1

Welded flange hot-rolling technique

InactiveCN101422860AOvercome Raw Material WasteAccelerateMetal rolling arrangementsStraight segmentSheet steel

The invention relates to a technique of flat welding flange hot rolls, which comprises the procedures of: putting a steel billet into a furnace and heating, then according to the thickness and width of flange blank, immediately rolling the hot billet intoto strip hot-rolled flat plate of which the cross-section approximates an isosceles trapezoid; then arc curling the plate toward the narrow side and making into spiral multi-layer circular steel rings of which the ends are connected successively; next cutting the connected rings into independent rings along the bus; and then flattening the rings and welding docking ports at above 700 DEG C, and making into flange blank. The invention overcomes the disadvantages of the prior flange manufacturing technique such as waste of raw materials, relatively low precision of flange blank and low production efficiency, thereby realizing mass production of multiple circular curling, speeding up production, improving quality, and greatly improving production efficiency. Besides, the technique which is easy to be operated, popularized and implemented, solves the problem existing in head and tail straight segment, raises utilization rate of the raw materials, and has good social and economic benefit.

Owner:CHANGTONG TECH

Manufacturing method of inclined electroslag welding component shaped like Chinese character 'ri'

The invention relates to a manufacturing method of an inclined electroslag welding component shaped like a Chinese character 'ri'. The process of the manufacturing method comprises the step of lofting and marking-off, the step of assembly and welding, the step of assembling H-shaped steel, the step of assembling inner diaphragm lining strips and inclined electroslag lining strips and milling edges, the step of installing and welding an inner diaphragm, the step of assembling box body covering plates at two sides, the step of correction and end milling of the component shaped like the Chinese character 'ri', the step of assembling corresponding brackets, and the step of rust removal and coating. Compared with the prior art, the manufacturing method of the inclined electroslag welding component shaped like the Chinese character 'ri' has the advantages of effectively guaranteeing the manufacturing quality of the small-section and thick-plate inclined electroslag welding component shaped like the Chinese character 'ri', not only achieving large-batch edge milling operations of the inclined electroslag lining strips, but also resolving the problems of difficult welding, difficult assembly and large deformation of the structure, obviously improving the production efficiency of workshops, and saving production cost.

Owner:成军

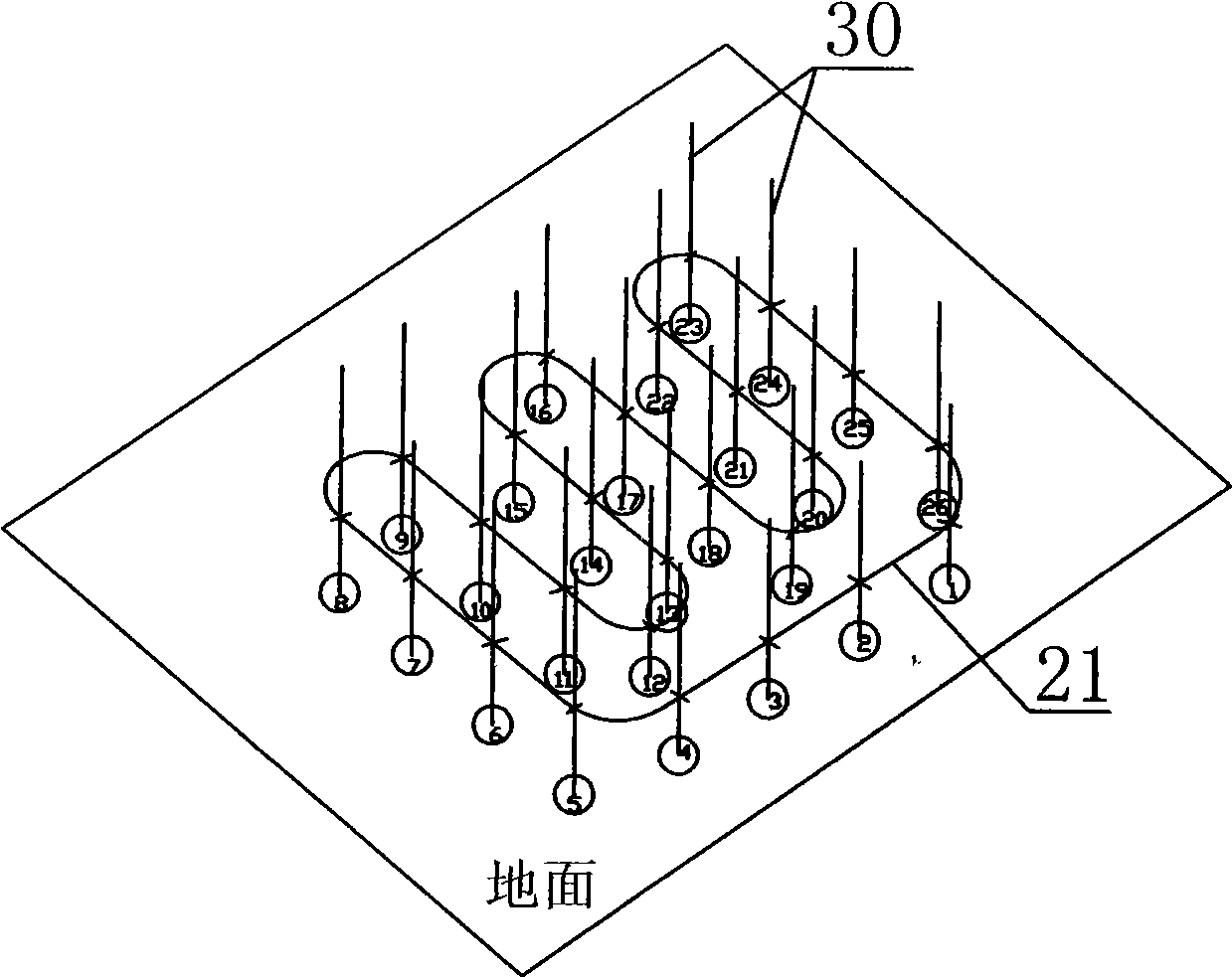

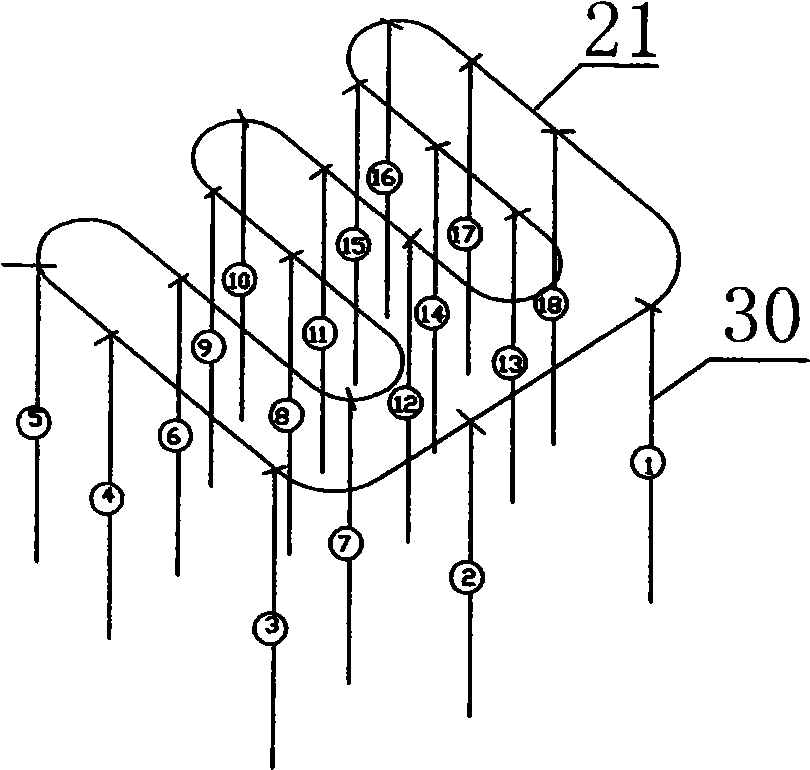

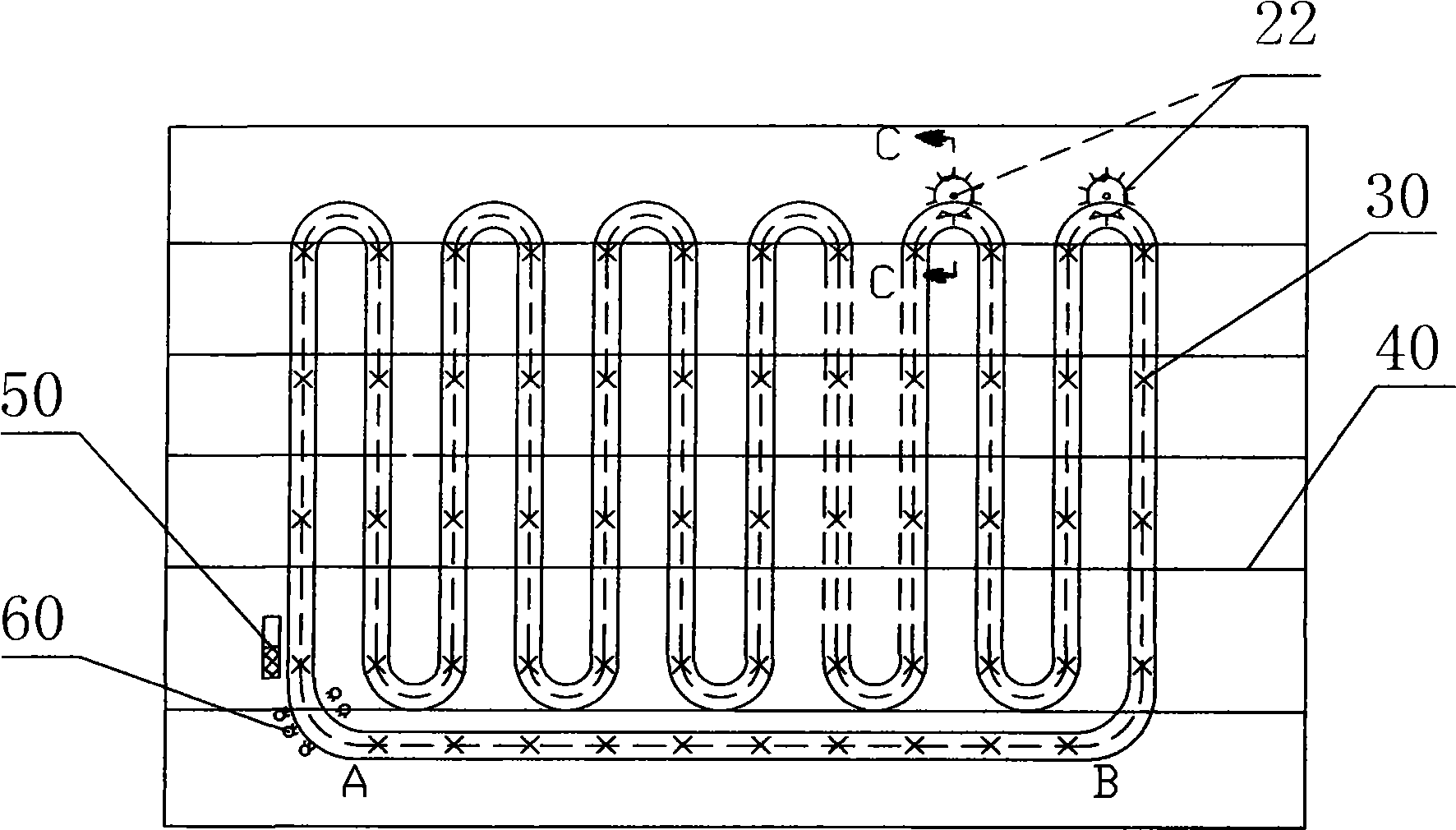

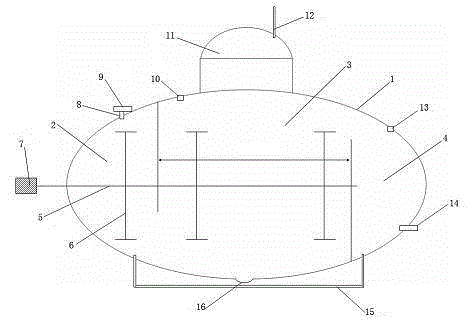

Tridimensional planting system for plants

InactiveCN101518192ARealize industrial productionAchieving Pipeline OperationsClimate change adaptationGreenhouse cultivationCropping systemHigh density

The invention relates to a plating system for plants, in particular to a tridimensional plating system for plants, which comprises a plurality of tridimensional plating units. The tridimensional plating system is characterized by also comprising a belt-shaped closed orbit and an orbit running unit, wherein the tridimensional plating units can move along the belt-shaped closed orbit by being driven by the orbit running unit. Because the belt-shaped closed orbit is adopted, each tridimensional plating unit has an opportunity to rotate to the periphery of the tridimensional plating system, thus the invention solves the problem of the insufficient lighting and the poor ventilation of high-density plating in the prior art. The invention reduces the work intensity of workers, enhances the work efficiency, saves the labor cost and the fund cost and effectively realizes the industrialized production of crops and the assembly line work of agricultural production.

