One-time stamping forming mold for ball pocket of holder

A stamping forming and cage technology, which is applied to the field of one-step stamping and forming molds for cage ball pockets, can solve the problems of difficulty in meeting technical standard requirements, large errors in the circumferential spacing of pockets, and easy distortion and deformation, and achieves uniform force, The effect of reducing axial position error and increasing punch strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

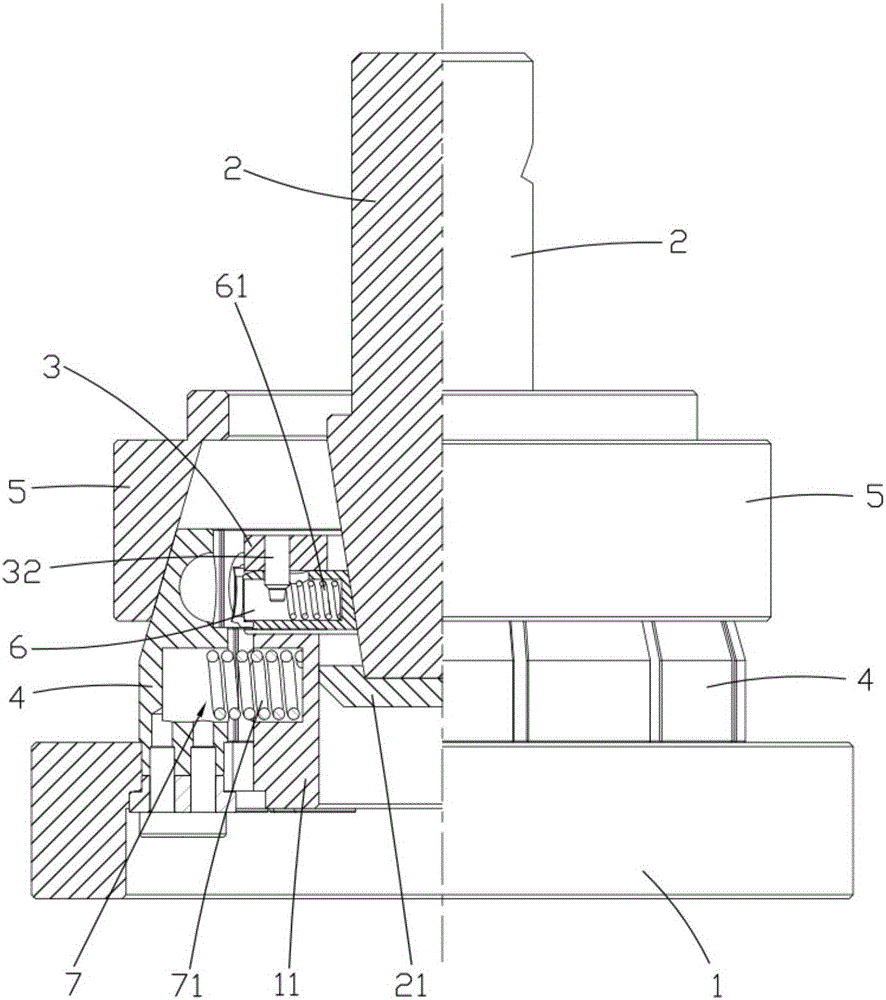

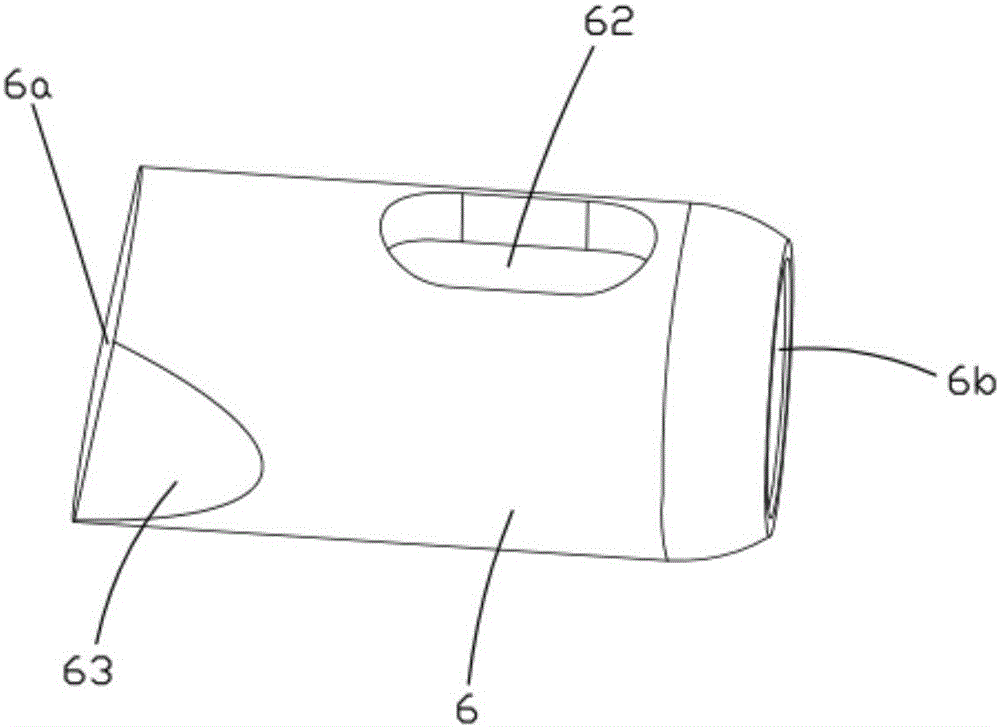

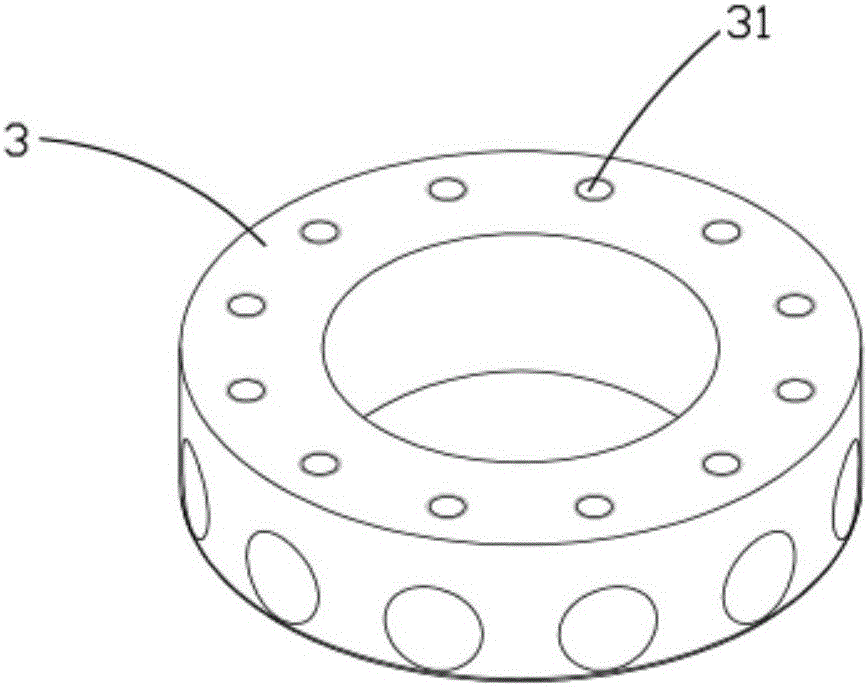

[0030] Such as figure 1 As shown, the present invention provides a one-time stamping mold for a cage ball pocket, including a base 1, a main slider 2, an inner mold 3, an outer mold 4, a shrink sleeve 5 and several elastic recovery mechanisms 7, the base 1, The main sliding body 2, the inner mold 3, the outer mold 4 and the shrink sleeve 5 are arranged coaxially. The main sliding body 2 is in the shape of an inverted cone, which is placed vertically in the base 1. The inner mold 3 is sleeved on the main sliding body 2. Outside; the base 1 is evenly distributed with several outer molds 4 along its circumference, and the outer molds 4 are all placed outside the inner mold 3, and the upper part of the outer mold 4 is covered with a shrink sleeve 5; the side wall of the inner mold 3 is along the Several punches 6 are evenly arranged in its circumferential direction, and the inner end surface 6a of the punch 6 is in conflict with the main sliding body 2, and the inner wall of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com