Owner:田辉勤 +1

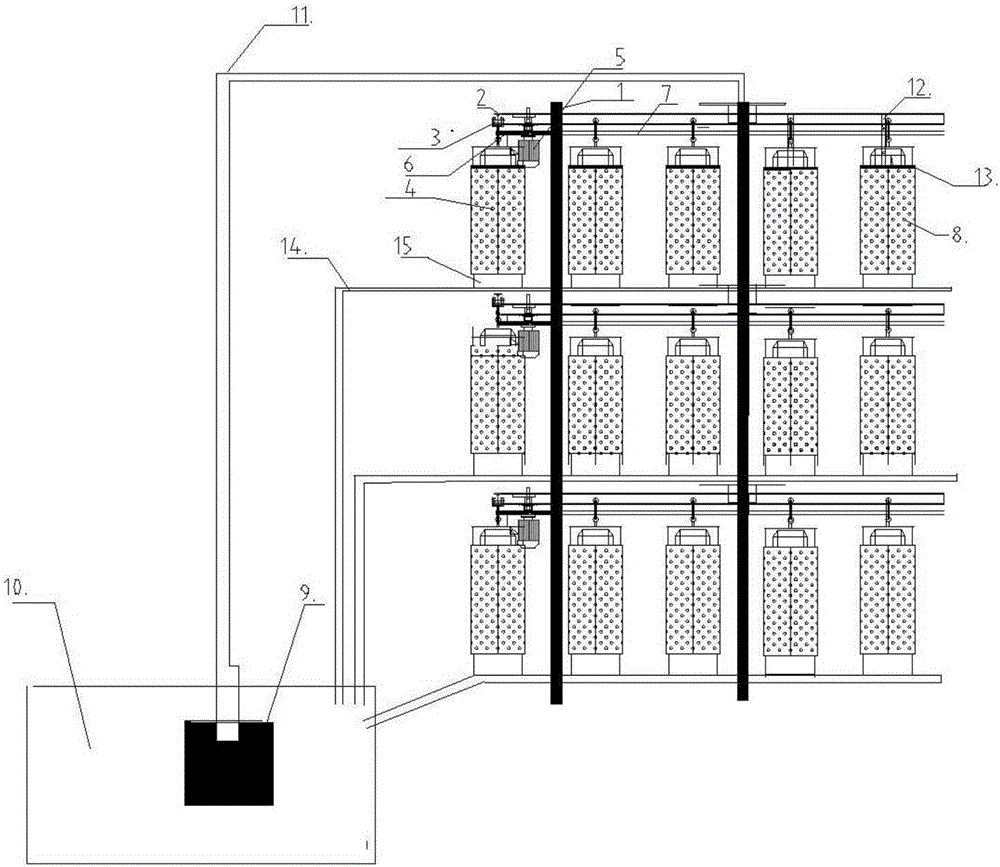

Vegetable three-dimensional planting device

InactiveCN105724225AAchieving Pipeline OperationsIncrease productionAgriculture gas emission reductionCultivating equipmentsAgricultural engineeringAssembly line

The invention discloses a vegetable three-dimensional planting device.The vegetable three-dimensional planting device comprises planters and a support device where the planters are hung.The support device is arranged into multiple layers.A plurality of planters are hung in each layer, a liquid inlet of each planter is connected with a liquid supply pipe, and a water returning groove is formed in the bottom of each planter and connected with a liquid returning pipe for conveying remaining nutrient liquid in the corresponding planter into a nutrient pond.The vegetable three-dimensional planting device achieves three-dimensional planting, the vegetable yield is increased, the vegetable quality is improved, land is saved, idle factory workshops can be utilized, operation of a factory assembly line is achieved, and production efficiency is improved.

Owner:辛海

Method for producing liquid wood integral door

The invention discloses a method for producing a liquid wood integral door, which comprises the following steps of: 1) preparing liquid wood, namely (1) drying and grinding raw materials; (2) mixing the raw materials to obtain a mixture; and (3) generating the liquid wood, wherein the liquid wood comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 40 parts of calcium carbonate, 60 parts of wood fiber powder, 4.5 parts of stabilizer, 8 parts of chlorinated polyethylene (CPE), 5 parts of acrylamide (ACR), 3 parts of H530, 0.5 part of polyethylene (PE) wax, 0.6 part of stearic acid, and 1 part of pigment; and 2) performing extrusion molding on the liquid wood at one time to obtain the integral door. In the method, the raw materials are molded at one time at a high temperature and under high pressure, do not contain formaldehyde, and are subjected to surface treatment by adopting thermal transfer technology; the integral door is free of paint, has no any toxic harmful gas and smell release in the production and use process, is environmental-friendly and has practicality.

Owner:杨华

Automatic collection type one-time forming device for perforated workpieces

InactiveCN104690154ADoes not affect workImprove work efficiencyPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an automatic collection type one-time forming device for perforated workpieces. The automatic collection type one-time forming device comprises a blanking die, a punching die and a power mechanism, the punching die and the power mechanism are positioned above the blanking die, the end face of the blanking die is provided with a cavity, and the bottom of the cavity is provided with punching holes. The punching die is matched with the cavity, and punches are arranged on an operation surface of the punching die and matched with the punching holes. The bottom of the cavity is further provided with an ejection hole, and an ejection device is arranged below the ejection hole. A sweeping device is arranged on the blanking die and comprises a supporting rod, a moving rod and a first driving mechanism. One end of the moving rod is connected with the first driving mechanism, and a brush is mounted a the other end of the moving rod; the bottom end of the supporting rod is fixed onto the end face of the blanking die, and the top end of the supporting rod is movably connected onto an axial face of the moving rod; one side, in the cavity, of the first driving mechanism is used for driving the brush on the moving rod to swing back and forth above the cavity. The automatic collection type one-time forming device for the perforated workpieces is safe, high in operation efficiency and capable of cooperate with an automatic blank conveying mechanism to realize flow line production.

Owner:WUHU JINGFENG GARDEN MACHINERY TECH

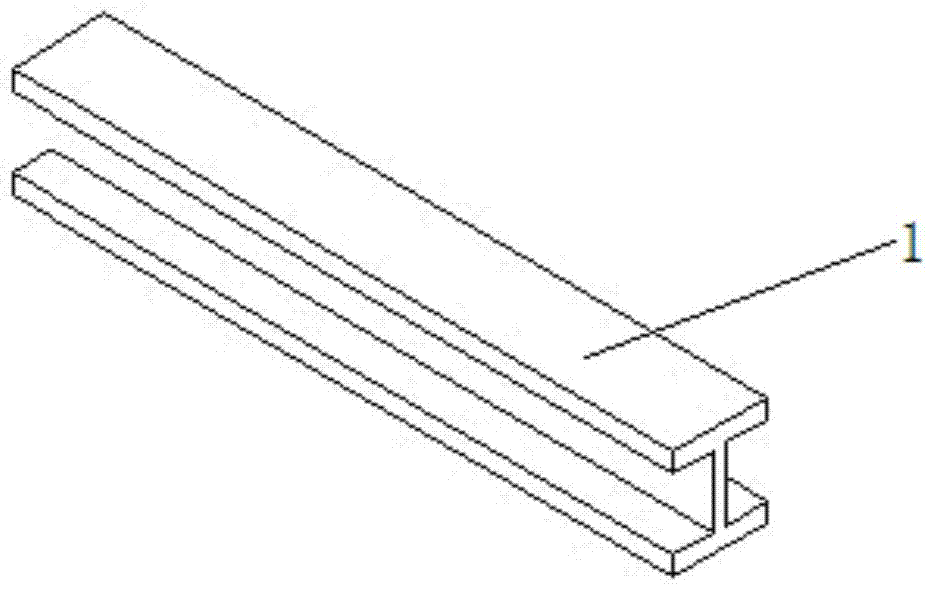

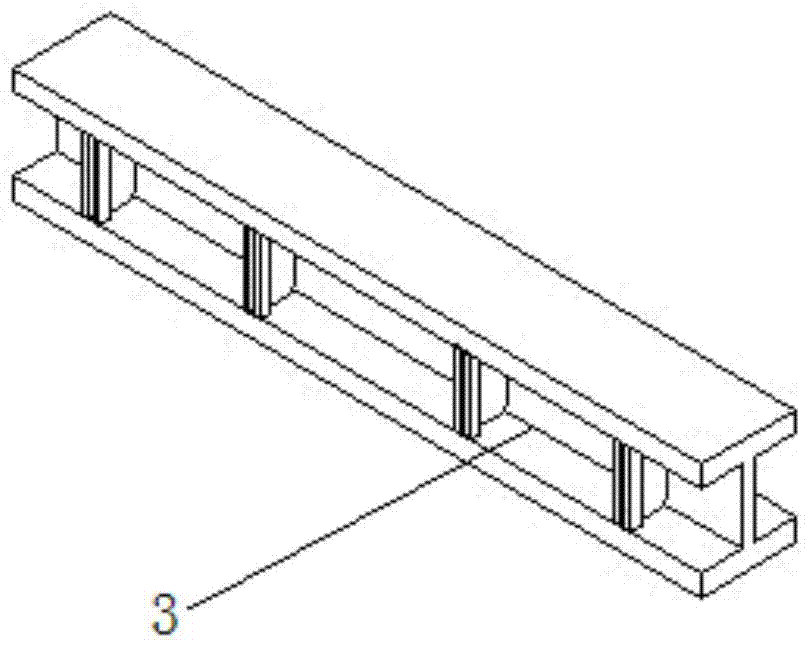

Assembling welding forming method of H-shaped steel

InactiveCN108465904ASmooth molding stepsAchieving Pipeline OperationsArc welding apparatusWelding/soldering/cutting articlesEngineeringAssembly line

The invention discloses an assembling welding forming method of H-shaped steel. The assembling welding forming method is characterized by comprising the following steps that 1, pre-assembly is performed; 2, spot welding is performed so that an H-shaped steel frame can form a preliminary whole; 3, seam abutting and full-length welding are performed; and 4, deformed workpieces after welding are straightened by an H-shaped steel straightening machine in the forward conveying process of the workpieces, so that the qualified H-shaped steel is completed. The assembling welding forming method of theH-shaped steel has the beneficial effects that the H-shaped steel adopts a horizontal placement mode during welding forming, the forming steps are smooth, and assembly line work can be realized; and at the same time, at least one pair of submerged arc welding machines are arranged on both sides of a welding transfer roller bed, and according to the working conditions of the submerged arc welding machines, the workpieces are sent to the submerged arc welding machine which is available for welding, the production cycle is compact, and the production efficiency is greatly improved.

Owner:NINGBO JINFENG WELDING & CUTTING MACHINERY MFR

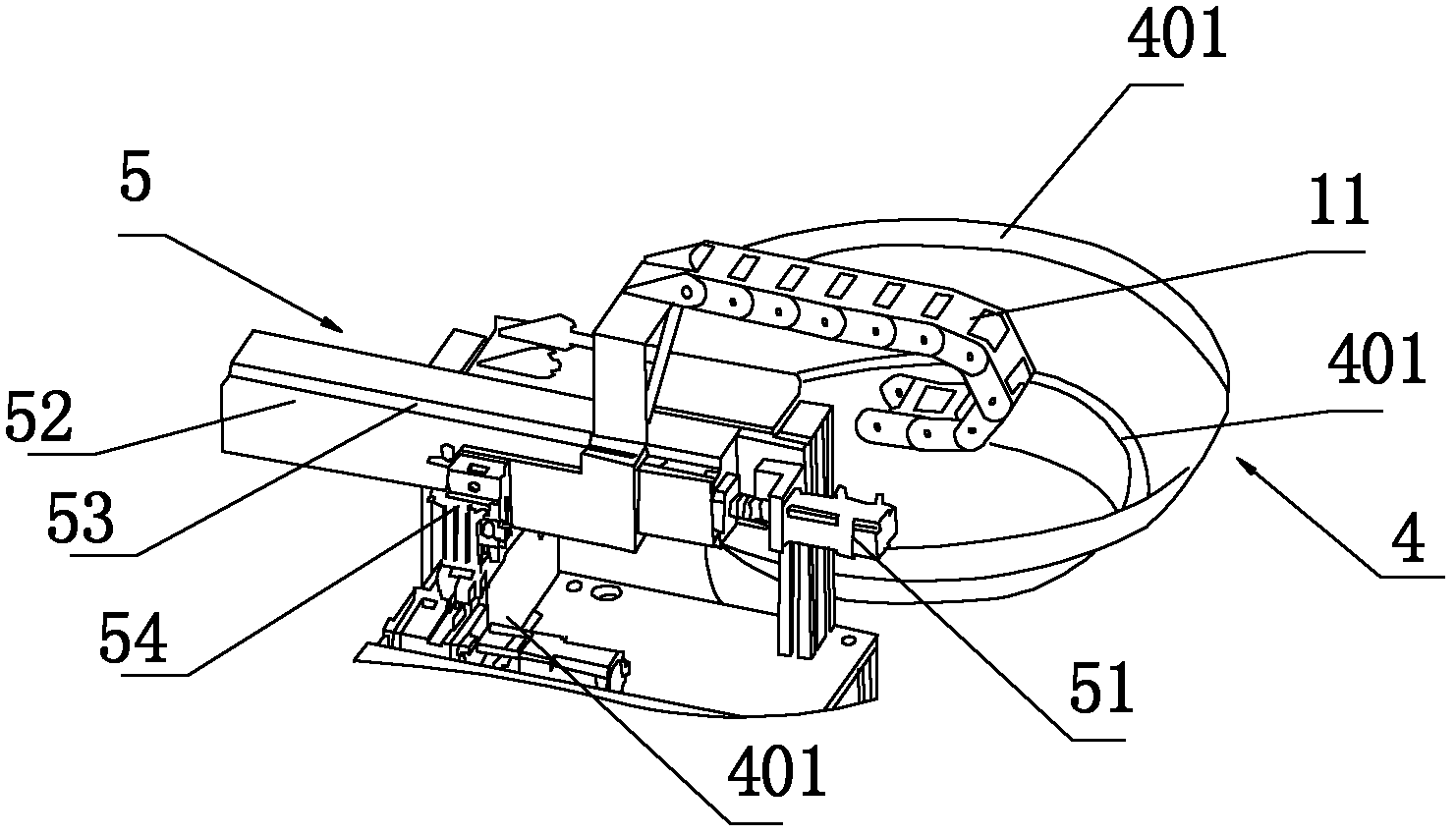

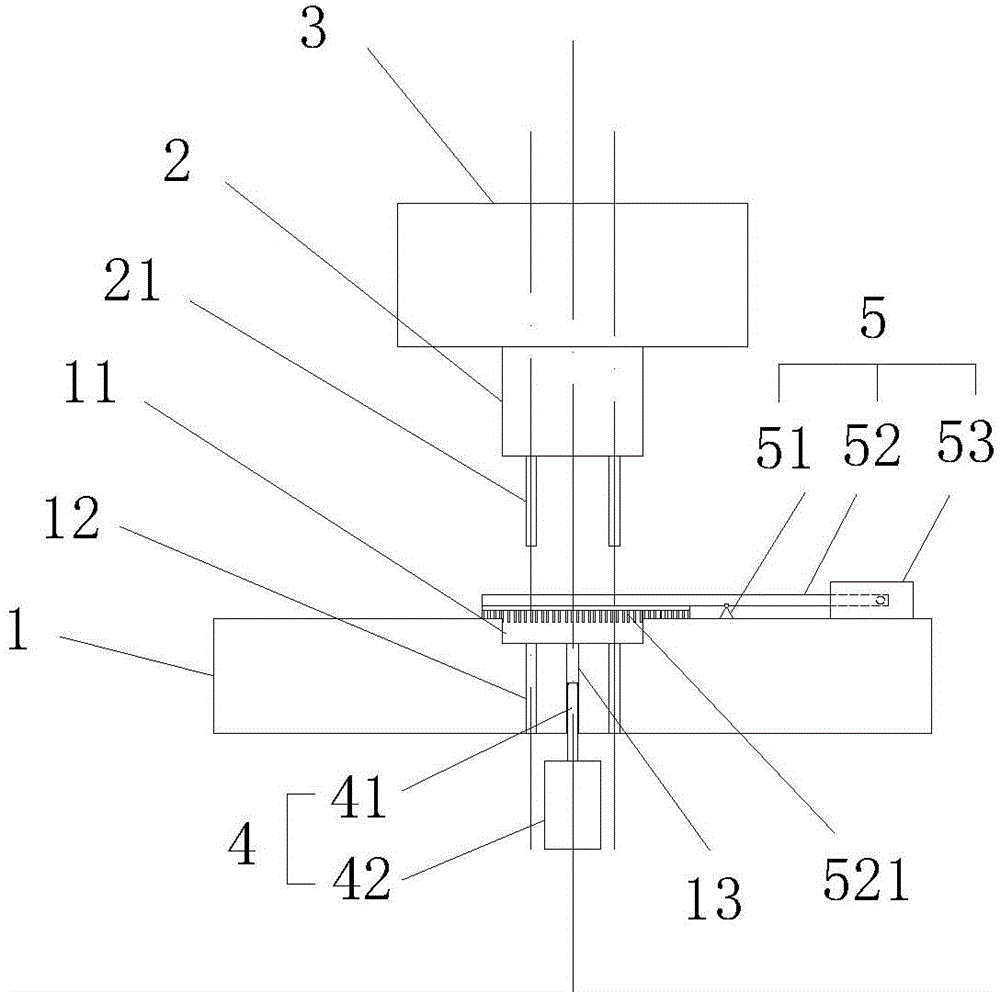

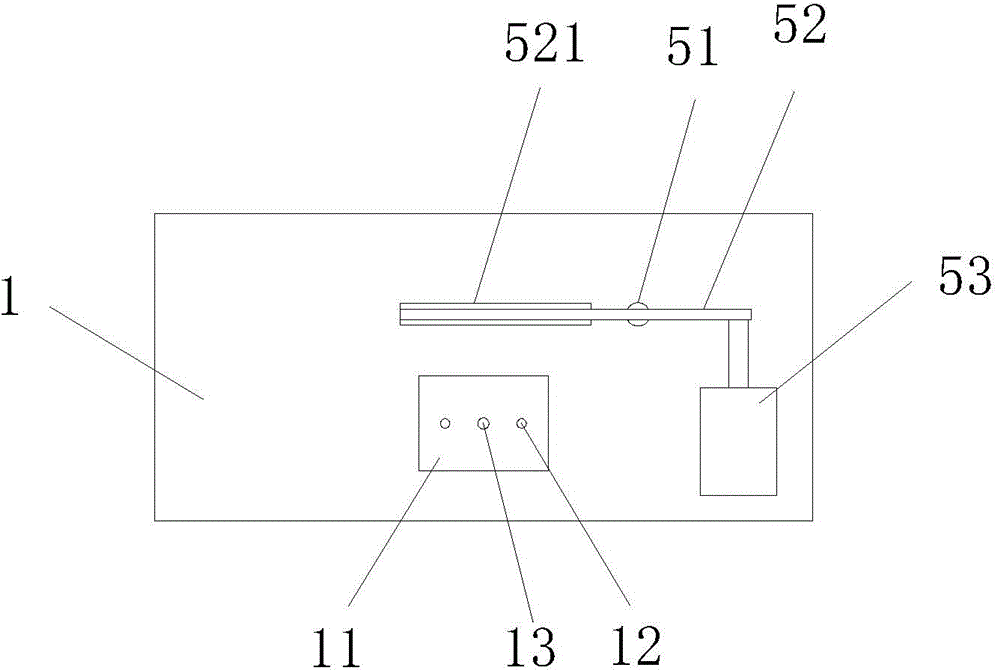

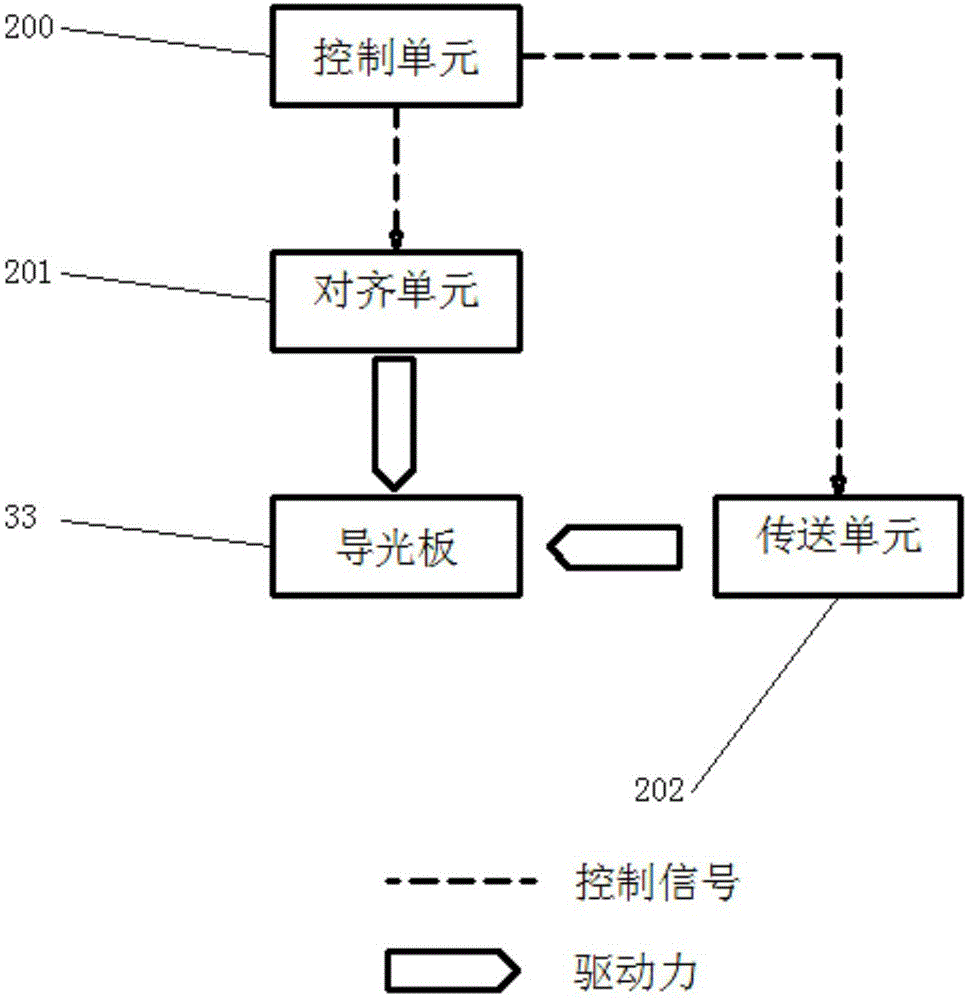

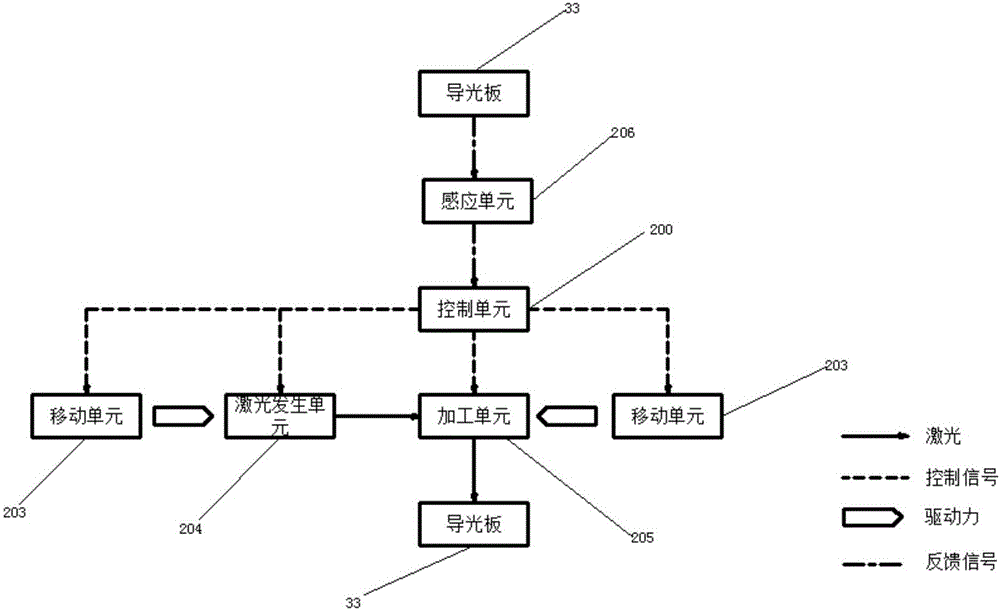

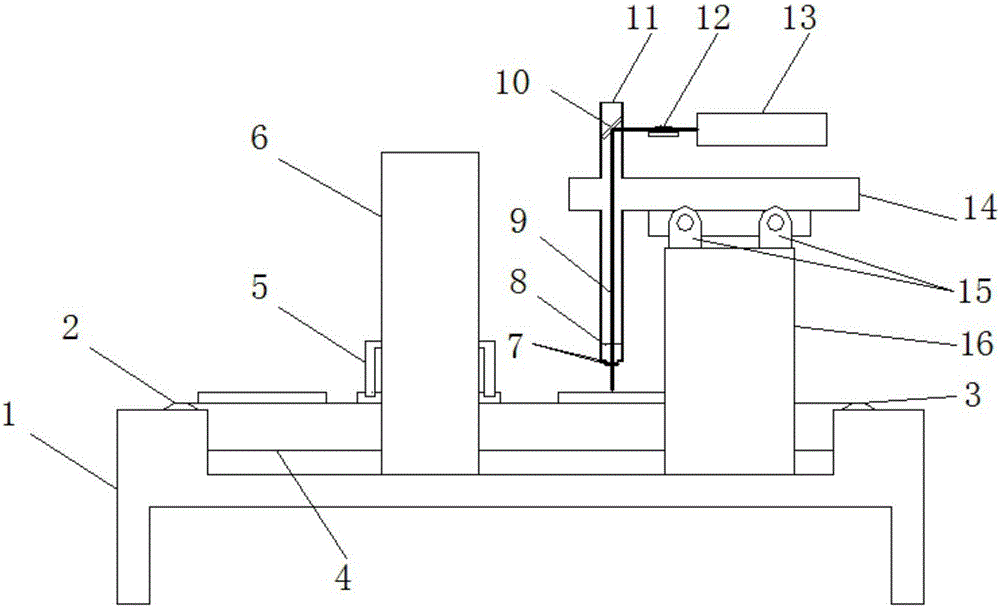

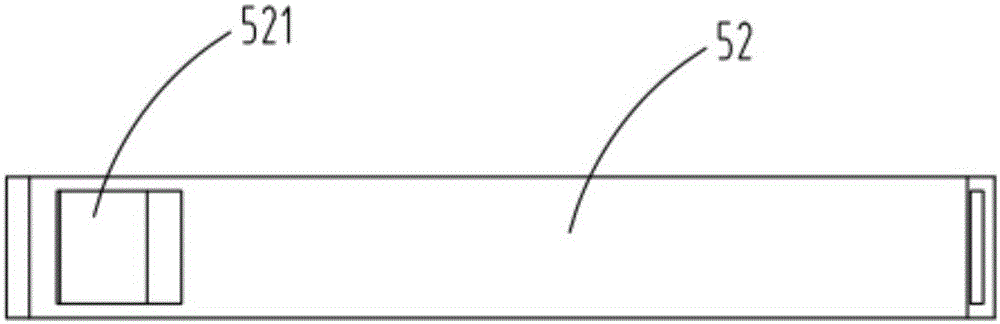

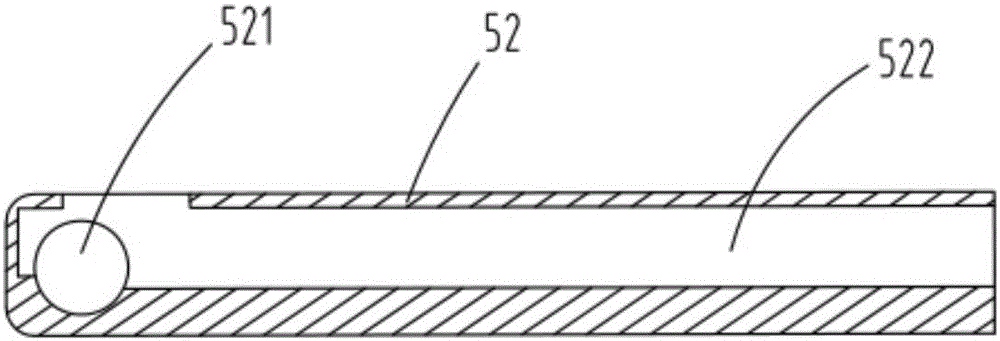

Laser precision micro machining device and method of light guide plate

ActiveCN106216849AReduce labor costsImprove efficiencyUsing subsonic/sonic/ultrasonic vibration meansLaser beam welding apparatusLight guideEngineering

The invention discloses a laser precision micro machining device and method of a light guide plate. The laser precision micro machining device comprises a laser generating unit, a moving unit, an automatic alignment unit, an induction unit and a control unit, wherein the laser generating unit is used for generating laser required by machining; the moving unit is used for conveying the light guide plate required by machining; the automatic alignment unit is used for adjusting the position of the light guide plate required by machining; the induction unit is used for locating the light guide plate required by machining; and the control unit is used for controlling the laser generating unit, the moving unit, the automatic alignment unit and the an induction unit in a laser machining process. According to a dotting device of the light guide plate by utilizing laser, the light guide plates of different sizes can be machined by virtue of a full-automatic system, the machining precision and the machining efficiency of the light guide plates are greatly improved, and the defective rate of machined parts is effectively reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Large-scale cultivation method for Guangdong fruiting bodies of cordyceps military

The invention relates to the technical field of cultivation of fruiting bodies of cordyceps military, in particular to a large-scale cultivation method for Guangdong fruiting bodies of cordyceps military. The large-scale cultivation method includes the steps: A, distribution; B, preparation of strains including B1, slope strains, B2, shake flask strains and B3 fermented strains; C, inoculation and mycelium culture; D, fruiting body culture; and E, recovery. The deep fermented strains replace existing multistage shake flask strains and are high in hyphae vigor, mycelium pellets are fine in size uniformity, inoculation can be performed by an automatic inoculation machine or manual spraying in a sterile environment, assembly line operation is realized, inoculation amount is stable, each bottle is 40-60mL, spraying is uniform, hyphae rapidly sprout, contamination rate is reduced, fruiting body coming time is 3-5 days shorter than that of the prior art, the whole production cycle is shortened by about 10 days, and labor and raw material costs can be saved as compared with shake flask strain inoculation in the prior art.

Owner:韶关市星河生物科技有限公司 +2

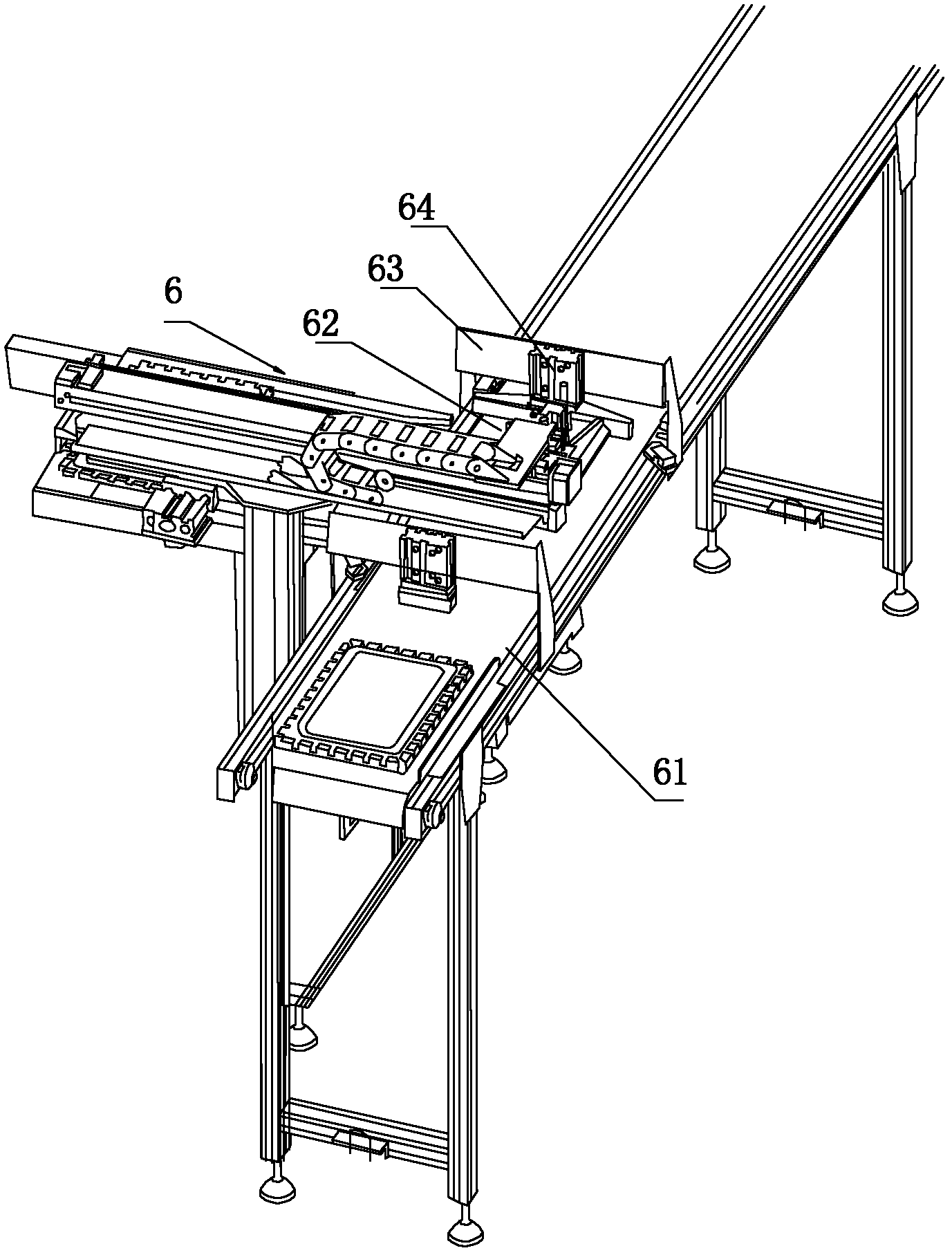

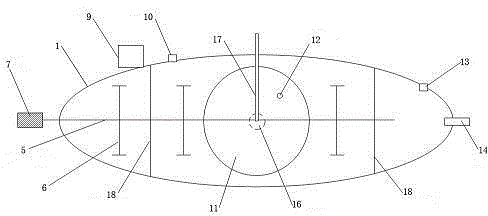

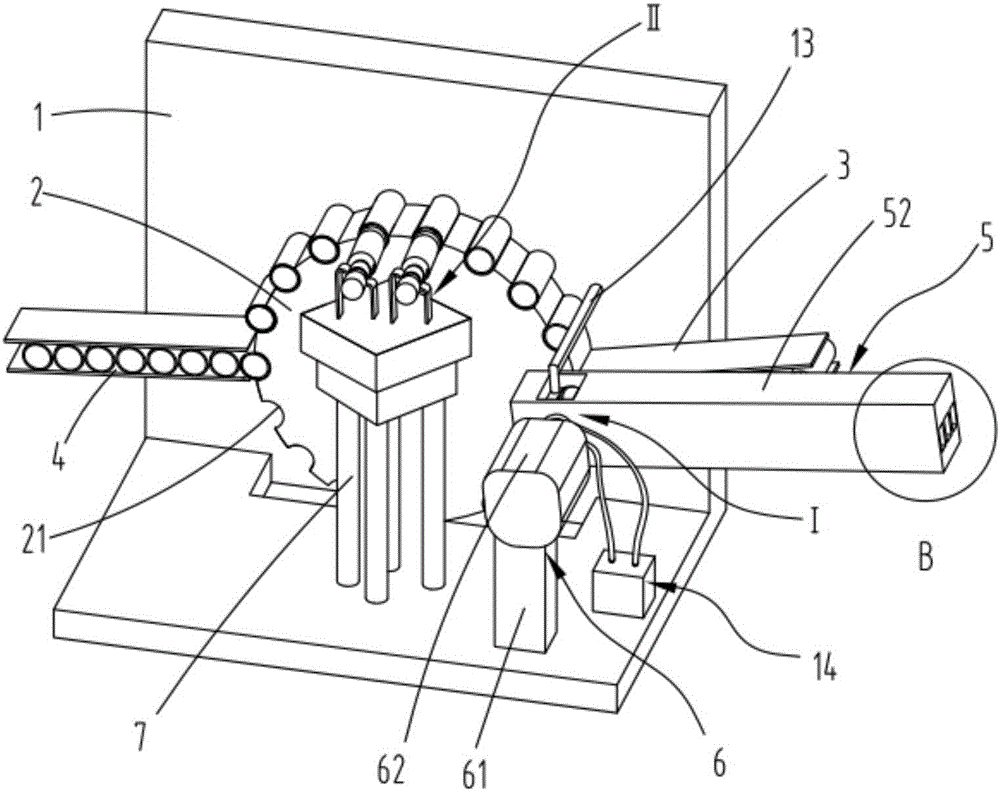

Sample delivery system for chemiluminescence instrument

ActiveCN107389965AImprove the sampling methodRealize continuous sample loadingMaterial analysisAutomatic controlElectric machinery

The invention relates to a sample delivery system for a chemiluminescence instrument. A loading delivery mechanism has a second micro-switch for automatically controlling the starting of the loading delivery mechanism, a pair of first micro-switches are used to monitor whether a test tube rack is located at a desired position or is inclined, an L-shaped pushing rod structure is driven by a servo motor and can push the sample tube rack to transversely move forward along the X direction in a sample treatment zone, a sample release communication structure is provided with a forth micro-switch for detecting whether the test tube rack is driven to a desired position through the L-shaped pushing rod structure, the forth micro-switch controls starting of a sample release conveyer belt mechanism, and the sample release conveyer belt mechanism for conveying the test tube rack along the -Y direction and a third micro-switch for detecting whether the test tube rack is released to the desired position are arranged in a sample release zone. The sample delivery system has a high loading automation degree, realizes line work with other devices, utilizes the multiple micro-switches and has a high control precision.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Method for producing high-macroelement liquid organic special fertilizer

InactiveCN104692847AFull of nutritionIncrease contentBio-organic fraction processingOrganic fertiliser preparationFiltrationSlag

The invention relates to a method for producing a high-macroelement liquid organic special fertilizer. The method comprises the following steps: selecting raw materials, pretreating the raw materials, performing anaerobic fermentation, performing slag-liquid separation, performing oxygen exposure filtration, mixing and blending and performing refined filtration filling. The content of the macroelement is improved to a high level, and the topdressing problem of organic cultivation is solved; and moreover, the production efficiency is high, the cost is low, and the problems that waste of biogas slurry and sewage is severe even the environment is polluted are solved.

Owner:王本明

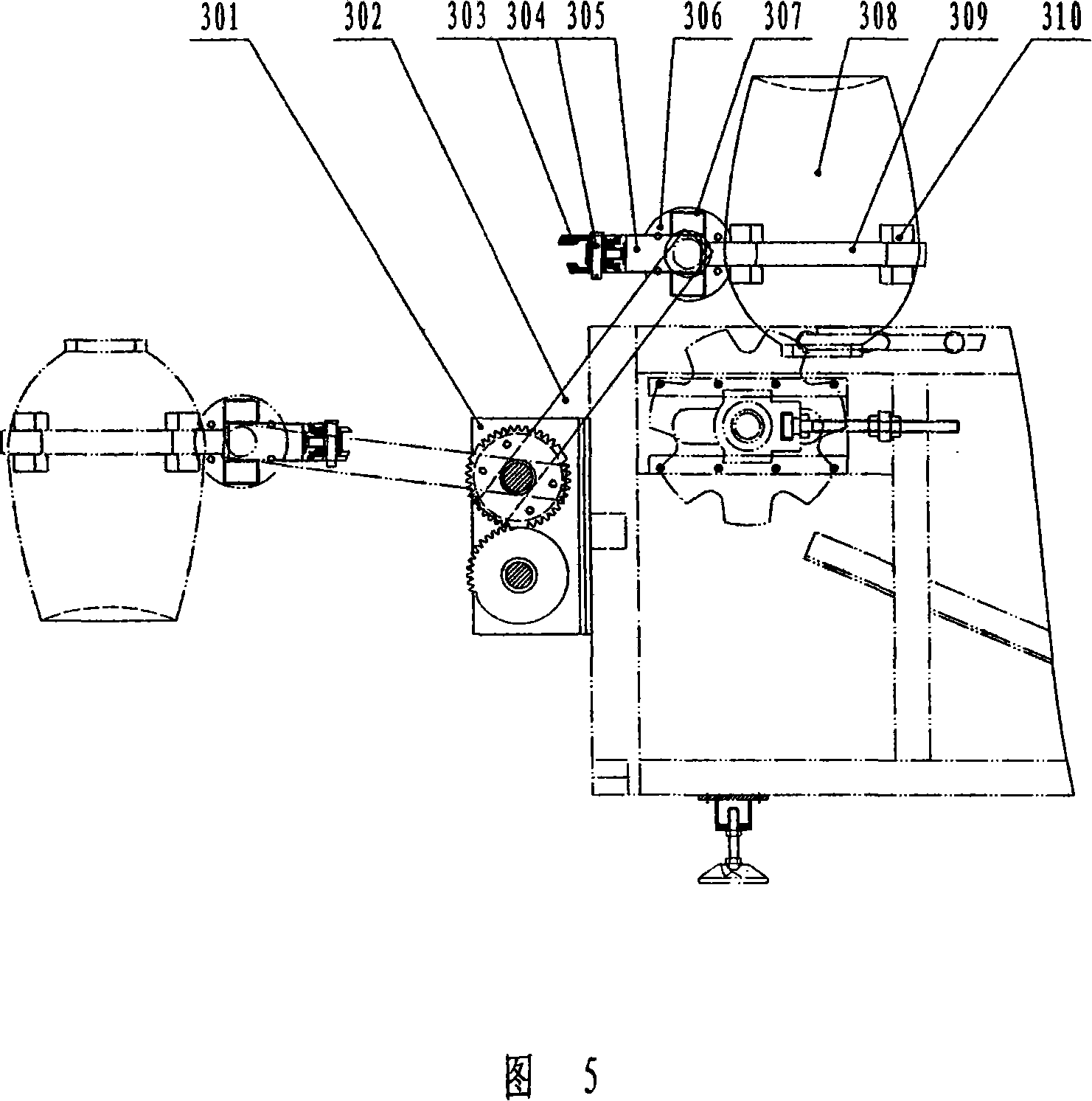

Lime water smearing device for outer walls of wine jars

ActiveCN104907228AAchieving Pipeline OperationsRealize individual workPretreated surfacesCoatingsBrush deviceMechanical engineering

The inventionrelates to the technical field of white spirit processing and in particular relates to a lime watersmearing device for outer walls of a wine jars. The device comprises a conveying device, a lime water brushing device, a water tank and a drying device, wherein rolling wheels are arranged on theconveying device andare divided into a front group of rolling wheelsand a rear group of rolling wheels; a track is arranged onthe front group of rolling wheels; a certain distance is reserved between the front and rear groups of rolling wheelsand is slightly largerthan themaximum diameter of wine jarsto be washed; the conveying device is used for conveying the wine jars; the lime water brushing device is positioned between the front and rear groups of rolling wheelsand is used for uniformly coating the outer walls of the wine jars with lime water; the water tank is positioned right below the lime water brushing device and is filled withthe lime water; the drying device is positioned above the rear group of rolling wheels and is used for stoving the outer walls of the wine jars. By using the device, the processes of automatically coatingthe outer wall of the wine jars with the lime water andautomatically stoving the outer walls of the wine jars can be realized; the damage of the wine jars can be detected so thatthe damaged wine jars can be treated in real time, so that the loss is reduced.

Owner:湖南省鼎谷一酒业有限公司

Numerical control equipment

InactiveCN102941512AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersNumerical controlClosed loop

The invention provides numerical control equipment, wherein a main supporting frame is in a closed loop structure of which the opening faces the vertical direction; an X forward guide rail and an X backward guide rail which are matched with each other are arranged between the main supporting frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod; the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; a rotation stopping structure for preventing the Z-direction guide rod from rotating along the horizontal direction of the axis of the guide rod is also arranged; the rotation stopping structure comprises a third rotation stopping block, a fourth rotation stopping block, a third spring and a limit mechanism; an accommodation groove is formed in the top part of the Z-direction guide rod; the limit mechanism limits the third rotation stopping block and the fourth rotation stopping block to move in the setting range of the accommodation groove; a rotation stopping groove is formed in a guide hole matched with the Z-direction guide rod; the third spring is installed between the third rotation stopping block and the fourth rotation stopping block; and the third rotation stopping block protrudes from the outer periphery of the Z-direction guide rod and is matched with the rotation stopping groove. The numerical control equipment has the advantages that when a main processing head moves up and down, the stability is good and the imbalance torsion is not easy to generate.

Owner:杨东佐

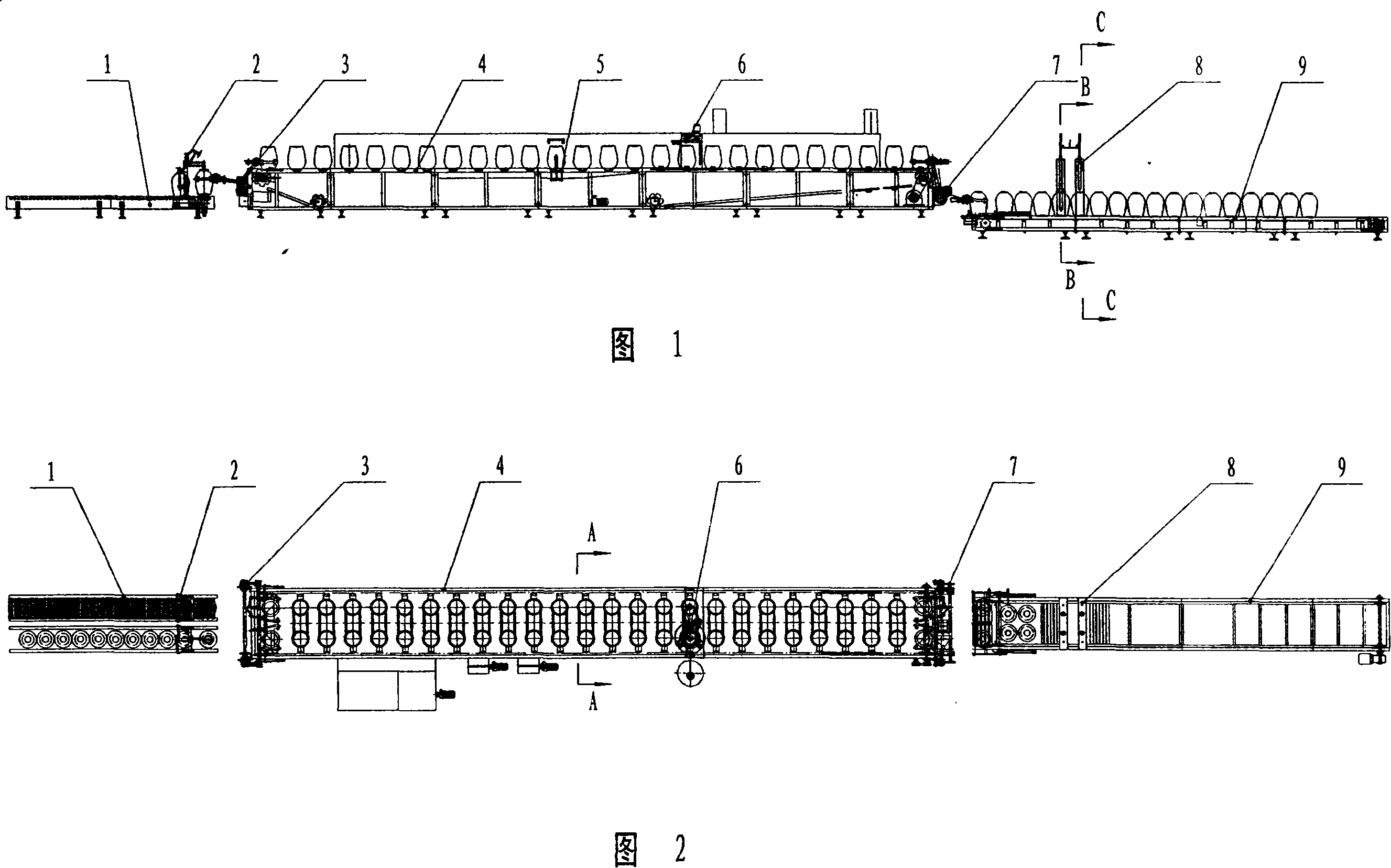

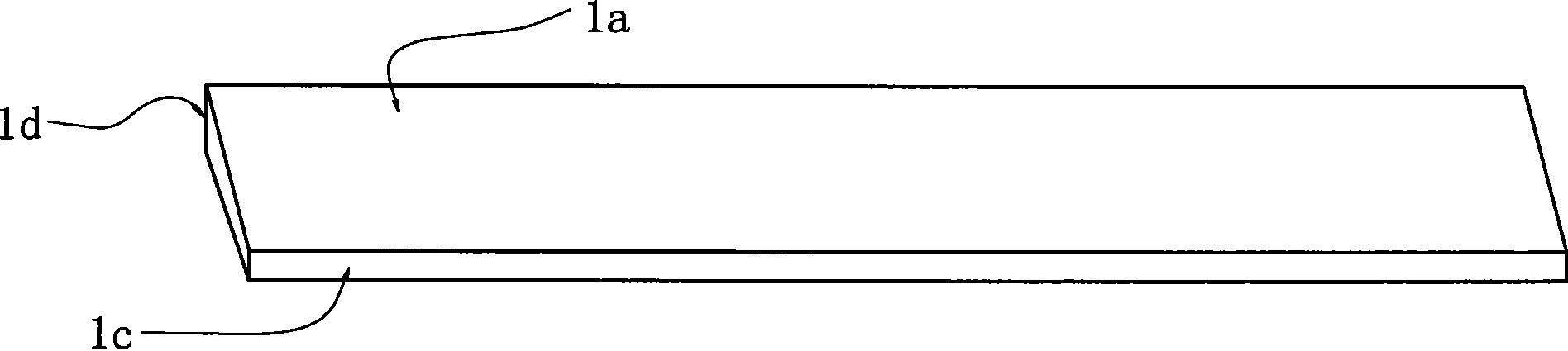

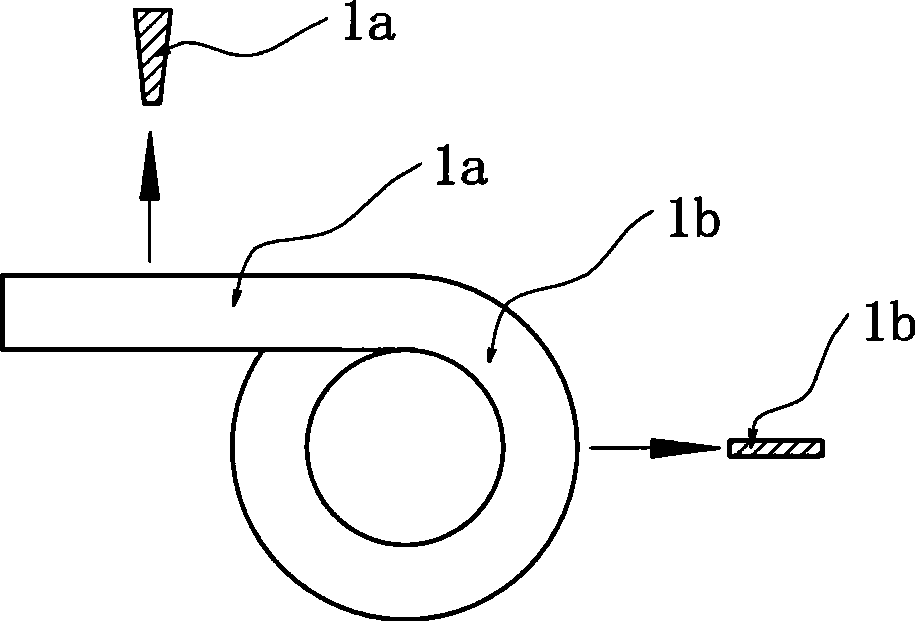

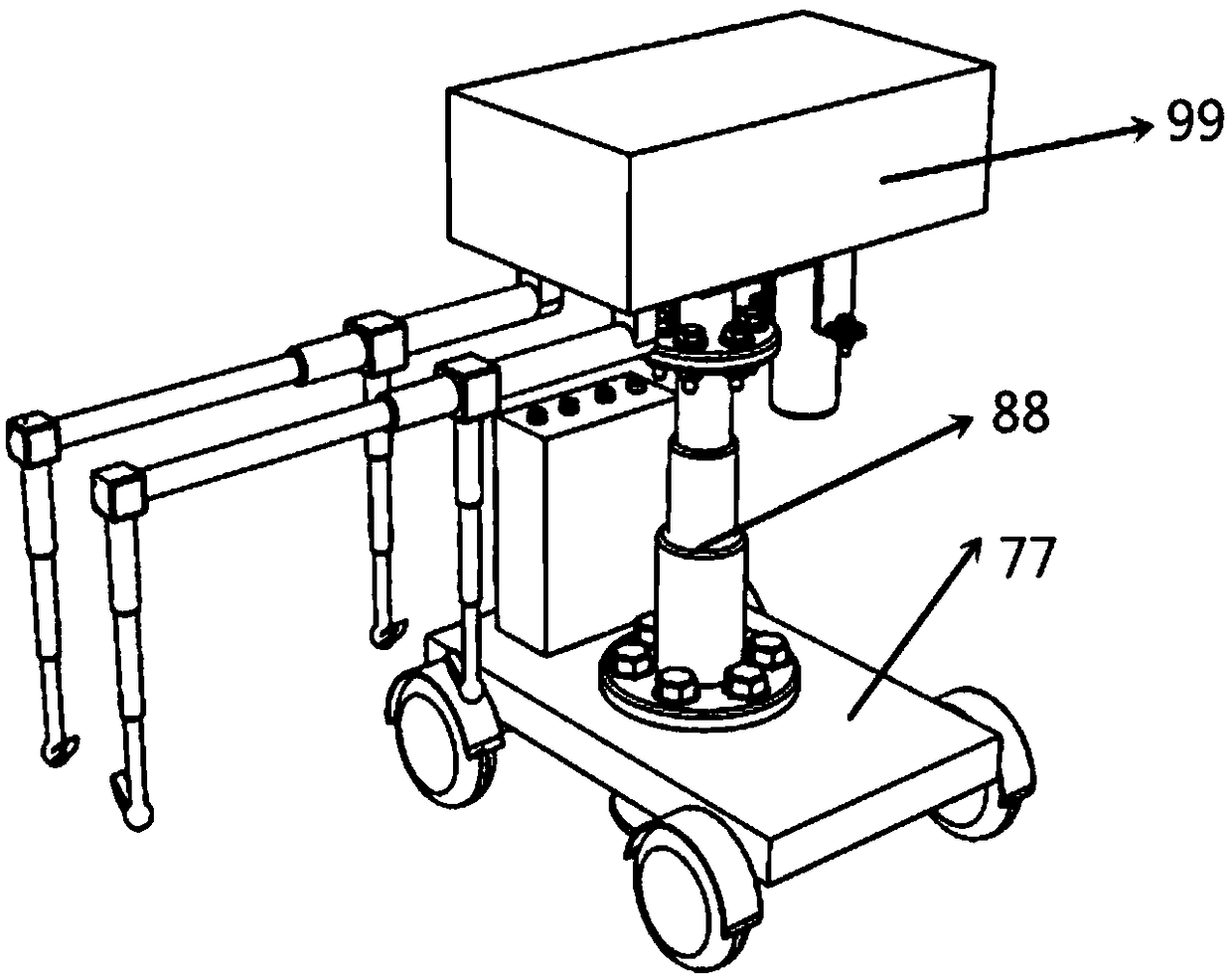

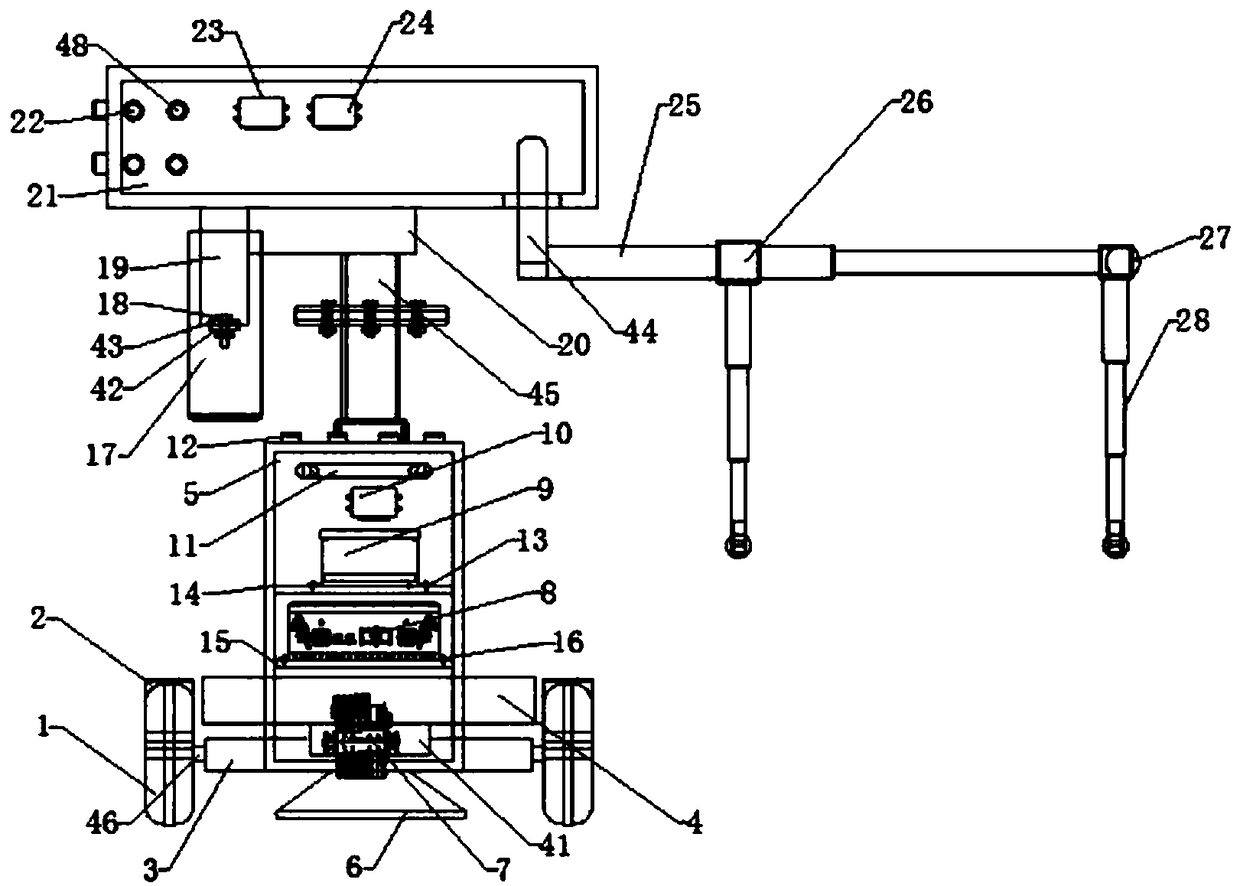

Manufacturing equipment and manufacturing method for flexible metal tube

ActiveCN104014864ASmall footprintAchieving Pipeline OperationsTube shearing machinesAssembly linePulp and paper industry

The invention provides manufacturing equipment and a manufacturing method for a flexible metal tube. The manufacturing equipment comprises a tube making machine body, a cutting machine body, a suspension portal frame and a PLC control cabinet, wherein the tube making machine body is connected with the cutting machine body, and the cutting machine body is connected with the suspension portal frame. The tube making machine body comprises a tube making machine, a zero material halt warning device, a raw material connecting device and a material tray support, wherein the material tray support is provided with the zero material halt warning device, and the raw material connecting device is connected with the input end of the tube making machine. The cutting machine body comprises a cutting machine and a first air cylinder, wherein the first air cylinder is connected with the PLC control cabinet, the cutting machine is connected with the first air cylinder, and the suspension portal frame is provided with an overturn rail. The manufacturing equipment is small in occupied space, improves the production capacity, achieves assembly line work, greatly lowers labor cost and increases benefits.

Owner:刘仰柯

Intelligent folding packaging line

PendingCN111392154AFolded surface is flatRealization of horizontal foldingWrapper twisting/gatheringEngineeringAssembly line

The invention provides an intelligent folding packaging line. The intelligent folding packaging line comprises a conveyor line for conveying clothes from a feeding end to a discharging end, and a conveyor belt of the conveyor line includes a plurality of conveying strips arranged at intervals; a transverse folding mechanism used for folding the clothes along the width direction, wherein the transverse folding mechanism comprises a first pressing component and a transverse folding component, the first pressing component can press one part of the clothes along the length direction of the clothes, and the transverse folding component can fold the clothes along the width direction; and a longitudinal folding mechanism used for folding the clothes along the length direction, wherein the longitudinal folding mechanism comprises a second pressing component and a longitudinal folding component, the second pressing component can press one part of the clothes along the width direction of the clothes, the longitudinal folding component comprises a second drive member, a second rotating shaft connected with the second drive member, and at least two folding levers fixed on the second rotating shaft, wherein the second drive member can drive the folding levers to pass through the gap of the conveying strips to flip upwards to fold the clothes. The intelligent folding packaging line providedby the invention can be continuously operated in an assembly line and has high folding efficiency.

Owner:苏州迅益科系统科技有限公司

One-time stamping forming mold for ball pocket of holder

ActiveCN105689591AEven by forceNot easy to damagePerforating toolsBearing componentsPunchingEngineering

The invention relates to a one-time stamping forming mold for a ball pocket of a holder. The one-time stamping forming mold comprises a base, a main sliding body, an inner mold, outer molds and a shrink sleeve. The main sliding body is arranged inside the base vertically; the main sliding body is sleeved with the inner mold, and a plurality of outer molds are evenly arranged on the base in the circumferential direction; the outer molds are all arranged outside the inner mold; the shrink sleeve is arranged on the upper portions of the outer molds in a sleeving mode; a plurality of punches are evenly arranged on the side wall of the inner mold in the circumferential direction; and limiting grooves are formed in the inner walls of the outer molds. A first spring is placed horizontally inside each punch; a kidney-shaped hole is formed in the upper portion of each punch; a plurality of pin holes are evenly formed in the upper end face of the inner mold; and a plug pin is arranged inside each pin hole. According to the one-time stamping forming mold for the ball pocket of the holder, the diameter variation of the main sliding body is utilized to push the punches to move radially in a divergent way along the main sliding body, so that multiple holes are punched in the ball pocket of the holder at a time; through the elastic effect of the first springs arranged inside the punches, automatic resetting of the punches after the completion of the punching is achieved. The mold is simple, punching is stable and highly precise, and automation and flow line operation can be easily achieved.

Owner:ZHEJIANG GUNAI RUBBER & PLASTIC SCI & TECH

Equipment with functions of concurrently enabling carbon rings to enter steel shell and coating sealing agent quantitatively

The invention relates to equipment with functions of concurrently enabling carbon steels to enter a steel shell and coating a sealing agent quantitatively. The equipment comprises an equipment table, a rotary plate, a feeding channel, a mechanism for enabling the corresponding carbon rings to enter the corresponding steel shell, a mechanism for coating the sealing agent, and a discharging channel, wherein the feeding channel and the discharging channel are correspondingly arranged along the feeding direction and the discharging direction of the rotary plate respectively; the mechanism for enabling the corresponding carbon rings to enter the corresponding steel shell comprises a carbon ring conveying mechanism and a material-pushing mechanism; the carbon ring conveying mechanism comprises a carbon ring material-dividing tray and a carbon ring conveying channel; three mutually-independent through slots are formed in the carbon ring conveying channel in parallel; the mechanism for coating the sealing agent comprises a fixed base, a flow adjustment mechanism, spin-coating mechanisms and a transmission mechanism; the spin-coating mechanisms are positioned on the edges of the corresponding clamping grooves, and mounted at the front end part of the flow adjustment mechanism; and the transmission mechanism drives the spin-coating mechanisms to move left and right through the flow adjustment mechanism. According to the equipment, the mechanism for enabling the corresponding carbon rings to enter the corresponding steel shell and the mechanism for coating the sealing agent are designed into one body, so that the non-working-procedure waiting time among the working procedures is reduced; the way of enabling the corresponding carbon rings to enter the corresponding steel shell is optimized; and continuous and uniform coating is realized.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Middle packaging machine

ActiveCN102649485BCompact structureFast sealing and cuttingWrapper twisting/gatheringPackaging machinesProduction linePlastic packaging

The invention relates to a plastic packaging machine, in particular to a middle packaging machine for packaging sanitary products, such as sanitary towels, paper diapers, toilet paper and the like. The middle packaging machine comprises a material feeding streamline, a packaging bag conveying line and a packaging bag sealing and cutting machine, wherein the material feeding streamline, the packaging bag conveying line and the packaging bag sealing and cutting machine are connected in sequence; and the middle packaging machine further comprises a push rod mechanism for pushing products from the material feeding streamline to the packaging bag sealing and cutting machine. The middle packaging machine can be abutted against sanitary towel and diaper manufacturing equipment of the upper stage so as to form a full-automatic production line, so that the production efficiency is increased; the packaging bag conveying line can be used for realizing multi-layer packaging, so that requirements on different specifications of packaging are satisfied; the sealing and cutting machine can be used for rapidly sealing and cutting the packaging bags with good effects; the middle packaging machine provided by the invention has the advantages of compact structure, manpower cost conservation and capability of continuously working; the streamline operation is achieved in the whole packaging process; the production efficiency is increased; and uniform packaging quality is guaranteed.

Owner:JINJIANG HAINA MACHINERY

Compartment drying production line and conveying system thereof

InactiveCN105600409AReduce energy consumptionExtended service lifeConveyor partsEngineeringEnergy consumption

The invention discloses a compartment drying production line and a conveying system thereof. The conveying system comprises a roller bed with a preset height, wherein a sliding sled is placed on the roller bed, and a workpiece to be conveyed is arranged on the sliding sled; the conveying system also comprises an adaptor assembly, and the adaptor assembly comprises a sliding joint ring mounted on a conveying chain in a sliding mode, a connecting rod mounted at the lower end of the sliding joint ring and a first hook and a second hook which are arranged on the connecting rod; a first hanging ring detachably connected with the first hook in a hanging mode and a second hanging ring detachably connected with the second hook in a hanging mode are mounted on the sliding sled. In this way, in the operating process of the conveying system, the roller bed does not need to enter a drying chamber; compared with the prior art, heat required for heating the roller bed is avoided, so that energy consumption is lowered, the roller bed is prevented from undergoing repeated heat expansion and cold shrinkage, and then the service life of the roller bed is prolonged; meanwhile, since the roller bed does not enter the drying chamber, the space occupation area of the drying chamber and a storage region is reduced, and production cost is lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Table board used for automatic stacking of ultrahigh-voltage iron core

PendingCN110783092AReasonable structural designEasy to operateInductances/transformers/magnets manufactureWork benchesEngineeringAssembly line

The invention relates to a table board used for automatic stacking of an ultrahigh-voltage iron core. The table board comprises supporting legs which are arranged in parallel at intervals. Two ends ofeach supporting leg are provided with cross beams vertical to the supporting leg respectively. Transverse sliding rails are fixedly installed on the two cross beams respectively. Vertical fixed beamsare fixedly installed in the middle of upper surfaces of the two transverse sliding rails at the same time, the vertical fixed beam is vertical to each transverse sliding rail, two sides of the uppersurfaces of the two transverse sliding rails are provided with vertical sliding long beams, and the two vertical sliding long beams oppositely or reversely slide along the transverse sliding rails with the vertical fixed beam as a center line. In the invention, the vertical sliding long beams oppositely or reversely slide through two sets of transmission devices, and the table board is suitablefor iron core lamination operation of different sizes and types; through a door-frame-shaped structure formed by cross beam supporting legs, an air cushion vehicle can conveniently lift and convey thetable board inside and outside a workshop, and operation with an automatic hydraulic turnover mechanism of an automatic lamination stacking machine can be realized so as to achieve assembly line work; and work efficiency and finished product quality are greatly improved.

Owner:WUXI PUTIAN IRON CORE CO LTD

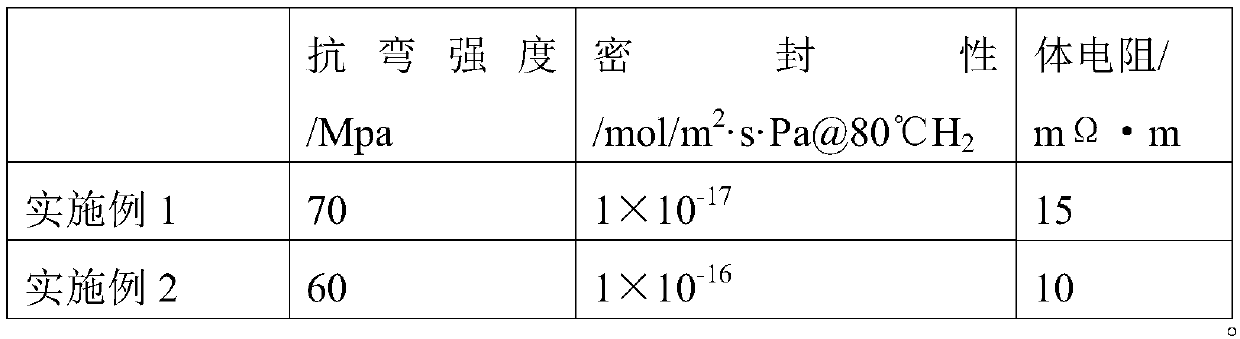

Fuel cell pole plate forming method based on expanded graphite

The invention relates to a fuel cell pole plate forming method based on expanded graphite. The fuel cell pole plate forming method comprises the following steps of (1) powder vacuum impregnation, wherein putting raw material powder of a fuel cell graphite plate into a reaction kettle, vacuumizing and maintaining for 10-30 minutes, and injecting the liquid resin under the condition that the vacuumcondition is not released, so that the raw material powder can be completely immersed; fully mixing and releasing the vacuum to obtain a wet material for later use; (1) preparing a plate, wherein preparing the wet material into an expanded graphite plate through an extrusion method; (3) cutting and forming; and (4) curing. Compared with the prior art, the substrate prepared by the fuel cell pole plate forming method has the advantages of being conductive, high in strength, good in sealing performance and the like.

Owner:SHANGHAI SHENLI TECH CO LTD

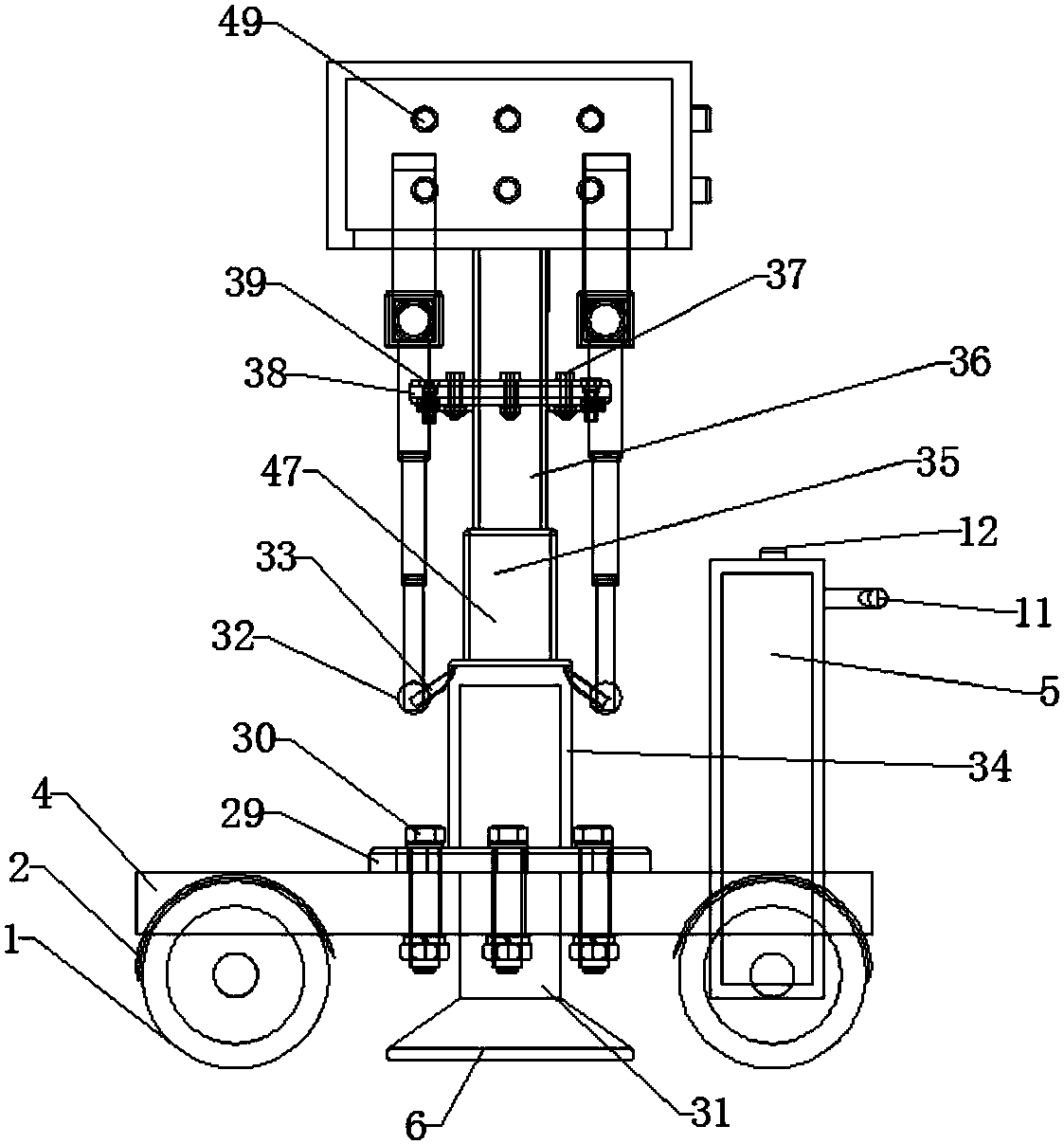

Electric multidirectional general-purpose manipulator

ActiveCN108237518AReduce in quantityFully automatedProgramme-controlled manipulatorGripping headsGeneral purposeControl system

The invention discloses an electric multidirectional general-purpose manipulator. The manipulator comprises a trolley electric control system, an oil pump lifting system and a pneumatic left-right lifting system. The trolley electric control system comprises wheels, wheel hoods, an axle, a bottom plate, a mounting cabinet, a thousand pounder and a motor. The oil pump lifting system comprises an oil pump oil cylinder, an oil pump fixing support, an oil pump lifting rod and a base. The pneumatic left-right lifting system comprises a combined control cabinet, a pneumatic telescopic rod connectingrod mechanism, a horizontal telescopic rod, vertical telescopic rods and hanging hooks. The exterior of the combined control cabinet is mechanically connected with a supporting plate, and the interior of the combined control cabinet is connected with the pneumatic telescopic rod connecting rod mechanism. Through the synergistic effect of the three combined systems which are the trolley electric control system, the oil pump lifting system and the pneumatic left-right lifting system, the manipulator achieves multidirectional and multi-degree-of-freedom carrying, loading and unloading of objects, and is flexible, changeable, convenient to operate and high in safety.

Owner:ANHUI ANKAI AUTOMOBILE

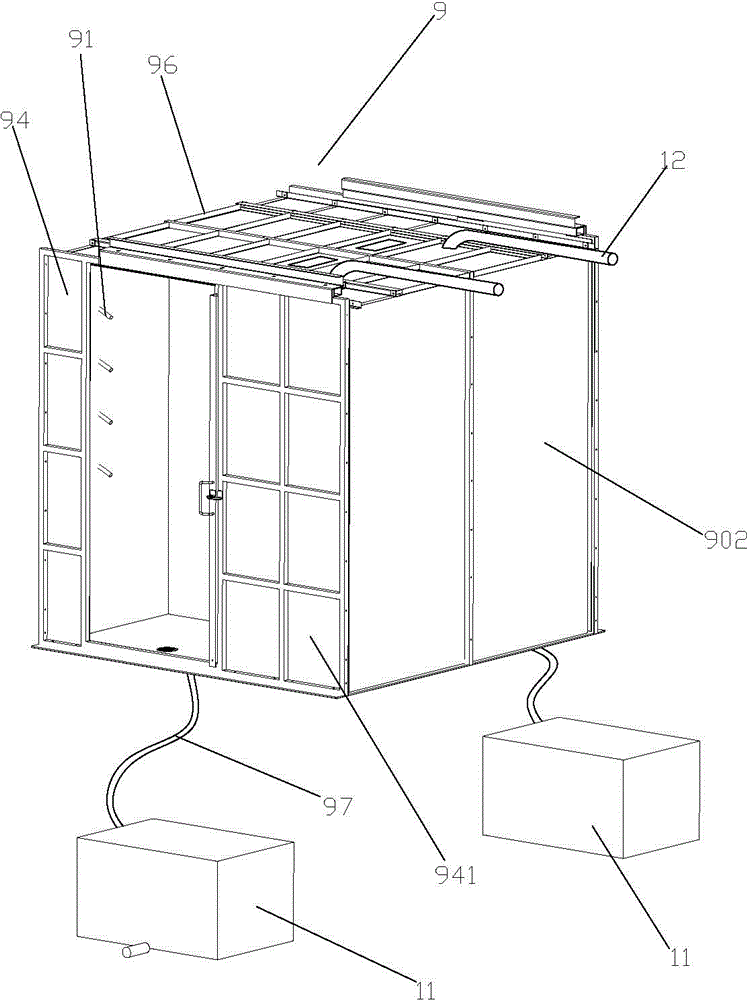

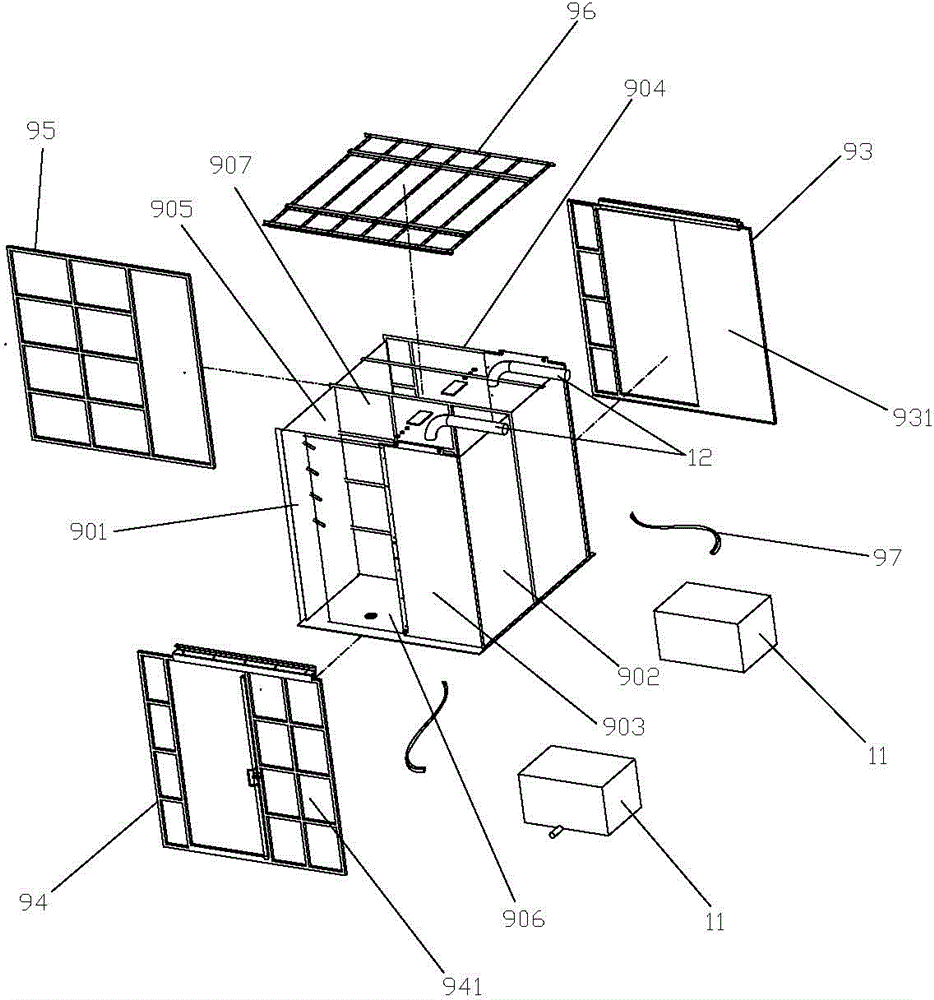

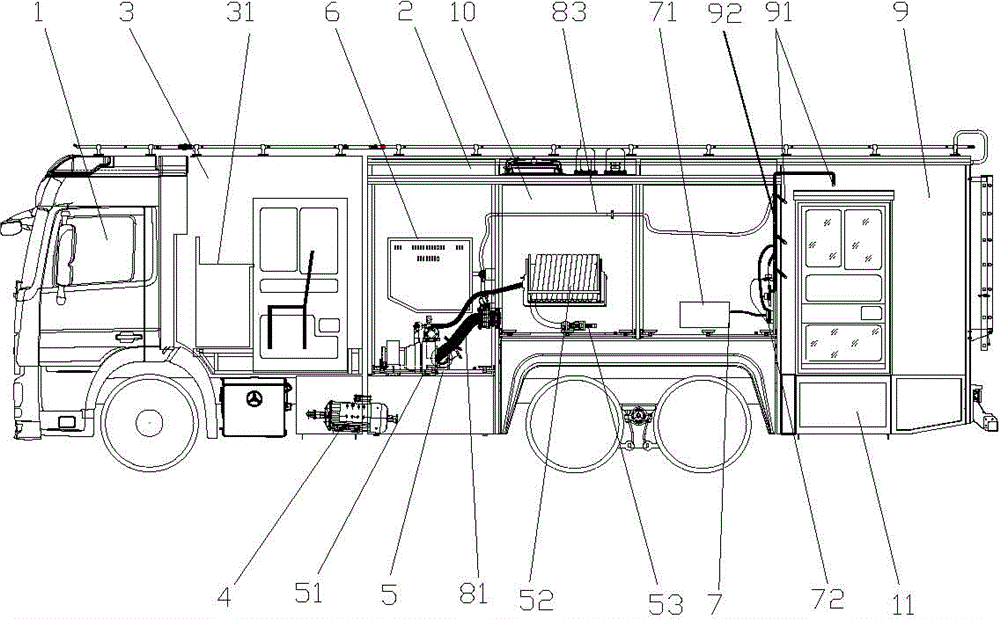

Fire-fighting truck chemical washing chamber and fire-fighting truck

InactiveCN104826258ASimple processing and assembly processReduce weightFire rescueTruckAutomotive engineering

The invention relates to the technical field of fire-fighting truck, and especially relates to a fire-fighting truck chemical washing chamber and a fire-fighting truck. The fire-fighting truck comprises a driver cab and a carriage; a power supply device, a washing device, and a chemical washing chamber are arranged in the carriage; the washing device comprises a water storage tank, a washing heating machine, a neutralizing liquid device for chemical washing, and a washing pipeline system; the washing heating machine is communicated with the water storage tank, the neutralizing liquid device and the chemical washing chamber through the washing pipeline system; the chemical washing chamber comprises a washing chamber skeleton assembly, a front sealing plate and a rear sealing plate, which are arranged oppositely, a left sealing plate and a right sealing plate, which are arranged oppositely, a top plate and a bottom plate, which are arranged oppositely, and a middle partition plate. Compared with the prior art, the provided fire-fighting truck has a plurality of functions such as indoor / outdoor washing, cold / hot water supplying, electricity supplying, and the like, and has the advantages of high washing efficiency, convenient operation, safety, and reliability.

Owner:GUANGDONG YONGQIANG ALB INT FIRE FIGHTING ENGINE

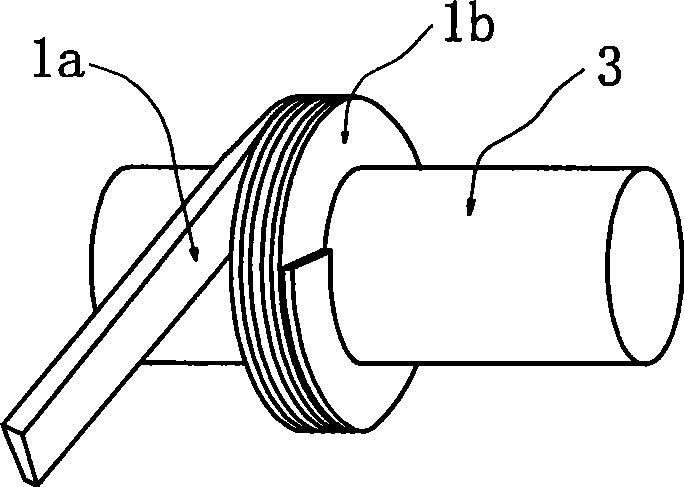

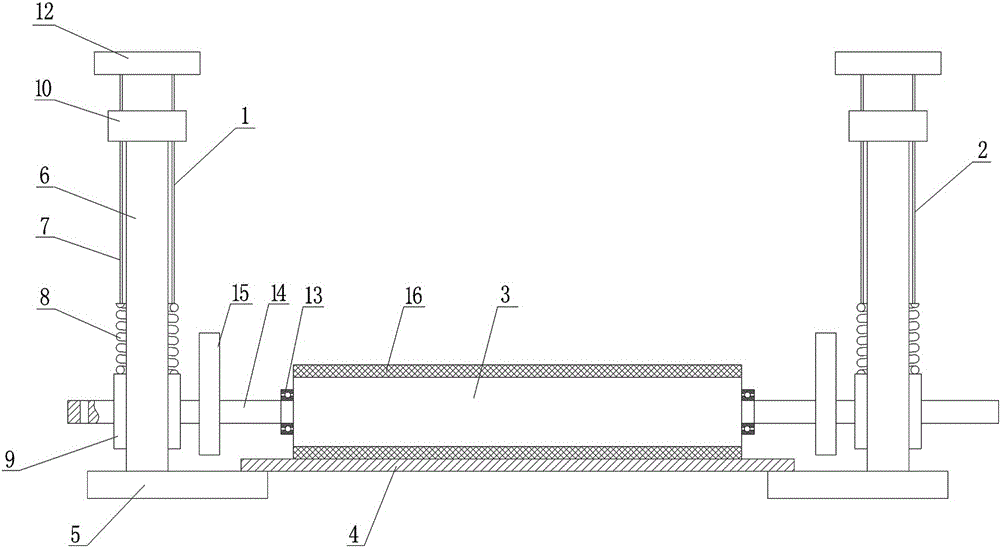

Film-rolling device with edge-folding sheet

InactiveCN106003987ADrive out completelyGuaranteed firmnessLamination ancillary operationsLaminationEngineeringSilica gel

The invention discloses a film-rolling device with an edge-folding sheet. The film-rolling device comprises a left supporting mechanism (1), a right supporting mechanism (2), a roller (3) and a conveying flat belt (4), wherein a supporting base (6) is fixed on a base plate (5); sliding blocks (9) and a compression spring (8) are successively arranged between the bottom of a groove (11) and a mounting plate (10) in the groove (11); fixing rods (14) are mounted in a bearing (13); the fixing rod (14) on the left side is fixed on the sliding block (9) of the left supporting mechanism (1); the fixing rod (14) on the right side is fixed on the sliding block (9) of the left supporting mechanism (1); semicircular parts (15) are mounted on the two fixing rods (14); a silica gel drum (16) sleeves the roller (3); the silica gel drum (16) is tangent with the conveying flat belt (4). The film-rolling device with the edge-folding sheet has the beneficial effects that the film pasting efficiency is increased, the labor intensity of worker is relieved, the film rolling is thorough and the product quality is high.

Owner:CHENGDU HOMIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com